The functionality and efficiency of an excavating machine rely heavily on its various components. Understanding the configuration and relationship between these elements is crucial for optimal operation and maintenance. Proper knowledge aids in troubleshooting and ensures that each part is functioning as intended.

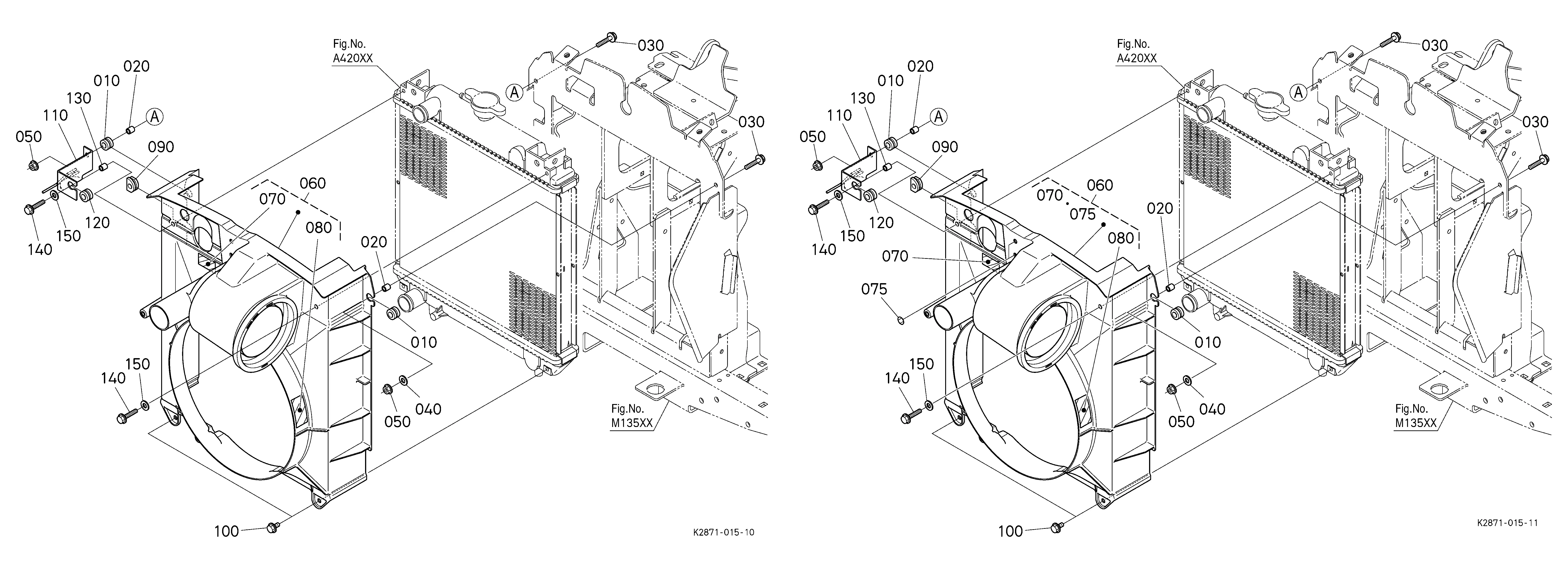

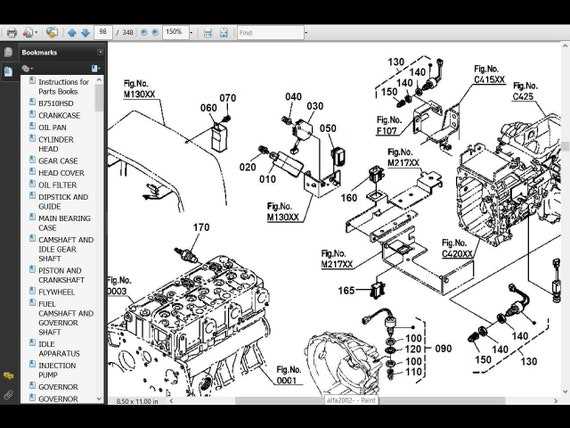

Detailed visual representations provide valuable insights into how these elements interact within the machinery. They serve as guides for identification and replacement, facilitating the repair process and enhancing the overall performance of the equipment. A thorough grasp of the assembly layout can prevent costly errors and extend the life of the machinery.

