Understanding the intricate system of vehicle mechanisms is vital for ensuring proper maintenance and optimal performance. Identifying various mechanical elements helps in addressing potential issues and enhancing the longevity of your machine.

This guide provides a detailed breakdown of key elements that play crucial roles in the overall functionality. By exploring the specific functions and interconnections of these elements, you can gain a deeper insight into maintaining and troubleshooting your equipment effectively.

From understanding how different sections work together to identifying the necessary replacements, this information serves as an essential resource for those looking to maintain the efficiency and reliability of their machine over time.

Overview of the Kubota RTV 900 Parts

This utility vehicle is made up of a wide range of essential elements that contribute to its performance and reliability. Understanding these components helps ensure smooth operation and maintenance. Below is an outline of key mechanical and functional units that make this model versatile and durable.

- Engine System – Powers the machine, providing energy for all functions and movements.

- Transmission – Ensures the efficient transfer of power from the engine to the wheels.

- Hydraulics – Controls various operations, including steering and lifting capabilities.

- Suspension – Offers stability and comfort by absorbing shocks during movement.

- Braking Mechanism – Provides safe stopping power, essential for controlling speed and halting the vehicle when needed.

- Electrical System – Powers the lights, gauges, and other electronic components for optimal functionality.

Each section of the

Essential Components in the 2008 Model

Understanding the primary mechanisms of this vehicle is crucial for ensuring its efficient operation. The design incorporates several key elements that work together to deliver both performance and durability.

Power and Transmission Systems

The core of this machine’s functionality relies on the engine and transmission systems. These components are responsible for generating and transmitting energy, ensuring smooth driving and handling over various terrains.

- Engine: Powers the vehicle, providing the necessary torque and efficiency.

- Transmission: Ensures power is delivered to the wheels, adapting to different speed and load conditions.

Chassis and Suspension

The foundation of this vehicle lies in its durable frame, supported by a robust suspension. These elements absorb shocks, ensuring stability and safety during operation.

- Frame: A reinforced structure that supports the entire system, maintaining durability under heavy loads.

- Suspension: Absorbs impact, providing a smoother ride and improving overall control.

