When it comes to maintaining machinery, having a comprehensive understanding of its various elements is crucial. Every piece plays a vital role in ensuring optimal performance and longevity, making it essential for operators and technicians alike to familiarize themselves with their specific functions.

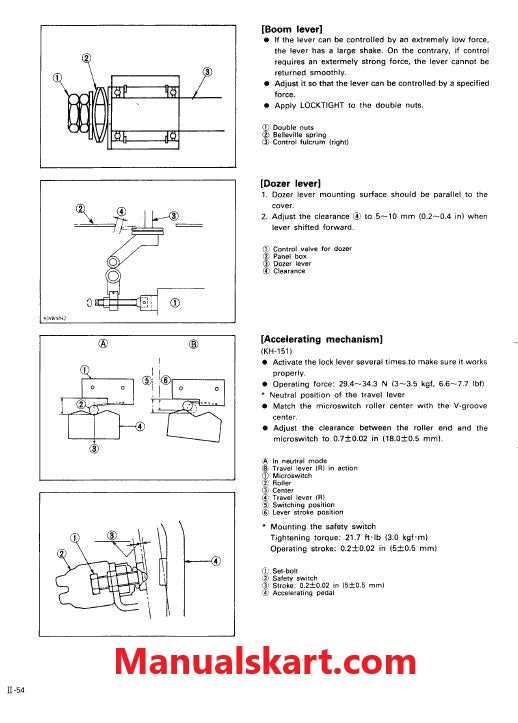

Visual representations of machinery components can significantly enhance one’s ability to identify and troubleshoot issues. Such illustrations not only clarify the interrelations between parts but also serve as invaluable references during repairs and maintenance tasks.

By delving into detailed schematics, users can grasp the ultimate configuration of their equipment, empowering them to make informed decisions regarding repairs and replacements. This knowledge not only streamlines maintenance efforts but also boosts overall efficiency in operations.

Kubota B3200 Overview

This section provides a comprehensive insight into a compact utility vehicle designed for versatility and efficiency in various tasks. Ideal for both agricultural and landscaping applications, it combines power with ease of use, making it a popular choice among enthusiasts and professionals alike.

Key Features

With a robust engine and a range of attachments, this model excels in performance and adaptability. Its user-friendly controls and ergonomic design enhance operator comfort, allowing for extended use without fatigue.

Applications

Whether tackling heavy-duty chores on a farm or performing light-duty tasks in a garden, this vehicle proves to be an invaluable asset. Its capability to handle diverse tasks contributes to its reputation as a reliable workhorse in various environments.

Key Features of Kubota B3200

This compact utility vehicle is designed for versatility and efficiency in various tasks. It combines robust engineering with user-friendly features, making it an excellent choice for both professionals and hobbyists. Below are some of the standout characteristics that make this machine a valuable asset.

Performance and Power

- Equipped with a reliable engine that delivers strong horsepower for demanding applications.

- Advanced hydraulic system for superior lifting capabilities and efficient operation.

- Excellent torque for handling heavy loads, ensuring optimal performance in tough conditions.

User-Friendly Design

- Ergonomic controls that enhance operator comfort and reduce fatigue during extended use.

- Compact size allows for easy maneuverability in tight spaces, ideal for landscaping and farming tasks.

- Durable construction with high-quality materials that ensure longevity and reduce maintenance needs.

