When working with heavy machinery, understanding how various components interact is essential. The detailed layout of these systems can provide valuable insights into the functionality and maintenance of the equipment. This understanding ensures smoother operations and helps in identifying potential issues before they become larger problems.

Each system is composed of numerous intricate elements that must work in harmony to achieve optimal performance. A clear understanding of the connections between these elements is crucial for anyone involved in operating or maintaining such equipment. Having access to a clear and well-organized visual guide significantly simplifies this process.

This guide aims to break down the inner workings of a robust system, offering a clear view of its various segments. Whether you’re handling routine upkeep or more in-depth repairs, having a structured reference to the equipment’s layout will enhance efficiency and reduce downtime.

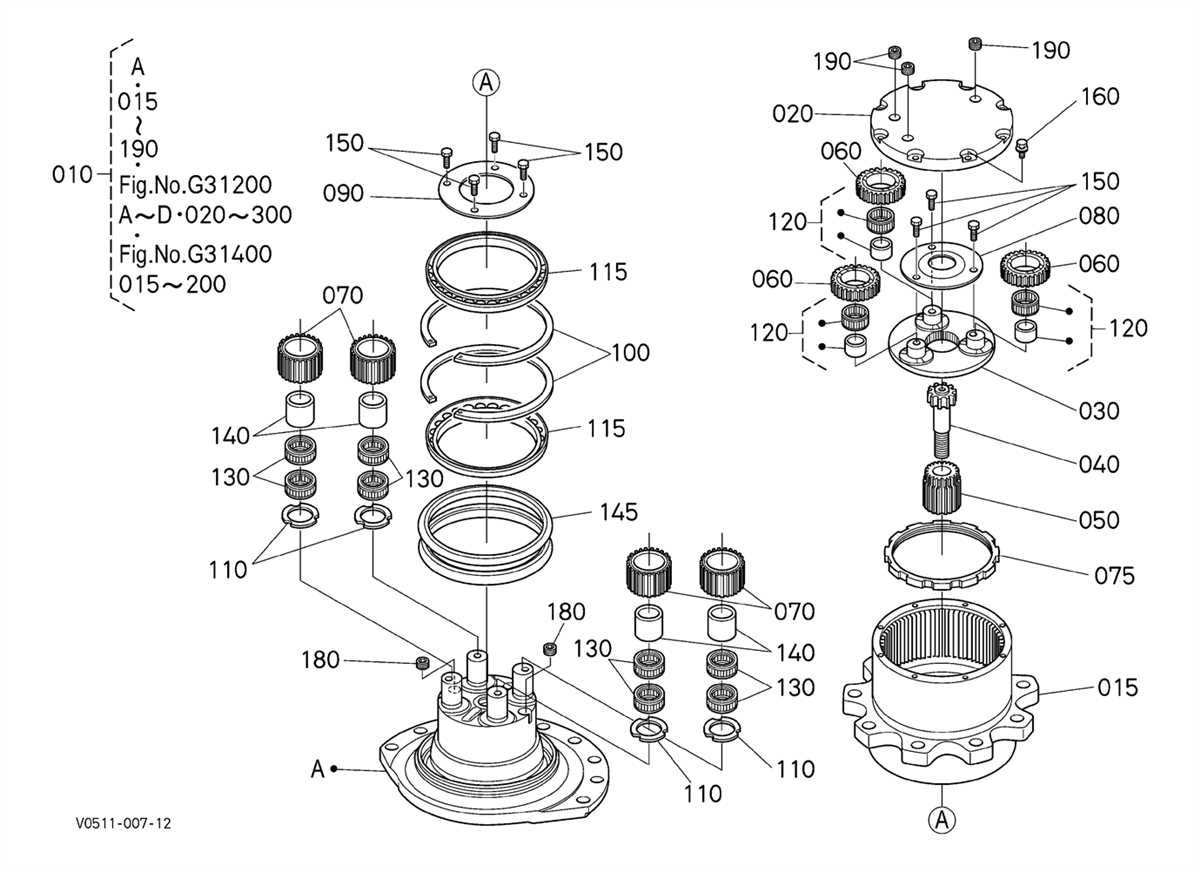

Kubota SVL75-2: Understanding the Parts Diagram

Grasping the internal structure and components of heavy machinery is crucial for maintaining and repairing it effectively. Visual guides provide a comprehensive layout of the system, illustrating each element’s function and placement. With such schematics, even the most complex mechanical assemblies can be easily broken down, helping users understand the machine’s essential operations.