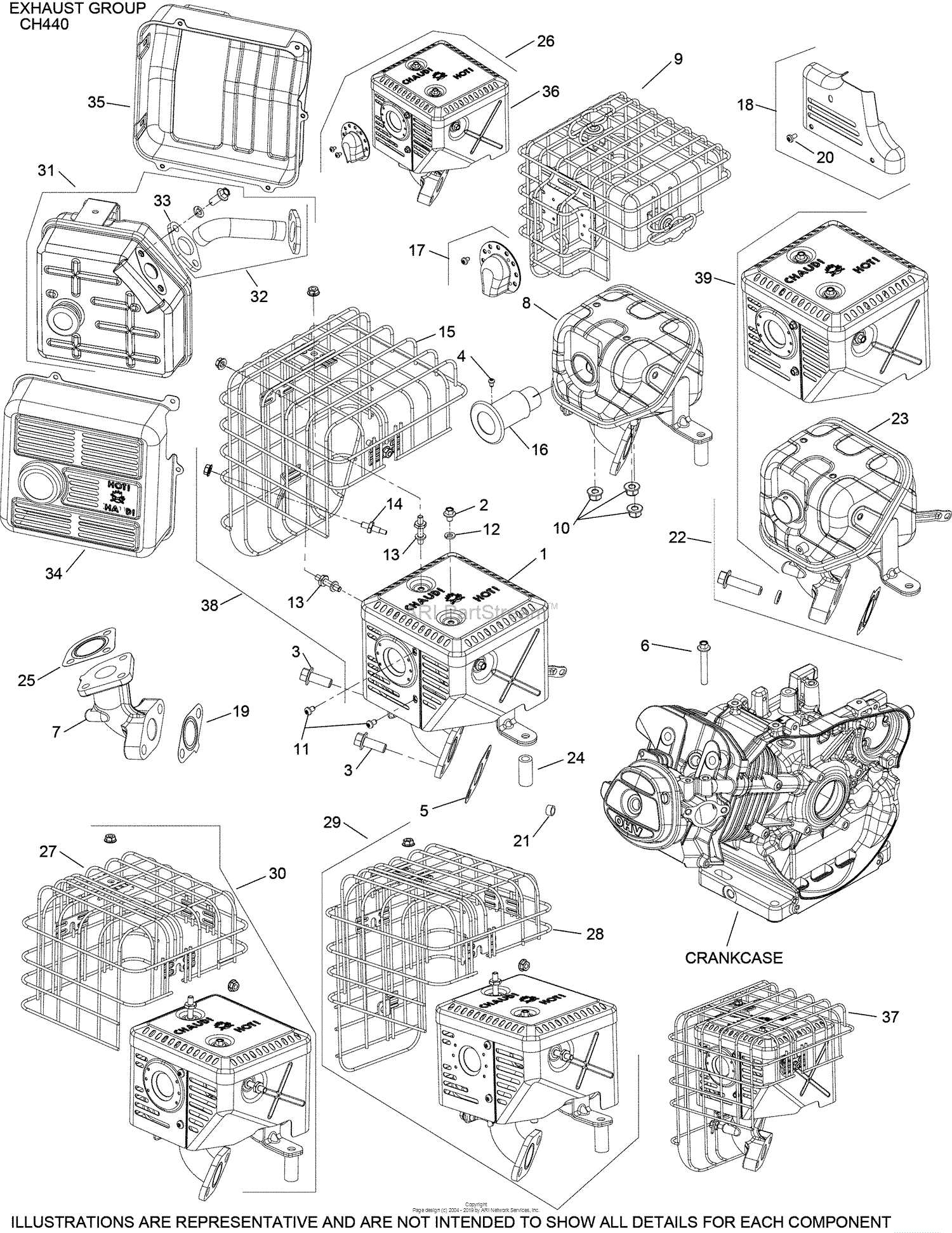

Engine Parts and Maintenance Guide

The proper upkeep of the engine is essential for ensuring the longevity and efficient operation of any machine. Regular inspection, cleaning, and timely replacement of worn-out components can prevent larger issues and reduce downtime. Understanding the various elements that make up the engine and how to maintain them is crucial for optimal performance.

Maintaining the engine involves checking key areas such as fuel delivery systems, cooling mechanisms, and lubrication points. Keeping these systems in good condition helps the engine run smoothly and minimizes wear over time. Ensuring clean filters, proper fluid levels, and well-maintained seals can extend the life of the engine.

