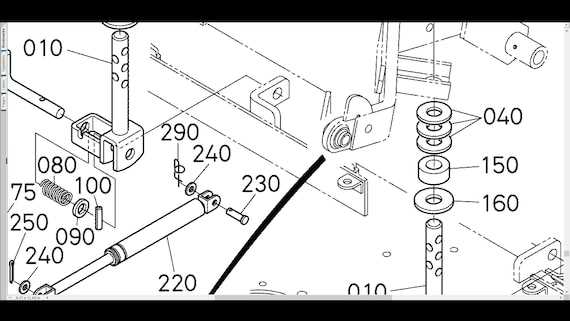

Understanding the structure and layout of various machine components is essential for effective maintenance and troubleshooting. Whether you’re dealing with issues related to performance or simply looking to keep everything running smoothly, a clear overview of how elements are connected and interact can make a significant difference.

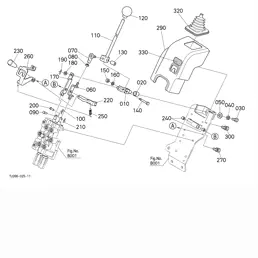

Each mechanical system is made up of various intricate pieces working together to perform tasks efficiently. Knowing the precise arrangement of these elements allows for quicker repairs and replacements, minimizing downtime and ensuring continued functionality.

In this guide, we’ll explore the specific connections and configurations that are vital for ensuring the smooth operation of your machinery. A well-organized layout of the core elements provides clarity when identifying, repairing, or upgrading key sections of the system.

Kubota L4400: Essential Components Overview

In this section, we will explore the critical elements that keep your machine operating smoothly. By understanding the vital systems and their functionality, you can ensure better performance and maintenance efficiency.

| Component | Function | |||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Block | The powerhouse that drives all major operations, converting fuel into mechanical energy. | |||||||||||||||||||||||||||||||

| Hydraulic System | Controls lifting and other tasks requiring fluid pressure, enabling efficient load handling. | |||||||||||||||||||||||||||||||

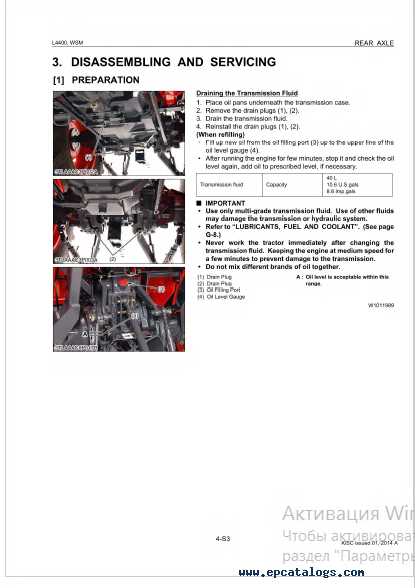

| Transmission | Manages speed and torque, allowing smooth transitions during operation and handling various terrains. | |||||||||||||||||||||||||||||||

| Cooling Mechanism | Prevents overheating by regulating temperature during extended use, ensuring optimal performance. | |||||||||||||||||||||||||||||||