In this section, we will explore the intricate details of the excavator’s components, offering a clearer understanding of their roles and arrangements. Whether you’re a professional technician or a passionate enthusiast, this information will equip you with the knowledge needed for effective maintenance and repair tasks.

This section aims to provide insight into the various elements that make up the digging machinery. Understanding how each component operates is crucial for effective maintenance and troubleshooting.

Key Components of the Machinery

- Engine: Powers the entire system.

- Hydraulic System: Controls movement and function of attachments.

- Frame: Provides structural support and stability.

- Bucket: Used for digging and moving materials.

- Stabilizers: Ensure balance during operation.

Functions of Individual Parts

- Engine: Converts fuel into mechanical energy.

- Hydraulic System: Transfers fluid to control movements.

- Frame: Acts as the backbone for all components.

- Bucket: Allows for excavation and material handling.

- Stabilizers: Prevent tipping and improve performance.

Maintenance Tips for Longevity

- Regularly check fluid levels in the hydraulic system.

- Inspect the engine for signs of wear and tear.

- Clean the bucket after use to prevent rust.

- Ensure stabilizers are functioning properly before operation.

Key Parts of the Kubota BX23S

This section highlights essential components that contribute to the efficient operation of this versatile machinery. Understanding these elements is crucial for maintenance and effective usage.

Primary Components

- Engine Assembly

- Hydraulic System

- Transmission Unit

- Frame Structure

Additional Features

- Control Levers

- Operator Seat

- Rear Attachments

- Wheels and Tires

Maintenance Tips for Backhoe Parts

Regular upkeep is essential for ensuring the longevity and efficiency of your excavation equipment. Implementing a consistent maintenance routine can prevent costly repairs and improve overall performance.

- Check fluid levels frequently and top them up as needed to avoid overheating.

- Inspect hoses and connections for any signs of wear or leaks.

- Keep all moving components well-lubricated to reduce friction and wear.

- Examine the undercarriage and tires for damage or excessive wear.

- Clean air filters regularly to ensure optimal airflow and engine performance.

By following these practices, operators can enhance the functionality and lifespan of their machinery, making it a more reliable asset in various projects.

Common Issues and Solutions

When operating heavy machinery, various challenges may arise that affect performance and efficiency. Identifying these common problems and implementing effective solutions can enhance the longevity and functionality of the equipment.

Frequent Problems

- Hydraulic leaks that can lead to reduced power.

- Engine overheating due to inadequate cooling.

- Electrical failures causing operational malfunctions.

- Wear and tear on moving components impacting performance.

Proposed Solutions

- Regularly inspect hydraulic systems for leaks and replace damaged seals.

- Ensure coolant levels are adequate and check the radiator for blockages.

- Examine electrical connections for corrosion and repair any faulty wiring.

- Perform routine maintenance on moving parts to minimize wear.

Parts Replacement Guide

This section focuses on the essential steps for swapping out components of your machinery to ensure optimal performance. Proper maintenance and timely replacements can greatly enhance the longevity and efficiency of your equipment.

1. Identification: Before proceeding, it is crucial to accurately identify the specific components that require replacement. Utilize your operator’s manual or reference materials to locate the correct items.

2. Tools Needed: Gather the necessary tools for the replacement process. Commonly needed tools include wrenches, screwdrivers, and pliers. Ensure that you have everything ready before starting.

3. Safety Precautions: Always prioritize safety. Disconnect the power source and wear appropriate protective gear, such as gloves and goggles, to prevent injuries during the replacement process.

4. Replacement Steps: Follow the manufacturer’s guidelines for the removal and installation of the components. Take care to secure all fasteners properly and double-check connections before reassembling the machinery.

5. Testing: After replacing the components, perform a thorough check to ensure everything is functioning as expected. Run the equipment for a short period to identify any potential issues.

