Exploring the mechanical setup of an all-terrain vehicle can provide invaluable insights into how its various elements function together. By analyzing a detailed breakdown of its components, one can gain a deeper understanding of the machine’s core structure and functionality. Each piece plays a vital role in the vehicle’s overall performance and durability.

Having a clear visual overview of the key mechanical elements allows users to effectively maintain and repair their vehicles. It ensures that any replacements or upgrades are done efficiently, with full knowledge of the interconnections between the parts. Whether you are maintaining, troubleshooting, or enhancing your vehicle, a well-organized view of the essential components is indispensable.

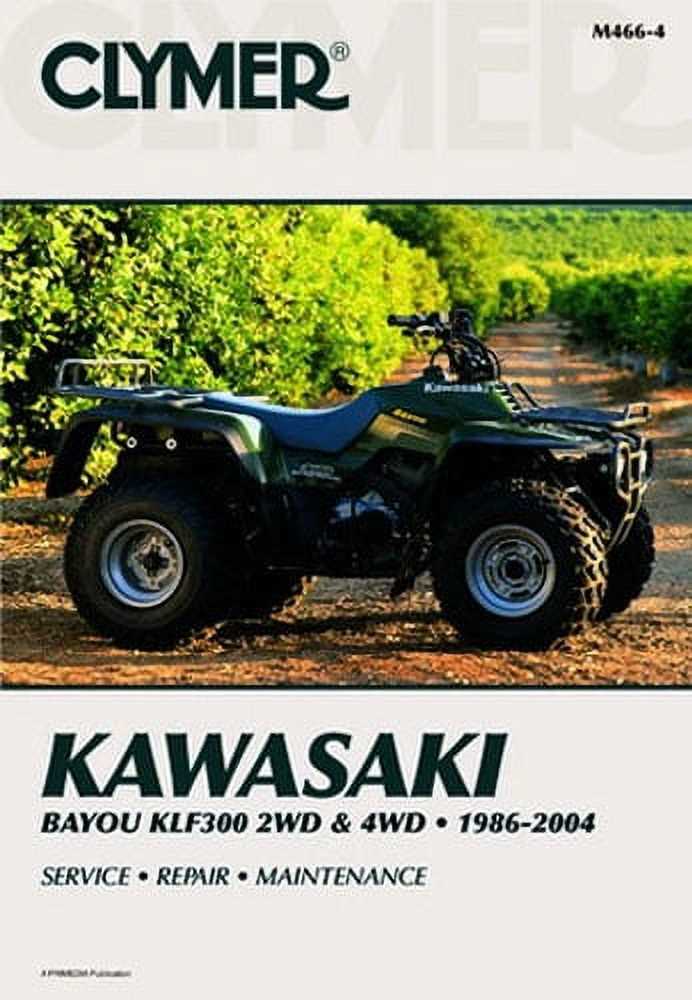

Kawasaki Bayou 300 Parts Diagram

Understanding the layout and components of this model’s mechanical system is crucial for proper maintenance and repair. The detailed visualization of its elements helps in identifying each part’s role in ensuring smooth operation, as well as offering clarity on how various components interact with each other.

Component Overview

Each element in the system serves a distinct purpose, from the engine components to the electrical connections. The visual breakdown provides insight into how these sections are arranged, allowing for efficient troubleshooting and part replacement when needed.

Maintenance and Repair Benefits

A clear schematic aids significantly in the process of maintaining and repairing the vehicle. It helps technicians and owners alike to pinpoint issues quickly and select the right components for replacements, ensuring longer operational life and reliable performance.

Overview of the Kawasaki Bayou 300

The vehicle in question is a highly reliable machine known for its performance and adaptability in a variety of environments. This all-terrain vehicle offers a combination of power and user-friendly features, making it a popular choice for both novice riders and experienced outdoor enthusiasts. Its robust construction and efficient design ensure long-term durability and ease of maintenance.

Designed for versatility, the vehicle excels in handling challenging terrains, from rough trails to open fields. Its sturdy frame and well-engineered engine make it a dependable companion for tasks ranging from recreational use to practical applications, such as transportation or light-duty work.

Additionally, its ease of operation and functional layout provide a seamless experience for riders, ensuring that they can focus on the adventure or task at hand without unnecessary complications. The engineering behind this vehicle prioritizes both performance and comfort, making it an ideal option for those looking for a balanced riding experience.