Component Breakdown

Every key element of the equipment is strategically positioned, from the hydraulics to the drivetrain. Viewing these elements in a well-structured guide ensures you can quickly identify their location and role. Whether it’s the power unit or control system, each segment is presented clearly to avoid confusion during service or repair tasks.

Maintenance Benefits

Using a visual layout allows technicians to anticipate potential wear points and weak areas. It streamlines the maintenance process, ensuring that every necessary element is checked and addressed in time. With proper inspection, downtime can be reduced, maximizing the machine’s efficiency.

| Section | Description | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Block | Houses the power source and essential components driving the machine. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Hydraulic System | Enables movement and control of

Key Components in Kubota SVL75-2

Understanding the primary elements of this machine is crucial for efficient operation and maintenance. These essential features work together to ensure smooth functionality, offering durability and reliability in various tasks. Below is a detailed breakdown of the most important aspects that contribute to its performance.

How to Read a Kubota SVL75-2 DiagramUnderstanding the layout of technical schematics is essential for effective maintenance and troubleshooting. These visuals provide a clear and structured representation of a machine’s components, making it easier to identify connections and interactions between parts. Mastering the ability to interpret such diagrams will enhance your ability to pinpoint issues and perform repairs efficiently. One key element is recognizing symbols and lines that represent different sections of the machine. These elements are often accompanied by labels or numbers, allowing for quick identification. The layout also typically follows a logical order, guiding the reader through the system step by step. Below is an example of how a basic schematic might be structured:

By familiar Hydraulic System Overview for Kubota SVL75-2

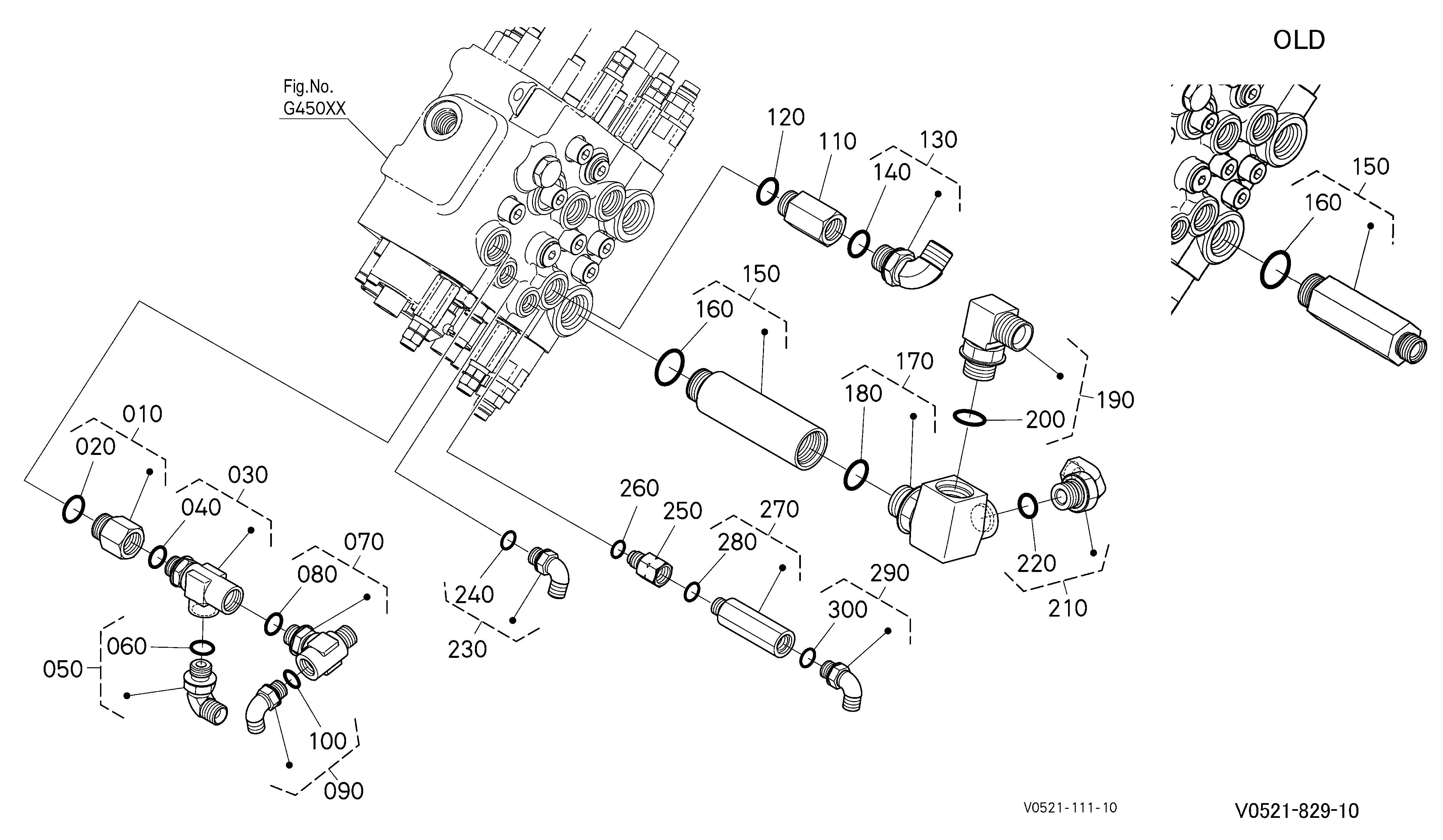

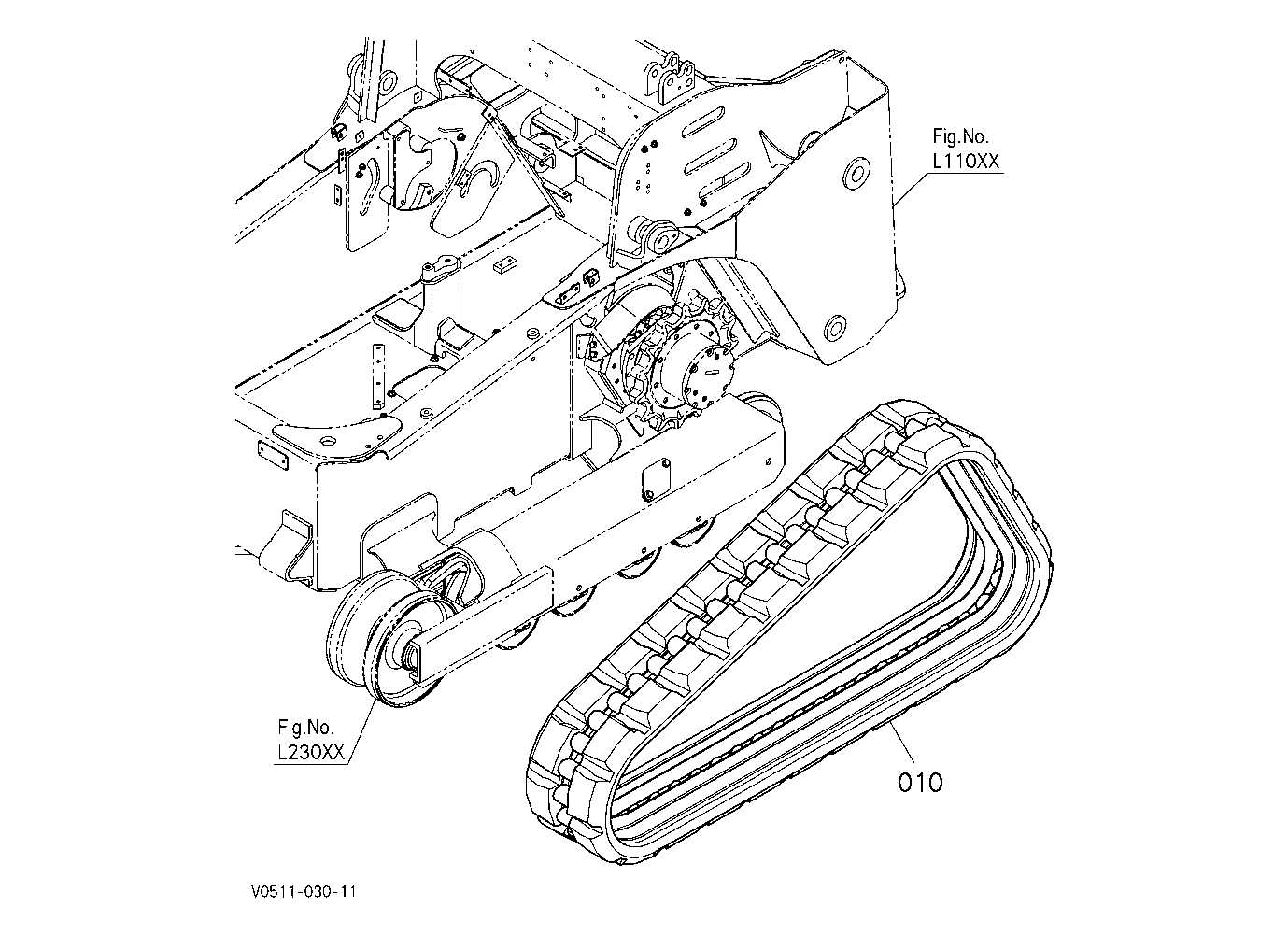

The hydraulic system plays a crucial role in powering essential functions of the equipment, ensuring smooth operation of its primary mechanisms. It serves as the lifeblood of the machine, driving multiple components that rely on fluid pressure to perform tasks efficiently. Understanding how this system works can help operators maintain performance and avoid unnecessary downtime. Core Components and Functions This intricate system consists of pumps, valves, and actuators working in harmony to convert fluid pressure into mechanical energy. Each element has a specific role, from generating pressure to controlling the flow and direction of the hydraulic fluid. These components allow precise control over various motions, including lifting, tilting, and steering. Key Benefits of Hydraulic Operation Using hydraulic power enables greater efficiency and force compared to mechanical alternatives. The fluid-driven system ensures that heavy loads are managed with ease, while providing the operator with smooth, responsive handling. Proper maintenance and periodic checks are essential to keep this system functioning at its best, prolonging the lifespan of the equipment. Track System Breakdown for Kubota SVL75-2The track system of this versatile machinery is designed to provide optimal traction and durability. With the right structure in place, it ensures smooth operation on a variety of terrains, reducing wear and tear during heavy-duty tasks. Understanding the elements of the track assembly can help maintain efficient performance and extend the longevity of the equipment. Track Frame plays a crucial role in holding the entire structure together. It provides the necessary foundation for the components to operate seamlessly, supporting the weight and movements of the machine. The rollers and idler wheels are essential for guiding the rubber belts in place. These