In the realm of machinery maintenance, comprehending the intricate layout of essential elements is crucial. This knowledge not only enhances operational efficiency but also aids in troubleshooting and repairs. Recognizing how each component interacts within the overall system empowers users to make informed decisions regarding upkeep and enhancements.

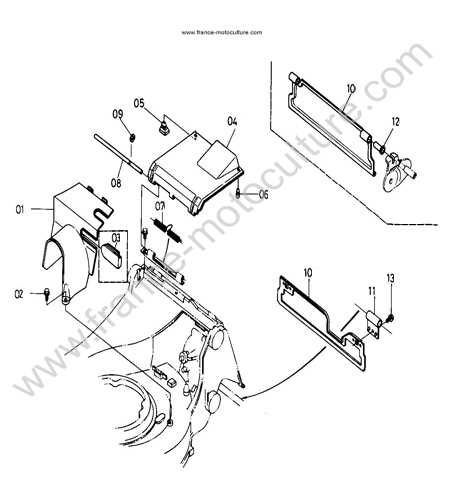

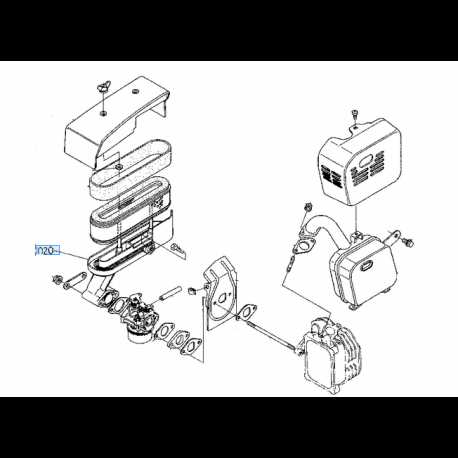

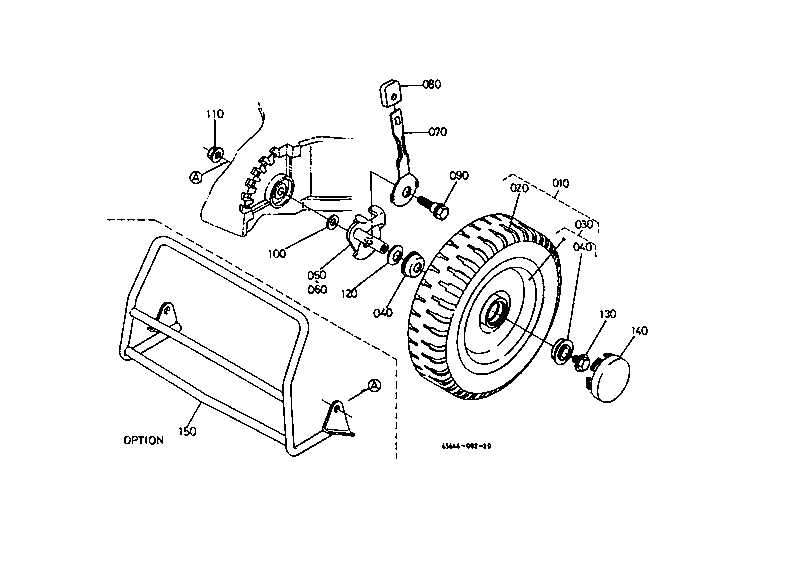

