The intricacies of mechanical systems are often challenging to navigate without a clear visual representation. Understanding the interplay of various components in a complex structure requires precise schematics that lay out each element’s role in a straightforward and accessible manner. For anyone working with these systems, having a well-organized guide is crucial to ensuring smooth operation and proper maintenance.

In this guide, we explore the essentials of deciphering equipment layouts, providing clarity on how to read and interpret different sections of a mechanical blueprint. Whether you’re troubleshooting an issue or performing routine upkeep, being familiar with the individual elements and their arrangement can significantly reduce downtime and improve efficiency.

Each section will break down specific modules, helping you to visualize the connections and functions of various segments. This resource is invaluable for both professionals and hobbyists who seek to keep their machinery in optimal working condition by understanding the relationships within its structural layout.

Understanding Kubota GR2110 Components

Familiarity with the various elements of a compact utility vehicle is essential for effective maintenance and operation. Each component plays a significant role in ensuring the machine functions optimally, making it crucial to understand their interrelationships and functionalities.

Key Components Overview

The vehicle consists of several key parts that work together seamlessly. These elements range from the engine and transmission to the hydraulic system and chassis. Understanding how these components integrate will help users troubleshoot issues and perform necessary repairs more efficiently.

Component Functionality Table

| Component | Function |

|---|---|

| Engine | Powers the vehicle and drives all mechanical functions. |

| Transmission | Transfers power from the engine to the wheels, allowing for speed adjustments. |

| Hydraulic System | Controls various implements and attachments, providing lifting and maneuvering capabilities. |

| Chassis | Houses the core components and provides structural integrity to the vehicle. |

