Proper upkeep of heavy machinery requires a thorough understanding of the individual elements that make up the equipment. For those involved in machine maintenance, knowing how each component connects and functions is essential. Without this knowledge, even minor issues can lead to bigger problems over time, affecting the efficiency and longevity of the equipment.

In this section, we will look at the arrangement and structure of various machine elements that ensure optimal performance. Understanding the layout and positioning of these critical parts not only simplifies repairs but also helps in preventive care, minimizing unexpected breakdowns and ensuring smooth operations.

By focusing on the key elements and their relationships, operators and technicians can better navigate maintenance tasks. This knowledge empowers them to quickly identify issues, replace faulty components, and maintain the overall health of the machinery with confidence.

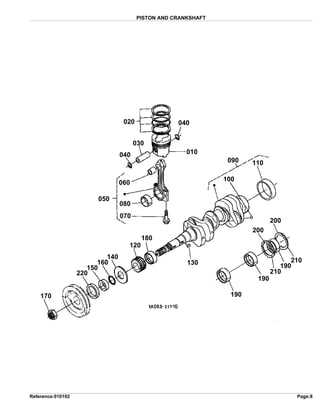

Engine Component Overview

The heart of any machine relies heavily on the efficiency and performance of its engine. To ensure smooth operations and maintain peak functionality, a close look at the internal and external elements that drive power generation is crucial. Understanding how various sections of the engine contribute to overall productivity can help in both troubleshooting and routine upkeep.

Main Power Unit

The core power unit is responsible for converting fuel into mechanical energy. This section includes several key components such as cylinders, pistons, and combustion chambers, all working in harmony to generate the necessary force to drive the equipment. Proper synchronization of these elements is essential for maximizing energy output and ensuring operational efficiency.