Main Components of the Engine

The essential elements of an engine play a critical role in its overall performance and functionality. These core components ensure the engine operates smoothly and efficiently, providing power for a variety of tasks. Understanding these parts and their roles is key to maintaining and repairing any mechanical system.

Key Elements of the Engine

Below is a breakdown of the primary elements found in most engines, along with their respective functions:

| Component | Function | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Piston | Converts the energy from combustion into mechanical motion. | ||||||||||

| Cylinder | Houses the piston and guides its movement during operation. | ||||||||||

| Crankshaft | Transforms the linear motion of the piston into rotational energy. | ||||||||||

| Camshaft | Controls the timing of the intake and exhaust valves. | ||||||||||

| Valves | Regulate the flow of

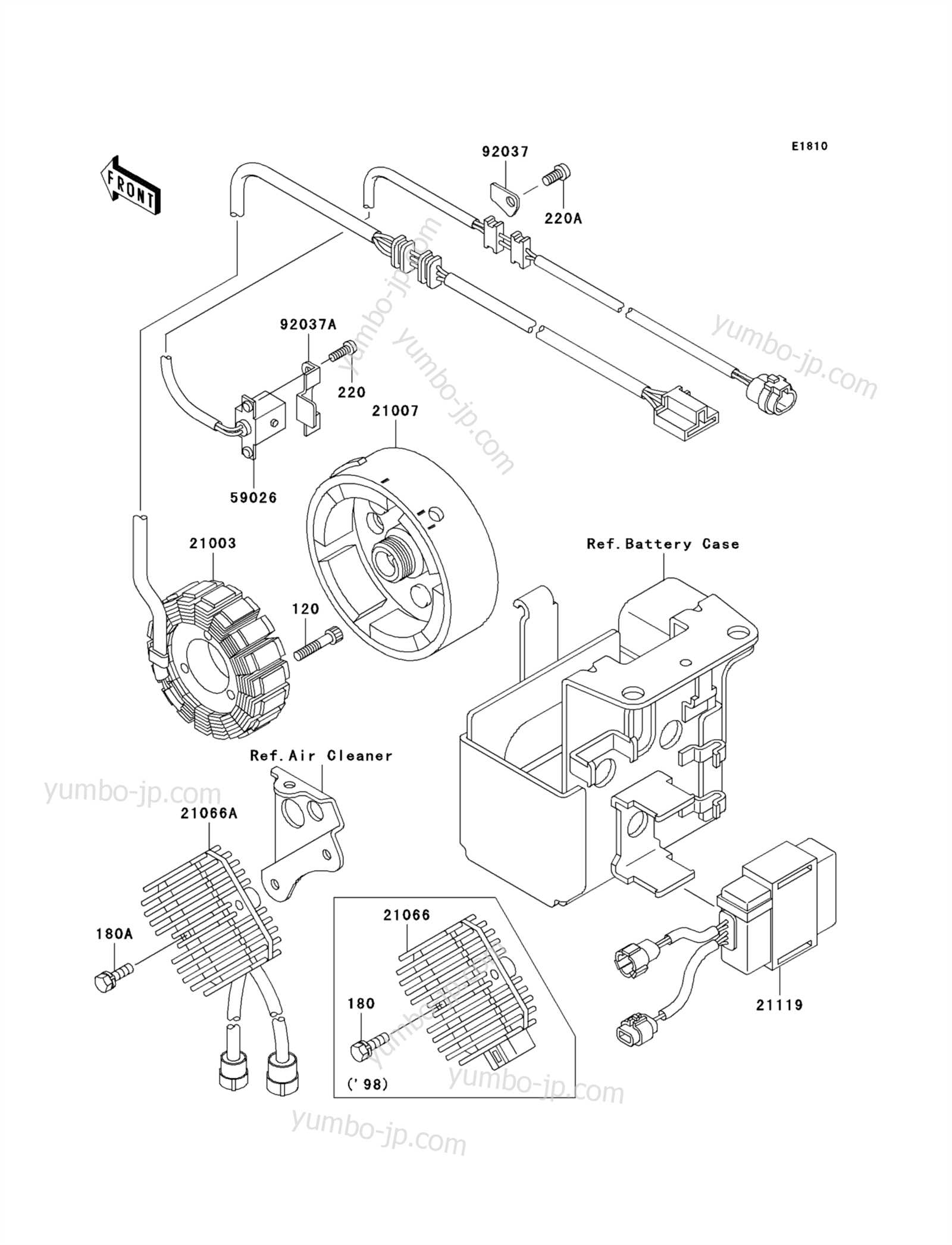

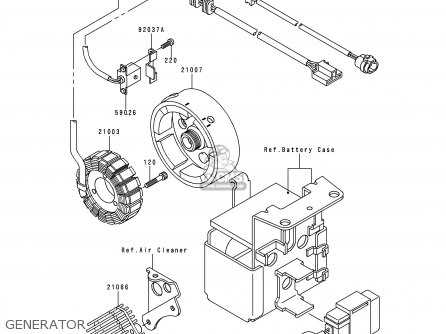

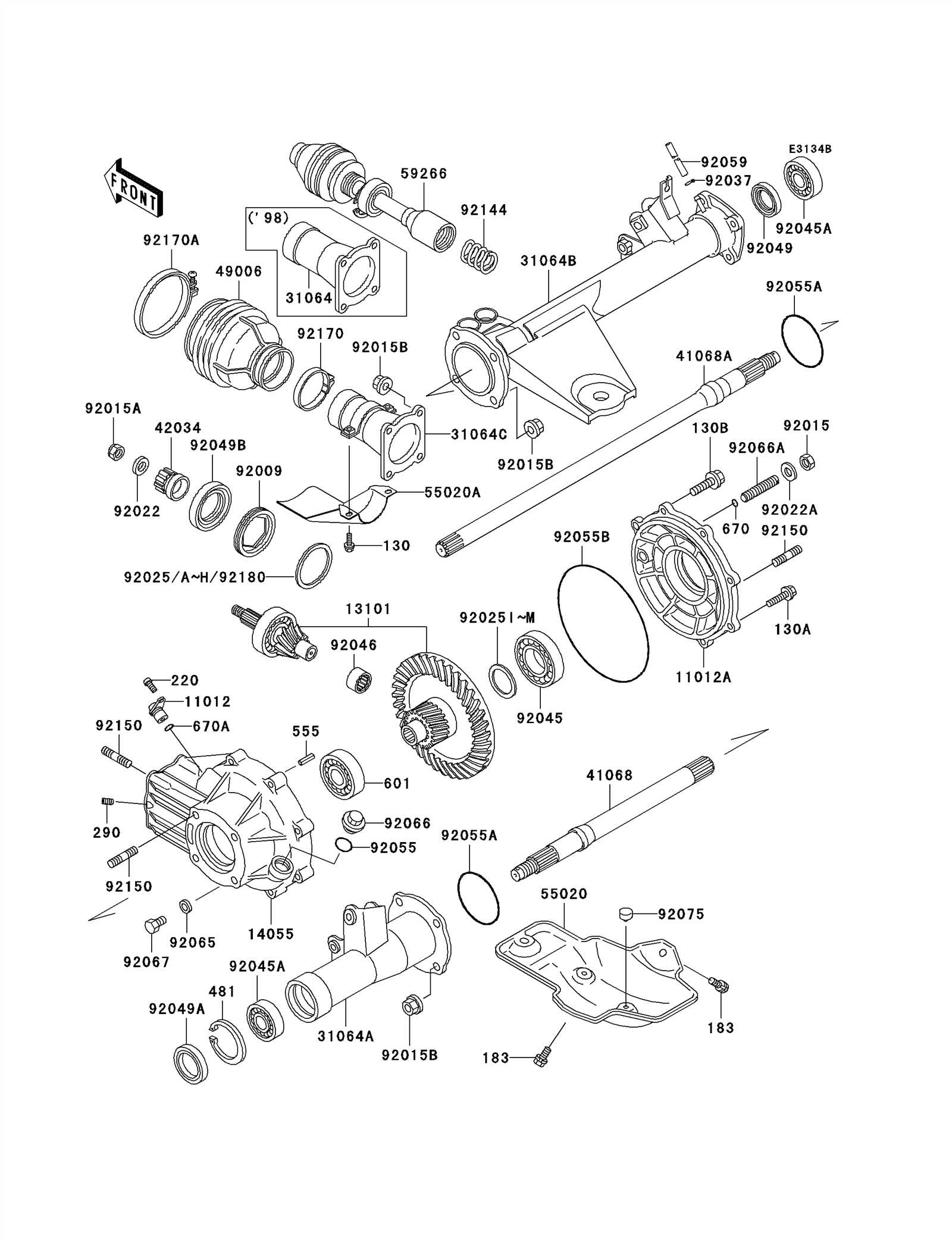

Transmission Parts BreakdownThe transmission system is a crucial component that ensures power is properly transferred from the engine to the wheels, enabling smooth and efficient movement. Understanding the internal mechanisms of this system can help diagnose issues and maintain optimal performance. Gears: These interlocking components manage the distribution of power by adjusting the torque based on the vehicle’s speed. Each gear set plays a vital role in balancing force and speed, allowing for both high-power output and efficient fuel usage. Clutch Assembly: The clutch is responsible for disconnecting the engine from the drive system during shifts. It allows for smooth gear changes and helps prevent wear by momentarily disengaging the power flow. Shafts: The primary and secondary shafts hold the gears in place, ensuring alignment and smooth operation. These shafts allow torque to transfer efficiently throughout the system, enabling consistent motion. Bearings: These components reduce friction between