parts help distribute the load evenly across the ground, allowing for consistent movement while minimizing damage to the surface. Rubber tracks are specifically designed to offer high levels of grip, ensuring that the machine can handle rough environments without losing stability. The durable material also helps to absorb shock, contributing to a smoother ride. Finally, the sprockets engage with the tracks, driving the entire system forward. These components ensure that the belts are properly aligned, allowing for precise and powerful operation even under challenging conditions. Engine Parts Layout in Kubota SVL75-2

This section provides an overview of the arrangement and function of essential components within the engine of the specified heavy machinery. Understanding how these elements work together is crucial for effective maintenance and troubleshooting, ensuring optimal performance in various applications. Overview of Engine ComponentsThe engine consists of various elements that each play a vital role in its operation. From the ignition system to the fuel delivery mechanisms, each part contributes to the overall efficiency and reliability of the machine.

Importance of Proper Maintenance

Regular inspection and servicing of the engine components are essential for maintaining the machinery’s performance and longevity. Ensuring that each element functions correctly can prevent costly repairs and downtime, enhancing overall productivity. Cooling System Components of Kubota SVL75-2

The efficient functioning of any machinery relies heavily on its cooling system, which plays a crucial role in maintaining optimal operating temperatures. This segment delves into the essential elements that constitute the cooling mechanism of a particular compact track loader, ensuring reliable performance and longevity. Key Elements of the Cooling MechanismUnderstanding the primary components involved can shed light on how the cooling system effectively regulates temperature during operation.