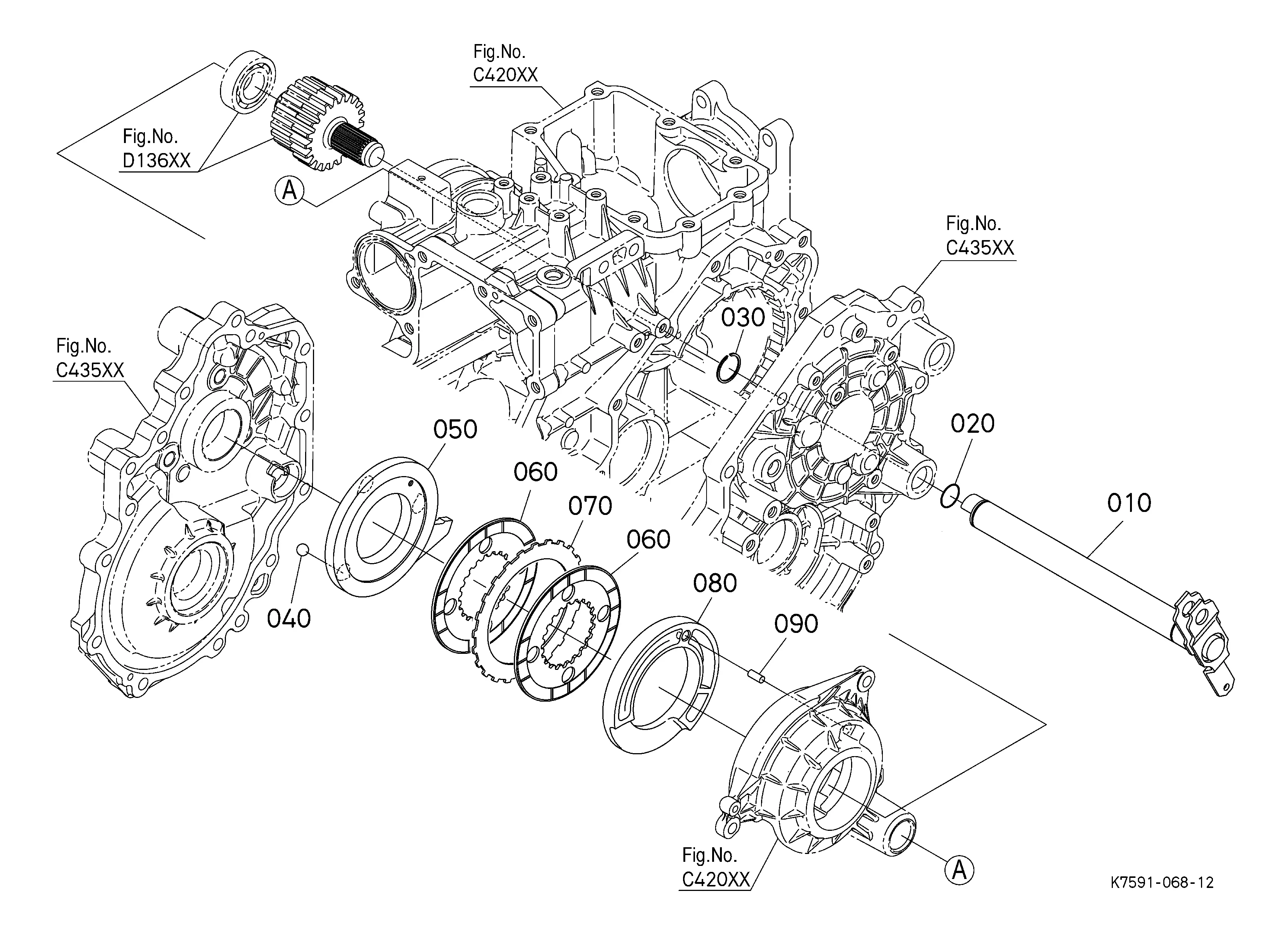

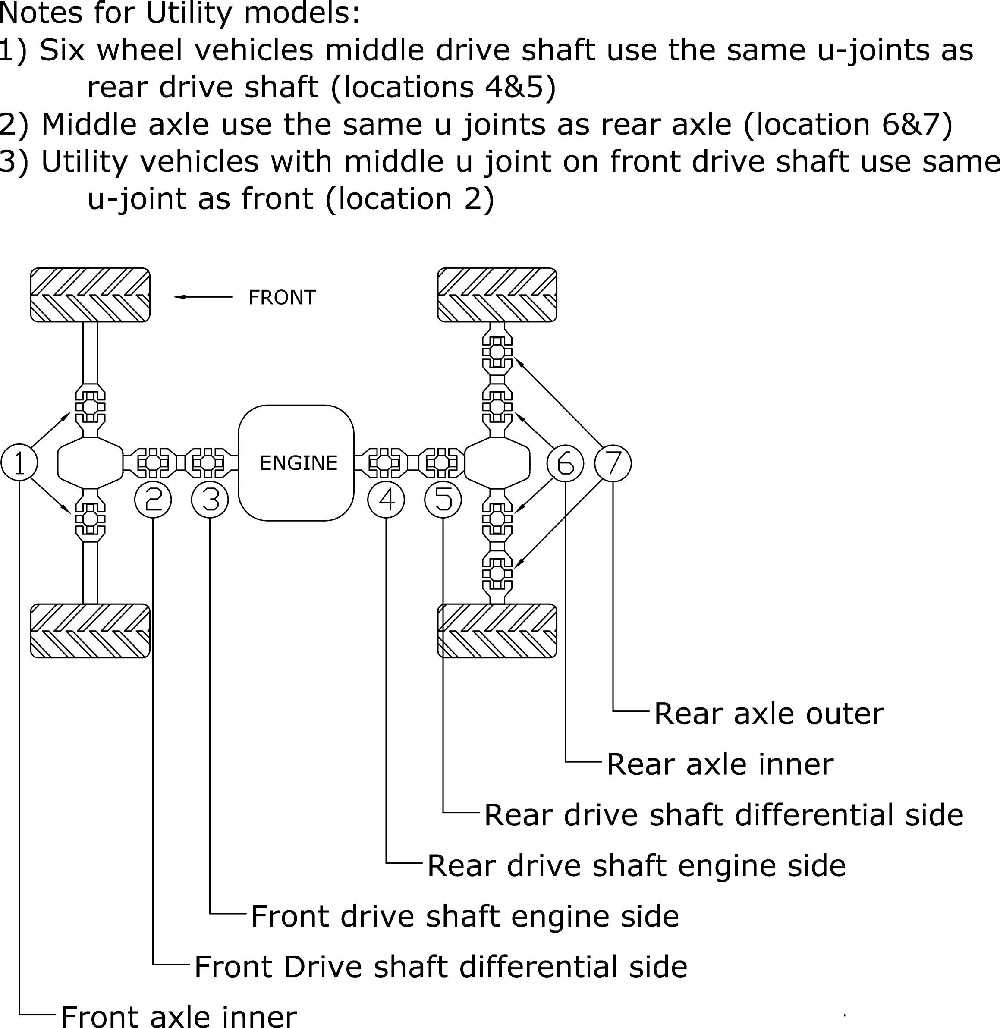

Transmission System and Key Elements

The transmission system plays a critical role in ensuring smooth operation by transferring power from the engine to the wheels. This mechanism allows for controlled movement and flexibility in handling different terrains. The system’s structure involves multiple interconnected components that work together to optimize performance and durability.

Gearbox serves as the central component of the transmission, responsible for managing speed and torque. By adjusting the gear ratios, it allows the vehicle to adapt to various driving conditions, from slow maneuvering to high-speed travel.

Another essential element is the driveline, which facilitates the transfer of mechanical power from the gearbox to the axles. It ensures a consistent flow of power, helping the machine maintain stability even on challenging surfaces.

The differential plays a crucial part in distributing torque between the wheels, enabling them to rotate at different speeds

Suspension and Chassis Breakdown

The suspension and chassis system plays a critical role in ensuring smooth operation and stability across different terrains. It combines multiple components designed to provide balance, enhance comfort, and support the overall frame of the vehicle. This section offers a detailed look into the key elements of this system, highlighting their functions and significance in the structure.

Core Suspension Components

- Shock Absorbers: Responsible for minimizing the impact from uneven surfaces and maintaining smooth rides.

- Springs: Provide the necessary cushioning to counteract road bumps and stabilize movement.