Understanding Parts Diagrams

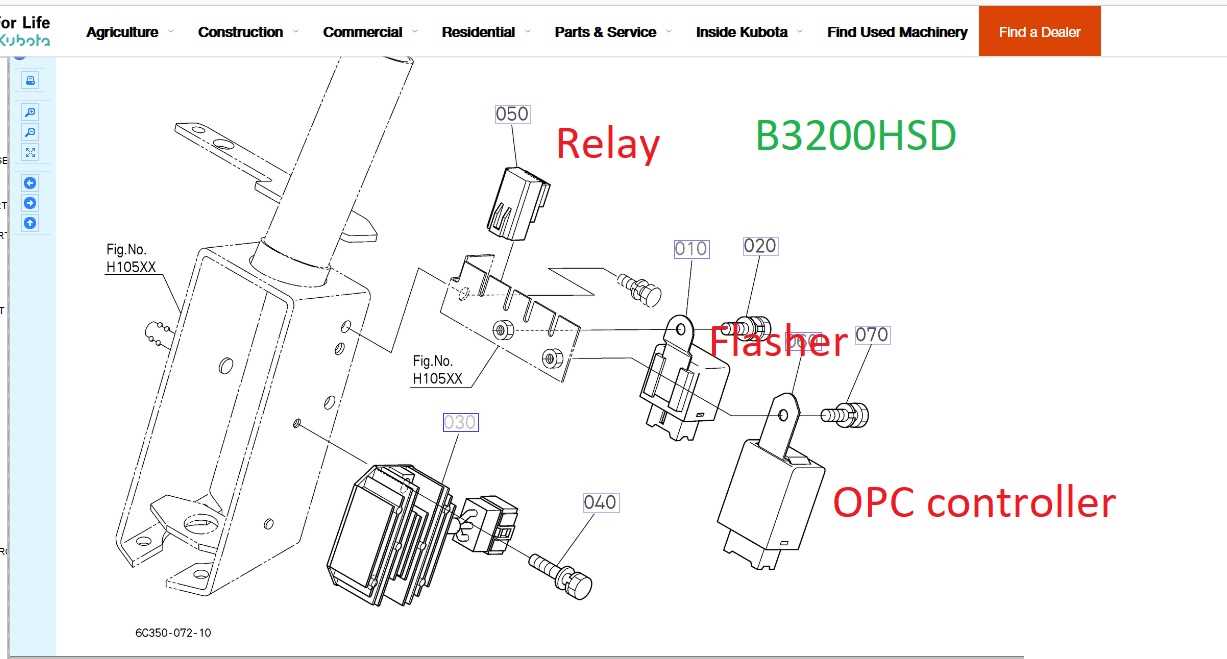

Visual representations of components play a crucial role in maintenance and assembly processes. They provide clarity, ensuring that users can easily identify individual elements and their relationships within a larger system. This understanding is essential for effective troubleshooting and repairs, ultimately enhancing the longevity and performance of machinery.

Importance of Visual Representation

Utilizing graphical illustrations allows for quick reference and aids in comprehension. Users can navigate complex assemblies, identifying which segments are crucial for specific functions. This approach not only simplifies the identification process but also minimizes the risk of errors during repairs.

Benefits for Maintenance and Repairs

Engaging with these visual tools enhances efficiency and accuracy. By grasping the layout of each component, individuals can delve deeper into the functionality of the entire system, leading to informed decisions when conducting maintenance. Ultimately, this knowledge empowers users to perform repairs confidently and effectively.

Importance of Accurate Diagrams

Precision in technical illustrations is crucial for effective maintenance and repair. These visuals serve as essential guides, ensuring that users can identify components correctly and execute tasks efficiently. Inaccurate representations can lead to costly errors, delays, and even safety hazards.

Enhanced Understanding

Clear illustrations provide a better grasp of complex systems, allowing technicians and users to navigate machinery with confidence. When every element is depicted accurately, it simplifies troubleshooting and facilitates smoother operations.

