When maintaining or repairing complex machinery, it’s essential to have a clear visualization of how everything is connected. Knowing the structure and arrangement of various elements can significantly simplify the process, helping you stay organized and efficient in your tasks. Whether you’re handling small repairs or larger projects, having an outline of how everything fits together provides a solid foundation.

In mechanical systems, understanding the placement of individual units is crucial for troubleshooting and optimizing performance. It allows you to quickly identify the source of potential issues, ensuring smoother operations. This overview serves as a guide to help make sense of intricate setups, making sure each component is accounted for and correctly positioned.

Essential Components of the Kubota RTV-X1140

Understanding the key elements of this versatile utility vehicle is crucial for maintaining performance and reliability. Each mechanical system plays a specific role, ensuring the smooth operation and durability of the machine in various working conditions. The core structure includes several vital assemblies that work together to support its functionality, from power generation to handling.

The engine, for example, is designed to provide the necessary force, while the transmission ensures efficient transfer of power to the wheels. Suspension systems contribute to a stable and comfortable ride, even over rough terrain. Additionally, the braking mechanism is essential for safety and control, allowing for precise stopping when needed. These components form the backbone of the vehicle’s performance and should be well-maintained for optimal operation.

Understanding the Engine Assembly

The engine assembly plays a crucial role in ensuring smooth and efficient operation of any vehicle. It consists of various interconnected components that work in harmony to deliver the necessary power and functionality. Each part of the engine assembly is designed to serve a specific purpose, contributing to the overall performance and reliability of the machine.

From the combustion system to the cooling mechanisms, the engine assembly is a complex arrangement of systems that requires proper maintenance and attention. By understanding how each component operates, you can gain insights into improving longevity, efficiency, and preventing potential issues that may arise over time.