the moving parts of the transmission, ensuring a long lifespan and preventing excessive wear. They are critical to the smooth operation of the entire system. Electrical System Parts IdentificationThe electrical system plays a crucial role in ensuring the smooth operation of any vehicle, providing power to essential components such as the ignition, lights, and control systems. Understanding the various elements within this system is vital for both maintenance and repair. In this section, we will explore key components that contribute to the functionality of the electrical system, offering clarity on their purposes and how they interconnect. Main Electrical ComponentsAt the core of the electrical system is the battery, which stores and supplies power to all essential circuits. Connected to the battery is the alternator, responsible for recharging the battery during operation and ensuring consistent power distribution. The voltage regulator manages the flow of electricity, preventing overloading or short circuits. Wiring and Connections

The electrical wiring links the various components, creating a network of power flow. Fuses Understanding the Suspension AssemblyThe suspension assembly plays a crucial role in ensuring the smooth operation of a vehicle. It is designed to absorb shocks and vibrations from the terrain, providing stability and comfort to the rider. This section will explore the components and functions of this vital system. Components of the Suspension AssemblyThe suspension system comprises several key elements that work together to deliver optimal performance. The primary components include:

Functions of the Suspension AssemblyThe primary functions of the suspension assembly are as follows:

Understanding the intricacies of the suspension assembly is essential for proper maintenance and performance optimization. Regular inspection and timely replacement of worn components can significantly enhance the riding experience. Brake System ComponentsThe braking mechanism is a critical aspect of any vehicle, ensuring safe and effective deceleration. Understanding the various elements involved in this system is essential for proper maintenance and functionality. 