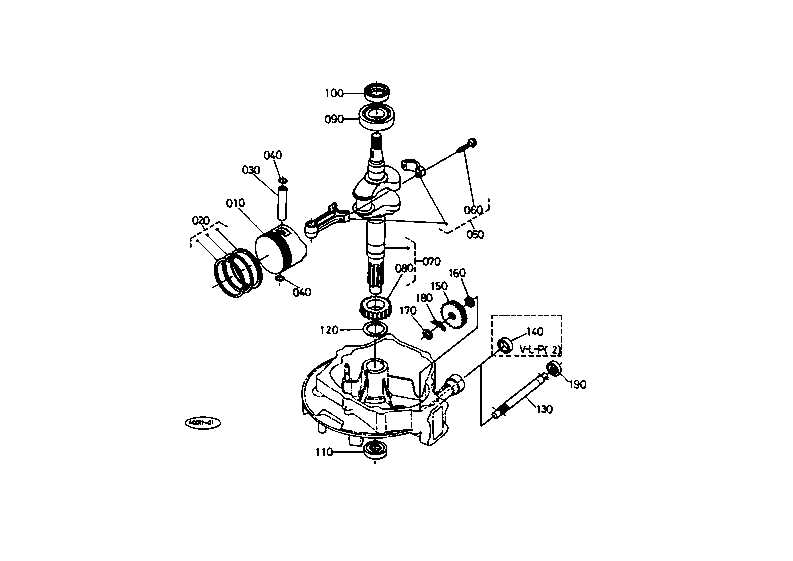

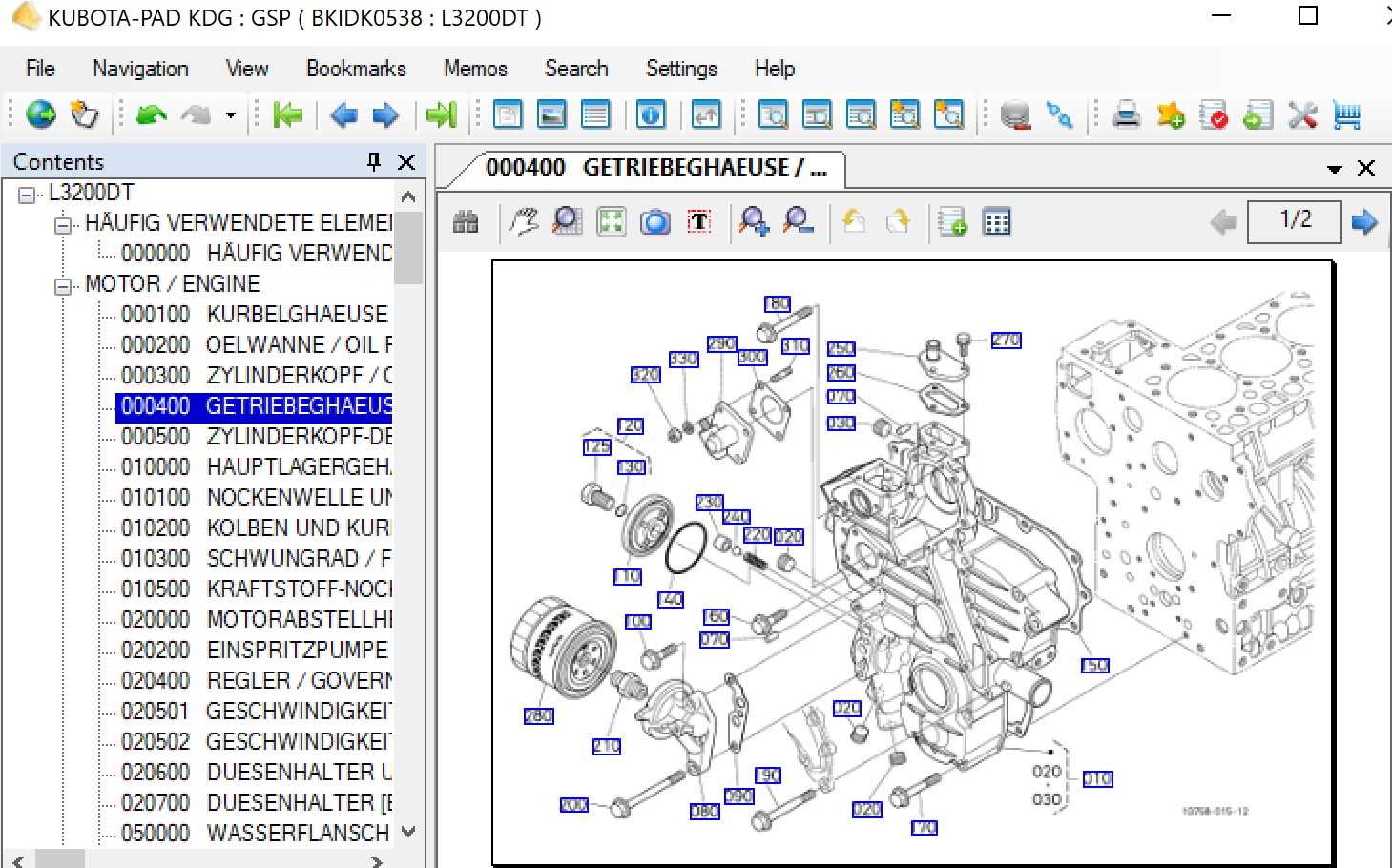

Detailed illustrations that depict the positioning and relationship of various elements serve as invaluable resources. They simplify the complex interplay of mechanical parts, allowing for a clearer understanding of how each piece contributes to the functionality of the entire system. By studying these visual aids, operators can effectively plan maintenance tasks and identify potential areas for improvement.

