The intricate design of machinery often includes a variety of essential elements that work in harmony to ensure optimal performance. A comprehensive exploration of these components provides valuable insights into their functions and interactions. By delving into the arrangement of these crucial parts, users can enhance their understanding of operational efficiency and maintenance requirements.

In this section, we will examine the organization and categorization of various mechanical elements, offering a detailed overview of their roles within the system. Knowledge of how these components are structured not only aids in effective troubleshooting but also fosters better maintenance practices, ensuring longevity and reliability of the equipment.

Ultimately, grasping the intricacies of component layouts equips operators and technicians with the necessary tools to diagnose issues accurately and perform repairs efficiently. This understanding is fundamental for anyone looking to maximize the lifespan and performance of their machinery.

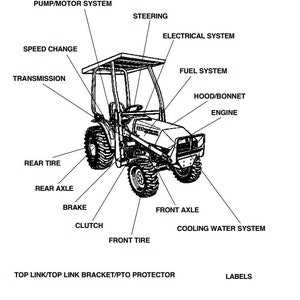

Grasping the arrangement of components in heavy machinery is essential for efficient maintenance and repair. A well-structured layout enables operators to quickly identify and access the necessary elements for servicing, ensuring optimal performance. Understanding the configuration helps in troubleshooting issues and enhances the overall operational efficiency of the equipment.

This section will outline the key segments and their respective functions, allowing users to become familiar with the equipment’s anatomy.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives all mechanical operations. |

| Hydraulic System | Controls movement and operation of attachments through fluid pressure. |

| Cab | Provides a protected area for the operator with controls and visibility. |

| Tracks | Facilitates movement across various terrains and supports the weight of the machine. |

| Attachment Points | Connects various implements for specific tasks, enhancing versatility. |

Essential Components of SVL90

Understanding the key elements of heavy machinery is crucial for efficient operation and maintenance. Each component plays a significant role in the overall functionality and performance of the machine, ensuring it meets the demands of various tasks. Below are the fundamental elements that contribute to the effectiveness of this robust equipment.

Core Elements

- Engine: The powerhouse that drives the entire system, providing the necessary power for operation.

- Hydraulic System: Facilitates movement and operation of attachments, essential for versatile applications.

- Transmission: Transfers power from the engine to the wheels or tracks, enabling smooth movement.

- Cab: The operator’s workspace, designed for comfort and visibility to enhance control.

Additional Features

- Track System: Ensures stability and traction on various terrains, optimizing maneuverability.

- Cooling System: Maintains optimal operating temperature, preventing overheating during extensive use.

- Electrical System: Powers controls, lights, and other electronic components, essential for operation.