1. Brake Pads: These components are responsible for creating friction against the brake rotor, allowing the vehicle to slow down or stop. Regular inspection and replacement of brake pads are vital for optimal performance. 2. Brake Discs: Also known as rotors, these flat, circular components work in conjunction with the brake pads to facilitate braking. They must be kept in good condition to ensure efficient braking force. 3. Brake Calipers: These devices house the brake pads and use hydraulic pressure to push them against the rotors. Proper functioning of the calipers is crucial for effective braking. 4. Master Cylinder: This component converts the force from the brake pedal into hydraulic pressure, enabling the brake system to function. Maintaining the master cylinder is essential for a responsive braking experience. 5. Brake Lines: These tubes carry brake fluid from the master cylinder to the calipers. They must be free from leaks and damage to ensure proper fluid flow and braking efficiency. 6. Brake Fluid: A vital hydraulic fluid that transmits force within the braking system. Regularly checking and replacing brake fluid can prevent brake failure. Fuel System Parts and FunctionsThe fuel system is a crucial component of any off-road vehicle, responsible for delivering the right amount of fuel to the engine for optimal performance. Understanding the various components of this system helps ensure proper maintenance and functionality. Key elements of the fuel assembly include the fuel tank, which stores the gasoline, and the fuel pump, which is vital for transferring fuel to the engine. The fuel filter plays an essential role in removing impurities from the fuel, protecting the engine from damage. Additionally, the carburetor is significant for mixing air with fuel to create the proper combustion mixture. Each of these elements works in harmony to ensure efficient fuel delivery and engine operation. Chassis and Frame Diagram