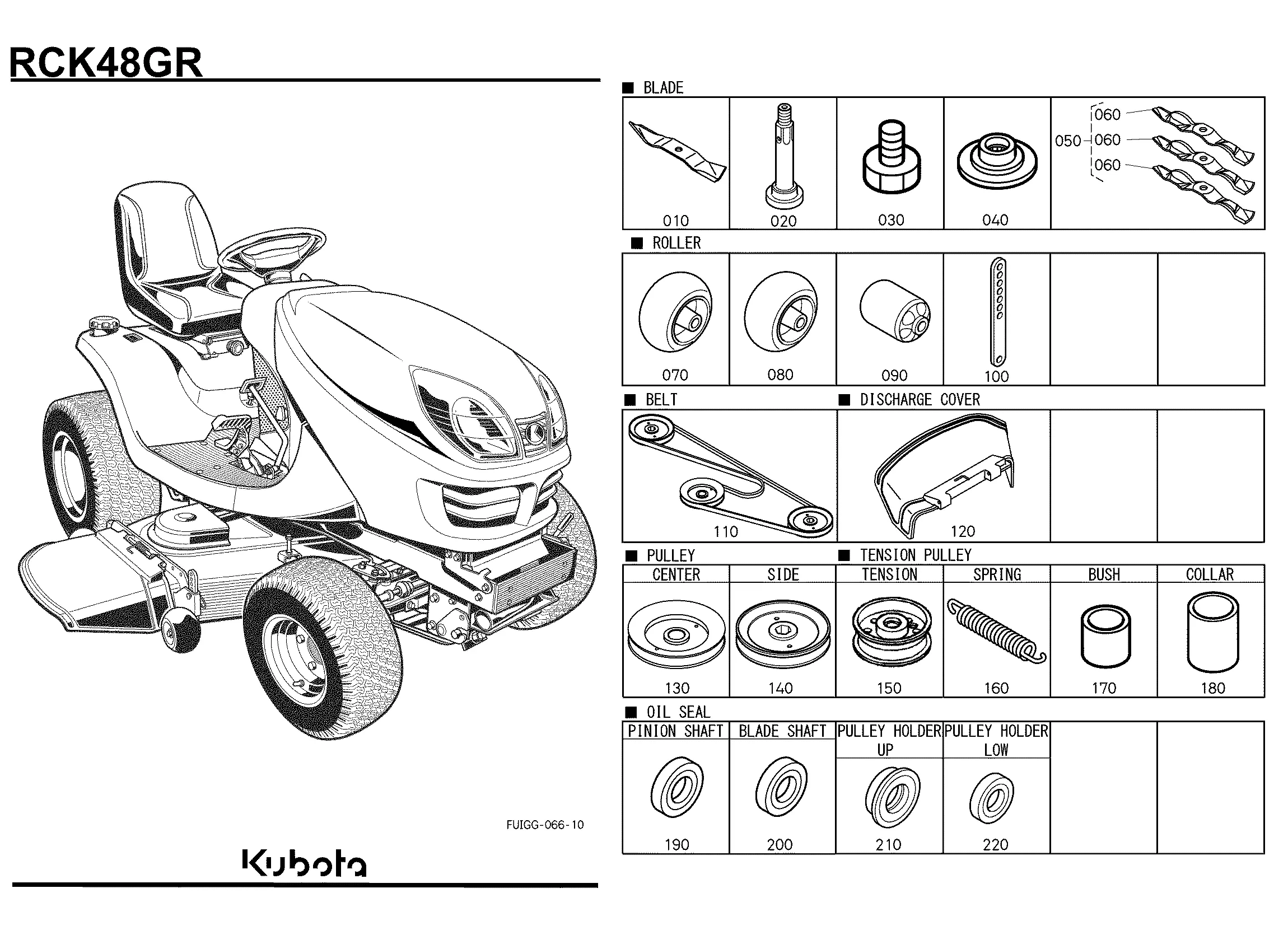

Overview of Key Parts

This section provides an insight into essential components found in compact agricultural machinery, focusing on their functions and interrelationships. Understanding these elements is crucial for effective maintenance and operation.

