The maintenance and repair of small engines often necessitate a clear understanding of their various components. This section provides a comprehensive overview of the intricate assembly and organization of engine parts, essential for ensuring optimal performance and longevity. By familiarizing oneself with the layout of these elements, users can streamline troubleshooting and maintenance processes.

Recognizing each component’s role and interconnections is crucial for efficient operation. An organized visualization of the engine’s structure aids in identifying potential issues and implementing effective solutions. This approach not only simplifies repairs but also enhances overall engine management practices.

Whether you are a seasoned technician or a DIY enthusiast, mastering the configuration of engine elements empowers you to make informed decisions. The following content will guide you through the essential aspects of engine assemblies, offering valuable insights for better maintenance and repair outcomes.

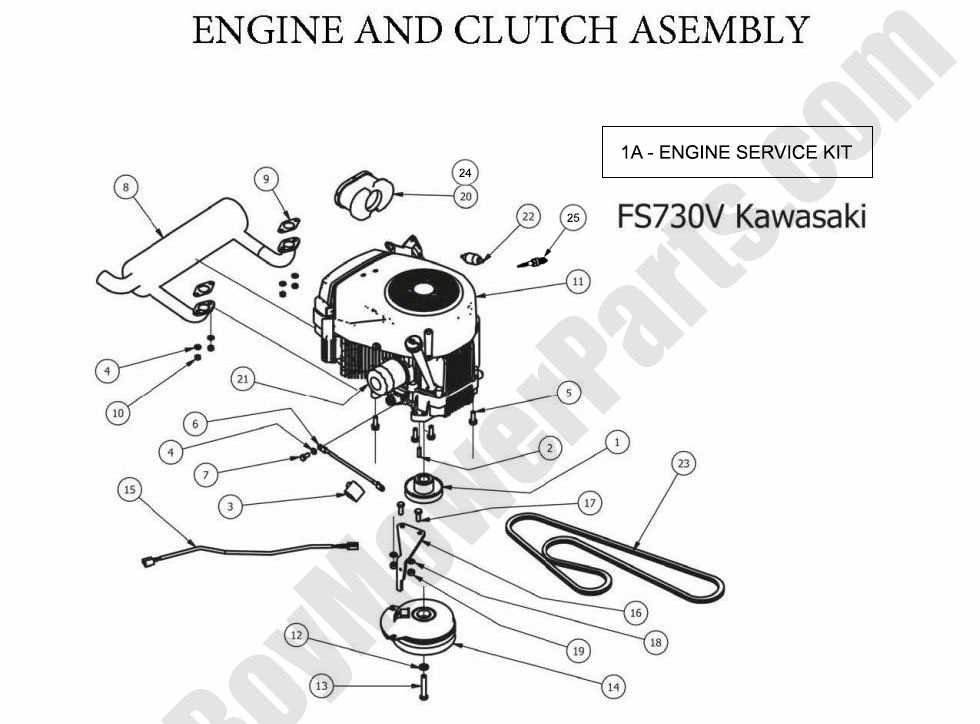

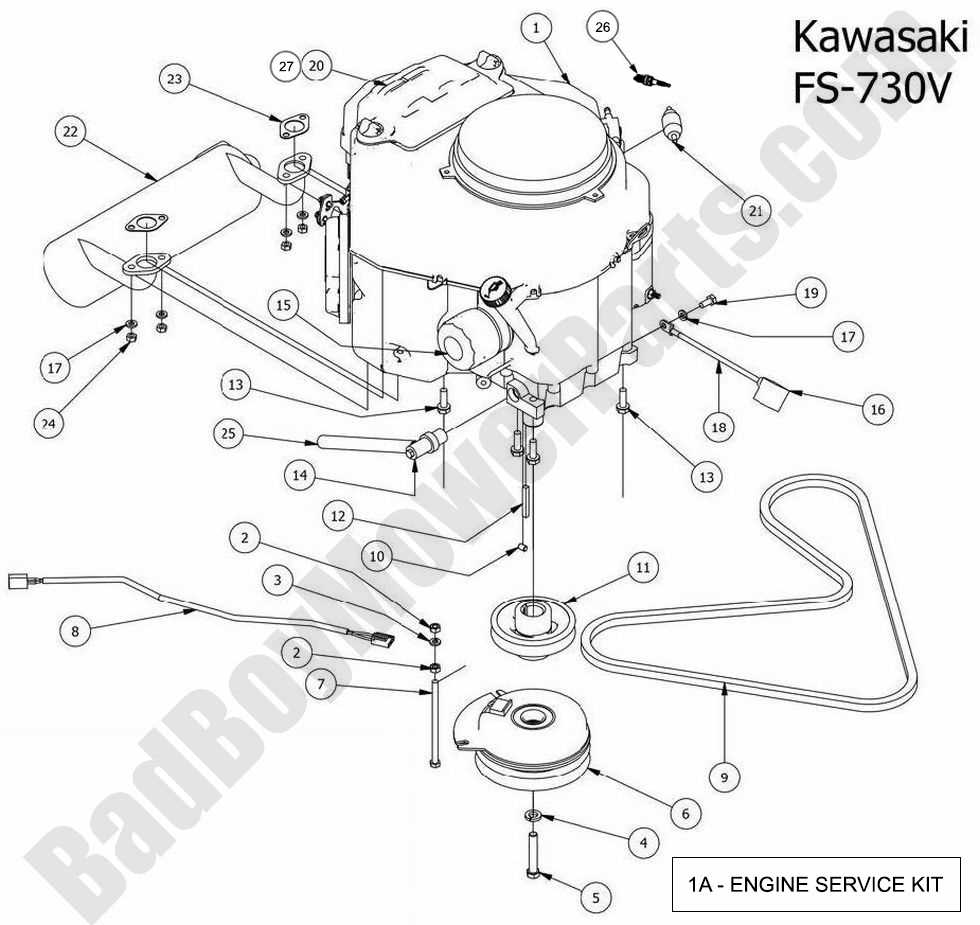

This section presents a comprehensive overview of a powerful engine model commonly utilized in various outdoor equipment. Understanding its essential components is crucial for maintenance and optimization of performance.

The following key aspects are important when exploring this engine:

- Engine Specifications: Explore the technical specifications, including horsepower, torque, and displacement.

- Component Functionality: Gain insights into the roles of various parts, such as the fuel system, ignition, and lubrication mechanisms.

- Maintenance Practices: Learn about recommended maintenance schedules and procedures to ensure longevity and reliability.

- Common Issues: Identify frequent problems that users may encounter and effective troubleshooting strategies.

By delving into these elements, readers can better understand the workings of this engine model, enabling them to make informed decisions regarding upkeep and repairs.