Cooling and Fuel Systems

A well-designed

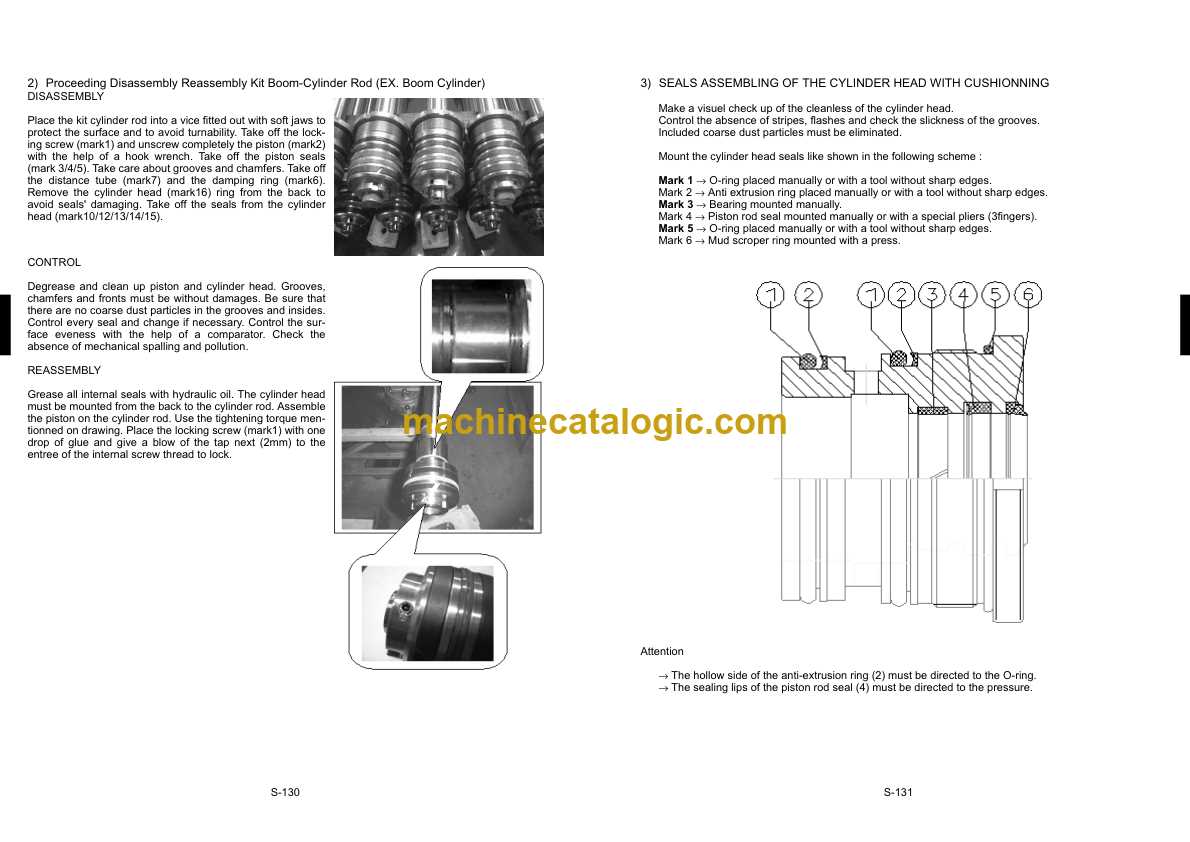

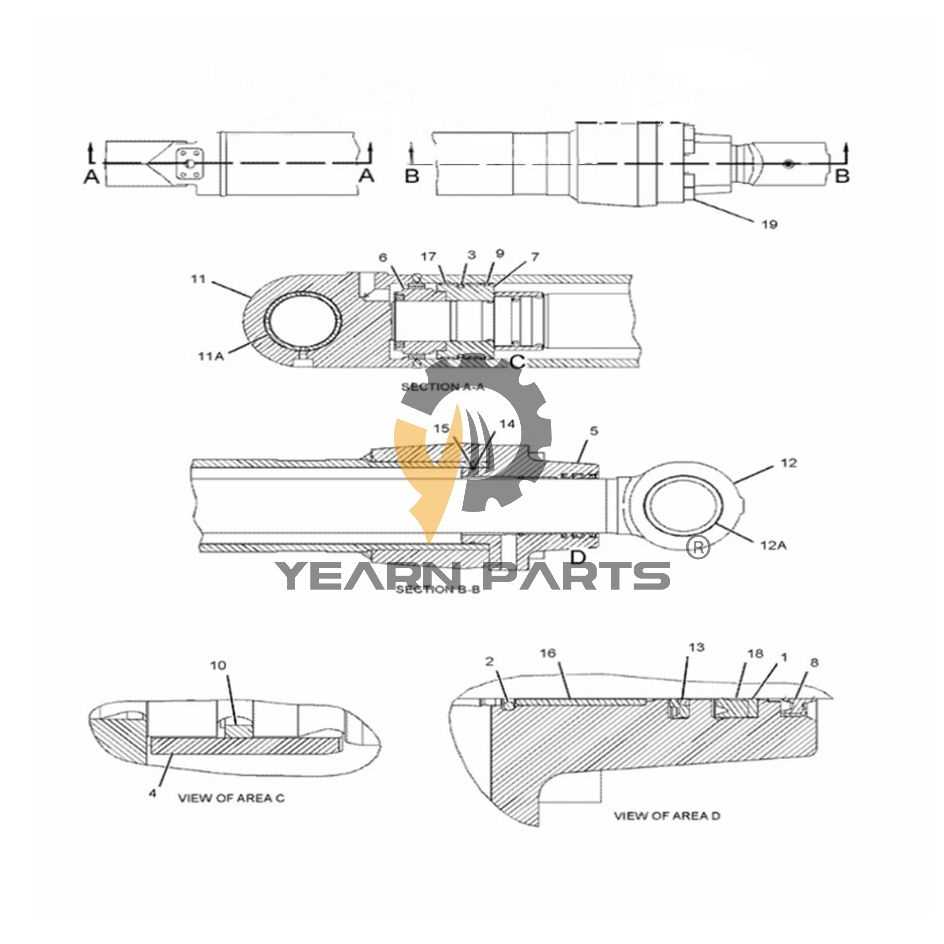

Hydraulic System Parts Layout

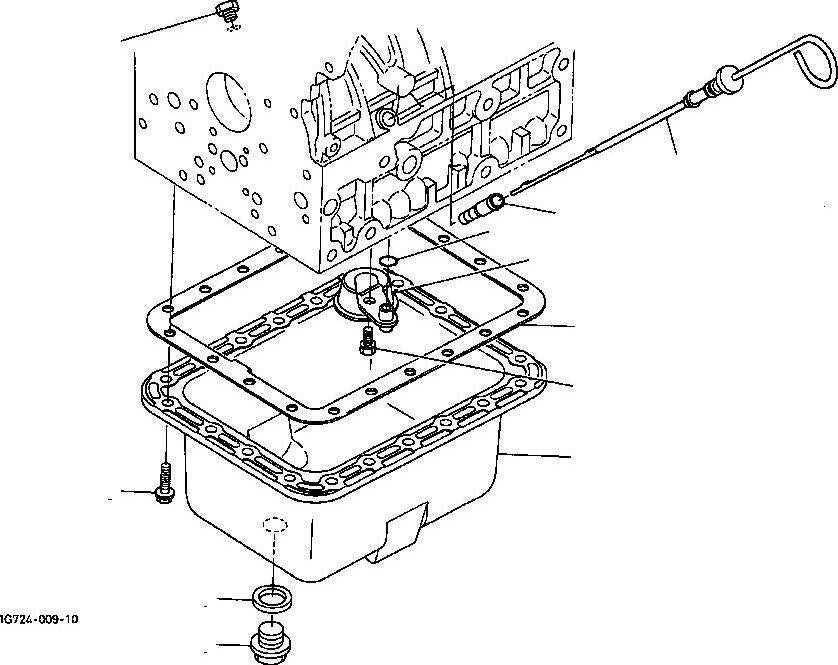

The hydraulic system is a crucial component in machinery, responsible for managing fluid flow and power transfer. Understanding how each element is interconnected within this network is essential for maintenance and operation. This section provides an overview of the different components involved and their arrangement to ensure optimal system functionality.

Key Components Overview

Within the hydraulic system, the primary elements include pumps, valves, hoses, and actuators. These units work together to create a continuous flow of pressurized fluid, enabling movement and control. Each part plays a specific role in managing the force and direction of the hydraulic fluid, which powers various mechanical functions.

Flow Control and Power Distribution

Proper fluid management relies on the precise configuration of valves and cylinders, ensuring that pressure is evenly distributed across the system. Hoses and fittings connect these components, directing the hydraulic fluid where it is needed most. Maintaining a well-organized layout of these elements helps prevent leaks and ensures smooth operation under various load conditions.