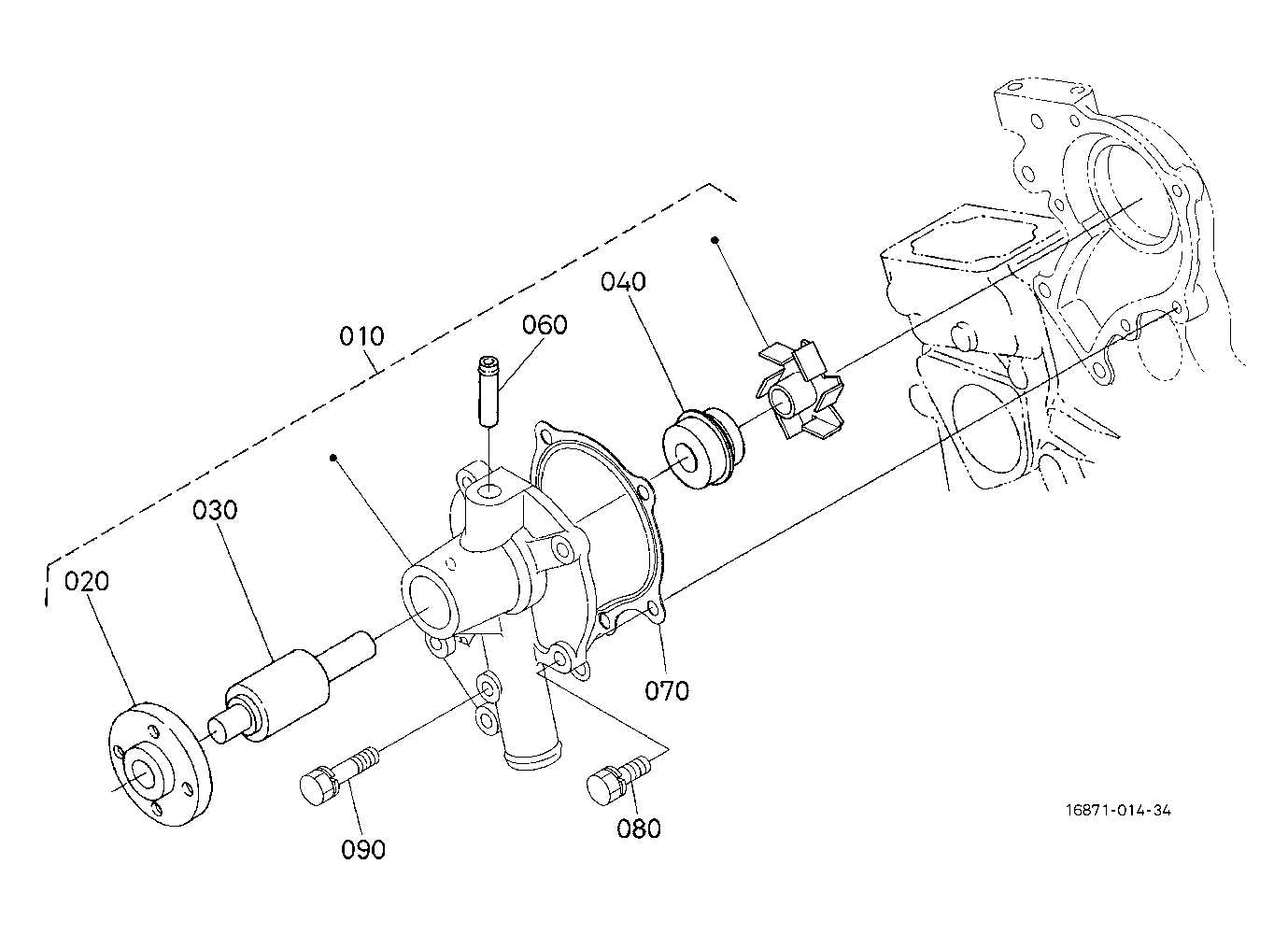

Engine Assembly: The heart of the machine, responsible for generating power. It plays a vital role in performance and efficiency, influencing fuel consumption and overall functionality.

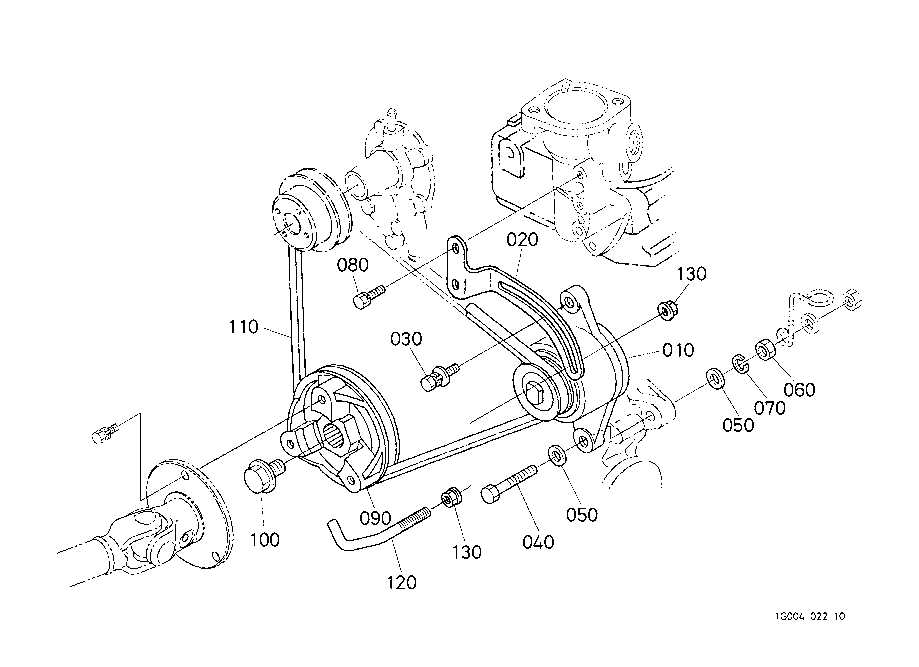

Transmission System: This mechanism transmits power from the engine to the wheels. Its design impacts speed regulation and torque delivery, ensuring optimal maneuverability across varied terrains.

Hydraulic Components: These elements facilitate lifting and moving attachments. They enhance operational versatility, allowing for a range of tasks from tilling to mowing.

Chassis Structure: The framework supports the entire unit, providing stability and durability. Its construction affects weight distribution and overall handling during operation.

