Agricultural machines are intricate systems composed of various interconnected elements that work together to perform essential tasks efficiently. To maintain and repair these machines effectively, it’s important to have a clear understanding of how different elements interact with one another. By exploring the layout of each element, one can ensure the machinery operates smoothly and remains in good working condition for years to come.

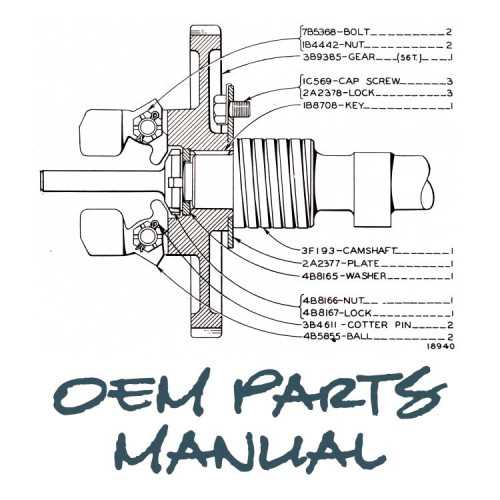

Detailed visual representations provide crucial insights into how each element is arranged within the machine, allowing operators and technicians to quickly identify and address any issues that may arise. These visuals offer a comprehensive view, helping to pinpoint specific sections that require attention during maintenance or upgrades.

In this article, we’ll delve into the structure and layout of critical elements within farming equipment, helping you become more familiar with their roles and how they contribute to the overall functionality of the machinery.

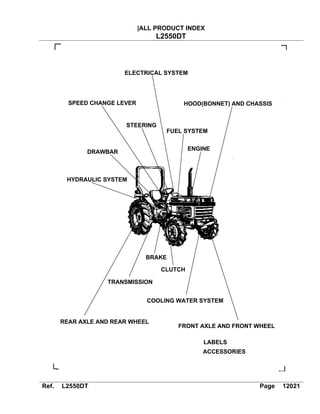

Kubota L2550 Parts Diagram Overview

This section provides an in-depth examination of the essential components and their relationships within the overall structure of the machinery. Understanding how these elements are organized is crucial for effective maintenance and troubleshooting, allowing for precise identification of key features.

Main Component Structure

The machinery is designed with a well-ordered configuration of its critical systems. Each section serves a specific function that contributes to the seamless operation of the equipment. Knowing how these areas interconnect can simplify both diagnostics and repair efforts.