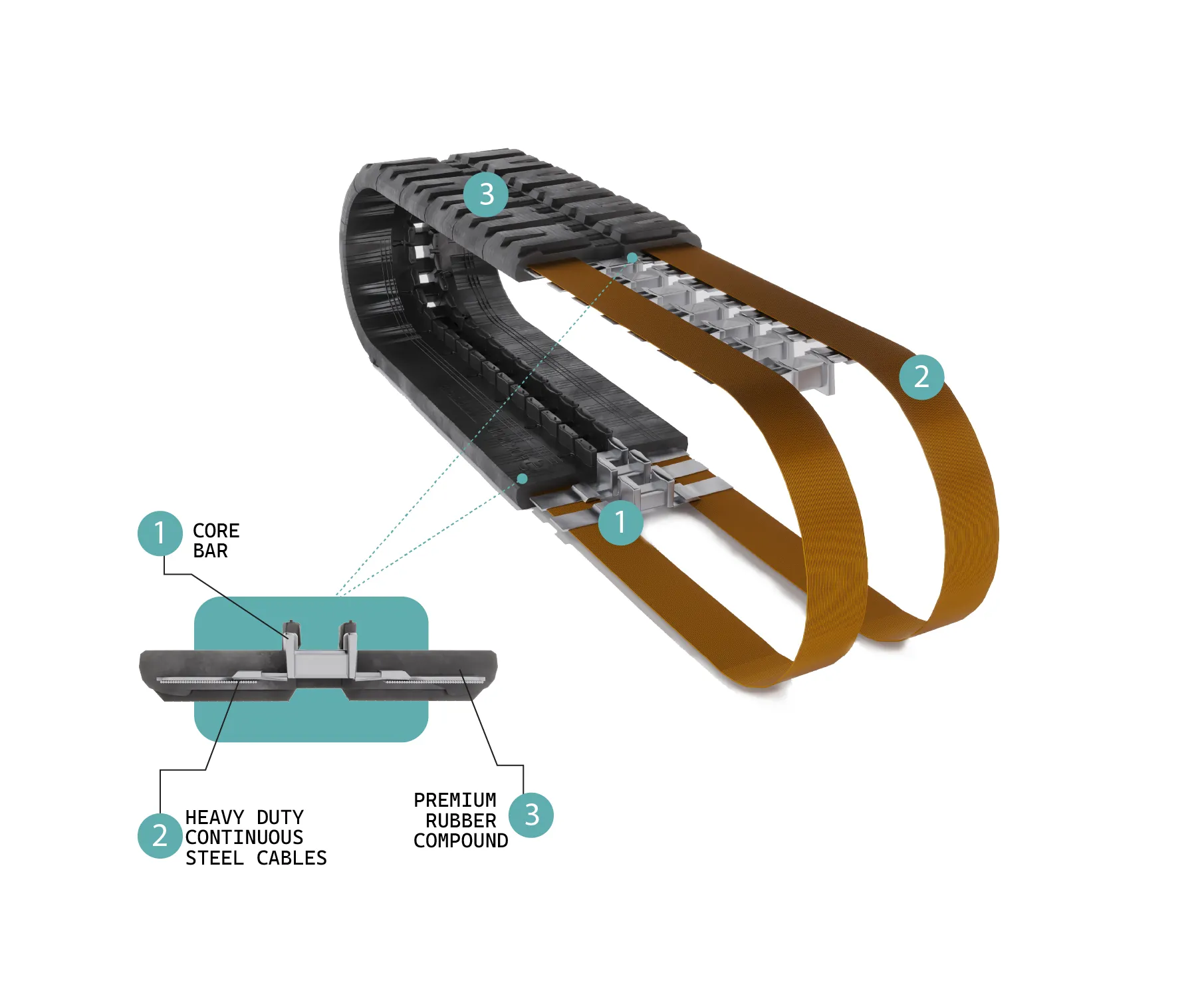

Undercarriage Parts and Functionality

The components located beneath the frame are crucial for ensuring stability, mobility, and overall performance of a machine. These elements play a vital role in distributing weight evenly and enabling smooth movement across various terrains. Understanding how each element interacts allows for better maintenance and improved operational efficiency.

Main Structural Elements

Key structural elements found under the frame include the track system, which provides traction, and the rollers, which support the frame’s movement. The entire setup is designed to withstand harsh environments while maintaining mobility. The tensioners adjust the tightness of the tracks, ensuring optimal performance on uneven surfaces.

Supportive Components

Supporting elements like idlers help guide the tracks, while the sprockets engage the links to drive the tracks forward. These components work in sync to maintain balance and provide forward momentum. Proper care and routine checks of these components are essential for smooth operation and longevity.