By adhering to these guidelines, you can effectively manage component replacements and maintain the efficiency of your machinery.

Identifying Compatible Components

Understanding the suitable elements for your machinery is crucial for optimal performance. Compatibility ensures that each component works seamlessly together, contributing to the overall efficiency and longevity of the equipment.

To find the right elements, consider the specifications of your equipment and cross-reference them with available components. Here are some key factors to look for:

| Factor | Description |

|---|---|

| Model Number | Verify the model number to ensure proper fitment. |

| Manufacturer Specifications | Check the manufacturer’s guidelines for compatible parts. |

| Material Quality | Choose components made from durable materials for longevity. |

| Performance Ratings | Look for performance ratings to gauge efficiency. |

By focusing on these factors, you can make informed decisions and enhance the functionality of your equipment.

Visual Reference for Backhoe Parts

This section provides a comprehensive visual guide to the components of the excavation machinery. Understanding the various elements is essential for effective maintenance and repairs. By familiarizing oneself with the layout and function of each piece, operators can enhance their efficiency and troubleshoot issues more effectively.

Detailed illustrations serve as an invaluable tool for both novice and experienced users. They facilitate easier identification of individual components, ensuring that replacements and servicing are carried out accurately. This reference aims to streamline the process of understanding the structure of this powerful equipment.

Where to Find Diagrams Online

Locating detailed illustrations and schematics for machinery components is essential for effective maintenance and repair. Numerous resources are available online to assist in this search.

Here are some reliable sources:

- Manufacturer’s Website: Check the official website of the equipment manufacturer for technical manuals and service guides.

- Online Forums: Participate in industry-specific forums where enthusiasts and professionals share valuable resources and links.

- Parts Retailers: Websites that specialize in selling machinery components often provide visual aids and diagrams for reference.

- Technical Service Providers: Companies that offer repair services might have resources or links to detailed schematics.

- YouTube Tutorials: Video tutorials can offer insights into locating parts and understanding their functions.

Utilizing these sources can significantly enhance your ability to find the necessary illustrations for your machinery.

Ordering Parts: Best Practices

When it comes to acquiring components for machinery, following effective strategies can enhance the experience and ensure timely access to necessary items. Being organized and informed plays a crucial role in streamlining the procurement process.

Research and Verify: Before placing an order, it is essential to thoroughly research the required items. Utilize reputable sources and confirm the specifications to avoid errors. This minimizes the risk of receiving incorrect components that may delay repairs.

Utilize Official Channels: Whenever possible, order through authorized dealers or manufacturers. This approach guarantees the quality and compatibility of the items, along with access to customer support for any inquiries.

Plan Ahead: Anticipate future needs by maintaining an inventory of frequently used components. This proactive measure helps in avoiding last-minute rush orders that can lead to mistakes and increased costs.

Keep Records: Maintain a detailed log of previous orders, including part numbers and supplier information. This documentation can simplify reordering and help in identifying reliable sources for future purchases.

Communicate Clearly: When placing an order, provide precise details to the supplier. Clear communication about specifications, quantities, and delivery timelines reduces the likelihood of misunderstandings and ensures that the right items arrive on time.

Using OEM vs. Aftermarket Components

When it comes to selecting components for machinery maintenance and repairs, two primary options arise: original equipment manufacturer (OEM) products and aftermarket alternatives. Each option presents distinct advantages and drawbacks, influencing both performance and cost-effectiveness.

Advantages of OEM Components

OEM products are specifically designed for particular machines, ensuring perfect compatibility and reliability. These components often come with warranties and are backed by the manufacturer’s reputation for quality. Users can expect optimal performance, as these parts adhere to strict industry standards.

Benefits of Aftermarket Alternatives

Aftermarket components offer greater flexibility and often come at a lower price point. Many manufacturers provide a wide range of options that can enhance or modify machine performance. However, it’s essential to research the quality and compatibility of these alternatives, as not all aftermarket parts meet the same standards as their OEM counterparts.