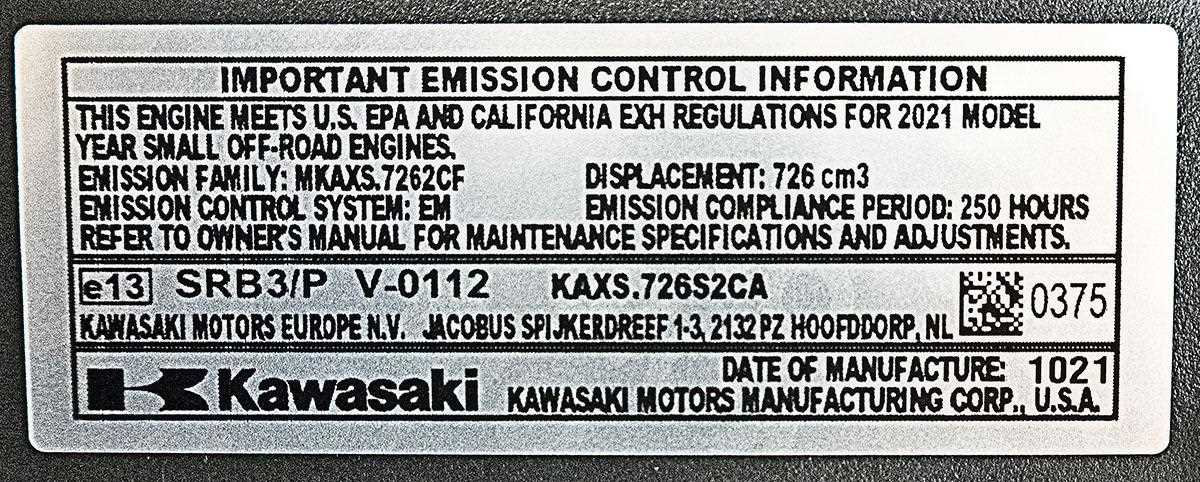

Understanding Engine Specifications

Engine specifications are crucial for comprehending the performance and functionality of a power unit. These details provide insights into how the engine operates, its efficiency, and its compatibility with various applications. Knowing the key characteristics helps in assessing performance metrics, maintenance needs, and potential upgrades for enhancing overall efficiency.

Key Components

Several fundamental components define the efficiency and reliability of a power unit. These include the displacement, which indicates the engine’s capacity to generate power, and the compression ratio, affecting the combustion process’s efficiency. Additionally, fuel type and cooling methods play a vital role in determining performance and longevity.

Performance Metrics

Performance metrics such as horsepower and torque are essential for evaluating an engine’s capabilities. Horsepower refers to the engine’s ability to do work over time, while torque measures the rotational force produced. Understanding these metrics enables users to select the right engine for their specific needs, ensuring optimal performance in various applications.

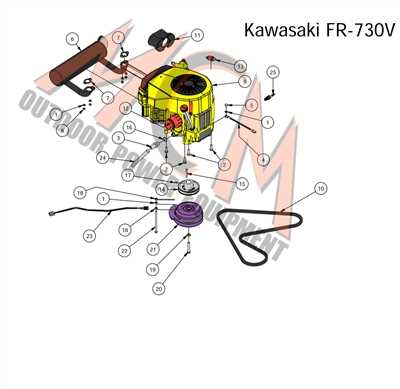

Key Components of the FR730V

The efficient operation of small engines relies on a variety of crucial elements that work in harmony to deliver optimal performance. Understanding these essential components can greatly enhance maintenance practices and troubleshooting skills, ensuring that the engine operates smoothly over time.

1. Engine Block: This is the core structure that houses the main components, providing support and strength. Its durability is vital for the engine’s overall longevity.

2. Cylinder Head: Positioned on top of the engine block, this part is responsible for sealing the combustion chamber. It plays a critical role in the intake and exhaust processes, influencing engine efficiency.