Furthermore, familiarity with the configuration of critical components fosters confidence in performing repairs. This understanding equips individuals with the ability to quickly locate specific elements, ensuring timely interventions and minimizing downtime. Ultimately, a comprehensive grasp of the arrangement of parts is indispensable for anyone involved in the care and operation of such machinery.

This section provides an overview of a specific model of agricultural machinery, highlighting its key features and functions. Understanding the components and their arrangements is crucial for effective maintenance and operation.

Below are the primary characteristics of this machinery:

- Engine Specifications: Insight into the power output and engine type.

- Dimensions: Key measurements that define the size and capacity of the machine.

- Weight: Information regarding the overall weight, affecting transport and stability.

- Operational Capacity: Details on what the machinery can handle in terms of workload.

In addition to the specifications, this section will also explore the design elements that enhance performance:

- Durability: Materials used in construction to withstand harsh conditions.

- Ergonomics: User-friendly features that improve operator comfort and efficiency.

- Maintenance Accessibility: Design choices that facilitate easier repairs and upkeep.

Understanding these aspects will provide a solid foundation for those looking to maximize the use of their machinery while ensuring it operates at peak performance.

Key Features of Kubota W5021

This section highlights the essential attributes and specifications of a particular compact tractor model, emphasizing its efficiency and reliability. Designed for various agricultural tasks, it showcases advanced engineering and user-friendly features that enhance performance.

Engine Performance

The power unit of this machine is engineered to deliver robust performance, ensuring smooth operation even under demanding conditions. Its efficient fuel consumption maximizes productivity while minimizing operational costs.

User-Friendly Design

Equipped with intuitive controls and ergonomic seating, this tractor enhances the operator’s comfort during extended use. The layout is designed for easy access to essential functions, allowing for seamless adjustments and improved handling.

Importance of Accurate Parts Diagram

Having a precise representation of components is crucial for anyone involved in machinery maintenance or repair. A detailed illustration not only aids in identifying individual elements but also ensures that the correct replacements are made. This is particularly essential in complex equipment where each part plays a vital role in overall functionality.

Enhancing Efficiency

An accurate schematic significantly improves the efficiency of the repair process. Technicians can quickly locate the necessary components, minimizing downtime and enhancing productivity. With a clear visual guide, the likelihood of mistakes during assembly or disassembly is greatly reduced.

Cost-Effectiveness

Investing time in understanding a well-crafted representation can save considerable expenses in the long run. By ensuring that the right parts are chosen and installed, users can avoid the costs associated with incorrect orders or repeated repairs due to improper installations. Thus, a thorough visual guide contributes to both time and financial savings.

| Benefits | Description |

|---|---|

| Improved Identification | Helps users easily recognize components needed for maintenance. |

| Reduced Errors | Minimizes the chance of making mistakes during repairs. |

| Time Savings | Shortens repair time by providing clear guidance. |

| Cost Savings | Prevents unnecessary expenses from incorrect replacements. |

Understanding Kubota W5021 Components

In the realm of agricultural machinery, comprehending the various elements that contribute to optimal performance is essential. Each component plays a pivotal role in ensuring efficiency and reliability, thereby enhancing overall functionality. This section delves into the critical elements, highlighting their significance and interrelationships.

| Component | Function |

|---|---|

| Engine | Powers the machinery, converting fuel into mechanical energy. |

| Transmission | Facilitates the transfer of power from the engine to the wheels, ensuring smooth movement. |

| Hydraulic System | Enables lifting and moving heavy loads through hydraulic fluid pressure. |

| Chassis | Provides structural support, housing all essential components for stability. |

| Fuel System | Stores and delivers fuel to the engine for combustion. |

| Cooling System | Regulates engine temperature to prevent overheating during operation. |

Understanding these fundamental parts equips operators with the knowledge needed for effective maintenance and troubleshooting. Awareness of how these components interact can lead to improved performance and longevity of the machinery.