Importance of Maintenance

Regular upkeep of the cooling components is vital to prevent overheating and ensure the longevity of the equipment. Here are some key maintenance practices:

Electrical Wiring Overview in Kubota SVL75-2

The electrical system of a compact track loader is a crucial aspect that ensures optimal performance and reliability. This system encompasses various components that work together to facilitate the machine’s functionality, allowing it to operate effectively in diverse conditions. Understanding the wiring layout and its elements is essential for maintenance and troubleshooting, ensuring smooth operation. Among the key elements are the wiring harness, connectors, and switches, which play a significant role in transmitting electrical signals throughout the machine. Proper knowledge of these components aids in identifying potential issues and performing necessary repairs, thus extending the lifespan of the equipment.

In summary, familiarity with the electrical wiring framework of the compact track loader is vital for ensuring that all components function cohesively. Regular inspections and understanding of the wiring layout can significantly enhance the machine’s reliability and performance, allowing it to handle demanding tasks efficiently. Cab Assembly Parts in Kubota SVL75-2The structure responsible for housing the operator is a crucial aspect of the machinery’s design. This assembly not only provides protection from the elements but also enhances the overall user experience by ensuring comfort and accessibility to essential controls. Understanding the components of this assembly can greatly assist in maintenance and repairs, ensuring optimal performance. Key Components of the Cabin AssemblyWithin the cabin structure, several essential components work together to create a functional workspace. These elements include structural frameworks, visibility features, and operator interfaces, all designed to enhance usability and safety. Below is a summary of these components:

Maintenance ConsiderationsRegular upkeep of the cabin assembly is vital for maintaining the functionality and longevity of the machinery. Checking for wear and tear, ensuring proper sealing of windows, and inspecting the climate control system are essential tasks. Addressing any issues promptly can prevent more significant problems and ensure a safe and comfortable working environment. Maintenance Points on the Kubota SVL75-2

Regular upkeep is essential for ensuring the longevity and efficiency of heavy machinery. Proper maintenance not only enhances performance but also reduces the likelihood of unexpected breakdowns. Understanding key maintenance aspects can lead to a more reliable operation and a longer service life for your equipment. Essential Maintenance Tasks

Inspection Recommendations

Common Wear Parts for Kubota SVL75-2In any heavy machinery, certain components are prone to deterioration over time due to constant usage and exposure to challenging environments. Understanding which elements typically require replacement can significantly enhance the longevity and performance of the equipment. This section focuses on the most frequently replaced components, emphasizing their importance and the role they play in maintaining operational efficiency. Track Shoes: The undercarriage is crucial for stability and traction, and the shoes endure substantial wear from rough terrain. Regular inspection and timely replacement ensure optimal grip and prevent further damage. Hydraulic Hoses: As the lifeblood of any hydraulic system, these hoses can wear out due to pressure fluctuations and exposure to the elements. Replacing worn hoses promptly can prevent leaks and maintain system integrity. Filters: Air and oil filters are essential for keeping the engine and hydraulic systems clean. Clogged filters can lead to reduced performance and potential damage. Routine changes are vital for efficient operation. Drive Belts: These components are critical for transferring power between various systems. Fraying or cracking can lead to performance issues. Regular checks can help identify wear before it leads to failure. Bucket Edges: For those who frequently engage in excavation or grading, the edges of the bucket will eventually show signs of wear. Replacing them ensures effective operation and prevents further damage to the attachment. By staying vigilant and addressing wear on these key components, operators can enhance their machinery’s reliability and extend its service life. Where to Find Genuine Kubota SVL75-2 PartsLocating authentic components for your machinery can be crucial for maintaining its efficiency and longevity. Reliable sources ensure that you receive quality items that meet the manufacturer’s specifications. In this section, we will explore various options for obtaining genuine replacements for your equipment. Authorized Dealers and Service Centers

One of the most dependable methods to procure authentic components is through authorized dealers and service centers. These establishments have direct access to original manufacturer supplies and are knowledgeable about the specific needs of your equipment. They can also provide expert advice on installation and maintenance, ensuring optimal performance. Online Marketplaces and Manufacturer Websites

The internet offers a wide array of platforms where genuine components can be purchased. Manufacturer websites often have sections dedicated to their products, allowing you to browse and order directly. Additionally, established online marketplaces can connect you with verified sellers offering high-quality items. Always check for customer reviews and ratings to confirm the seller’s reliability. |