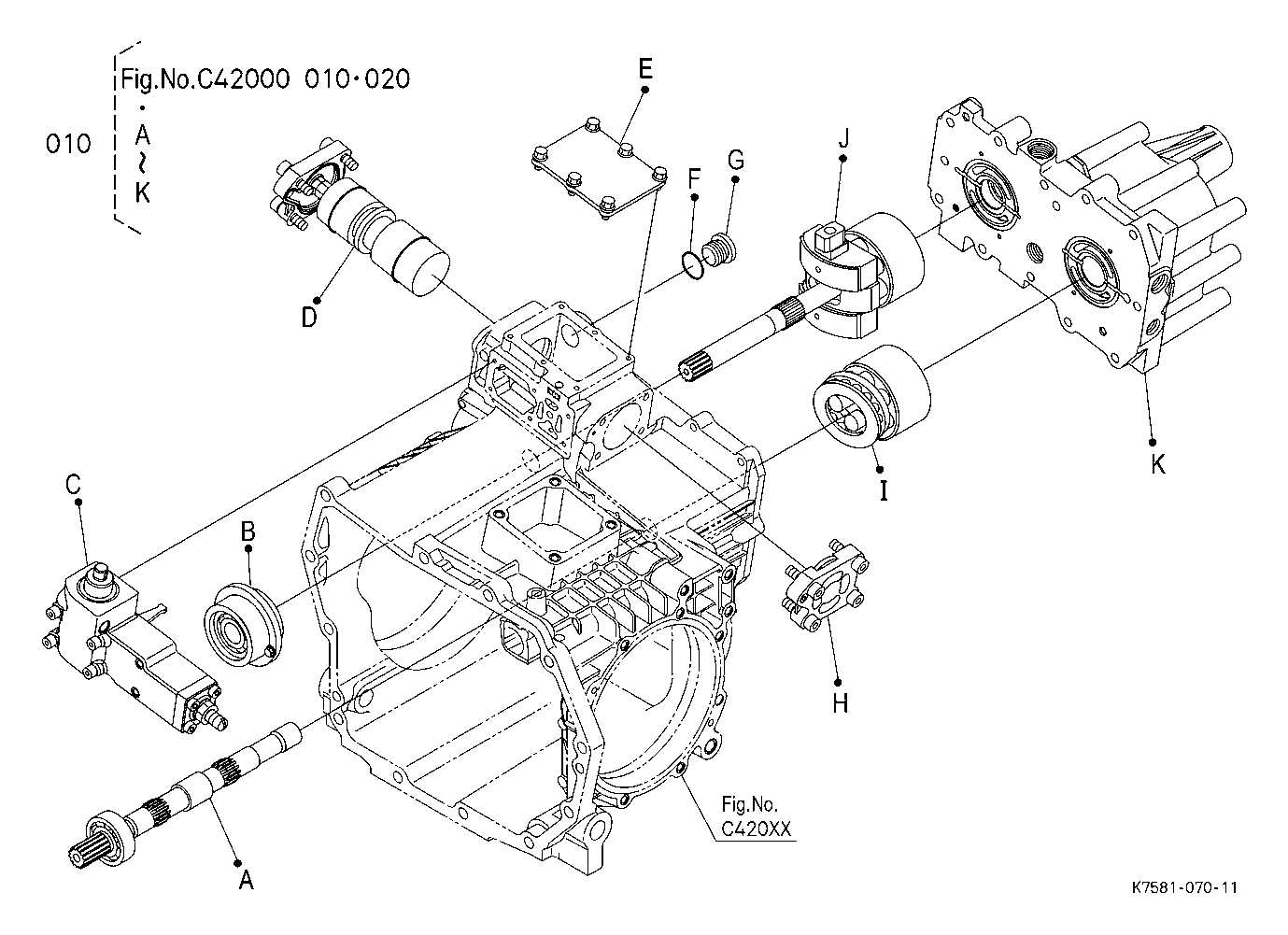

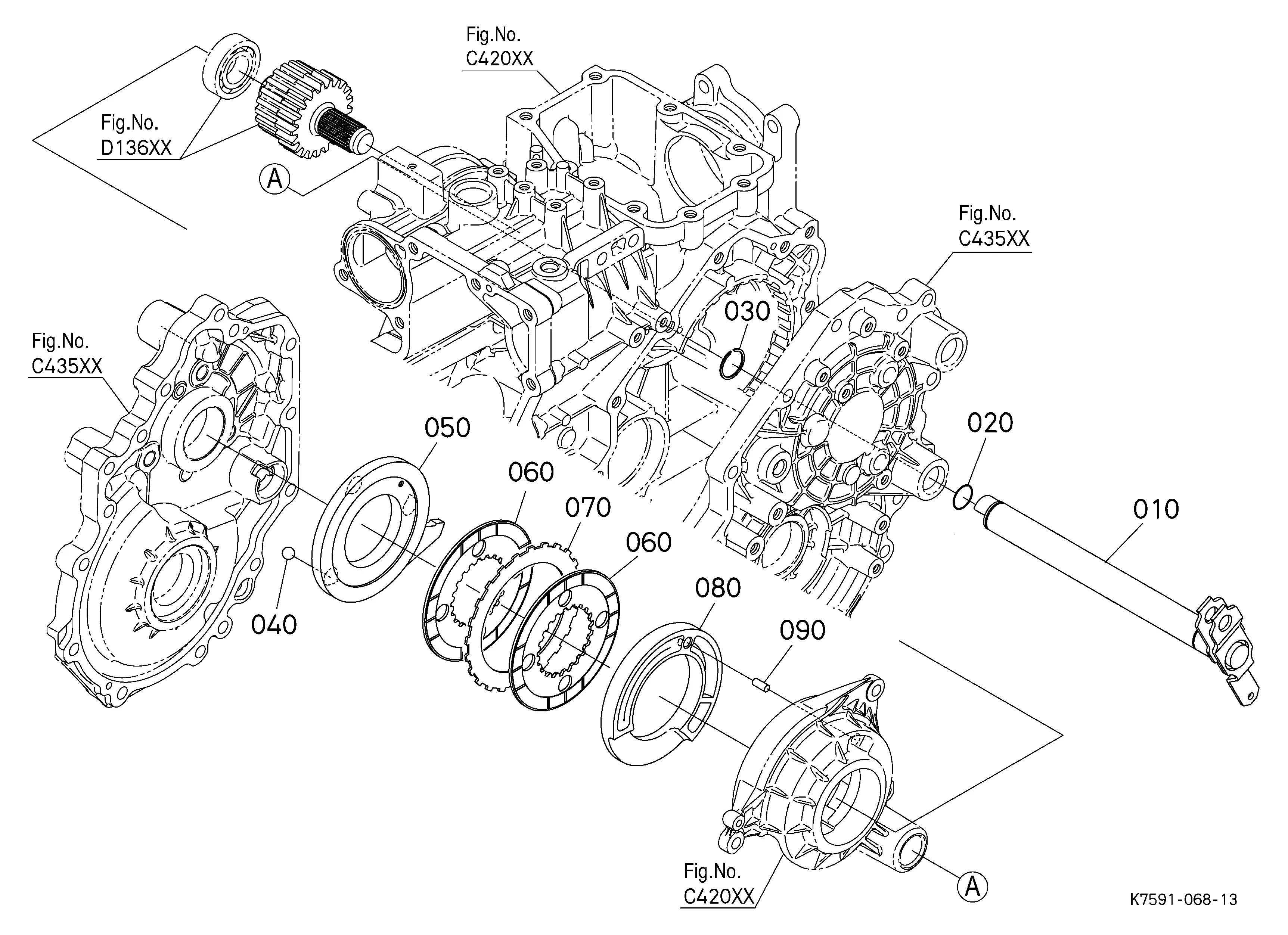

Exploring the Transmission System

The transmission system is a crucial component that facilitates smooth movement and ensures the proper functioning of the vehicle’s drivetrain. This system plays an integral role in distributing power, allowing the machine to operate efficiently under various conditions. Understanding its structure can help in maintaining optimal performance and longevity.

Main Functions of the Transmission

At its core, the transmission is responsible for transferring power from the engine to the wheels. It allows the vehicle to adapt to different speeds and terrains, ensuring steady operation regardless of the environment. With various gears and mechanisms involved, it effectively manages the speed and torque.

Key Components and Their Roles

Within this system, several elements work in unison to achieve fluid movement. These include gears, shafts, and clutches, each playing a vital role in adjusting the power flow. Regular inspection and proper care of these components can prevent wear and ensure continued reliability.