| Fuel Delivery |

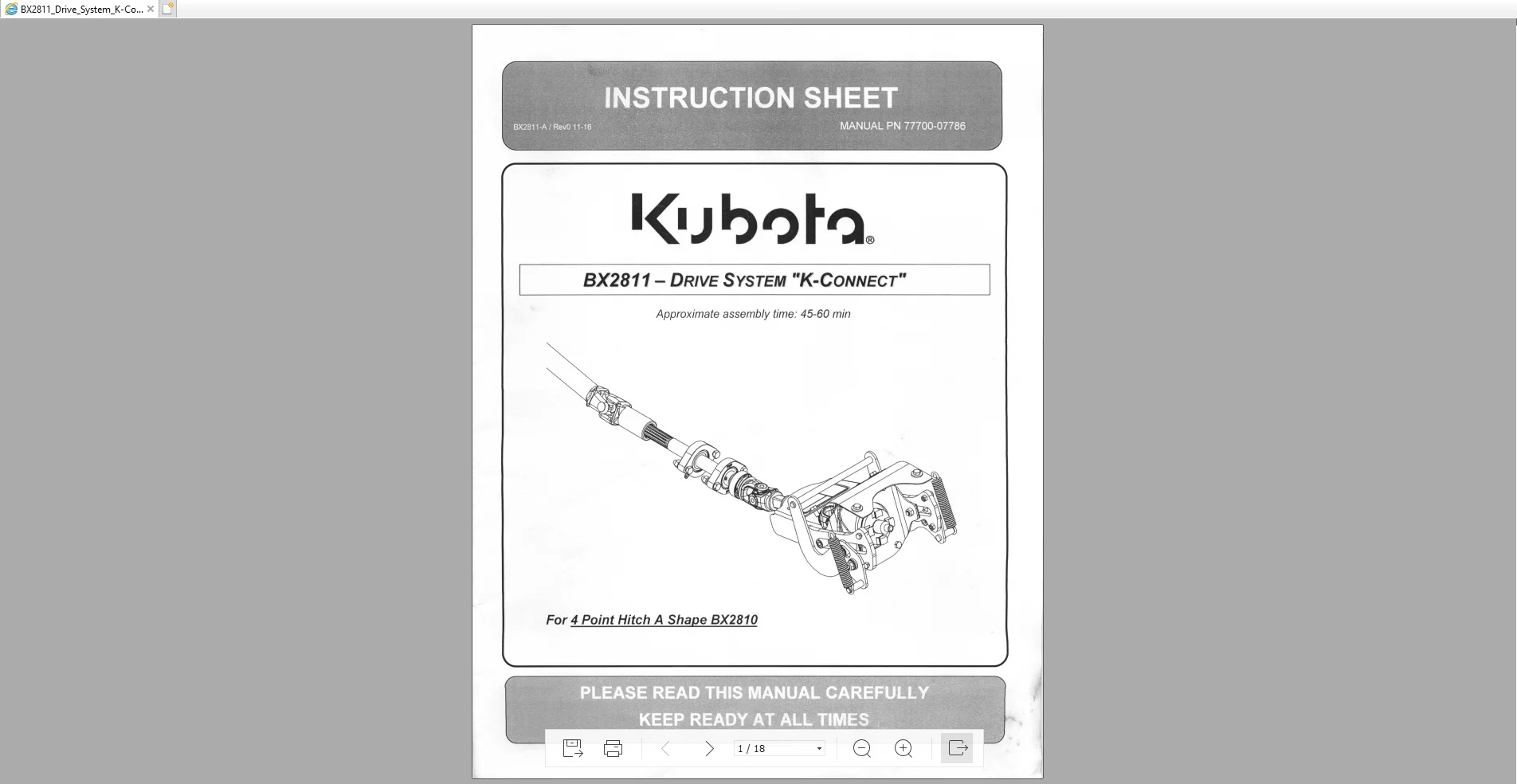

| Component | Function |

|---|---|

| PTO Shaft | Transmits power from the tractor’s engine to various attachments. |

| Universal Joint | Allows for angular movement between the tractor and implement, facilitating flexibility in operation. |

| PTO Clutch | Engages and disengages the power transfer to prevent damage to the implement. |

| Safety Guard | Protects against accidental contact with moving parts, enhancing user safety. |

Ensuring that these components are in good condition is paramount. Regular inspections and maintenance can significantly extend the lifespan of the PTO system, preventing costly repairs and downtime during crucial farming seasons.