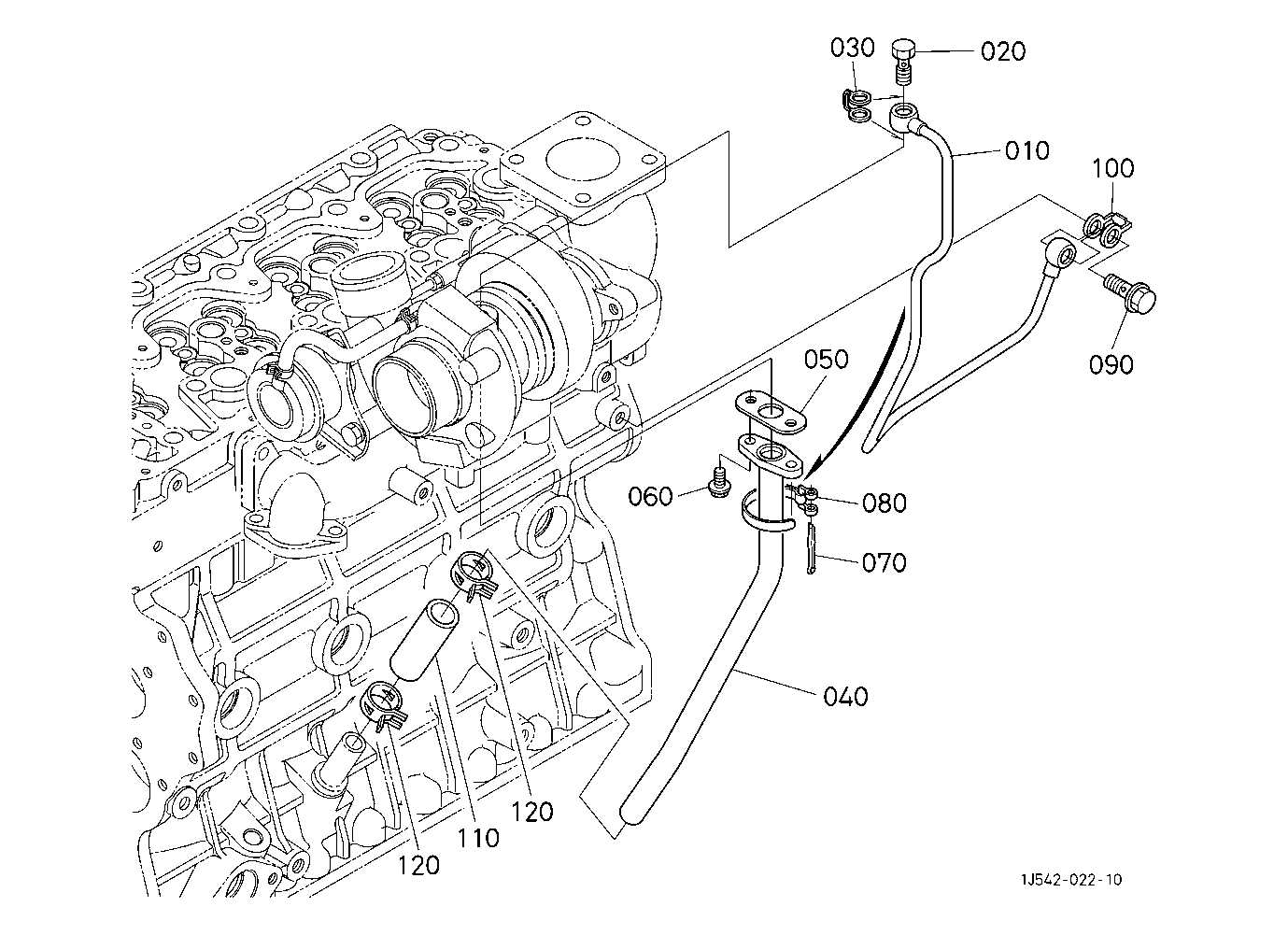

Detailed Engine Assembly Diagram

The engine assembly is a crucial component of any machinery, showcasing the intricate arrangement of its internal elements. Understanding this layout helps in performing maintenance, repairs, and upgrades effectively. This section delves into the essential parts and their connections within the engine structure, ensuring optimal performance and longevity.

The following are key components typically found in an engine assembly:

- Crankshaft: Converts linear motion into rotational motion, powering the vehicle.

- Pistons: Move up and down within the cylinders, facilitating the combustion process.

- Cylinders: House the pistons and provide the environment for fuel combustion.

- Camshaft: Regulates the timing of valve openings and closings, ensuring efficient air-fuel mixture intake.

- Valves: Control the flow of air and exhaust gases in and out of the cylinders.

- Timing Belt/Chain: Synchronizes the rotation of the crankshaft and camshaft.

Each component plays a vital role in the overall functionality of the engine. Proper understanding of their positions and interrelations is essential for effective troubleshooting and repair.

For those engaged in maintenance, having access to a detailed visual representation can greatly enhance comprehension of how each part integrates into the engine assembly. This knowledge not only aids in identifying potential issues but also fosters a deeper appreciation for the complexity of machinery operation.