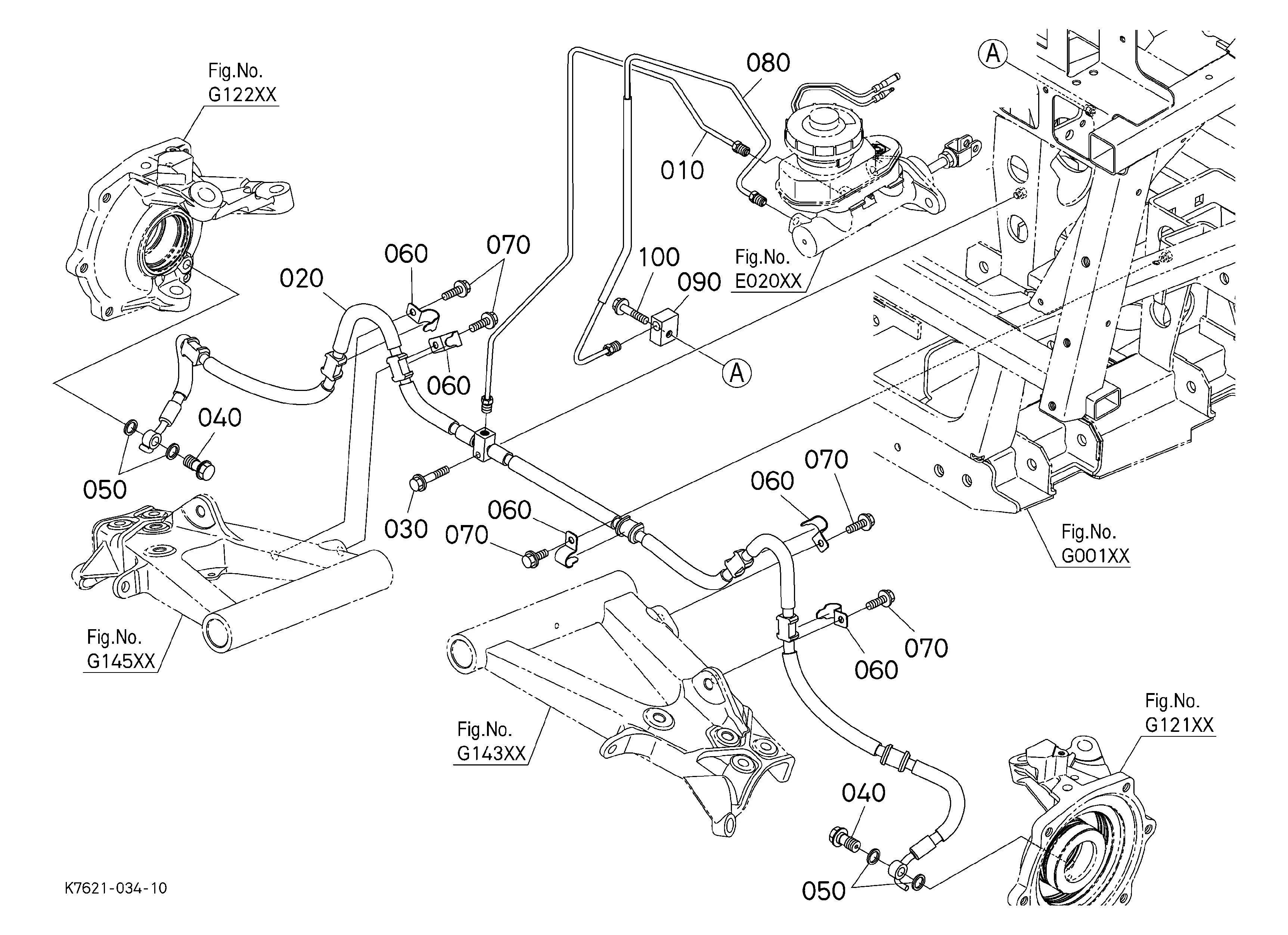

Key Features of the Suspension System

The suspension system plays a vital role in ensuring smooth movement and stability on various terrains. It enhances comfort and allows for better handling by absorbing shocks and vibrations during operation. This setup is designed to manage different loads, providing a balanced and steady ride even under challenging conditions.

One of the standout aspects of this system is its ability to maintain consistent performance, regardless of surface irregularities. Its design incorporates advanced components that contribute to the overall durability and longevity of the vehicle, allowing it to handle rough environments with ease.

Another significant advantage of this setup is its adaptability to different working conditions. Whether on uneven surfaces or heavy-duty applications, the suspension ensures optimal functionality, providing a reliable experience without compromising comfort.

Examining the Steering Mechanism

The steering system plays a critical role in ensuring precise control and maneuverability. By guiding the direction of movement, this mechanism helps in navigating through different terrains, providing a smooth driving experience. Understanding how this system operates can help in identifying issues and performing necessary adjustments for improved performance.

- Steering Wheel: This is the main interface for the operator to control the vehicle’s direction. It is designed to offer comfort and ease during operation.

- Steering Linkages: These components transmit the motion from the wheel to the rest of the steering system, allowing for smooth directional changes.

- Steering Column: A pivotal part that connects the wheel to the mechanisms responsible for adjusting the front wheels. It ensures the force applied by the operator is accurately transferred.

- Hydraulic Assistance: Some systems include hydraulic components to enhance control, reducing the effort required by the operator to turn the vehicle in challenging conditions.