Efficient Repairs

Having a reliable reference minimizes the time spent on repairs, maximizing productivity. When components are easily identifiable, the process becomes straightforward, leading to quicker resolutions and less downtime.

| Benefits | Impact |

|---|---|

| Clarity | Improved understanding of systems |

| Accuracy | Reduced risk of errors |

| Efficiency | Faster repair times |

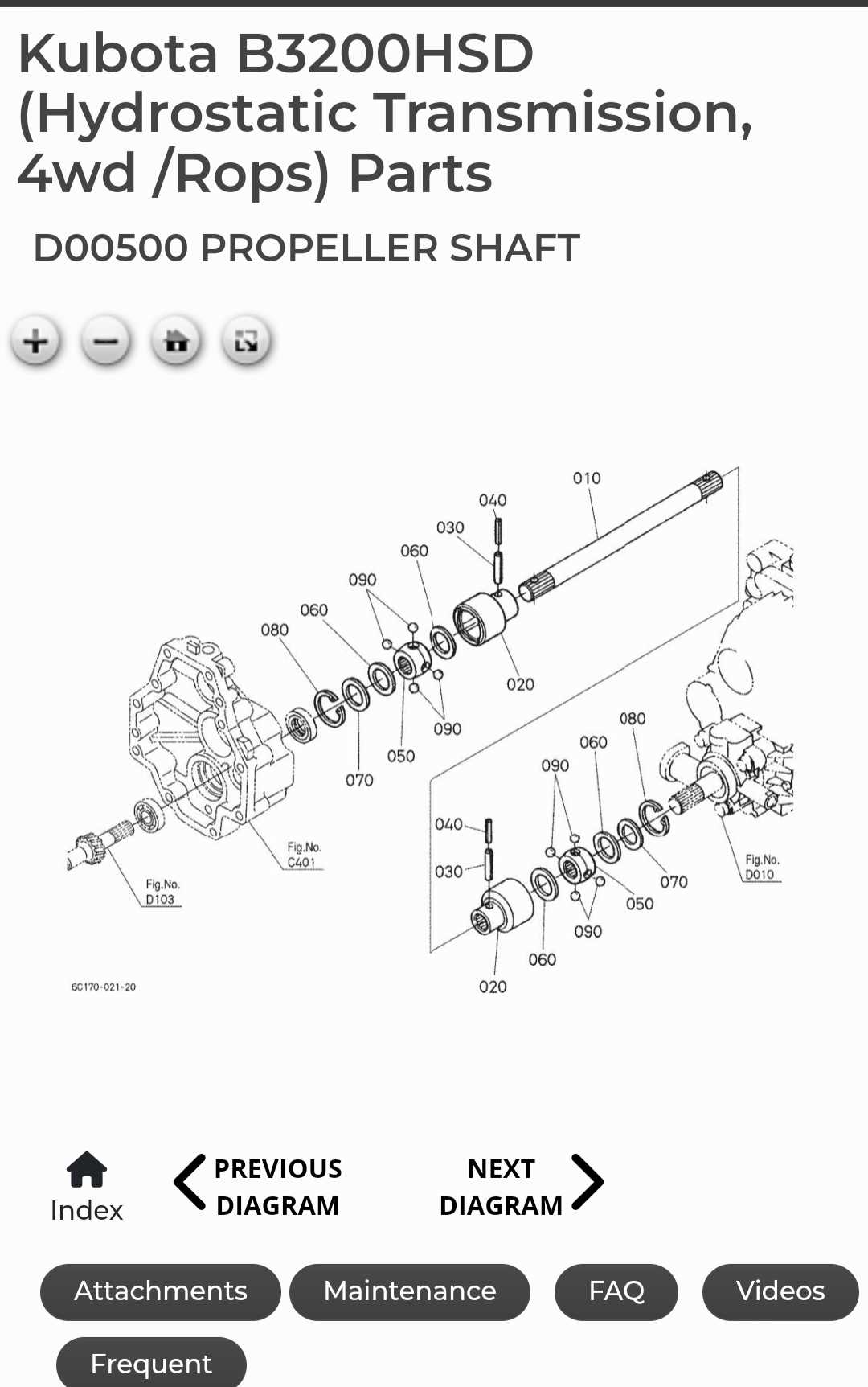