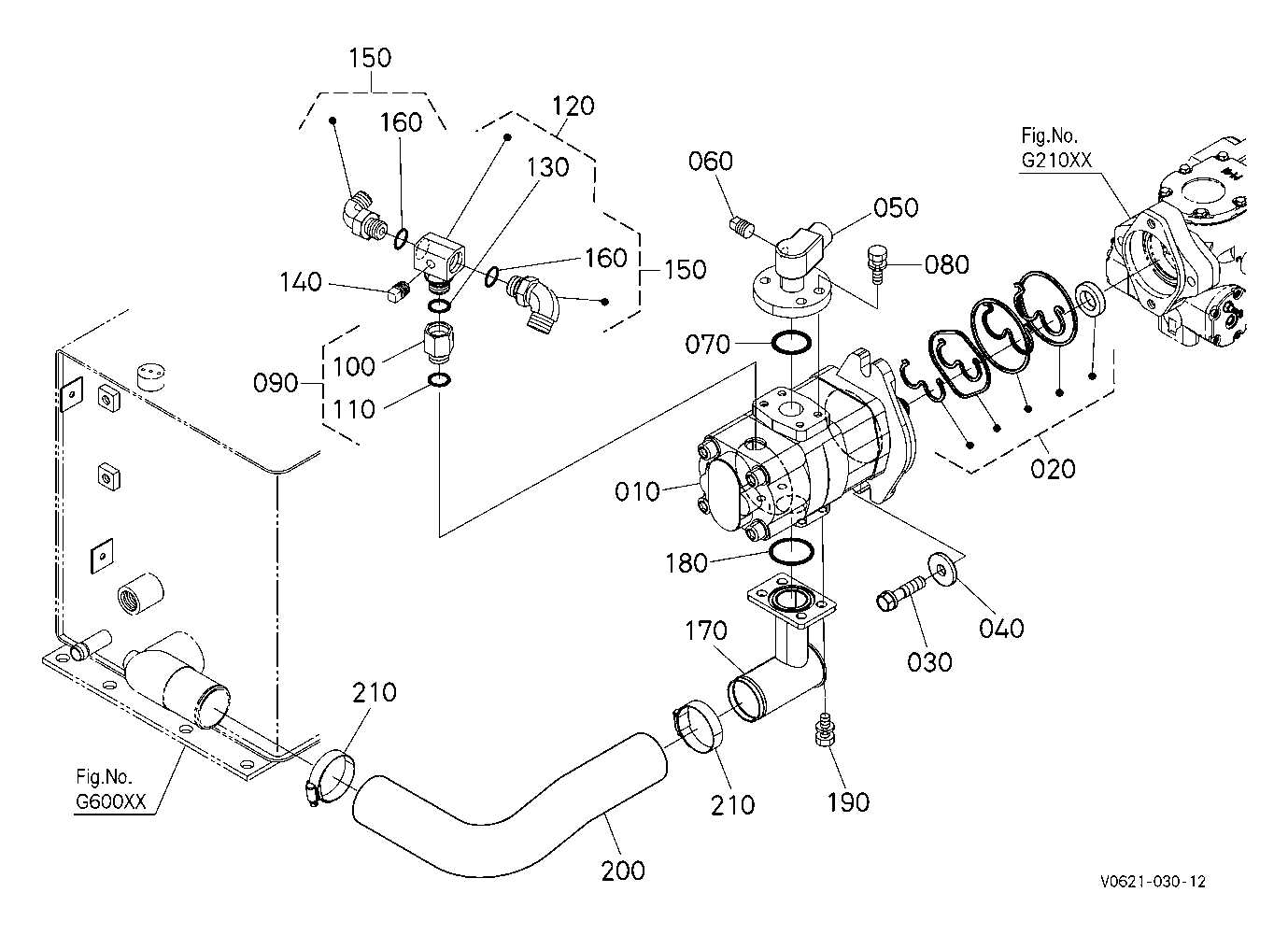

Hydraulic System Components Explained

The hydraulic system is a crucial part of many machines, facilitating smooth and efficient operations through fluid power. Understanding its various elements is essential for optimal performance and maintenance. Each component plays a specific role in the overall functionality, contributing to the effectiveness of the equipment.