Regular inspection of the steering components ensures

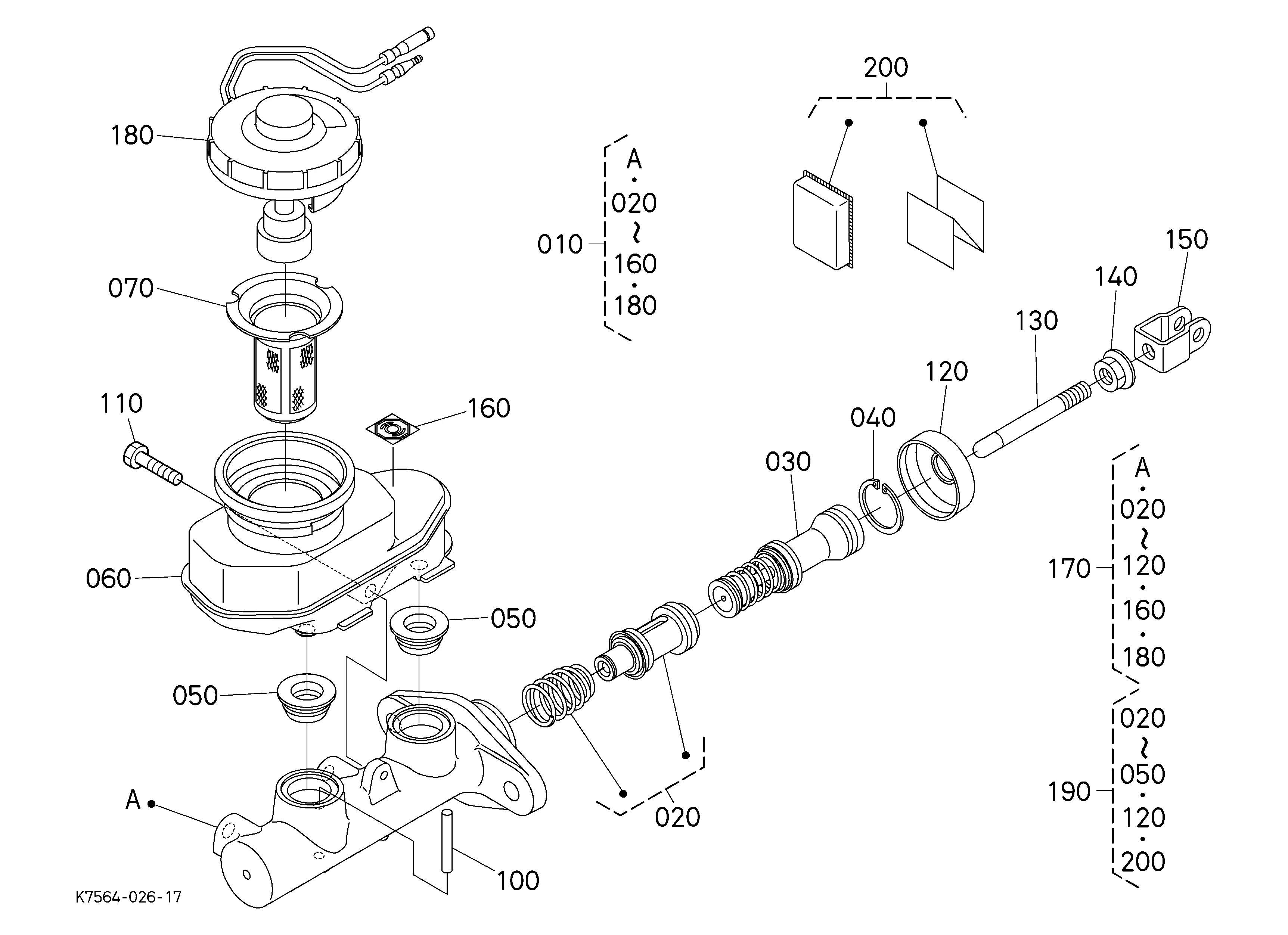

Detailed View of the Brake System

The braking mechanism is a crucial component of any vehicle, ensuring safety and control during operation. Understanding its intricacies can enhance maintenance practices and improve performance. This section provides an in-depth look at the various elements that comprise the braking system, focusing on their functions and interconnections.

- Brake Pedal: The initial point of interaction for the operator, it translates the force exerted by the driver into hydraulic pressure.

- Master Cylinder: This essential component converts the mechanical force from the brake pedal into hydraulic pressure, which is then transmitted to the brake calipers or wheel cylinders.

- Brake Lines: These tubes carry the hydraulic fluid from the master cylinder to the braking assemblies at each wheel, enabling the system to function effectively.

- Brake Calipers: Located at each wheel, these components house the brake pads and apply pressure to them against the rotor, facilitating the deceleration of the vehicle.

- Brake Pads: Friction materials that engage with the rotor to create the necessary stopping force when the brake is applied.

- Brake Rotors: Disc-shaped components that work in conjunction with the brake pads, providing a surface for friction to occur and slowing down the vehicle.

Each of these components plays a vital role in the overall functionality of the braking system. Regular inspection and maintenance of these elements are essential to ensure optimal performance and safety.