Control Systems: These interfaces enable operators to manage functions efficiently. A well-designed control setup enhances user experience and precision in executing tasks.

How to Read Diagrams Effectively

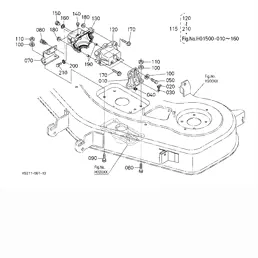

Understanding visual representations is crucial for efficient troubleshooting and maintenance. These illustrations provide a structured way to view components and their interconnections, making it easier to grasp complex systems at a glance.

Begin by familiarizing yourself with the symbols and notations used in the representation. Each element usually has a specific icon or abbreviation that indicates its function. Recognizing these symbols will allow you to navigate the illustration more swiftly.

Next, pay attention to the layout and flow of connections. Lines typically indicate relationships between components, guiding you through the assembly or circuit. Following these lines will help you trace the path of operation and identify how different parts interact.

Lastly, take notes while you analyze the visual guide. Writing down key observations can reinforce your understanding and assist you in recalling important details later. This methodical approach will enhance your ability to interpret complex information effectively.

Common Issues with GR2110 Parts

When operating and maintaining machinery, users often encounter a variety of challenges related to individual components. These issues can arise from wear and tear, improper installation, or even design flaws. Understanding these common problems can help owners effectively troubleshoot and ensure their equipment functions optimally.

Wear and Tear

One prevalent issue involves the gradual deterioration of certain components due to regular use. This can lead to decreased performance and efficiency. Regular inspections are essential to identify signs of wear, such as cracks or excessive play, which can ultimately prevent more significant failures.

Improper Installation

Another significant concern is related to the incorrect installation of various elements. This can result in misalignment or inadequate connections, causing the machinery to operate inefficiently. Ensuring that each part is installed according to manufacturer guidelines is crucial for longevity and optimal performance. Regular maintenance and following installation procedures can mitigate these risks.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and performance of your machinery. Implementing a few simple practices can significantly extend its lifespan and reliability, leading to optimal functionality over time.

1. Routine Inspections: Conduct frequent checks to identify any wear or damage early. This proactive approach can prevent minor issues from escalating into major problems.

2. Proper Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and minimizes wear, promoting smoother operation.

3. Cleanliness: Keep the equipment clean from dirt and debris. Regular cleaning not only enhances appearance but also prevents potential blockages that can hinder performance.

4. Fluid Levels: Monitor and maintain appropriate levels of all fluids, including oil and coolant. This is crucial for efficient operation and can help prevent overheating and other complications.

5. Storage: When not in use, store the machinery in a dry, sheltered location. Protecting it from the elements reduces the risk of rust and other weather-related damage.

By following these maintenance tips, you can ensure that your equipment remains in excellent condition, providing reliable service for many years.

Where to Source Replacement Parts

Finding suitable components for your machinery can be crucial for maintaining optimal performance. Numerous options are available to help you locate the necessary items, ranging from authorized dealers to online marketplaces. Each source has its unique advantages, whether it be pricing, availability, or quality assurance.

Local dealerships often provide reliable service and genuine replacements, ensuring compatibility and longevity. Alternatively, online platforms offer convenience and a wider selection, enabling users to compare prices and reviews easily. Additionally, aftermarket suppliers can be an excellent choice for those seeking cost-effective solutions without compromising on quality.

Before making a purchase, it is advisable to verify the specifications and compatibility of the components with your equipment. Consulting user manuals or technical resources can further aid in identifying the right replacements. Engaging with online communities or forums dedicated to machinery maintenance can also provide valuable insights and recommendations.

Assembly Instructions for New Components

This section provides a comprehensive guide for the installation of new elements within the machinery. Proper assembly is crucial for optimal performance and longevity of the equipment. Following these steps will ensure that each component is securely fitted and functions as intended.

Preparation Steps

- Gather all necessary tools and components.

- Read the instructions thoroughly before beginning the assembly.

- Ensure the workspace is clean and organized.