| Component | Function | |||||||

|---|---|---|---|---|---|---|---|---|

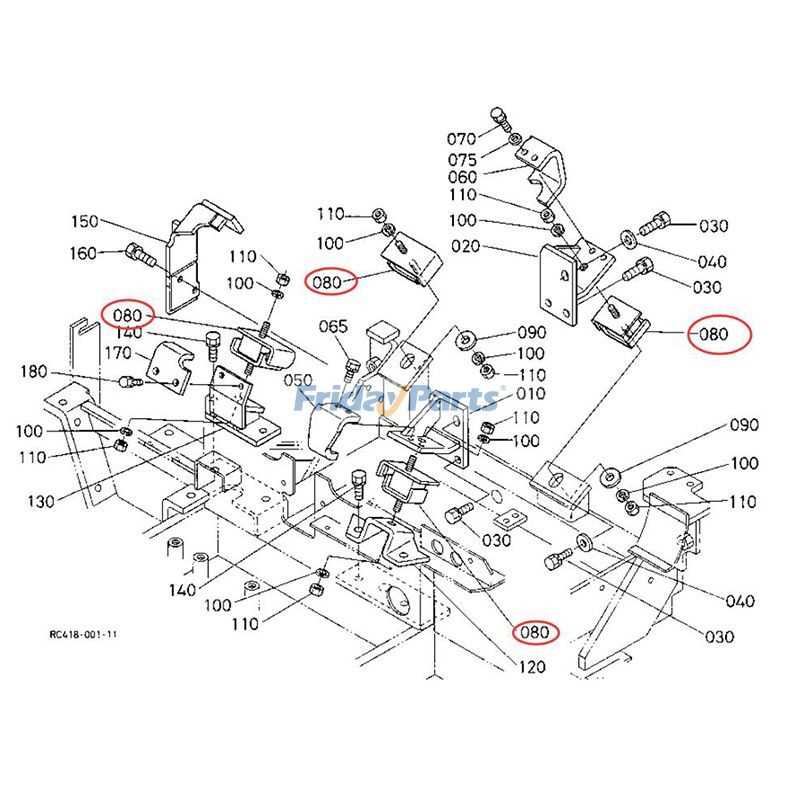

| Cabin Control Mechanism Diagram

The control system inside the cabin plays a vital role in ensuring efficient operation and ease of use for various functions. Understanding the layout and connectivity of different elements within the operator’s station is essential for proper functionality. The layout reflects the integration of various mechanisms that work together to provide smooth control and adjustments. Main Control LeversThe primary control levers are centrally positioned for quick and intuitive access. They allow for precise adjustments to the movement and operation of the equipment. Each lever is linked to specific control mechanisms that facilitate movement, lifting, and directional adjustments. The ergonomic design ensures that operators can maintain control with minimal effort. Connection of Pedals and SwitchesThe pedals and switches located within the cabin provide auxiliary functions necessary for secondary operations. These include managing speed, braking, and activating specific modes. The pedals are connected through mechanical or electronic linkages, offering responsive feedback. Switches are strategically placed for easy activation, enabling smooth transitions between different operational modes. Cooling System Components and StructureThe cooling system plays a crucial role in maintaining the temperature balance in machinery, ensuring that all parts operate smoothly. It consists of several interconnected elements designed to transfer heat efficiently, preventing overheating and maintaining optimal functioning. The design of this system allows for a continuous cycle of temperature regulation, ensuring consistent performance even under demanding conditions. Key elements in the system include the fluid container, which stores the coolant, and the circulation mechanism, responsible for moving the coolant through the system. These elements work together to absorb excess heat from the engine area and dissipate it through a heat exchanger, allowing the machine to stay within safe operating limits. Another essential part of the structure is the flow regulator, which controls the passage of coolant based on the temperature needs. This component ensures that the system reacts quickly to temperature changes, making it adaptable to various workloads and environments. The overall structure is designed to be both efficient and reliable, ensuring the machinery Track Tensioning Parts and Adjustments