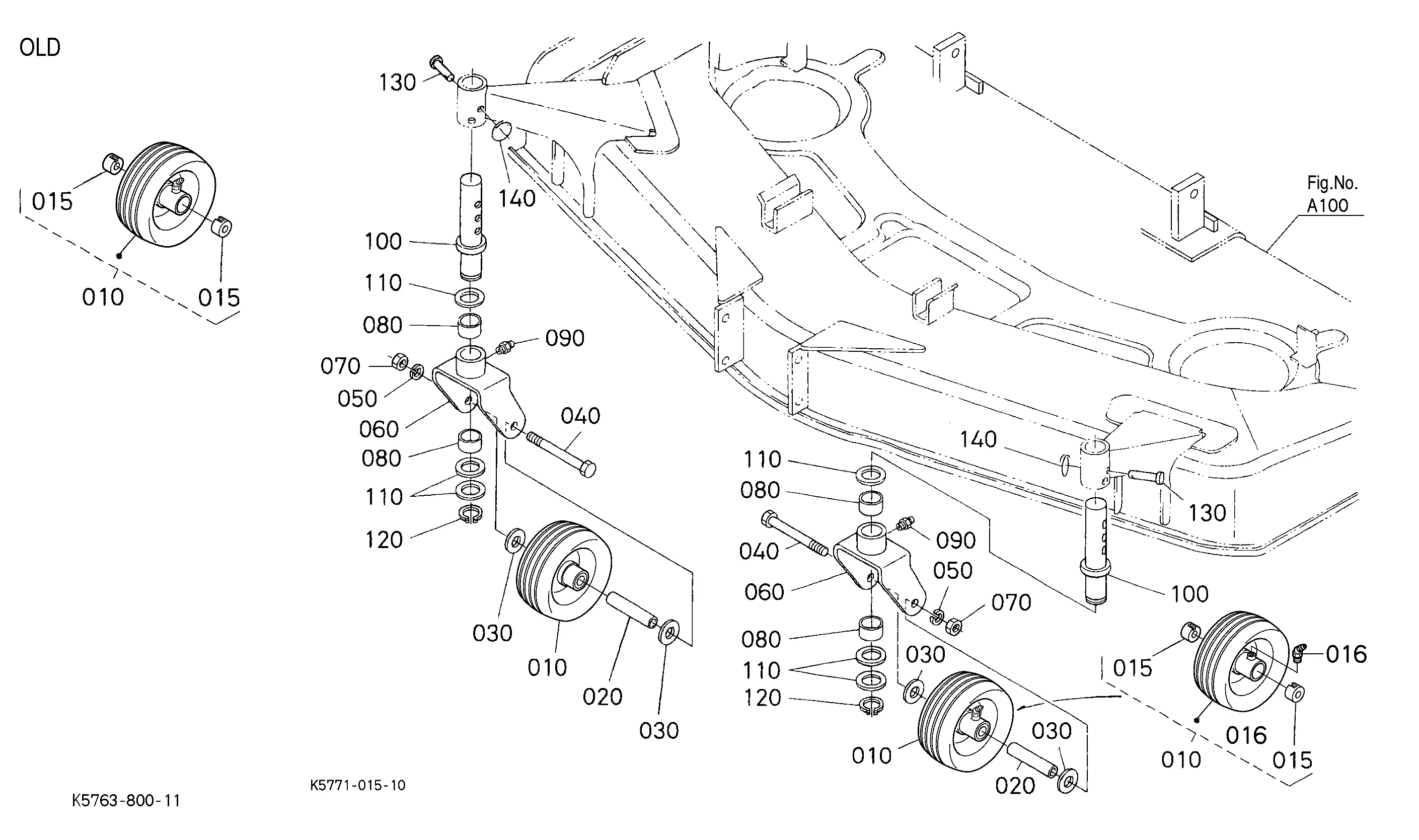

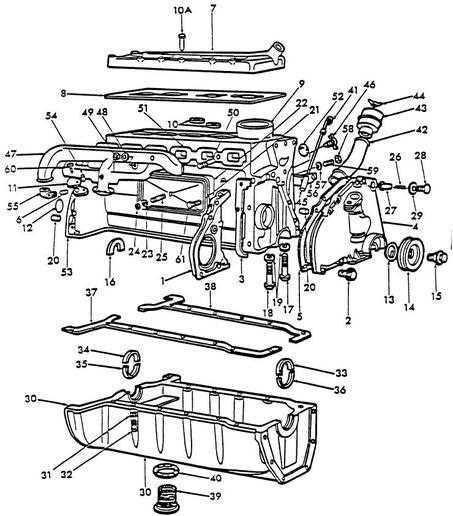

Main Components of B3200

The functionality of this compact utility vehicle relies on a variety of essential elements that work harmoniously together. Each component plays a pivotal role in ensuring optimal performance and efficiency in various tasks.

Engine: The powerhouse of the machine, responsible for providing the necessary energy to perform demanding tasks.