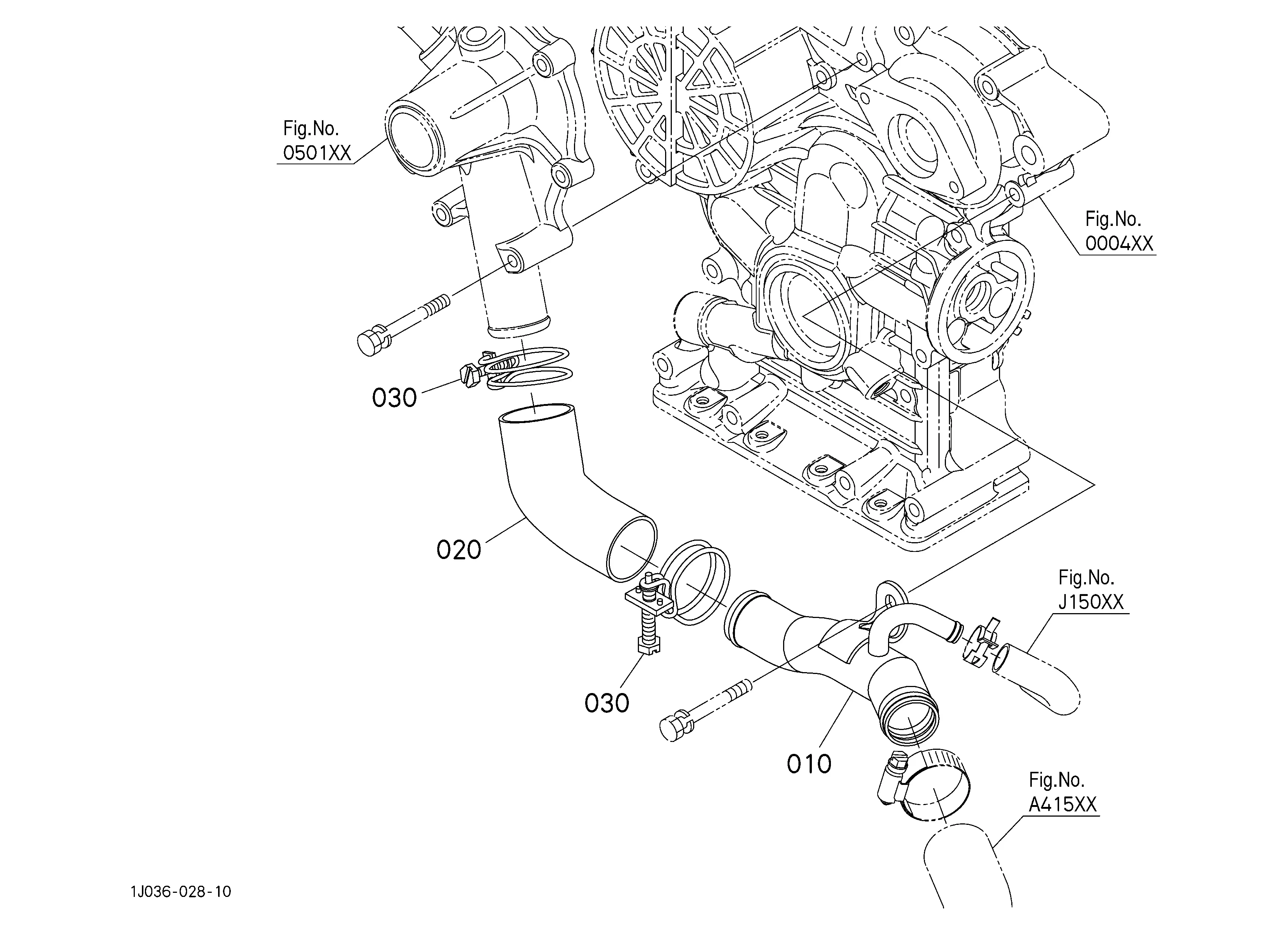

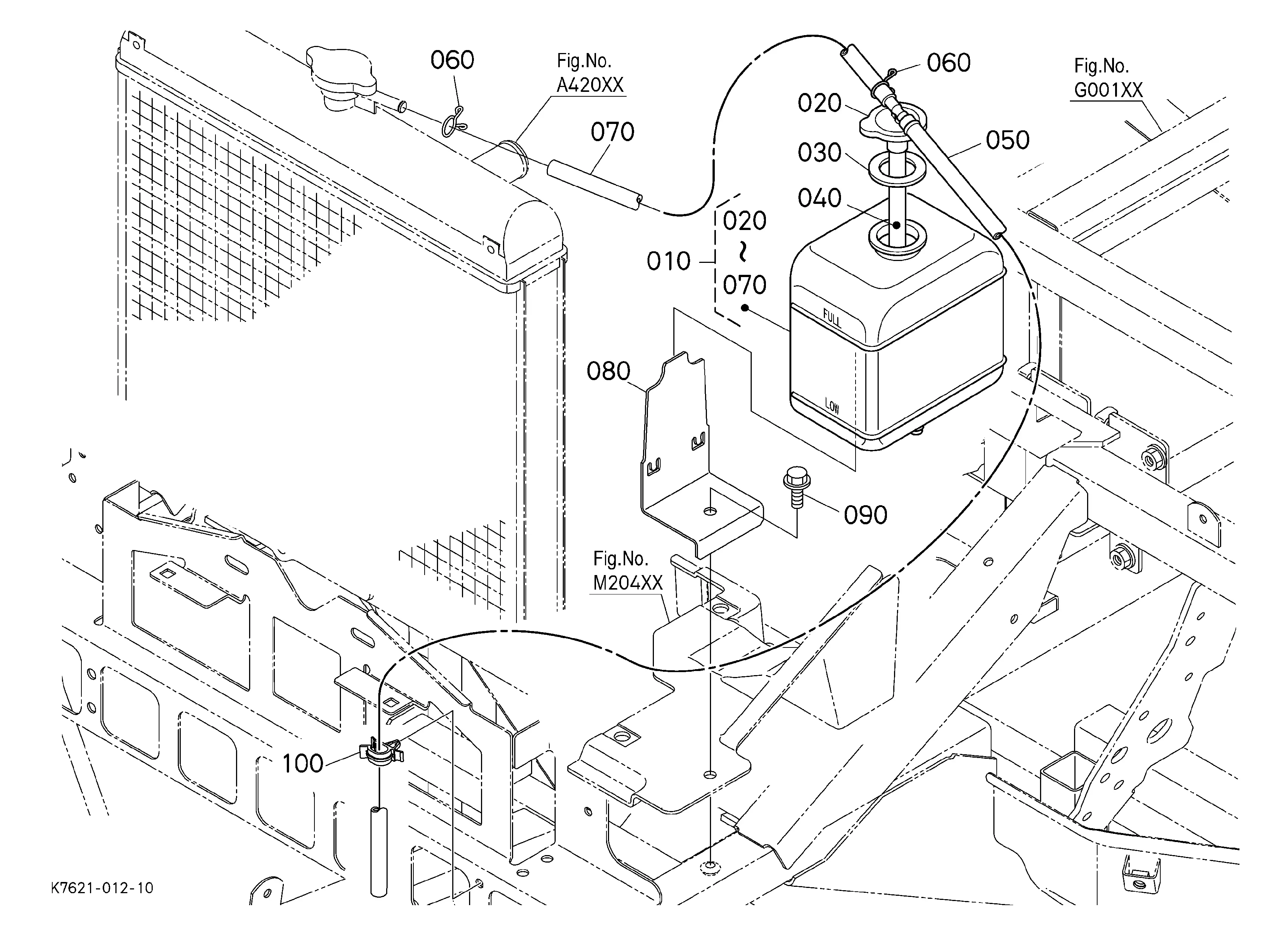

How the Cooling System Works

The cooling mechanism in vehicles plays a crucial role in maintaining optimal operating temperatures for the engine. This system prevents overheating by circulating a cooling liquid, ensuring that the engine components function efficiently and effectively.

Basic Components of the Cooling System

The primary elements include a radiator, water pump, and coolant. The radiator dissipates heat from the fluid as it flows through, while the water pump ensures the continuous movement of the cooling liquid throughout the engine. Coolant, typically a mix of water and antifreeze, absorbs heat, transferring it away from the engine parts.

Functionality in Action

When the engine operates, it generates heat. The coolant absorbs this heat and travels to the radiator, where it cools down before recirculating back into the engine. This cycle maintains a stable temperature, preventing potential damage due to excessive heat. Regular maintenance of the cooling system is essential to ensure its reliability and longevity.

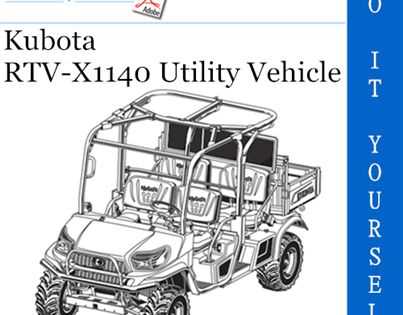

Fuel System Breakdown and Components

The fuel system plays a vital role in ensuring that the engine receives the necessary energy to function efficiently. It is comprised of several key components that work together to store, filter, and deliver fuel. Understanding these parts is essential for maintenance and troubleshooting.

Essential Elements of the Fuel System

At the heart of the fuel system is the fuel tank, which stores the liquid energy source. Connected to the tank, the fuel pump draws fuel and pushes it through the system. This pump is crucial for maintaining proper pressure and flow.

Filtration and Delivery

Before reaching the engine, the fuel passes through a filter, designed to remove impurities and debris. This ensures that only clean fuel enters the combustion chamber, promoting efficiency and longevity. Finally, the fuel injectors atomize the fuel, allowing for optimal mixing with air, which is essential for effective combustion.

Hydraulic Parts Overview and Functions

Hydraulic systems are essential components that enhance the functionality and efficiency of machinery. These systems operate by using fluid to transmit power, allowing various mechanical movements and operations. Understanding the elements involved in these systems can provide insights into their role in overall performance.

The primary components within hydraulic systems include pumps, cylinders, hoses, and valves. Each of these elements plays a critical role in facilitating movement and controlling fluid flow. Pumps generate the necessary pressure, while cylinders convert this pressure into linear motion. Hoses ensure the safe transportation of hydraulic fluid, and valves manage the direction and flow of the fluid throughout the system.