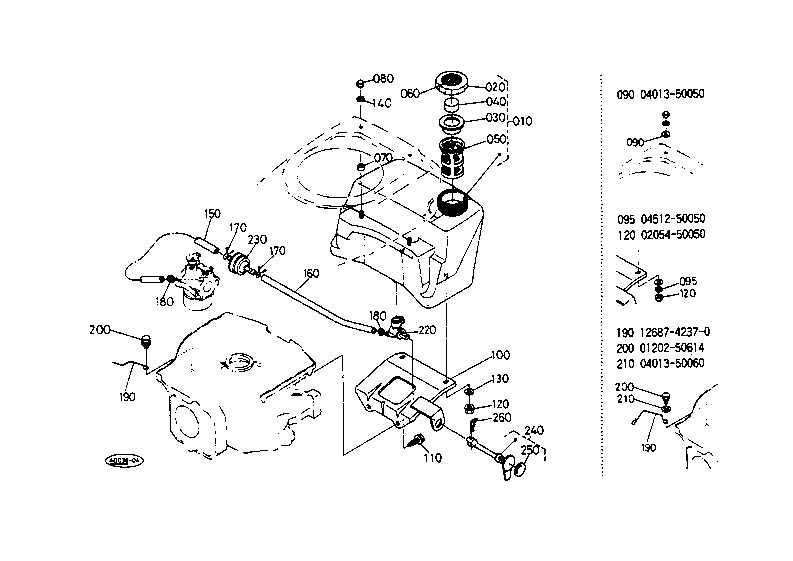

How to Use the Parts Diagram

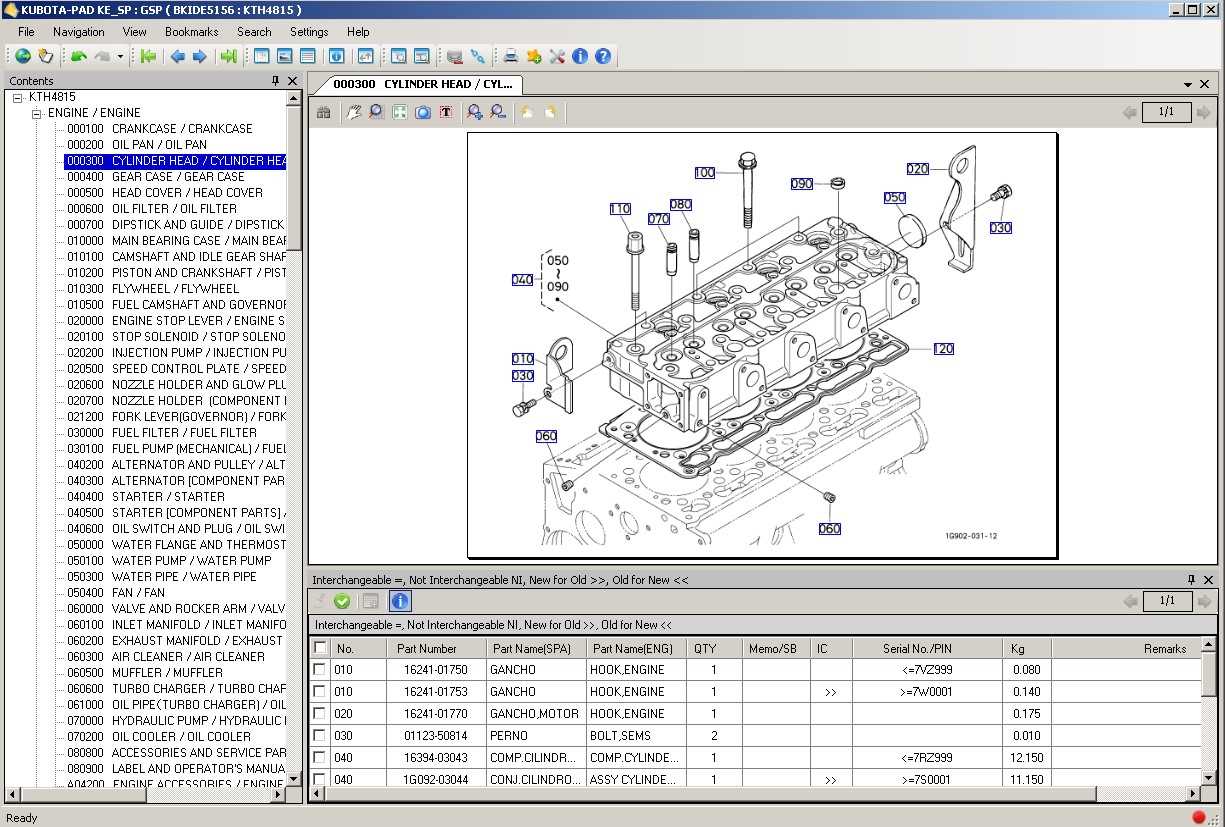

Understanding the visual representation of components is essential for effective maintenance and repair of machinery. This guide provides insights into how to navigate and utilize such illustrations to ensure you can identify, order, and replace parts efficiently.

To begin, locate the specific section that pertains to the equipment you are working on. Each segment typically highlights various elements, often categorized by function or location. Familiarizing yourself with these sections will streamline your search for the necessary components.

Next, pay close attention to the numbering system or labeling used within the illustration. Each part will usually have a corresponding number that matches a list, detailing specifications, availability, and pricing. This connection is crucial for accurate ordering and ensuring you receive the correct items for your repair tasks.

Lastly, take the time to review any accompanying notes or legends that may provide additional context. These annotations can offer valuable information regarding compatibility, installation tips, or maintenance recommendations. By leveraging these insights, you can enhance your understanding and improve the longevity of your equipment.

Common Repairs and Maintenance Tasks

Regular upkeep and essential repairs play a crucial role in ensuring the longevity and efficiency of machinery. Proper maintenance helps prevent unexpected breakdowns and extends the lifespan of various components. Familiarity with common tasks can empower users to perform routine checks and address minor issues promptly.

Routine Maintenance Checks

- Inspect and replace air filters to ensure optimal airflow and engine performance.

- Check fluid levels, including oil, coolant, and hydraulic fluids, and top up as necessary.

- Examine belts and hoses for signs of wear or damage, replacing them if needed.

- Clean or replace fuel filters to maintain fuel flow and engine efficiency.

Repairs and Adjustments