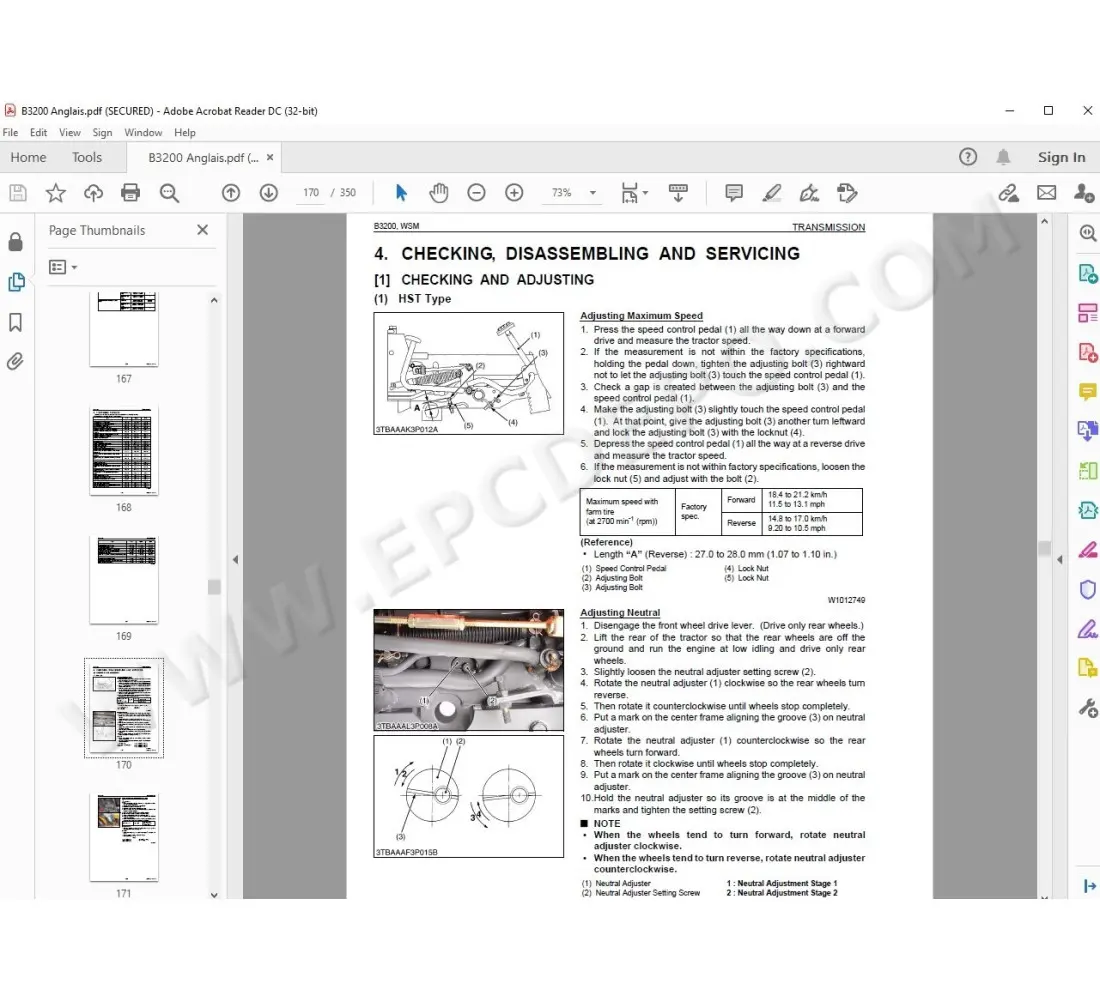

Transmission: This system enables smooth gear shifting and effective power transfer, enhancing maneuverability and control.

Hydraulic System: Vital for operating attachments and lifting mechanisms, this system provides the ultimate flexibility in handling different jobs.

Chassis: The frame supports all components, ensuring stability and durability while withstanding tough working conditions.

Wheels and Tires: These elements ensure traction and mobility across various terrains, contributing to the overall versatility of the vehicle.

Understanding these fundamental components allows users to delve deeper into maintenance and upgrades, maximizing the vehicle’s potential for diverse applications.

Where to Find Parts Lists

Locating detailed lists of components for machinery can be essential for maintenance and repair. Understanding where to find these resources ensures that users can easily identify the necessary items for their equipment, making the upkeep process smoother and more efficient.

Here are some reliable sources for accessing these lists:

- Manufacturer Websites: Official sites often provide downloadable resources, including lists and manuals tailored to specific models.

- Online Retailers: E-commerce platforms that specialize in machinery supplies usually have comprehensive catalogs featuring various components.

- Forums and Community Groups: Engaging with online communities can yield valuable insights. Many enthusiasts share resources and even post their own lists.

- Local Dealers: Authorized dealers can provide printed or digital lists and assist in sourcing specific items directly.

- Service Manuals: These documents often contain detailed breakdowns of all necessary components and are frequently available for purchase or download.

Utilizing these resources can greatly enhance the ease of finding the components needed for effective machinery operation.

Common Maintenance Tasks