3. Crankshaft: This component transforms linear motion from the pistons into rotational energy. Its precise design is crucial for effective power transfer and balance within the engine.

4. Camshaft: This vital element controls the timing of valve openings and closings, ensuring that air and fuel can enter and exit the combustion chamber at the right moments for optimal combustion.

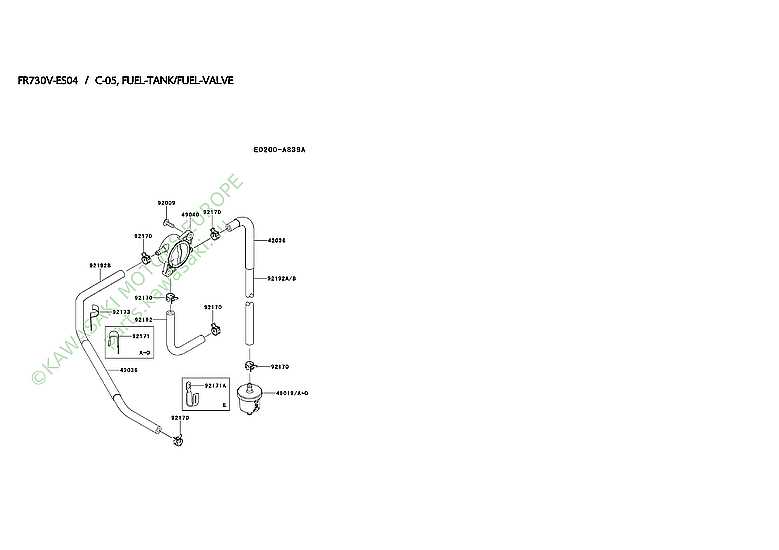

5. Fuel System: Comprising the carburetor or fuel injection system, this component is responsible for delivering the right mixture of air and fuel to the combustion chamber, directly impacting engine performance and efficiency.