System Interactions and Maintenance

The systems within the machine work in harmony, each playing a vital role

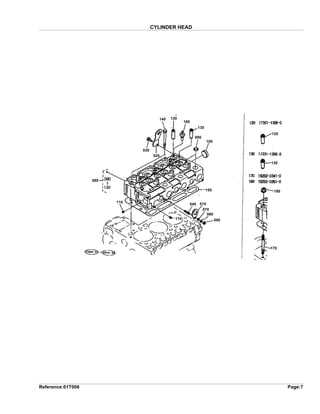

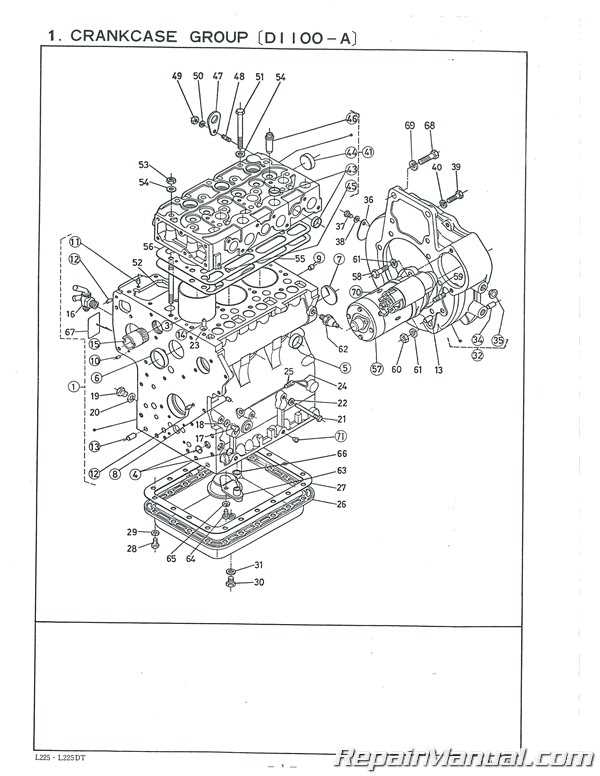

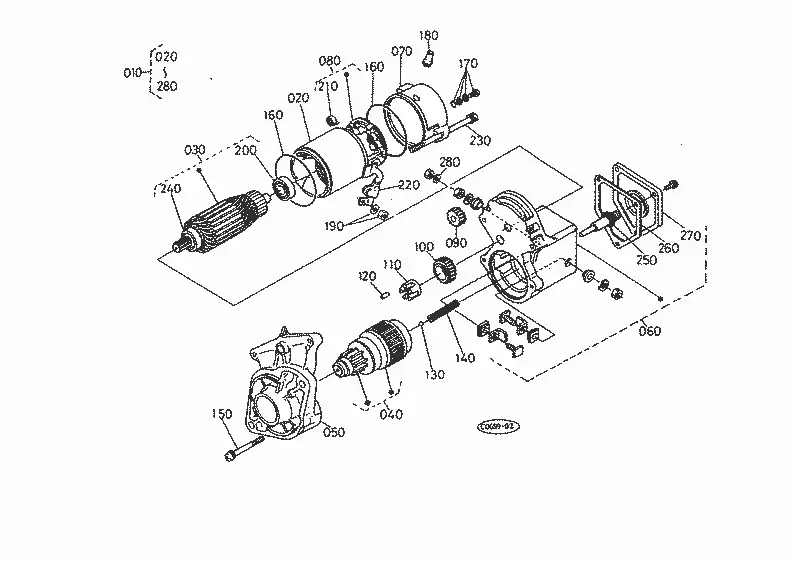

Understanding the Engine Components Layout

To fully grasp how the mechanical components of an engine work together, it’s essential to become familiar with their arrangement and purpose. Each part has a specific role in ensuring the engine operates smoothly, contributing to the overall performance. Understanding this layout helps in identifying key areas that require attention during maintenance and repairs.

Main Functional Sections

The engine can be divided into several primary sections, each responsible for distinct operations. The upper section includes components that regulate air and fuel intake, ensuring the right mixture for combustion. The lower section focuses on power generation, transferring energy from the combustion process to the wheels.

Key Component Interactions

At the heart of the engine are the combustion chamber and the pistons, working in sync to generate

Hydraulic System Breakdown for Efficient Maintenance

The hydraulic system is a vital component in ensuring the smooth operation of various mechanical functions. Understanding its layout and keeping each element in optimal condition are essential for maintaining performance and preventing potential failures. By breaking down the system into individual sections, maintenance can be carried out with greater precision, reducing downtime and improving overall efficiency.

Key Components of the Hydraulic System

Each hydraulic system consists of several key elements, including pumps, valves, cylinders, and hoses. The pump is responsible for generating the pressure needed to power the system, while the valves control the flow and direction of the fluid. Cylinders

Transmission Parts and Their Functions

The transmission system plays a crucial role in transferring power from the engine to the wheels, ensuring smooth operation and control of the vehicle. Understanding the key components within this system is essential for proper maintenance and optimal performance.

Main Components of the Transmission System

- Clutch: Engages and disengages the power flow from the engine to the transmission.

- Gearbox: Contains multiple gears that help adjust the vehicle’s speed and torque depending on the driving conditions.

- Shafts: Connects various transmission elements and transfers mechanical energy between them.

- Shift Mechanism: Allows the operator to change gears, controlling speed and torque levels.