- Control Arms: Ensure proper alignment and manage the movement of the wheels during driving.

Chassis Structure Overview

- Frame: Acts as the backbone, supporting the overall structure and holding other components together.

- Axles: Connects the wheels to the frame, allowing efficient transfer of power while maintaining stability.

- Brackets and Mounts: Secure the suspension parts to the chassis, ensuring proper alignment and durability under stress.

Hydraulic System: Key Parts and Function

The hydraulic system plays a crucial role in the operation of utility vehicles, providing the necessary force to perform various tasks efficiently. Understanding the essential components of this system and their respective functions is vital for optimal performance and maintenance.

Main Components

- Hydraulic Pump: This component generates hydraulic pressure by converting mechanical energy into hydraulic energy. It is fundamental for powering the entire system.

- Hydraulic Fluid: A special fluid that transmits power within the system, it lubricates components and ensures efficient operation.

- Actuators: These devices convert hydraulic pressure into mechanical motion, enabling various functions such as lifting and moving attachments.

- Valves: Control the flow and direction of hydraulic fluid, allowing precise operation and management of the system.

Functions of the Hydraulic System

- Power Transmission: The hydraulic system transfers power from the engine to various implements, ensuring effective operation.

- Load Handling: It provides the ability to lift and move heavy loads with minimal effort, enhancing productivity.

- Precision Control: The use of valves and actuators allows for fine control over movements, making operations smoother and more efficient.