- Tighten loose bolts and fasteners to prevent vibrations from causing damage.

- Adjust tire pressure and inspect tread for wear to enhance traction and safety.

- Replace worn-out blades or other cutting implements to ensure effective operation.

- Address any leaks in hydraulic systems by checking seals and connections.

Identifying Genuine Kubota Parts

Recognizing authentic components is essential for maintaining the performance and longevity of your machinery. Genuine replacements are designed specifically for optimal compatibility, ensuring that your equipment runs smoothly and efficiently. Understanding how to differentiate between original and counterfeit items can save you time and money while preventing potential operational issues.

Quality and Performance: Authentic items are manufactured to stringent standards, guaranteeing durability and reliability. They undergo rigorous testing to meet the specifications required for optimal functionality. In contrast, imitation components may not provide the same level of performance and can lead to premature wear or failure.

Packaging and Markings: Genuine components typically come in branded packaging that includes identifiable markings, such as logos and part numbers. Inspecting the packaging for these features can help confirm authenticity. Always look for the manufacturer’s seal, which serves as a mark of quality assurance.

Source of Purchase: Acquiring items from authorized dealers or trusted retailers is crucial. Authorized distributors maintain a direct relationship with manufacturers, ensuring that you receive legitimate products. Be cautious of third-party sellers or online marketplaces that may offer components at significantly reduced prices, as these could be counterfeit.

Warranty and Support: Authentic items often come with warranties that provide coverage for defects or failures. This assurance is not only a testament to the quality of the product but also reflects the manufacturer’s commitment to customer satisfaction. Always inquire about the warranty terms before making a purchase.