Functions of the Transmission Components

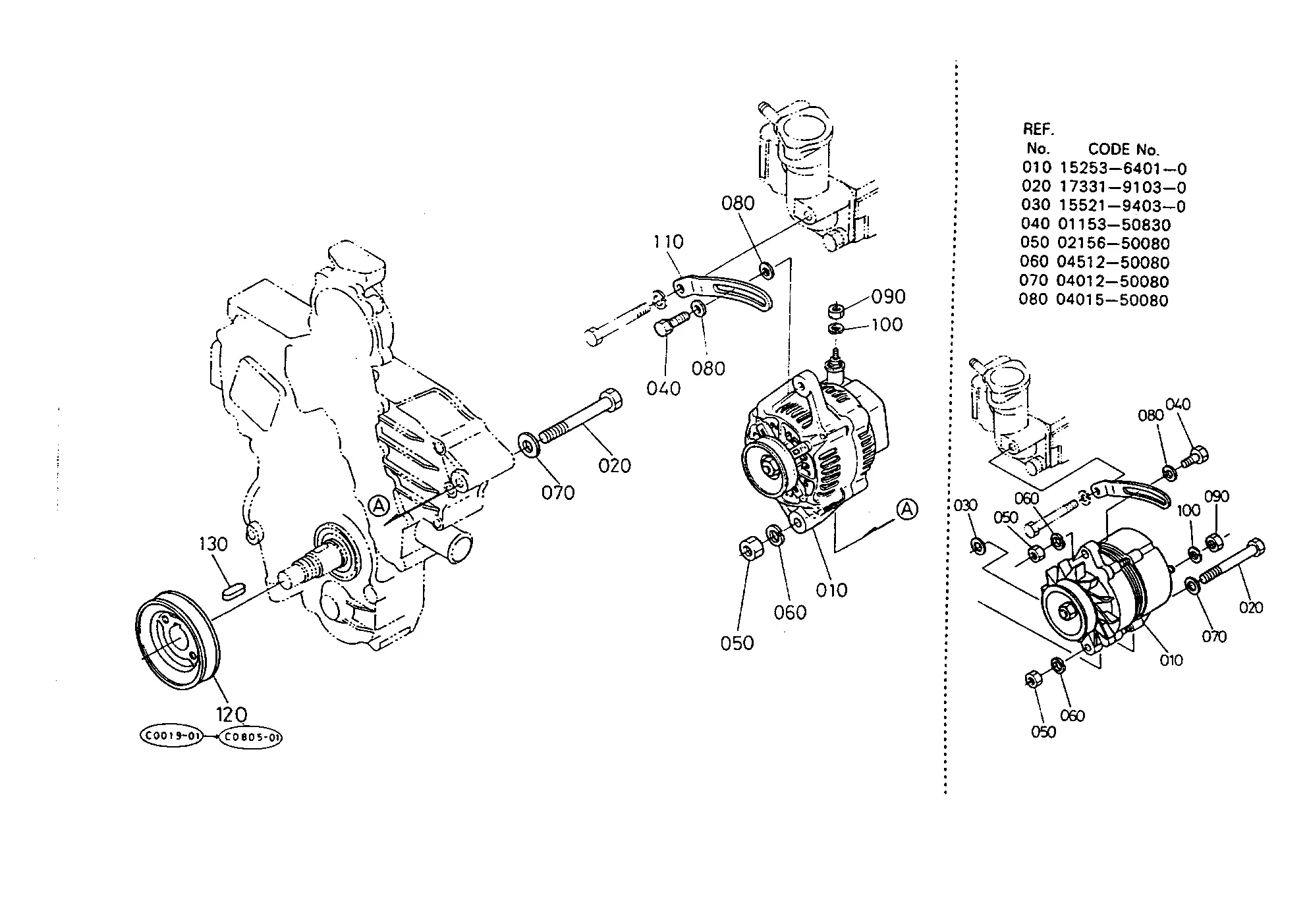

Exploring the Electrical System Configuration

The electrical system within any machinery is essential for ensuring seamless operation and functionality. This section delves into the various components and their interconnections that make up the overall structure, providing the necessary energy flow and control. By understanding how each element fits into the broader setup, users can gain a clearer perspective on maintaining, troubleshooting, and optimizing performance.

Main Components Overview

The key elements involved include wiring harnesses, fuses, relays, and connectors. These components are designed to work in harmony, allowing the system to function efficiently. Regular inspections of these parts can help prevent malfunctions and ensure the longevity of the machinery.

Wiring and Circuit Layout

The wiring and circuit configuration plays a critical role in distributing power to various sections of the equipment. Each wire is carefully laid out to provide uninterrupted

Cooling System Diagram and Key Elements

The cooling mechanism in machinery plays a crucial role in maintaining optimal operating temperatures. It ensures that the engine functions efficiently while preventing overheating. Understanding the various components involved in this system is essential for effective maintenance and troubleshooting.

Core Components

The primary elements of the cooling system include the radiator, water pump, thermostat, and coolant passages. Each of these parts works in harmony to circulate fluid and dissipate heat generated during engine operation. The radiator cools the liquid before it re-enters the engine, while the water pump maintains circulation throughout the system.

Functionality and Importance

A well-functioning cooling system not only enhances engine performance but also prolongs the life of the machinery. Regular checks of the coolant level and inspection of hoses and connections are vital to ensure the system operates smoothly. Proper maintenance can prevent costly repairs and ensure reliability in various working conditions.

Fuel System Parts and Flow Path

The fuel system plays a critical role in the efficient operation of an engine, ensuring that the proper amount of fuel reaches the combustion chamber. This system consists of various components working together to deliver, filter, and regulate fuel flow, contributing to optimal performance and reliability.