Key Elements of the Hydraulic System

At the core of the hydraulic system are several vital components. The hydraulic pump generates the necessary pressure, pushing fluid through the system. This fluid then travels through valves that control the flow and direction, allowing precise movement of the machinery. Actuators, such as cylinders and motors, convert the hydraulic energy back into mechanical power, enabling various operations.

Importance of Regular Maintenance

Maintaining these components is critical to prevent breakdowns and ensure longevity. Regular inspections can identify wear and tear, allowing for timely replacements. Proper maintenance also involves monitoring fluid levels and quality, as contaminated or low fluid can lead to inefficiencies or damage. Keeping the hydraulic system in optimal condition is essential for reliable machine performance.

Transmission Parts and Functions

The transmission system is essential for the effective operation of machinery, playing a crucial role in the transfer of power from the engine to the wheels. Understanding the components and their functions enhances maintenance and troubleshooting capabilities. This section outlines the key elements of the transmission system and their respective roles in ensuring optimal performance.

Main Components of the Transmission

The transmission consists of several critical components, including the gearbox, torque converter, and clutch. The gearbox facilitates the selection of different speed ratios, allowing for efficient operation under varying load conditions. The torque converter serves to multiply engine torque and facilitate smoother acceleration, while the clutch engages and disengages the engine from the transmission, enabling gear shifts.

Functionality and Maintenance

Each component in the transmission system has specific functions that contribute to overall performance. Regular maintenance, including fluid checks and filter replacements, is vital for ensuring longevity and reliability. Understanding how each part interacts and its importance in the system will aid operators in achieving optimal machinery performance.

Electrical Wiring and Connectors

Effective electrical systems are crucial for the optimal functioning of machinery. Understanding the layout and organization of wiring, along with the associated connectors, ensures reliable performance and safety during operation.

Here are some key components involved in electrical wiring:

- Wires: Conductors that transmit electrical current, available in various gauges depending on the application.

- Connectors: Devices that link two or more electrical circuits, providing a secure and efficient connection.

- Relays: Electromechanical switches that control the flow of electricity based on specific conditions.

- Fuses: Protective devices that prevent overcurrent by breaking the circuit when necessary.

Proper installation and maintenance of these components are essential to prevent electrical faults and ensure longevity. Here are some best practices:

- Always refer to the specific wiring guidelines when making connections.

- Regularly inspect wiring for signs of wear or damage.

- Ensure connectors are securely fastened to prevent intermittent connections.

- Use appropriate gauge wires to match the load requirements.

By adhering to these principles, the reliability and efficiency of electrical systems can be significantly enhanced.

Chassis and Frame Parts Breakdown

This section provides a detailed overview of the structural components that form the foundation of the machine. Understanding these elements is essential for maintenance and repairs, ensuring optimal performance and longevity.

The chassis and frame play a crucial role in supporting various attachments and systems, while also contributing to the overall stability and durability of the equipment. Each component has its unique function, and recognizing their arrangement helps in identifying potential issues and facilitates effective troubleshooting.

| Component | Description | Function |

|---|---|---|

| Main Frame | The primary structure that supports all other components. | Provides stability and structural integrity. |

| Subframe | A secondary structure that reinforces the main frame. | Enhances support for heavy attachments. |

| Cross Members | Horizontal beams connecting the sides of the frame. | Distributes loads evenly across the chassis. |

| Mounting Brackets | Attachments for securing various components. | Facilitates the connection of hydraulic and electrical systems. |

| Underbody Protection | Shielding components beneath the frame. | Protects against debris and impacts during operation. |

Operator Controls and Interface Design

The functionality and efficiency of machinery heavily depend on the effectiveness of its control systems and interface layout. A well-designed operator interface not only enhances user experience but also improves productivity by facilitating intuitive interaction with the equipment. This section explores the key aspects of control elements and their arrangement to optimize operation.