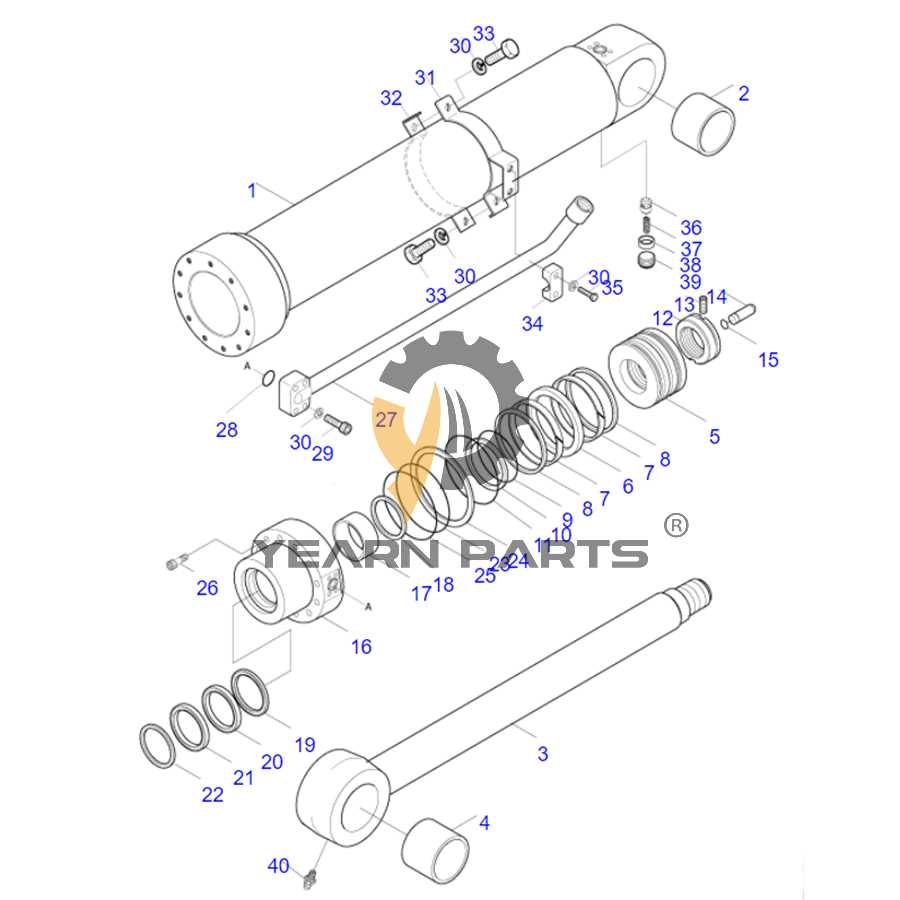

The maintenance of undercarriage components is essential for ensuring optimal performance and longevity of machinery. Proper tensioning of the tracks contributes to effective power transmission and stability during operation. Understanding the various elements involved in adjusting and maintaining track tension can enhance efficiency and reduce wear on the machine. Key components involved in the tensioning system include the tensioning cylinder, which applies pressure to the track, and the adjustment mechanism that allows operators to fine-tune the tension to desired specifications. Regular inspections and adjustments are vital to address any slack or excessive tightness that may occur due to wear or environmental conditions. To achieve the ideal tension, operators should refer to the manufacturer’s guidelines for the correct procedures. Utilizing the appropriate tools during adjustments is crucial to ensure accuracy and safety. By maintaining proper tension, operators can maximize the lifespan of the undercarriage and enhance the overall performance of the equipment. Fuel System Layout and Key Parts

The layout of the fuel system plays a crucial role in the overall performance of compact machinery. This system is designed to deliver the necessary fuel to the engine, ensuring efficient operation and optimal power output. Understanding the arrangement and components of this system is essential for effective maintenance and troubleshooting. At the core of the fuel distribution system is the tank, which stores the fuel and provides a reliable supply to the engine. Attached to the tank, a fuel pump ensures that the fuel is delivered at the correct pressure. This pump is often accompanied by a filter that removes impurities, safeguarding the engine from potential damage. Connecting the tank and the engine, a series of lines transport the fuel, allowing for smooth flow and minimizing the risk of leaks. A fuel injector or carburetor regulates the amount of fuel entering the combustion chamber, working in tandem with the air intake system for optimal combustion. Additionally, various sensors monitor fuel pressure and flow, providing real-time data to the engine control unit for adjustments as needed. By familiarizing oneself with the layout and essential components of the fuel distribution system, operators can ensure their equipment runs efficiently, extending its lifespan and enhancing overall productivity. Electrical Components BreakdownThe electrical system of machinery plays a vital role in ensuring optimal performance and functionality. Understanding the various components within this system can significantly enhance troubleshooting and maintenance efforts. Each element contributes to the overall operation, from power distribution to control mechanisms. Key Electrical Elements