Tools Required for Repairs

When undertaking maintenance and repair tasks, having the right tools at your disposal is crucial for ensuring efficiency and effectiveness. A well-equipped workspace not only facilitates smooth operations but also minimizes the risk of damage to components. Familiarizing yourself with the necessary instruments can significantly enhance your ability to complete repairs successfully.

Essential Hand Tools

Basic hand tools such as wrenches, pliers, and screwdrivers form the foundation of any repair kit. These instruments allow for the tightening or loosening of various fasteners, making them indispensable during maintenance procedures. It’s advisable to have a variety of sizes and types on hand to accommodate different tasks.

Power Tools and Equipment

For more extensive repairs, power tools can provide the additional force needed to tackle stubborn components. Drills, impact wrenches, and grinders can expedite the process, but they should be used with care to avoid damaging delicate parts. Ensuring that all equipment is in good working order is essential for safe and efficient repairs.

Where to Find Replacement Parts

Finding suitable components for your machinery can greatly enhance its performance and longevity. Various sources are available to help you locate the necessary items for maintenance and repair. Whether you are looking for new or refurbished options, understanding where to search can save time and effort.

| Source Type | Description |

|---|---|

| Authorized Dealers | Official dealers provide authentic items and often have a wide selection of components tailored for specific models. |

| Online Retailers | Numerous e-commerce platforms offer a vast array of items. Ensure to check for reputable sellers with good reviews. |

| Local Repair Shops | Many local mechanics and repair shops may have access to components or can help order them for you. |

| Salvage Yards | These places often have used components at reduced prices, making them a cost-effective alternative. |

| Manufacturer’s Website | Checking the official website of the machinery can lead to additional resources or direct purchasing options. |

Troubleshooting Common Issues

When operating machinery, encountering problems is not uncommon. Identifying and resolving these issues promptly can enhance performance and prolong the lifespan of the equipment. This section outlines typical challenges faced by users and offers guidance on how to address them effectively.

Engine Fails to Start: If the engine does not respond when attempting to start, first check the fuel levels. Ensure that the fuel is clean and free of contaminants. Additionally, inspect the battery for proper connections and charge levels. A faulty ignition system may also be a contributing factor, so verifying the spark plugs and ignition coil is advisable.

Overheating: Overheating can lead to serious damage. Start by checking the coolant level; low coolant can prevent proper heat dissipation. Make sure the radiator is free of debris and that the cooling fan operates correctly. If the problem persists, there may be an issue with the water pump or thermostat.

Poor Performance: If the machine exhibits sluggish performance, consider examining the air filter. A clogged air filter can restrict airflow, leading to reduced power. Also, inspect the fuel system for blockages and ensure that the fuel filter is clean. Regular maintenance of these components is essential for optimal operation.

Unusual Noises: Unusual sounds during operation can indicate mechanical issues. Listen for any grinding, knocking, or rattling noises. Check for loose or damaged parts, such as belts or bearings, which may require tightening or replacement. Timely attention to these signs can prevent more significant problems down the line.

By systematically addressing these common issues, users can maintain their machinery in optimal working condition and ensure reliable performance throughout its service life.

Benefits of Regular Maintenance

Consistent upkeep of machinery plays a crucial role in ensuring optimal performance and longevity. By adhering to a routine maintenance schedule, operators can significantly reduce the risk of unexpected failures and costly repairs. Regular attention to equipment not only enhances efficiency but also contributes to safety and reliability in operations.

Enhanced Performance

One of the primary advantages of regular maintenance is the improvement in overall performance. By routinely checking and servicing key components, operators can ensure that the machinery operates at peak efficiency. This not only maximizes productivity but also minimizes energy consumption, leading to cost savings over time.

Extended Lifespan

Another significant benefit is the extension of the machinery’s lifespan. Proper maintenance helps identify potential issues before they escalate into serious problems. By addressing minor repairs and adjustments promptly, operators can prolong the life of their equipment, resulting in better return on investment and reduced need for replacement.

| Benefit | Description |

|---|---|

| Improved Efficiency | Routine maintenance ensures machinery operates at optimal levels, enhancing overall productivity. |

| Cost Savings | Preventive care reduces the likelihood of major repairs and extends the life of equipment. |

| Increased Safety | Regular checks can help identify safety hazards, reducing the risk of accidents and injuries. |