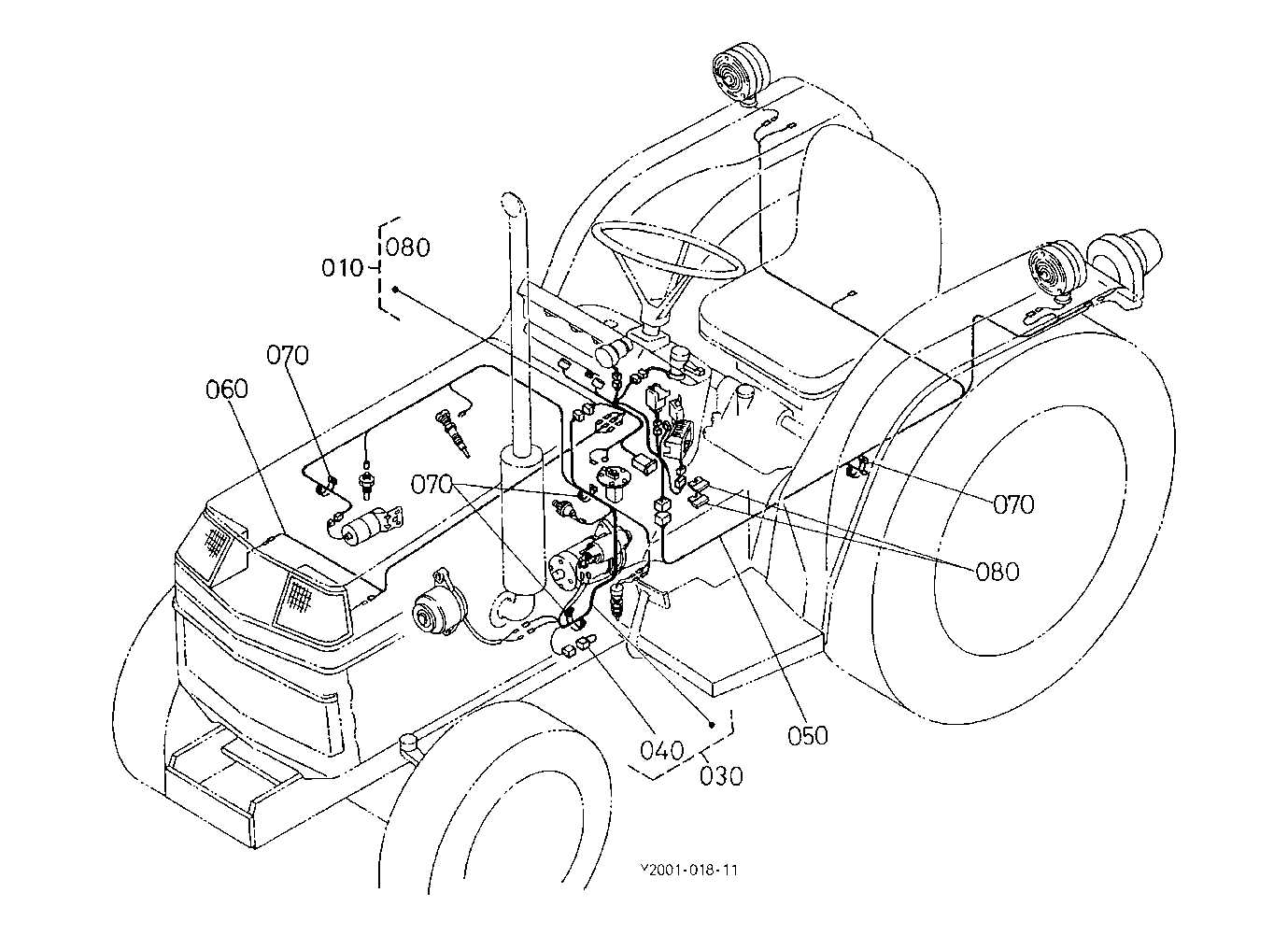

Electrical System Layout and Key Parts

The arrangement of the electrical components in machinery plays a vital role in its overall functionality. A well-structured electrical framework ensures efficient operation and reliability. Understanding the layout and the crucial elements involved can significantly aid in troubleshooting and maintenance, allowing operators to optimize performance and extend the lifespan of the equipment.

Essential Components of the Electrical Configuration

At the core of any effective electrical setup are several integral components. The battery serves as the primary power source, providing the necessary voltage to initiate the starting process. Additionally, the alternator is responsible for generating electrical energy while the engine runs, ensuring that the battery remains charged and other electrical systems receive adequate power.

Wiring Harness and Connectors

A comprehensive wiring harness connects various electrical units, facilitating seamless communication between components. Each connector plays a critical role in maintaining secure connections, reducing the risk of shorts or disconnections. Regular inspections of these elements can help prevent electrical failures, ensuring smooth operation and minimizing downtime.

Cooling System: Radiator and Related Components

The cooling mechanism plays a vital role in maintaining optimal operating temperatures for machinery. This system comprises several essential components that work together to dissipate heat effectively and ensure efficient performance. Among these, the radiator stands out as a crucial element, facilitating the transfer of heat away from the engine.

At the heart of the cooling assembly lies the radiator, designed to regulate temperatures by allowing coolant to flow through its core. As the fluid circulates, it absorbs excess heat and releases it to the surrounding air. This process is further enhanced by the presence of cooling fans, which increase airflow over the radiator, thus improving heat exchange.

Other significant parts include hoses, which transport coolant to and from the engine, and the thermostat, which controls the flow of coolant based on temperature. Additionally, the water pump is responsible for circulating the coolant throughout the system, ensuring a constant flow that supports efficient thermal management. Understanding the functionality and interaction of these components is essential for maintaining the longevity and reliability of the machinery.

Brake System Parts for Maximum Control

The braking mechanism plays a crucial role in ensuring optimal maneuverability and safety while operating machinery. A well-designed system enhances responsiveness, allowing the operator to maintain full command over the vehicle’s movements, even in challenging environments. Understanding the components involved in this system is essential for achieving peak performance and reliability.