Regular upkeep is essential for ensuring the longevity and efficient performance of any machinery. Proper maintenance not only helps in avoiding unexpected breakdowns but also enhances productivity and safety. Familiarizing yourself with routine tasks can lead to smoother operations and a more reliable machine.

Routine Checks

- Inspect fluid levels regularly, including engine oil, coolant, and hydraulic fluids.

- Examine belts and hoses for signs of wear or damage.

- Check air filters and clean or replace them as needed.

Seasonal Maintenance

- Change the engine oil and filter at regular intervals.

- Sharpen or replace cutting blades to maintain optimal performance.

- Inspect tires for wear and ensure proper inflation levels.

- Clean and lubricate moving parts to prevent rust and enhance functionality.

By staying proactive with these maintenance tasks, operators can significantly extend the lifespan of their equipment and reduce the risk of costly repairs.

Identifying Worn Parts

Recognizing when components have reached the end of their lifespan is crucial for maintaining optimal performance. Regular inspection can help ensure that machinery operates efficiently and safely.

Visual Inspection: Begin by examining each element for signs of wear, such as cracks, rust, or deformation. Any noticeable damage may indicate the need for replacement.

Functional Tests: Conducting operational assessments can reveal inefficiencies. If a part does not perform as expected, it might be time to consider a replacement.

Listen for Unusual Noises: Uncommon sounds during operation often signal issues. Grinding, squeaking, or rattling can be signs of worn components needing attention.

Check for Leaks: Fluid leaks can suggest degradation. Monitoring for any signs of leakage is essential for identifying compromised parts.

Consulting the Manual: Referencing the maintenance guide can provide insight into the typical lifespan of various elements, helping to determine when replacements are necessary.

By staying vigilant and proactive, you can ultimately enhance the longevity and reliability of your machinery.