Moreover, the efficiency of hydraulic operations greatly relies on the quality and maintenance of these components. Regular inspections and timely replacements can prevent system failures and enhance the longevity of the equipment. Understanding the functions of these hydraulic elements not only helps in troubleshooting issues but also ensures optimal performance during operation.

Electrical System and Wiring Layout

The electrical network of a utility vehicle plays a crucial role in its overall functionality and performance. A well-organized wiring arrangement ensures that various components operate efficiently, providing essential power distribution and communication pathways. Understanding this layout helps in troubleshooting and maintaining the vehicle’s electrical components effectively.

Overview of Electrical Components

This section highlights the various elements involved in the electrical framework, including the battery, alternator, and ignition system. Each part serves a specific function, contributing to the reliable operation of the vehicle. The battery supplies the necessary energy for starting, while the alternator recharges the battery during operation.

Wiring Configuration Insights

The wiring configuration is designed to connect all electrical components seamlessly. High-quality connectors and insulated wiring protect against short circuits and environmental factors. Proper routing of wires reduces interference and enhances durability, ensuring that the electrical system operates smoothly under various conditions.

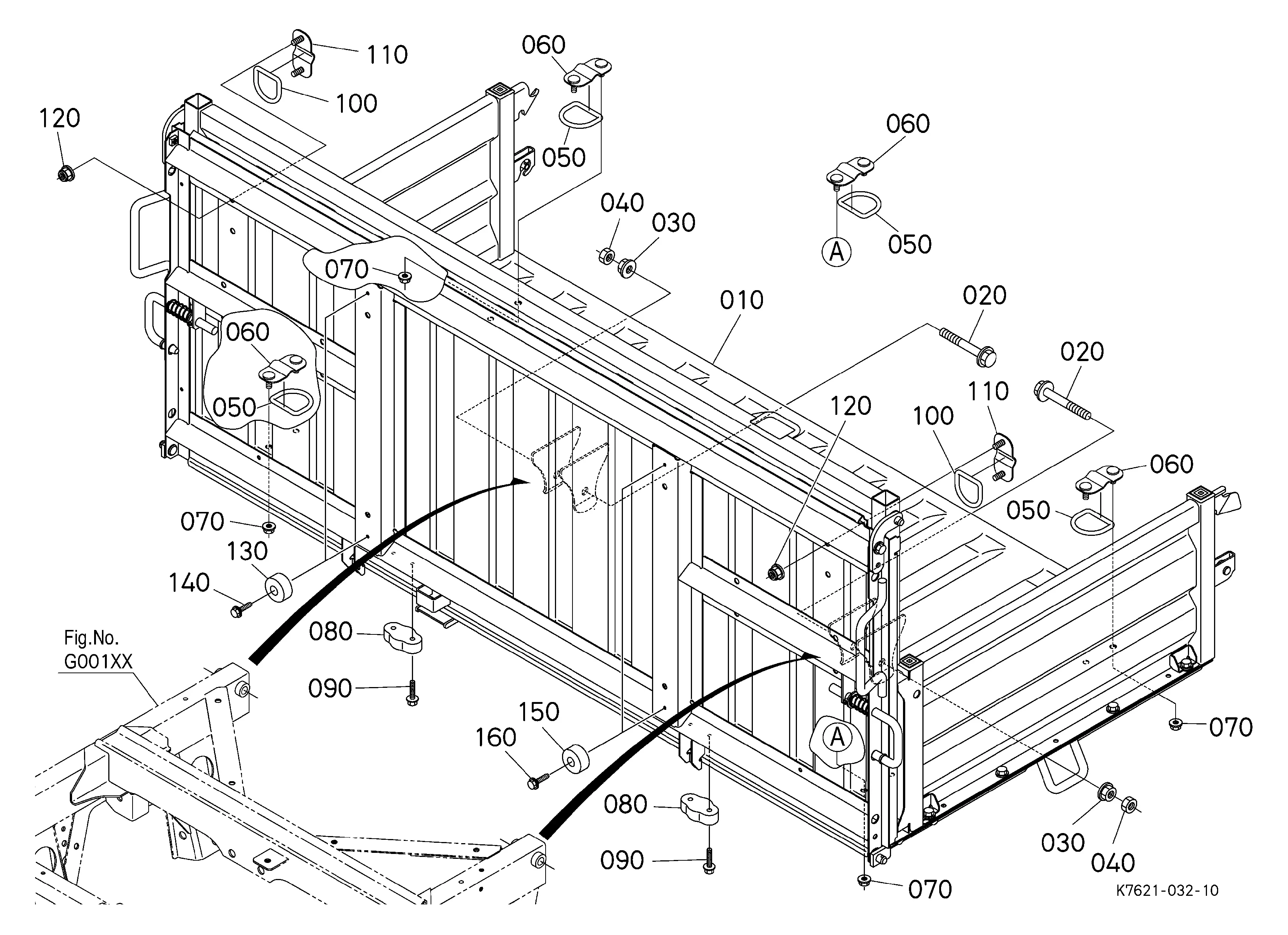

Body and Frame Structure Analysis

The analysis of the outer shell and chassis configuration of a utility vehicle provides essential insights into its durability and functionality. Understanding the materials and design choices can reveal the strengths and potential weaknesses of the vehicle’s overall structure.

Material Composition

The outer structure and frame are typically crafted from robust materials designed to withstand harsh conditions. Key elements include:

- Steel: Offers excellent strength and rigidity, making it a preferred choice for structural components.