Key elements include the brake pads, which provide friction to slow down the machine, and the rotors, which serve as the surface against which the pads press. Additionally, the hydraulic components are vital, as they transfer force from the brake pedal to the braking mechanism. Regular maintenance of these components ensures consistent functionality and minimizes the risk of failure.

Furthermore, attention should be given to the adjustment mechanisms that allow for precise control over the braking force. Ensuring that these parts are in optimal condition will enhance the overall effectiveness of the braking system, providing the operator with the confidence needed for safe operation in various conditions.

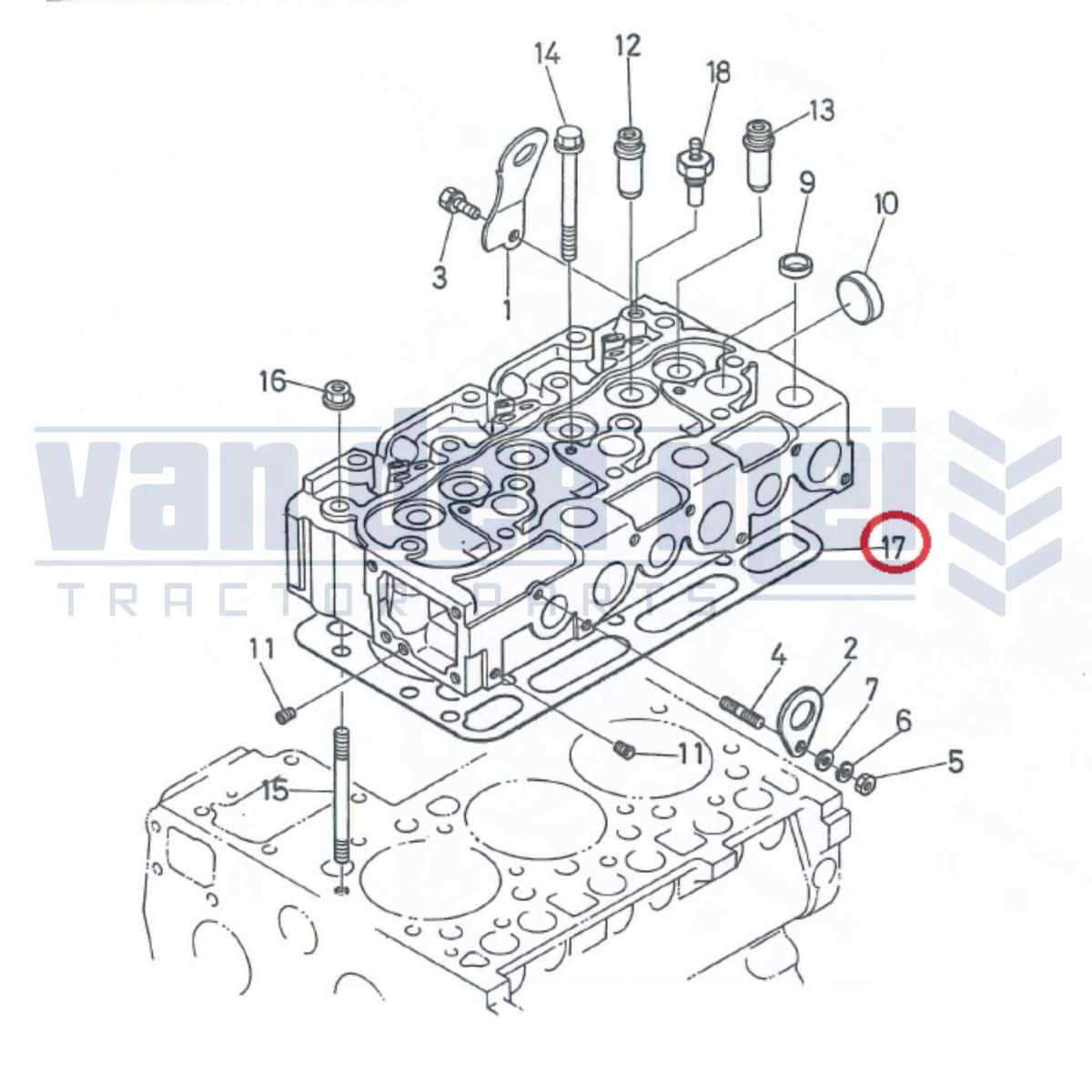

Fuel System: Diagram of Key Elements

The fuel delivery mechanism is a vital aspect of any machinery, ensuring that the engine receives the necessary fuel for optimal performance. Understanding the configuration and function of its main components helps in maintaining efficiency and preventing malfunctions. This section will outline the key elements involved in this essential system, providing insight into their roles and interconnections.