Ordering Replacement Components

Acquiring new components for your machinery is essential for maintaining optimal performance and extending its lifespan. Ensuring the right items are selected and ordered can save time and resources.

When looking to purchase replacements, consider the following steps:

- Identify the specific component needed by checking your user manual or existing machinery.

- Research reliable suppliers who specialize in machinery components.

- Compare prices and availability from different vendors to find the best deal.

- Review customer feedback to ensure product quality and vendor reliability.

- Confirm compatibility with your model before placing an order.

Following these guidelines will help streamline the ordering process and ensure you receive the correct replacements swiftly.

Using OEM vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between original equipment and alternative components can significantly impact performance and longevity. Original equipment manufacturer items often guarantee compatibility and reliability, as they are specifically designed for the machine in question. On the other hand, alternative components can offer cost savings and variety, appealing to budget-conscious users seeking practical solutions.

Ultimately, the decision hinges on factors such as cost, availability, and personal preferences regarding quality. While original components provide peace of mind, alternative options may deliver adequate performance without the higher price tag. Evaluating the pros and cons of each type can help users make informed choices that align with their needs.

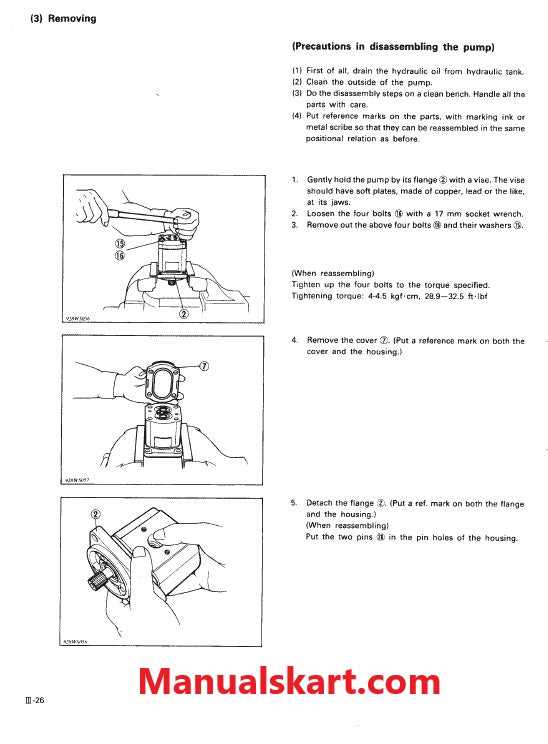

Assembly Instructions

This section provides detailed guidance for assembling components effectively, ensuring optimal performance and longevity of your machinery.

- Gather Necessary Tools:

- Wrenches

- Screwdrivers

- Pliers

- Torque wrench

- Prepare the Workspace:

- Clear the area of any debris

- Ensure proper lighting

- Organize all components

- Follow the Assembly Steps:

- Begin with the base structure, securing all joints tightly.

- Attach the main components, referring to the reference guide for alignment.

- Double-check all connections before proceeding to the next step.

- Final Inspection:

- Verify all fasteners are secure

- Ensure moving parts function smoothly

- Check for any misplaced components

By adhering to these steps, you will achieve a reliable assembly that meets the highest standards of efficiency.

Benefits of DIY Repairs

Engaging in self-repairs offers numerous advantages that extend beyond mere cost savings. By taking on these tasks, individuals can gain valuable skills, boost their confidence, and foster a deeper understanding of their equipment.

Firstly, completing repairs independently allows for significant financial savings. Instead of paying for labor, one can allocate resources towards necessary materials, making maintenance more economical.

Moreover, diving into repairs can enhance personal expertise. As individuals navigate the intricacies of their machinery, they develop a greater appreciation for its components and functions.

Finally, accomplishing repairs without external assistance instills a sense of achievement. This ultimate satisfaction can motivate individuals to tackle even more challenging projects in the future, further expanding their capabilities.