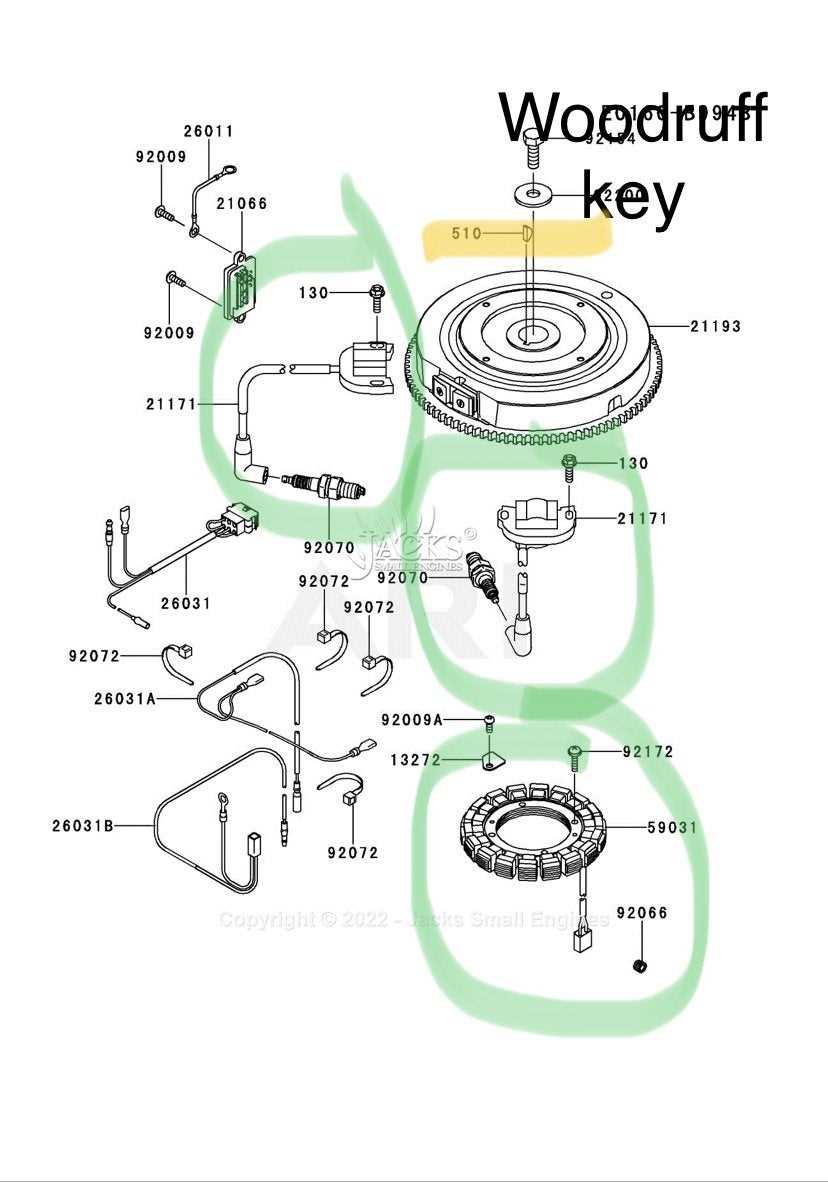

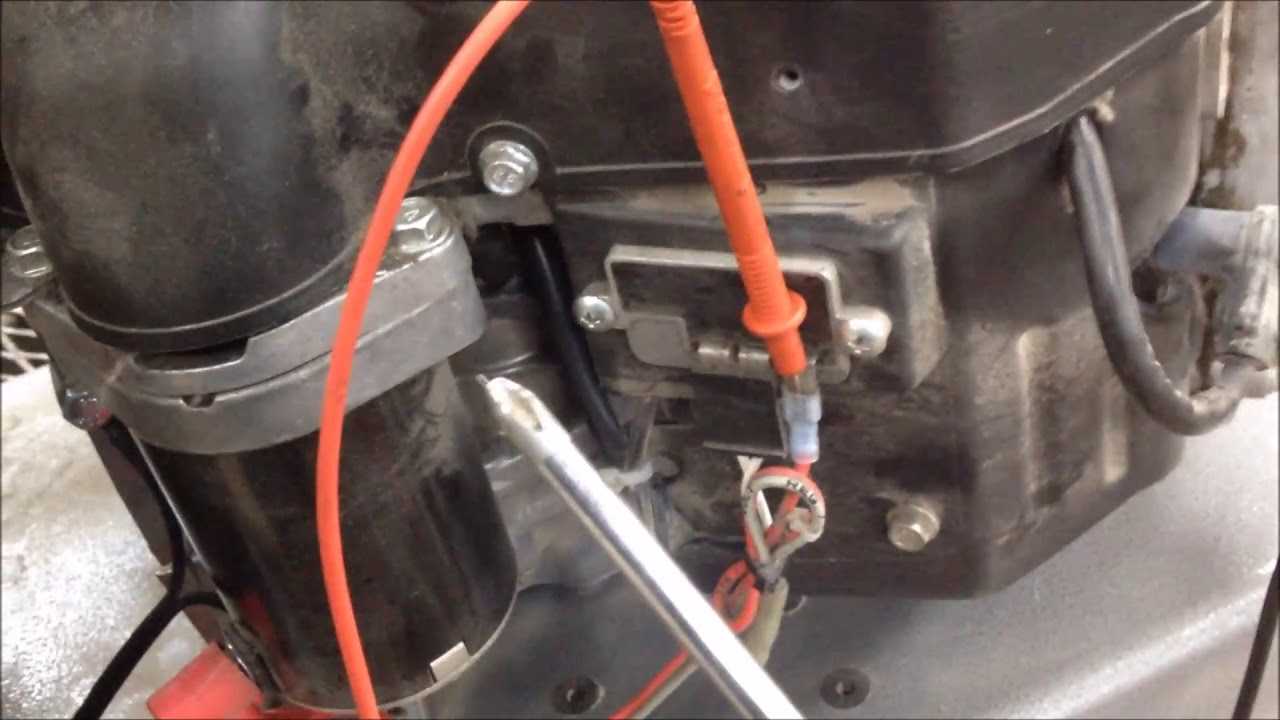

6. Ignition System: Essential for starting the engine, this system generates the spark needed for combustion. It includes components such as the ignition coil and spark plug, which must function correctly for reliable operation.

7. Lubrication System: This system minimizes friction between moving parts, ensuring smooth operation and extending the life of the engine. It includes the oil pump and various passages to distribute oil throughout the engine.

By familiarizing oneself with these fundamental elements, users can better appreciate the mechanics behind engine operation and take informed steps toward effective maintenance and repairs.