Control Layout and Accessibility

Strategic placement of control buttons, levers, and switches is crucial for ensuring that operators can easily access and manipulate them without diverting attention from their tasks. Controls should be positioned in a manner that aligns with the natural movements of the user, promoting a seamless workflow. Additionally, ergonomic considerations play a significant role in minimizing operator fatigue during prolonged use.

User Interface Feedback

Effective communication between the machinery and the operator is vital for safe and efficient operation. Implementing visual and auditory feedback mechanisms allows users to receive real-time information regarding the machine’s status. Indicators, alarms, and displays should be clear and easily interpretable, empowering the operator to make informed decisions quickly and accurately.

Maintenance and Replacement Parts Guide

Ensuring optimal performance and longevity of your machinery requires regular upkeep and timely component substitutions. Understanding the essential elements involved in maintaining equipment is crucial for both efficiency and reliability. This section provides insights into the necessary actions and components needed to keep your machinery operating at its best.

Regular Maintenance Practices

Routine inspections and preventive care are vital for minimizing unexpected breakdowns. Regularly checking fluid levels, lubricating moving parts, and cleaning air filters can significantly enhance performance. Keeping a maintenance log helps track these activities and identify any recurring issues early.

Essential Components for Replacement

As machinery ages, certain elements may wear out and require replacement to ensure continued functionality. Key components such as filters, seals, and hydraulic hoses should be prioritized. Using high-quality replacements ensures compatibility and durability, ultimately leading to improved operational efficiency.

Common Issues and Solutions

This section addresses typical challenges encountered with compact track loaders and their corresponding remedies. Understanding these common problems can enhance maintenance efforts and ensure optimal functionality of the equipment.

- Hydraulic System Failures:

Issues in the hydraulic system may lead to inadequate lifting capacity or sluggish performance. Regular inspections of hoses and connections are essential.

- Check for leaks in hydraulic lines.

- Ensure fluid levels are adequate.

- Replace worn seals and gaskets promptly.

- Engine Overheating:

An overheating engine can cause severe damage if not addressed. Monitoring the cooling system is crucial to prevent this issue.

- Inspect the radiator for blockages.

- Ensure the coolant is at the proper level.

- Replace faulty thermostats.

- Electrical System Malfunctions:

Electrical failures can hinder operational efficiency. Regular checks of the electrical components can prevent unexpected breakdowns.

- Test the battery and connections for corrosion.

- Examine fuses and relays for continuity.

- Ensure that all wiring is intact and secure.

- Track Issues:

Worn or misaligned tracks can lead to reduced traction and stability. Regular maintenance is necessary to avoid costly repairs.

- Inspect tracks for wear and damage.

- Adjust tension to the manufacturer’s specifications.

- Replace damaged track components as needed.

Where to Find Parts Diagrams

Locating illustrations for equipment components is essential for effective maintenance and repair. Understanding where to access these resources can significantly enhance the efficiency of your servicing tasks. Various options are available for obtaining these valuable references.

- Manufacturer’s Website: Often, the original equipment manufacturer provides detailed resources, including component illustrations, in their support or parts section.

- Authorized Dealers: Local authorized retailers typically have access to comprehensive manuals and can provide the necessary visuals for the equipment.

- Online Forums: Many online communities focus on machinery and can be valuable sources for shared diagrams and experiences.

- Repair Manuals: Purchasing or accessing repair guides specifically designed for your model can yield detailed visuals that assist in troubleshooting.

- YouTube Tutorials: Various content creators upload instructional videos that often include visual aids for equipment assembly and part identification.

By exploring these avenues, you can ensure that you have the necessary illustrations to assist with any service or repair task.