Assembly Procedure

- Identify the location for the new component.

- Carefully align the new piece with the existing structure.

- Secure the component using the appropriate fasteners.

- Double-check connections to ensure stability.

- Test the functionality of the newly installed part before full operation.

Following these guidelines will help achieve a successful assembly, ensuring that your machinery operates efficiently and reliably.

Tools Needed for Repairs

When undertaking maintenance or restoration tasks, having the right equipment is essential for ensuring efficiency and effectiveness. Proper tools not only facilitate smoother operations but also enhance safety, preventing accidents and damages during the process.

Basic Hand Tools

Essential hand tools should include wrenches, screwdrivers, and pliers. These instruments are crucial for loosening and tightening various components, allowing for easy access and adjustments. It’s also wise to have a good socket set on hand, as it provides versatility for different fasteners.

Specialized Equipment

In addition to standard tools, certain specialized equipment may be necessary. A reliable jack or hoist can assist in lifting heavier parts safely. Moreover, having a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications, preventing potential failures in the future.

Safety Precautions During Maintenance

Ensuring safety during servicing is crucial for both personnel and equipment. Adhering to specific guidelines helps prevent accidents and ensures efficient operations. Proper preparation and awareness of potential hazards can significantly mitigate risks associated with maintenance tasks.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, including gloves, goggles, and steel-toed boots, to minimize injury risk. |

| Work Area Inspection | Examine the workspace for hazards such as spills, clutter, or inadequate lighting before commencing work. |

| Equipment Shutdown | Ensure all machinery is powered off and properly locked out before performing any maintenance tasks. |

| Proper Tools | Use the correct tools for the job, and ensure they are in good condition to avoid accidents. |

| Follow Manufacturer Guidelines | Refer to the service manual for specific safety measures and instructions related to the equipment. |

Upgrading Your Kubota Equipment

Enhancing your machinery can significantly boost its performance and extend its operational lifespan. By focusing on key improvements and integrating advanced components, you can ensure that your equipment remains efficient and effective in the long term. This process not only increases productivity but also reduces maintenance needs over time.

Choosing the Right Upgrades involves understanding the current capabilities of your machine and identifying areas for improvement. Whether it’s enhancing power output, increasing versatility, or upgrading safety features, selecting the right components is essential. With the right enhancements, you can tackle more demanding tasks with ease.

Regular maintenance and upgrades are vital to keeping your equipment running smoothly. By incorporating new technologies or upgrading certain parts, you ensure that your machinery stays competitive and capable of handling various challenges.

Resources for Further Learning

For those interested in expanding their understanding of machinery and maintenance, a wealth of resources is available online and offline. Whether you’re looking to dive deeper into mechanical systems or enhance your repair skills, there are numerous platforms offering detailed guides, instructional videos, and expert advice. This section outlines a few of the best ways to continue your education and improve your technical knowledge.

Books and Manuals

Books and manuals are invaluable when it comes to understanding the intricate components and functions of equipment. They provide in-depth explanations and offer step-by-step instructions for assembly, disassembly, and troubleshooting. These resources are great for individuals who prefer a structured and comprehensive approach to learning.

| Resource | Description |

|---|---|

| The Mechanical Handbook | A complete guide to understanding the core mechanics of various machines, from basic to advanced concepts. |

| Repair Manual for Small Engines | Provides detailed insights into engine repair and maintenance, including diagrams and troubleshooting tips. |

| Maintenance Strategies | Focuses on preventive maintenance and long-term care for machines to keep them running smoothly. |

Online Platforms and Communities

The internet is rich with online platforms where enthusiasts and professionals share their knowledge. Websites, video tutorials, and forums provide real-time solutions and advice. Engaging in these communities allows you to interact with like-minded individuals and gain practical insights from real-world experiences.

| Platform | Features |

|---|---|

| Online Workshops | Interactive learning sessions hosted by experts that cover troubleshooting and repair techniques. |

| Video Tutorials | Step-by-step video guides that walk you through various maintenance tasks and repair procedures. |

| Expert Forums | A space to ask questions, share experiences, and get advice from professionals in the field. |