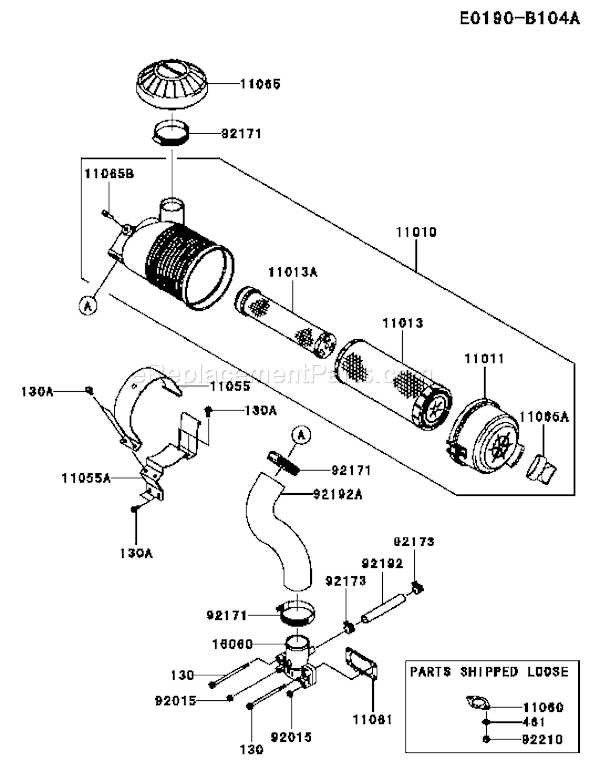

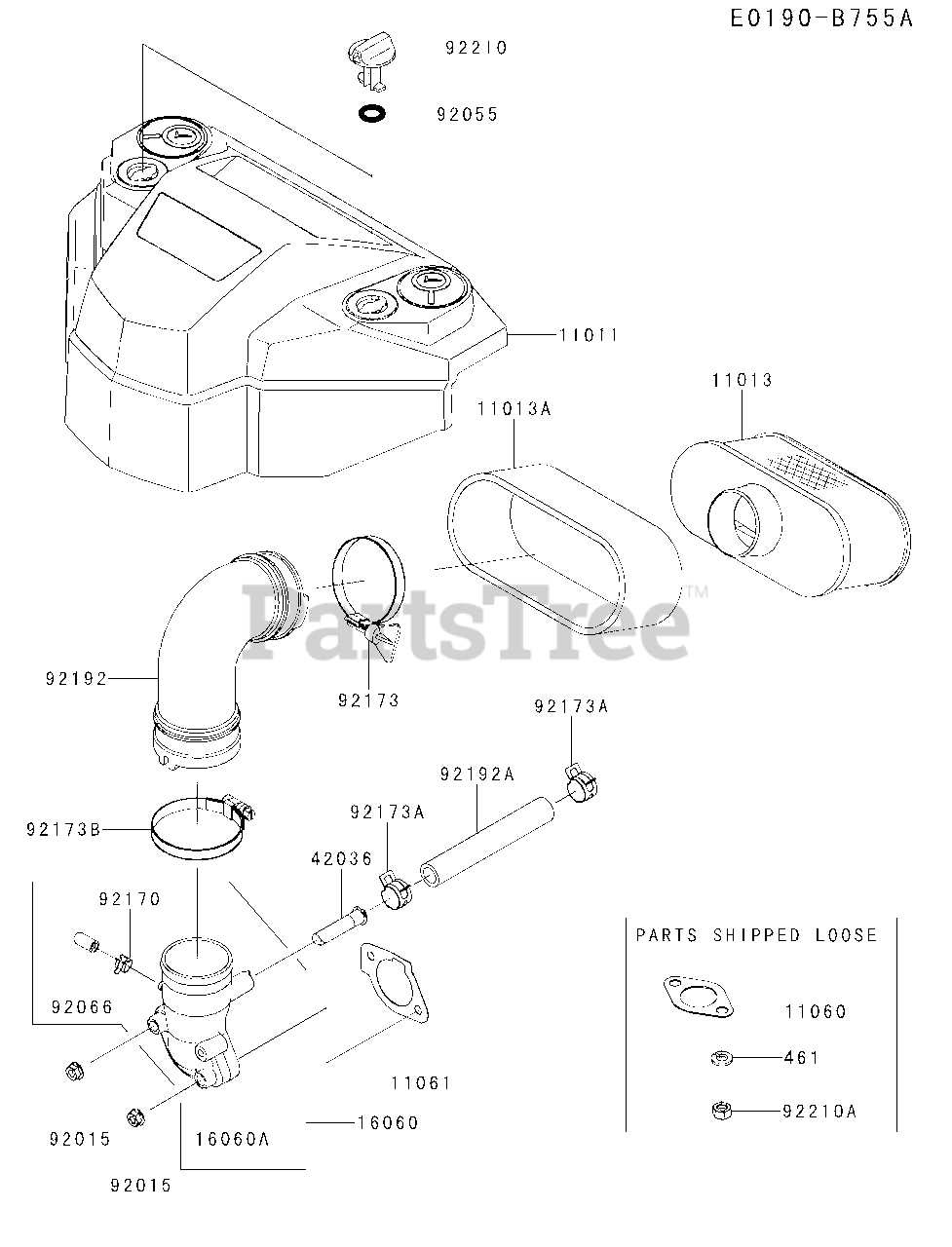

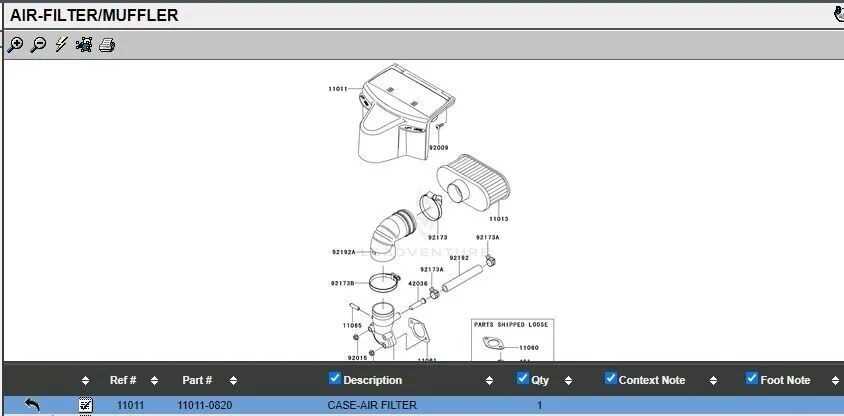

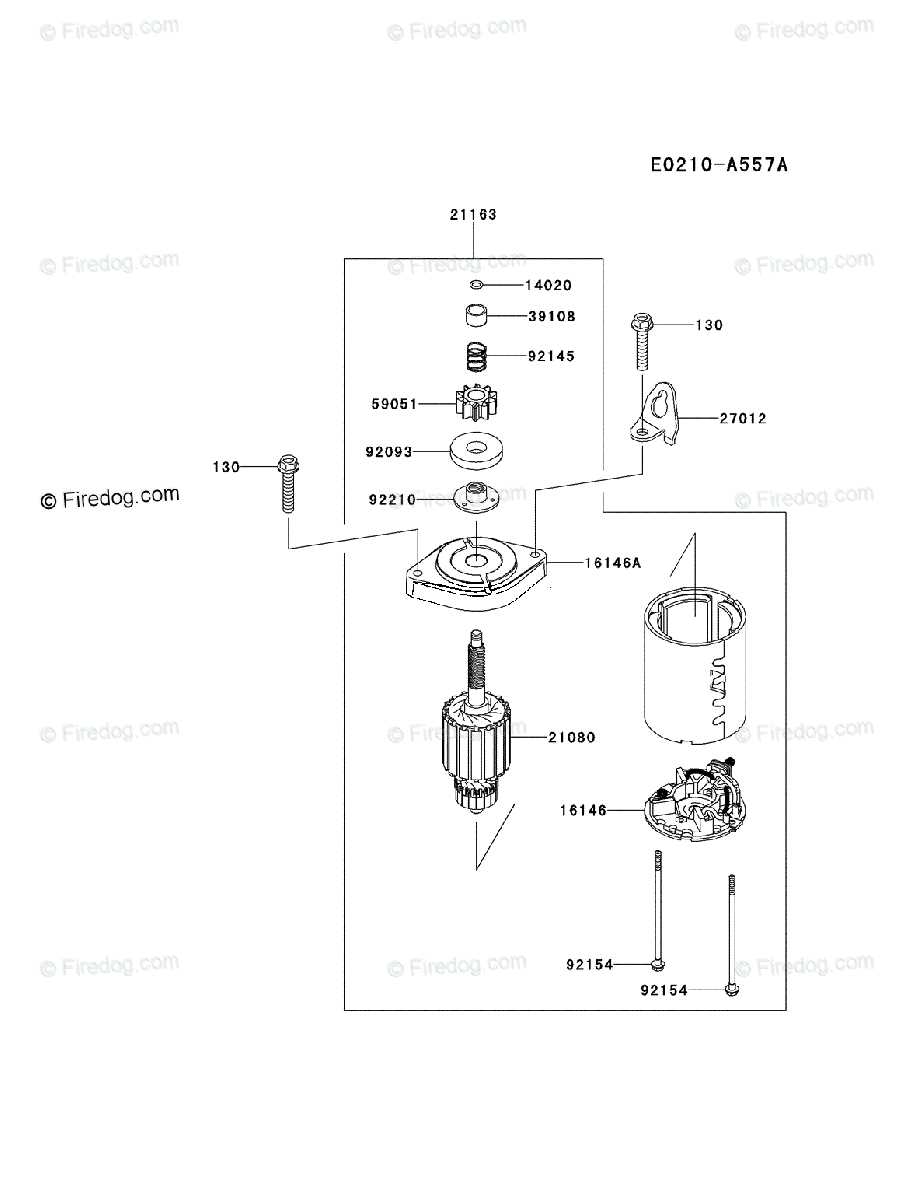

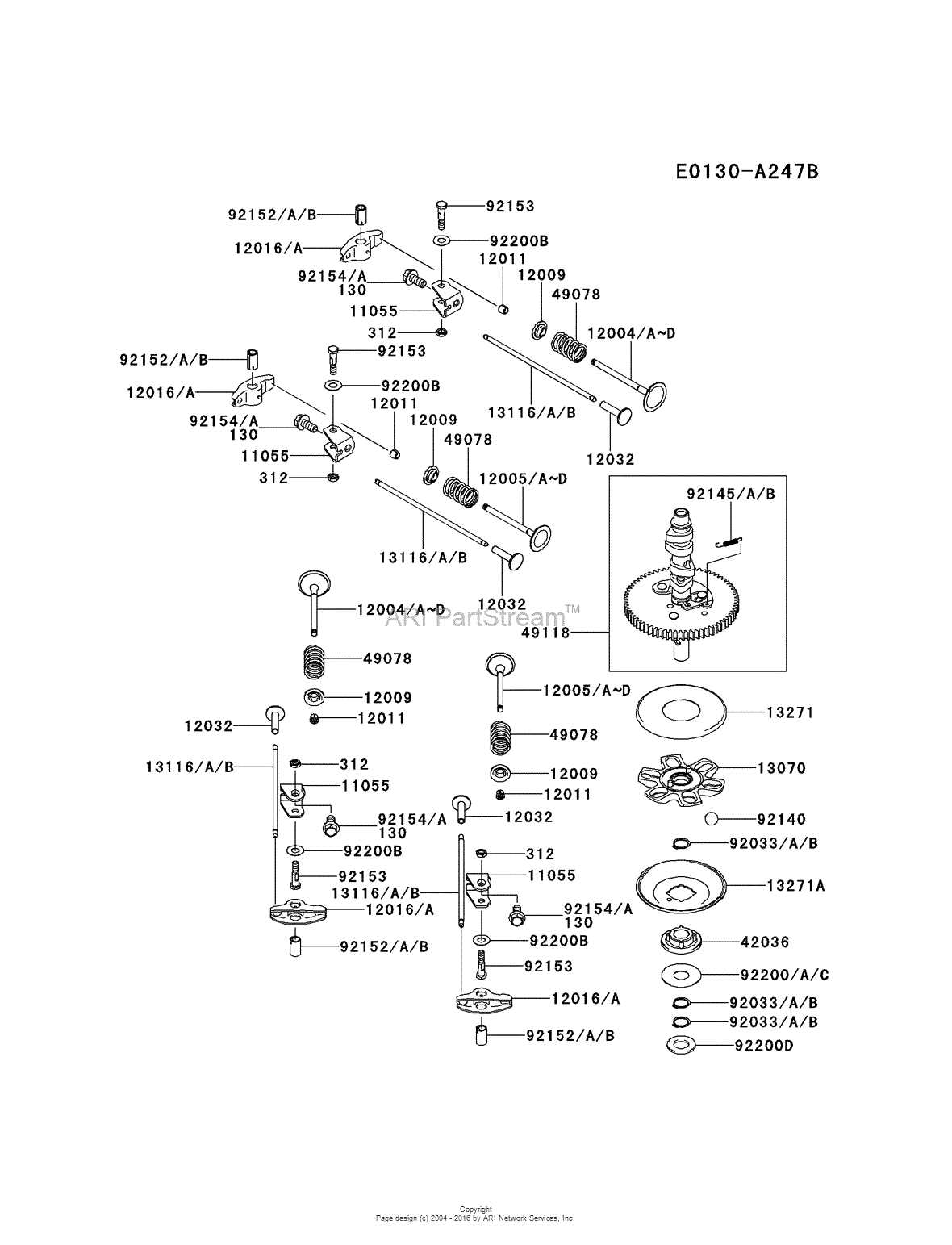

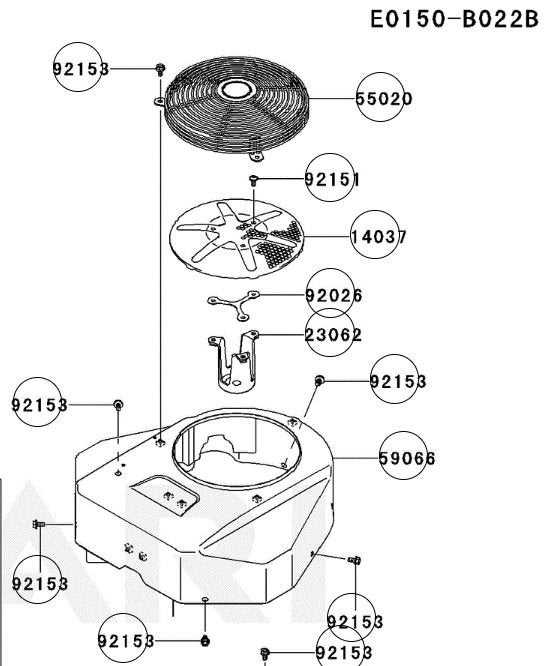

Importance of Accurate Parts Diagrams

Precise visual representations of components play a crucial role in various industries, facilitating efficient repairs and maintenance. These illustrations provide users with essential information about each element’s location, function, and interconnectivity within complex machinery. With accurate depictions, technicians can quickly identify the necessary items, reducing downtime and streamlining the repair process.

In addition to enhancing operational efficiency, reliable representations contribute to improved safety. Understanding the layout and specifications of each component allows users to follow proper procedures and avoid potential hazards during disassembly or reassembly. This knowledge not only protects the equipment but also ensures the safety of personnel working on it.

Furthermore, these visual guides serve as valuable educational tools. They assist in training new employees, enabling them to familiarize themselves with the equipment and its components. With a clear understanding of the various parts, newcomers can build confidence in their technical skills and reduce the likelihood of errors during maintenance tasks.