The structural framework of an all-terrain vehicle plays a crucial role in its overall performance and durability. This section delves into the intricate assembly of the chassis and frame, highlighting the various components that contribute to stability and strength. Understanding the layout and connections between these elements is essential for maintenance and modifications. A robust frame is designed to withstand the rigors of off-road use, ensuring that the vehicle maintains its integrity under challenging conditions. Key elements such as cross members, support brackets, and mounting points are meticulously arranged to provide optimal load distribution and handling. Each component serves a specific purpose, whether it is enhancing suspension performance or accommodating the powertrain. By examining the configuration of the chassis, enthusiasts and technicians can gain insights into potential upgrades and repairs. Knowledge of the framework allows for better troubleshooting of issues related to alignment, handling, and overall vehicle dynamics. This comprehensive understanding is invaluable for anyone looking to enhance their vehicle’s capabilities or ensure its longevity. Steering Mechanism Breakdown

The steering mechanism is a critical component in ensuring the smooth navigation of the vehicle. It comprises various elements that work in unison to provide precise control and responsiveness while maneuvering. Understanding the intricacies of this system can enhance maintenance and performance. At the core of the steering system lies the steering shaft, which connects the steering wheel to the mechanism itself. This shaft transmits the driver’s inputs directly, translating them into movement. Adjacent to this, the universal joint allows for flexible movement, accommodating any angle between the steering column and the steering gear. The steering gear plays a pivotal role in converting rotational motion into linear motion. Various types exist, including rack-and-pinion and recirculating ball systems, each offering unique advantages in terms of responsiveness and feel. Additionally, the tie rods connect the steering gear to the wheels, ensuring that the desired direction is accurately conveyed. Regular inspection of these components is essential for optimal performance. Signs of wear, such as looseness or unusual noises, can indicate that parts may need to be replaced. Keeping the steering mechanism in good condition not only enhances the vehicle’s handling but also contributes to overall safety on the road. Cooling System ComponentsThe cooling system plays a crucial role in maintaining optimal operating temperatures within the engine. Its components work together to effectively manage heat, ensuring that the engine performs efficiently and reliably. Key elements of the cooling system include the radiator, water pump, and thermostat. The radiator is essential for dissipating heat from the coolant as it circulates through the engine. By transferring heat to the surrounding air, it helps to maintain a stable temperature. The water pump ensures proper circulation of the coolant throughout the system, promoting consistent cooling performance. Meanwhile, the thermostat regulates the flow of coolant, allowing the engine to reach its ideal operating temperature quickly. In addition to these primary components, hoses and clamps facilitate the movement of coolant, ensuring that the entire system remains sealed and effective. Regular maintenance and inspection of these components are vital for preventing overheating and maintaining engine longevity. Exhaust System Overview

The exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. It is designed to direct combustion gases away from the engine, minimizing back pressure and optimizing engine output. A well-functioning exhaust setup enhances not only performance but also contributes to environmental compliance by reducing harmful emissions. Components of the Exhaust SystemThis system typically consists of several key components, each serving a specific purpose. Understanding these elements helps in maintaining and troubleshooting exhaust-related issues.

Importance of MaintenanceRegular inspection and maintenance of the exhaust system are essential for ensuring optimal performance. Neglecting this system can lead to increased emissions, decreased efficiency, and potential engine damage. Addressing issues promptly can prolong the life of the vehicle and enhance its overall functionality. Maintenance Tips Using the Parts DiagramUnderstanding the components of your vehicle is crucial for effective upkeep. By familiarizing yourself with the schematic representation of individual elements, you can identify necessary maintenance tasks and address potential issues before they escalate. This knowledge enhances not only the longevity of your machine but also its overall performance. Regular InspectionsConducting frequent evaluations of essential components can help you spot wear and tear early. Look for signs of deterioration, such as leaks or unusual noises. Regular checks of filters and fluids ensure that everything operates smoothly and efficiently. Utilizing Reference GuidesHaving access to a detailed reference guide allows you to understand the functionality and placement of each component. This can assist you in performing routine maintenance, such as replacing belts or adjusting cables. Knowing how each part interacts will enable you to make informed decisions regarding repairs and replacements. |