Regular maintenance and understanding of these components are essential for ensuring the hydraulic system operates at peak performance, ultimately leading to increased efficiency and longevity of the equipment.

Electrical System Overview for Kubota RTV

The electrical system of utility vehicles plays a crucial role in ensuring the efficient operation of various components. Understanding the layout and functionality of this system is essential for maintenance and troubleshooting. This section provides an overview of the electrical components, their functions, and key considerations for users.

Main Components

- Battery: Supplies power to the entire electrical system.

- Alternator: Charges the battery and powers electrical accessories.

- Starter Motor: Engages the engine during ignition.

- Fuses: Protects the electrical circuits from overloads.

- Wiring Harness: Connects all electrical components and allows for communication.

Key Functions

- Power Supply: Delivers electrical energy to all vehicle systems.

- Lighting: Operates headlights, taillights, and other illumination features.

- Instrumentation: Provides feedback on vehicle performance and status.

- Accessory Management: Controls various add-ons such as winches and heaters.

Regular inspection and understanding of these elements enhance vehicle reliability and performance. Addressing any issues promptly can prevent more significant problems and ensure long-lasting operation.

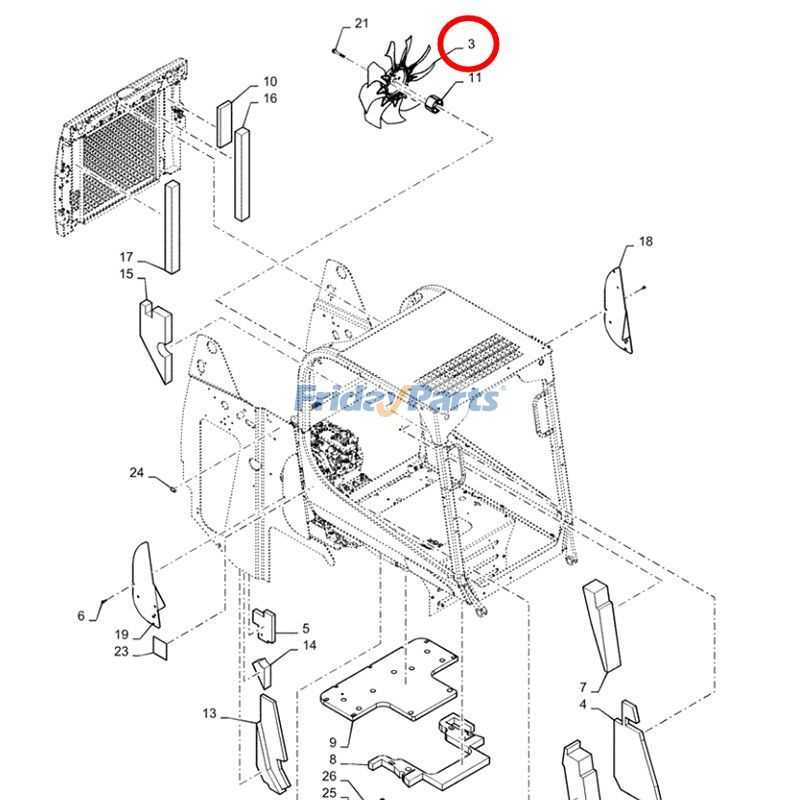

Cooling System: Parts and Diagrams

The cooling mechanism in vehicles is essential for maintaining optimal operating temperatures and preventing overheating. It consists of various components that work together to efficiently dissipate heat generated by the engine. Understanding the layout and function of these elements is crucial for effective maintenance and troubleshooting.

Key Components of the Cooling Mechanism:

- Radiator: A critical component that allows heat exchange, cooling the engine coolant before it circulates back into the engine.

- Water Pump: Responsible for circulating the coolant throughout the system, ensuring consistent flow and temperature regulation.

- Thermostat: A temperature-sensitive valve that regulates coolant flow based on the engine’s temperature, allowing the system to reach and maintain optimal operating conditions.

- Cooling Hoses: Flexible tubes that transport coolant between the engine, radiator, and other components, facilitating heat dissipation.

Familiarity with these components and their arrangement can assist in diagnosing issues and ensuring the longevity of the cooling mechanism.