Overall, accurate visual representations are indispensable for anyone working with intricate machinery, ensuring effective repairs, promoting safety, and fostering a knowledgeable workforce.

Common Issues and Replacement Parts

Maintenance of outdoor power equipment often reveals a range of common challenges that users encounter. Identifying these issues early can significantly enhance performance and prolong the lifespan of the machinery. Understanding which components may need to be replaced can streamline the repair process and ensure the equipment operates efficiently.

Frequent Problems

Users frequently report difficulties such as starting failures, engine misfires, and unusual noises during operation. These problems can often stem from a variety of sources, including fuel delivery issues, electrical malfunctions, or worn-out components. Regular inspections can help detect these concerns before they escalate into more serious complications.

Essential Replacement Components

To address common challenges, certain components are typically recommended for replacement. Filters, such as air and fuel filters, are crucial for maintaining optimal performance. Additionally, spark plugs should be checked regularly, as they play a vital role in ignition. Other important parts that may require attention include belts and blades, which are essential for smooth operation and efficient cutting.

Step-by-Step Repair Guide

Repairing small engines can seem daunting, but with a systematic approach, it becomes manageable. This guide outlines essential steps to effectively troubleshoot and resolve common issues found in these power units. By following this process, you can restore functionality and extend the life of your equipment.

1. Gather Necessary Tools and Materials: Before starting, ensure you have all the required tools at hand, including wrenches, screwdrivers, and replacement components. Having everything organized will streamline the repair process.

2. Review the Manual: Consulting the service manual is crucial. It provides valuable information about specifications, maintenance procedures, and troubleshooting tips specific to your engine model.

3. Identify the Problem: Start by observing the symptoms. Whether it’s difficulty starting, unusual noises, or

Where to Find Genuine Parts

When it comes to maintaining the performance of your machinery, sourcing authentic components is crucial. Reliable suppliers ensure you receive high-quality replacements that meet the original specifications, contributing to the longevity and efficiency of your equipment. Here are some effective ways to locate genuine components for your engine.