Essential Components

Every fuel delivery system comprises several crucial parts, each serving a specific function to facilitate the smooth flow of fuel from the tank to the engine. These elements work together to ensure that the engine operates effectively and reliably.

| Component | Function |

|---|---|

| Fuel Tank | Stores the fuel until it is needed by the engine. |

| Fuel Pump | Transfers fuel from the tank to the engine. |

| Fuel Filter | Removes impurities from the fuel before it reaches the engine. |

| Fuel Injectors | Spray the fuel into the combustion chamber in a fine mist for efficient burning. |

| Fuel Lines | Transport the fuel between the tank, pump, filter, and injectors. |

Interconnections and Flow

The effective operation of the fuel delivery mechanism relies on the seamless interaction between its components. Fuel flows from the tank through the pump and filter, reaching the injectors where it is atomized for combustion. Each part’s performance impacts the overall efficiency of the engine, highlighting the importance of regular maintenance.

Rear Hitch Components and Their Functions

The rear attachment system of a tractor plays a crucial role in enhancing its versatility and operational efficiency. This section explores the various elements that make up this mechanism, highlighting their roles and importance in the overall functionality of the equipment.

Main Components

- Drawbar: This is the primary link between the tractor and the implements. It facilitates the towing of various attachments while ensuring stability and control during operation.

- Hitch Arms: These arms connect the drawbar to the implement. They allow for adjustments in height and angle, enabling the proper alignment of the attached equipment.

- Quick Coupler: This device simplifies the process of attaching and detaching implements. It allows for quick changes, minimizing downtime between tasks.

- Limit Chains: These chains help maintain the desired height and angle of the hitch, preventing excessive movement that could affect performance.

Functions of the Hitch System

- Facilitates efficient towing of various implements such as plows, harrows, and trailers.

- Enhances maneuverability by allowing the operator to make necessary adjustments for different tasks.

- Improves safety by providing a secure connection between the tractor and the attachment, reducing the risk of accidents.

- Promotes versatility by enabling the use of a wide range of agricultural tools and equipment, catering to various farming needs.

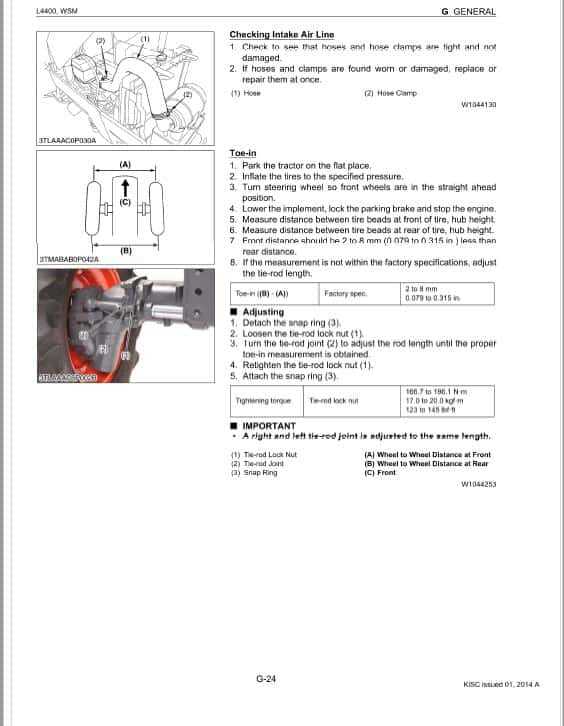

Tire and Wheel Assembly for Optimal Performance

The tire and wheel assembly is a critical component for ensuring efficient operation and longevity of machinery. Selecting the appropriate tire type and ensuring proper wheel alignment can significantly enhance traction and stability. Understanding the elements that contribute to the effectiveness of these components is essential for achieving peak performance in various terrains and conditions.

Importance of Proper Tire Selection

Choosing the right tire for your vehicle is essential for maximizing efficiency and reducing wear. Different types of tires offer specific advantages, depending on the terrain and intended use. Here are some key factors to consider:

| Factor | Description |

|---|---|

| Tread Pattern | Affects grip and traction on different surfaces. |

| Size | Impacts load-bearing capacity and overall stability. |

| Material | Determines durability and resistance to punctures. |

| Pressure | Must be maintained to ensure optimal performance and safety. |

Maintaining Wheel Assembly

Regular maintenance of the wheel assembly is vital for preventing issues that can affect overall performance. Key practices include:

- Inspecting for signs of wear and tear.

- Ensuring proper inflation levels to maintain optimal traction.

- Checking for misalignment, which can lead to uneven tire wear.

- Regularly cleaning and lubricating moving parts to prevent corrosion.