Braking System Components and Setup

The braking system is crucial for ensuring the safety and control of any vehicle. Proper understanding of its components and their configuration can significantly enhance performance and reliability. This section will delve into the various elements that constitute an effective braking mechanism, along with their arrangement and function.

Main Components

- Brake Pedal: The driver uses this component to initiate braking.

- Master Cylinder: Converts the force from the brake pedal into hydraulic pressure.

- Brake Lines: Transport hydraulic fluid from the master cylinder to the brakes.

- Brake Calipers: Clamp the brake pads against the rotor to create friction.

- Brake Pads: Material that contacts the rotor, generating the necessary friction.

- Rotors: The surface against which the brake pads apply pressure.

- Brake Fluid: Hydraulic fluid that transmits force within the braking system.

Setup and Maintenance

Proper installation and regular maintenance of the braking system are essential for optimal performance. Here are some key steps to follow:

- Ensure all components are compatible and in good condition.

- Check the hydraulic fluid levels and replace it as needed.

- Inspect brake pads and rotors for wear and replace them when necessary.

- Bleed the braking system to remove any air pockets that could hinder performance.

- Test the system after installation to confirm effective braking response.

Fuel System: Parts and Replacement Tips

The fuel system of a vehicle plays a critical role in ensuring optimal engine performance and efficiency. Understanding the components involved and knowing how to maintain or replace them can significantly enhance the longevity and reliability of the machinery. Proper care and timely replacements of worn or damaged elements can prevent costly repairs and ensure smooth operation.

Essential Components of the Fuel System

The main elements of a fuel delivery system include the fuel tank, pump, filter, and injectors. Each part contributes to the overall functionality:

- Fuel Tank: Stores the fuel and is designed to resist corrosion and leaks.

- Fuel Pump: Responsible for transporting fuel from the tank to the engine, ensuring consistent pressure.

- Fuel Filter: Removes impurities and debris, protecting the injectors and engine from damage.

- Injectors: Atomize the fuel, allowing it to mix properly with air for combustion.

Replacement Tips

Regular inspection of these components is essential. Signs of wear include difficulty starting, reduced power, or unusual noises. When replacing any part:

- Always use high-quality components to maintain performance.

- Refer to the manufacturer’s specifications for proper installation procedures.

- Consider seeking professional assistance if unsure about any replacements.

By staying vigilant and proactive with the fuel system, operators can ensure their vehicles run efficiently and reliably for years to come.

Steering Mechanism and Key Parts

The steering system in a utility vehicle is essential for navigating varied terrains and ensuring precise handling. This system comprises several components that work in harmony to provide drivers with control and stability. Understanding the key elements of the steering assembly can enhance maintenance practices and improve the overall performance of the vehicle.

Essential Components

At the core of the steering mechanism lies the steering wheel, which allows the operator to direct the vehicle’s movement. Connected to the wheel is the steering column, which transmits the driver’s input to the steering assembly. Another critical part is the rack and pinion system, which converts the rotational motion of the steering wheel into linear motion, enabling the vehicle to turn smoothly.

Maintenance Tips

Regular inspection of the steering components is vital for ensuring safety and performance. Pay close attention to the tie rod ends and ball joints, as wear and tear can lead to steering instability. Lubricating moving parts and replacing worn components promptly will help maintain optimal functionality and prolong the life of the steering system.

Detailed Diagrams of Exterior Components

The intricate design of outdoor machinery requires a comprehensive understanding of its external elements. Visual representations of these components provide valuable insights into their functions and interrelationships. Such illustrations serve as essential tools for maintenance and repair, ensuring users can effectively identify and address any issues that may arise.

Key Features of External Elements

Each exterior section plays a vital role in the overall performance of the equipment. These features not only enhance functionality but also contribute to safety and usability. Recognizing these elements allows operators to maintain optimal performance levels and extend the machinery’s lifespan.

Understanding Component Relationships

Interconnections among exterior parts are crucial for efficient operation. Awareness of how these elements interact can simplify troubleshooting processes. Familiarity with each component’s placement and role enhances user confidence when performing routine checks or repairs.