Key Components of the Fuel System

Essential elements of the fuel delivery system include the fuel tank, pump, filter, and injectors. The tank stores the fuel, while the pump draws it from the tank and delivers it to the filter. The filter removes any contaminants, ensuring that only clean fuel reaches the injectors, where it is atomized and mixed with air for combustion.

Flow Path of Fuel

Fuel flows from the tank through the pump and into the filter, following a carefully designed route that maximizes efficiency. After filtration, the clean fuel moves to the injectors, where precise timing and pressure control the delivery of fuel into the combustion chamber, facilitating a smooth and efficient engine operation.

Front Axle and Steering Mechanism Overview

The front axle and steering system are vital components in agricultural machinery, ensuring stability and maneuverability. These elements work together to support the weight of the machine while allowing for precise control during operation. Understanding their functionality can enhance maintenance practices and improve performance.

Key features of the front axle include:

- Weight Distribution: The axle distributes the weight evenly across the front wheels, contributing to overall balance.

- Durability: Made from robust materials, the axle withstands the rigors of agricultural tasks.

- Suspension Integration: The axle is often linked with the suspension system, providing shock absorption and a smoother ride.

The steering mechanism plays a crucial role in maneuverability, incorporating several components:

- Steering Wheel: The operator controls direction through the steering wheel, which is connected to the steering gear.

- Linkages: Various linkages connect the steering wheel to the front wheels, translating rotational movement into directional change.

- Power Steering: Some models feature power-assisted steering, enhancing ease of operation, especially in tight spaces.

Regular inspection and maintenance of these systems are essential to ensure longevity and optimal performance. Operators should be familiar with common issues, such as wear on the steering components or axle misalignment, to address problems promptly.

Clutch Assembly Components Explained

The clutch assembly is a crucial mechanism that enables smooth engagement and disengagement of power transmission in various machinery. Understanding its components is essential for maintaining optimal performance and ensuring efficient operation. This section delves into the individual parts that constitute the clutch assembly, highlighting their functions and significance in the overall system.

Main Components of the Clutch Assembly

The primary components of a clutch assembly include the clutch disc, pressure plate, and release bearing. The clutch disc serves as the interface between the engine and transmission, facilitating the transfer of power. The pressure plate applies force to the clutch disc, ensuring it engages with the flywheel. Meanwhile, the release bearing allows for smooth disengagement when the clutch pedal is pressed.

Each component plays a vital role in the functionality of the clutch system. The interaction between the clutch disc and pressure plate determines how effectively power is transmitted. A well-functioning assembly enhances performance and prolongs the lifespan of the machinery. Regular maintenance and inspection of these components are essential to prevent potential failures and ensure seamless operation.

Brake System Layout for Optimal Performance

The effectiveness of a vehicle’s braking mechanism is crucial for ensuring safety and control during operation. A well-designed braking system not only enhances performance but also contributes to the overall longevity of the vehicle. Understanding the layout and components of this system can lead to improved functionality and reliability.

Key Components of the Braking System

At the heart of any braking mechanism are several essential components. These include brake pads, rotors, calipers, and hydraulic lines. Each part plays a significant role in converting kinetic energy into thermal energy, allowing for smooth deceleration. Regular maintenance and timely replacement of worn-out parts are vital to maintaining optimal performance.

Importance of Proper Layout

A well-structured brake system layout ensures that all components work harmoniously. This arrangement not only maximizes braking efficiency but also minimizes wear and tear. By analyzing the system’s configuration, users can identify potential areas for improvement, leading to enhanced safety and driving experience.

Loader Attachment Parts and Compatibility

Understanding the components associated with loader attachments is crucial for effective operation and maintenance. These elements are designed to enhance functionality, ensuring that the loader can perform a variety of tasks efficiently. Compatibility among different models is vital, as it affects the performance and safety of the equipment.

Key Components of Loader Attachments

The main elements of loader attachments typically include buckets, forks, and grapples, each serving specific purposes. Buckets are essential for digging and lifting materials, while forks are ideal for transporting pallets and bulky items. Grapples provide versatility by allowing operators to handle irregularly shaped loads. Knowing the specifications of these components is essential for optimal performance.

Ensuring Compatibility with Various Models

When selecting loader attachments, verifying compatibility with the loader model is essential. Manufacturers often provide compatibility charts that detail which attachments work with specific models. Adhering to these guidelines ensures seamless integration, enhancing the loader’s operational efficiency and safety.