- Aluminum: Lightweight and resistant to corrosion, enhancing fuel efficiency and handling.

- Composite Materials: Increasingly used for specific parts to reduce weight while maintaining durability.

Design Features

Design elements play a critical role in the vehicle’s performance and safety. Notable characteristics include:

- Reinforced Sections: Strategic reinforcement in high-stress areas to enhance strength.

- Modular Design: Facilitates easier repairs and replacements of specific components.

- Vibration Dampening: Integration of features to minimize the effects of vibrations during operation.

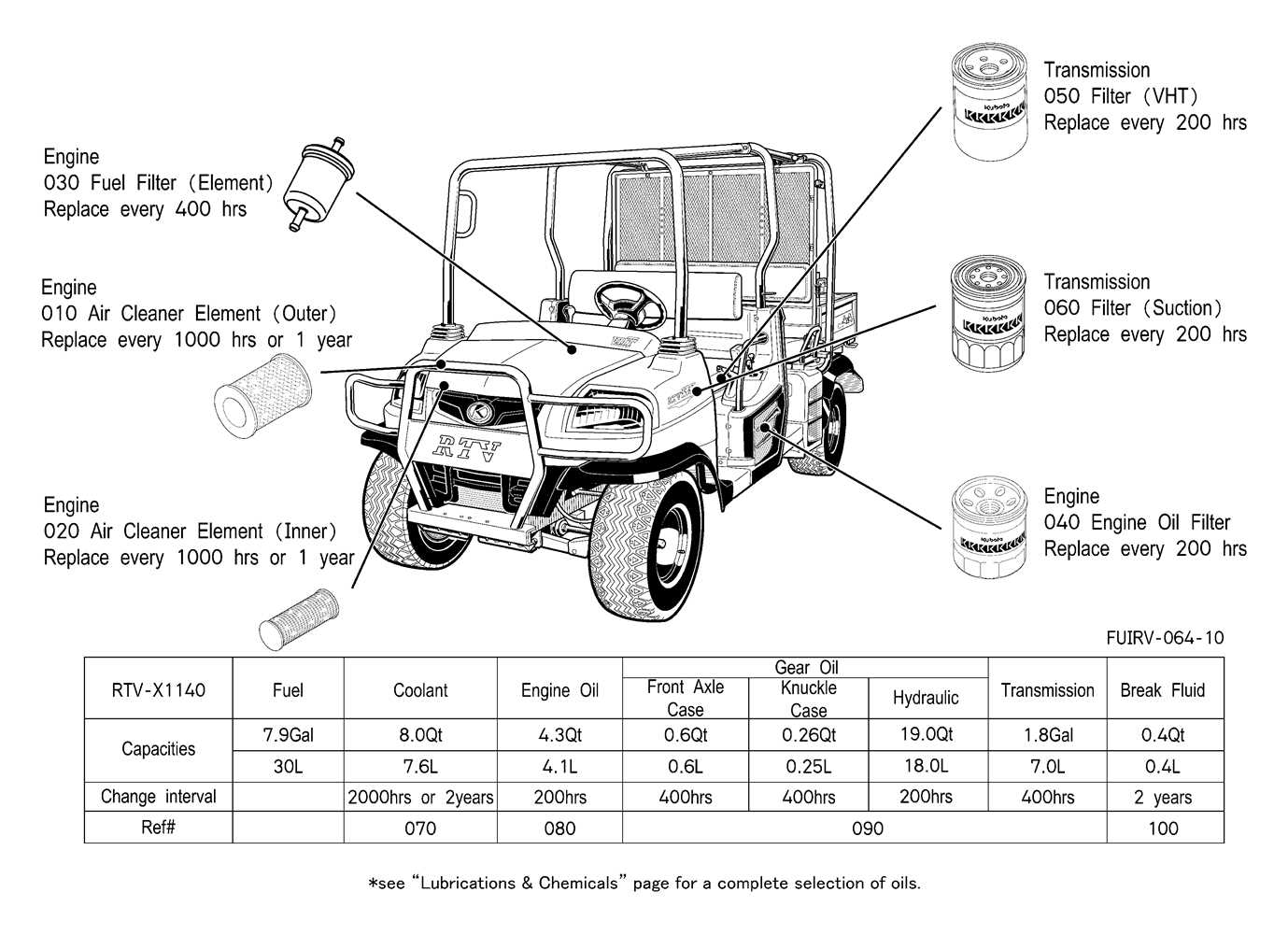

Maintaining and Replacing Key Parts

Proper upkeep and timely replacement of essential components are vital for ensuring the longevity and optimal performance of your vehicle. By regularly inspecting and addressing wear and tear, you can prevent larger issues and maintain efficient operation.

Routine Maintenance Tips

- Check fluid levels regularly and top up as needed.

- Inspect filters and replace them according to the manufacturer’s recommendations.

- Monitor tire pressure and tread condition to enhance safety and fuel efficiency.

- Clean and lubricate moving parts to reduce friction and wear.

Replacement Guidelines

- Identify components that show signs of damage or wear.

- Refer to the maintenance manual for specific replacement instructions.

- Use high-quality replacement parts to ensure compatibility and durability.

- Follow proper installation procedures to avoid future issues.