One of the best sources for authentic replacements is the manufacturer’s official website. They often provide a comprehensive catalog that allows you to search for specific components based on your engine model. Additionally, authorized dealers and service centers can offer expert advice and access to genuine replacements.

Another option is to explore reputable online retailers. Many of these platforms specialize in machinery components and can provide a wide range of genuine options. Always verify the seller’s credibility by checking reviews and ratings before making a purchase.

Local repair shops and specialty stores are also valuable resources. These establishments often have established relationships with suppliers and can help you obtain the necessary components. They may even offer installation services, ensuring that everything is fitted correctly.

| Source Type | Description | Advantages |

|---|---|---|

| Official Website | Manufacturer’s online catalog | Access to complete and accurate information |

| Authorized Dealers | Local dealerships specializing in machinery | Expert assistance and support |

| Online Retailers | E-commerce platforms with a focus on machinery | Convenient shopping and comparison options |

| Local Repair Shops | Community-based service providers | Personalized service and potential installation |

Comparing FR730V to Similar Models

When evaluating various engine options in the small engine market, it’s essential to consider the features and specifications that set each model apart. This analysis focuses on a specific model and its competitors, examining performance metrics, design aspects, and operational efficiencies. By understanding the nuances among these engines, potential buyers can make more informed decisions tailored to their needs.

One of the key factors to consider is the power output of each engine. While the model in question is known for its robust horsepower and torque, similar engines may offer variations that cater to different performance requirements. It is crucial to assess how each model handles load and responds under various working conditions, such as hills or heavy-duty tasks.

Another significant aspect is the design and construction quality of the engines. Certain models might feature advanced cooling systems or innovative materials that enhance durability and longevity. Evaluating the build quality and engineering behind each engine can provide insights into maintenance needs and overall reliability over time.

Fuel efficiency is also a critical consideration in this comparison. While some engines prioritize power, others may offer better consumption rates, resulting in lower operational costs. Potential users should weigh these factors according to their specific use cases and frequency of operation.

In addition to performance and efficiency, user experience, including ease of maintenance and serviceability, should not be overlooked. Some engines are designed for straightforward access to key components, making routine upkeep simpler and less time-consuming. This can be a deciding factor for those who prefer minimal downtime and straightforward repairs.

Ultimately, each engine has its unique strengths and weaknesses, making it imperative to analyze these elements closely. By comparing the various options, users can identify the engine that best aligns with their operational needs and expectations, ensuring optimal performance for their specific applications.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for maximizing the lifespan of your machinery. Implementing a few straightforward practices can significantly enhance performance and prevent costly repairs. Here are some effective strategies to ensure your equipment remains in top condition over time.

- Regular Inspections: Frequently check for signs of wear or damage. Look for leaks, cracks, or unusual noises during operation.

- Clean the Equipment: Keeping surfaces free of debris and dirt is crucial. Use compressed air or a soft brush to remove dust from vents and filters.

- Change Fluids: Periodically replacing oil and coolant can prevent overheating and ensure smooth operation. Follow the manufacturer’s guidelines for fluid change intervals.

- Sharpen Blades: If applicable, maintain sharp blades or cutting edges. Dull tools require more power and can lead to increased wear on the machinery.

- Check Belts and Cables: Inspect belts for fraying or cracking and ensure cables are intact. Replace any worn components promptly to avoid breakdowns.

By following these maintenance tips, you can extend the life of your machinery, improve efficiency, and reduce the likelihood of unexpected failures. Regular attention to these details not only enhances performance but also ensures a safer working environment.

Frequently Asked Questions

This section aims to address common inquiries related to the components and functionalities of various small engines. Here, we provide clear and concise answers to assist users in understanding their equipment better.

Common Queries

- What types of components are typically found in small engines?

- How can I identify the right parts for my engine model?

- What are the common signs of wear or malfunction in engine components?

- Where can I purchase replacement parts?

- Are there maintenance tips to prolong the lifespan of my engine?

Understanding Engine Maintenance

- Regularly inspect all moving parts for signs of wear.

- Keep the engine clean to prevent debris accumulation.

- Change filters and fluids as recommended by the manufacturer.

- Consult the user manual for specific maintenance schedules.

- Use quality replacement parts to ensure optimal performance.

Community Resources and Support

Engaging with a network of enthusiasts and experts can significantly enhance your understanding and maintenance of machinery. Whether you’re troubleshooting issues or looking for specific components, various community-driven platforms provide invaluable assistance. These resources often include forums, social media groups, and dedicated websites where individuals share experiences, advice, and solutions.

One of the most beneficial aspects of these communities is the collective knowledge base. Members often contribute detailed guides, tutorials, and user experiences that can help you navigate challenges more efficiently. Additionally, many platforms host discussions on best practices, enhancing your skills and knowledge in the field.

Participating in local clubs or online forums allows you to connect with others who share your interests. This interaction can lead to valuable insights and tips that may not be readily available in manuals or official documentation. Many enthusiasts are more than willing to help newcomers, making these communities welcoming spaces for all levels of experience.

Furthermore, local retailers and repair shops often engage with these communities, providing updates on new products and services. Establishing relationships with these businesses can lead to discounts, promotions, or early access to new tools and parts. By leveraging these connections, you can enhance your overall experience and ensure your equipment remains in optimal condition.