Among the essential components are the wiring harness, switches, and connectors. The wiring harness serves as the central pathway for electrical flow, linking various parts seamlessly. Switches control the power supply to different systems, allowing operators to manage functionalities effectively. Additionally, connectors provide secure connections between wires, ensuring reliable communication throughout the system. Maintenance and Care

Regular maintenance of the electrical system is crucial for preventing failures. Inspecting connections for corrosion and wear, as well as ensuring that all components are functioning correctly, can help maintain efficiency. Additionally, cleaning the connectors and ensuring proper insulation can prevent electrical issues, ensuring longevity and reliability in operation. Arm and Boom Parts Configuration

The arrangement of components related to the lifting arm and boom is crucial for the overall functionality of the machinery. This assembly plays a vital role in enhancing the performance and efficiency of various tasks, ensuring that the equipment operates smoothly under diverse working conditions. Understanding the relationship and positioning of these elements helps in maintaining optimal performance and longevity. The arm serves as a key element that connects the boom to the main body, providing the necessary leverage to perform lifting and digging operations. It is designed to withstand significant stresses while allowing for smooth articulation during use. Various joints and pivot points within the arm facilitate its movement, contributing to the versatility of the machine. The boom extends from the main chassis and acts as a support structure for the arm. Its length and angle can be adjusted to reach different heights and depths, making it indispensable for various applications, from excavation to material handling. The configuration of the boom is engineered to ensure stability and strength, allowing it to handle heavy loads effectively. Understanding the specific arrangement of these components can aid operators in diagnosing issues and performing maintenance. Regular inspections and knowledge of each element’s function are essential for ensuring that the lifting mechanisms operate reliably and efficiently, thereby enhancing the machine’s overall productivity. Exhaust System Components and Pathways

The exhaust system of a machinery unit plays a critical role in managing emissions and ensuring optimal performance. This system is designed to channel exhaust gases away from the engine, allowing for efficient combustion and reducing harmful pollutants. Understanding the key elements and their respective functions is essential for effective maintenance and troubleshooting. Main Components of the Exhaust System

The primary elements of the exhaust system include various pipes, mufflers, and catalysts, each serving a specific purpose in the overall function of gas expulsion. The components work together to facilitate the safe release of exhaust gases while minimizing noise and enhancing engine efficiency.

Gas Flow Pathways

The pathways through which exhaust gases travel are meticulously engineered to ensure minimal resistance and maximum efficiency. Starting from the engine, gases move through the exhaust manifold, into the primary piping, and ultimately pass through the muffler before being expelled. Understanding these pathways is vital for diagnosing performance issues and ensuring compliance with environmental standards. Maintenance Guide for Key ComponentsProper upkeep of essential machinery components is crucial for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances the efficiency of operations. This guide outlines fundamental practices that should be followed to keep critical parts in excellent condition, thereby extending their operational lifespan. Routine InspectionsConducting frequent examinations of significant elements is vital. Look for signs of wear and tear, leaks, or unusual noises that could indicate underlying issues. Identifying problems early can save time and resources in the long run. Always refer to the manufacturer’s specifications for guidance on recommended inspection intervals. Lubrication and Cleaning

Regularly applying the appropriate lubricants to moving parts reduces friction and wear. Ensure that all components are free from dirt and debris, as contaminants can lead to malfunction. Establishing a cleaning routine helps maintain the efficiency of machinery and supports seamless operation. Use only recommended cleaning agents and lubricants to avoid damaging the equipment. |