In the realm of machinery, a thorough grasp of individual components is essential for optimal performance and maintenance. Recognizing how each element interacts within the larger system can significantly enhance efficiency and longevity.

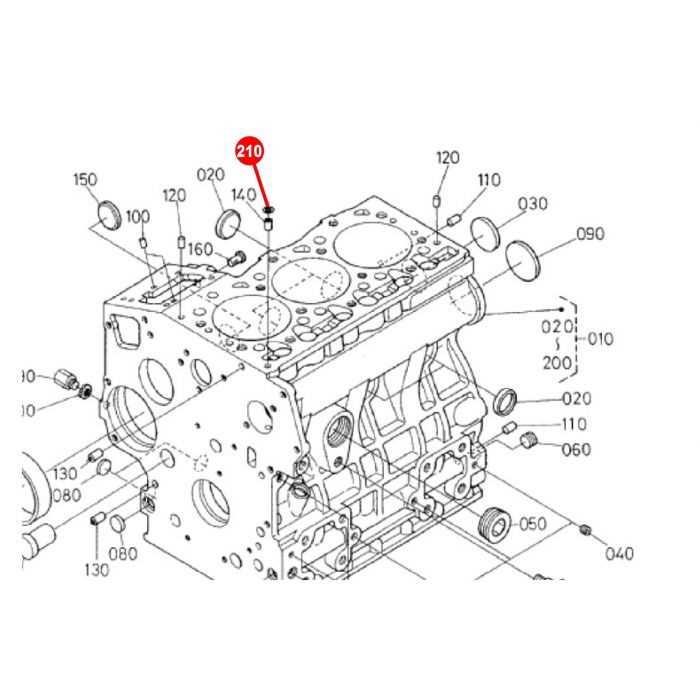

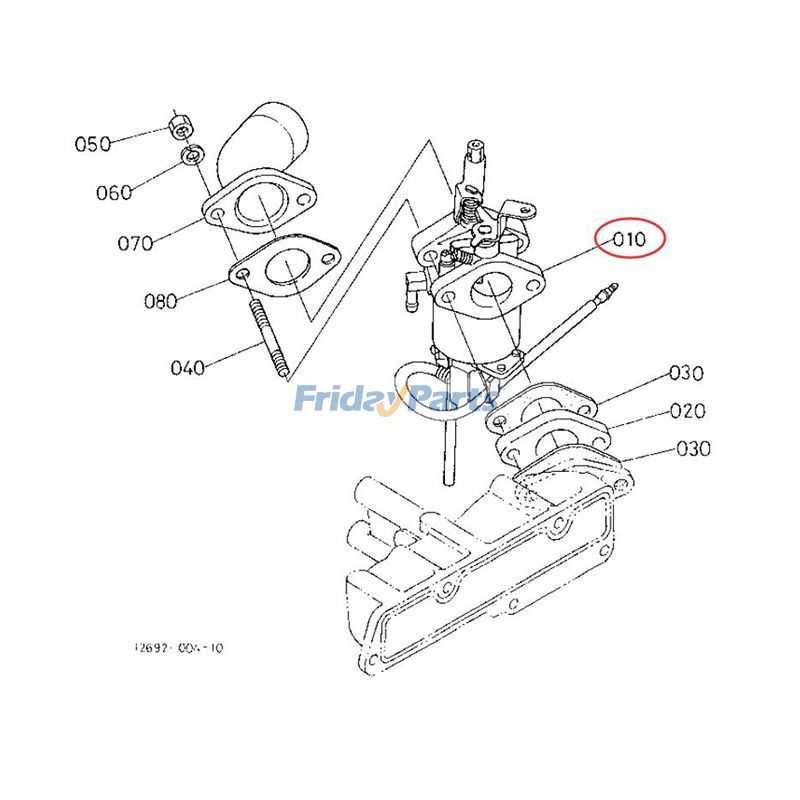

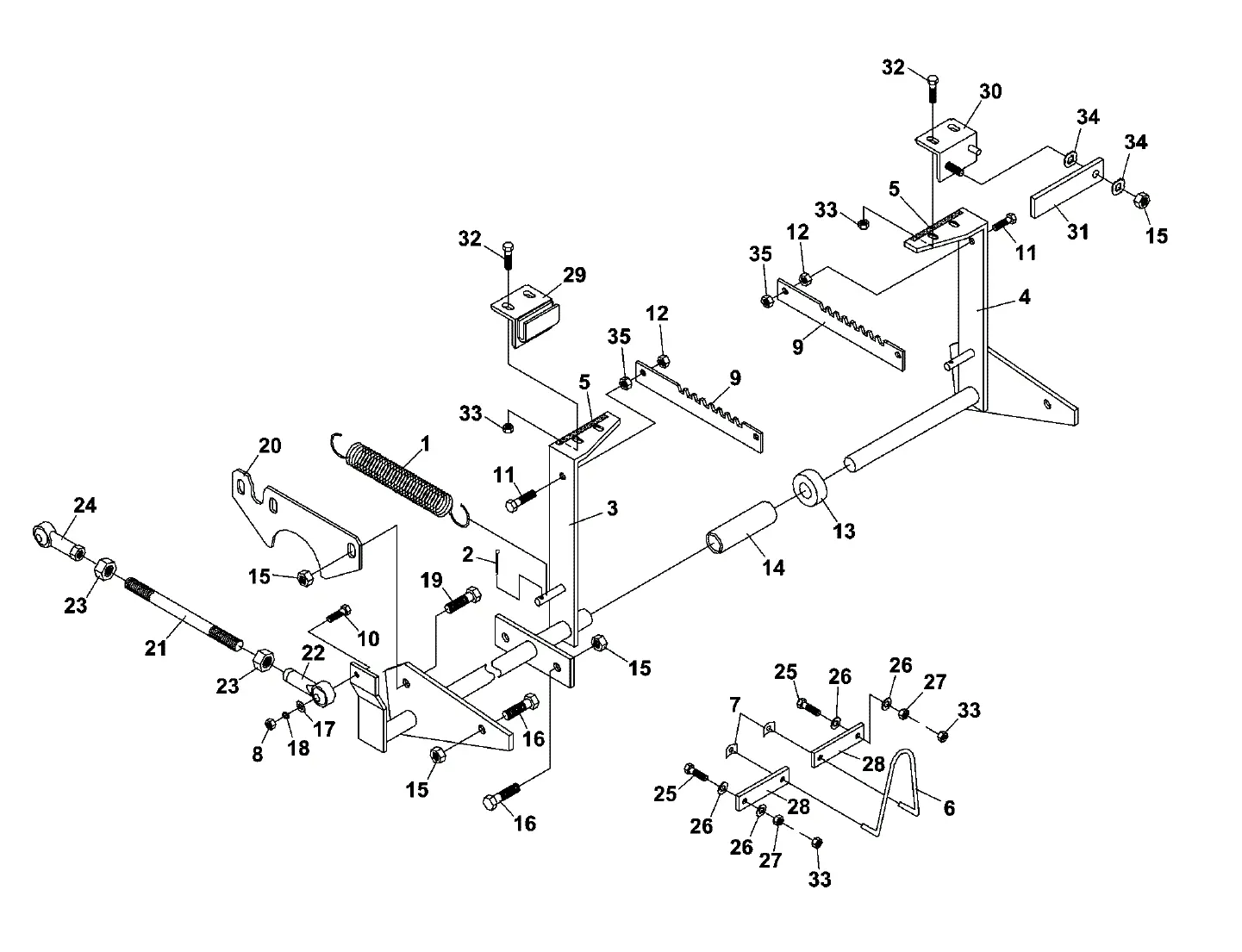

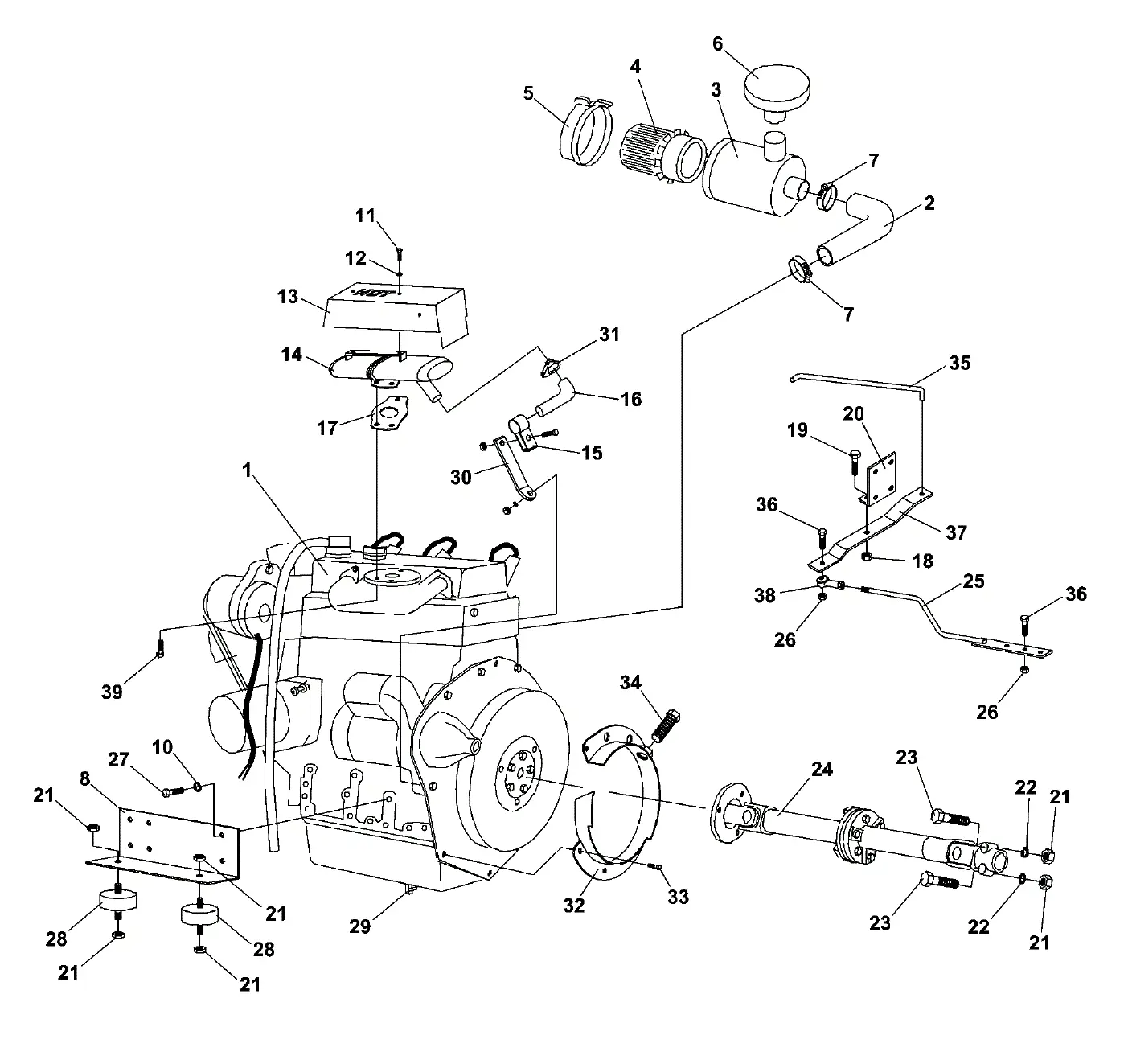

The intricate assembly of various parts plays a pivotal role in ensuring that the engine operates smoothly. A visual representation of these elements can provide invaluable insight, allowing users to pinpoint specific areas that require attention or replacement.

Furthermore, delving into the details of these components fosters a deeper understanding of their function and importance. This knowledge empowers operators and technicians alike, ultimately leading to more informed decisions regarding repairs and upkeep.

Kubota WG752 Overview

This section provides an insight into a particular engine model known for its efficiency and reliability. Designed for various applications, this power unit is recognized for its robust performance and adaptability in challenging environments.

Engineered with advanced technology, this model features a compact design, making it suitable for limited spaces while maintaining high output. The combination of durability and ease of maintenance ensures that users can depend on it for long-term operations.

Additionally, its fuel efficiency contributes to reduced operational costs, appealing to both commercial and industrial users. This unit’s versatility allows it to be integrated into multiple machines, enhancing overall functionality and performance.

In summary, this engine represents a blend of innovation and practicality, serving as a reliable choice for those seeking dependable power solutions.

Understanding Engine Components

Engines are intricate machines comprised of various parts that work together to generate power. Each component plays a vital role in the overall performance and efficiency of the engine. Understanding these elements can enhance maintenance practices and improve the longevity of the system.

Key Components of an Engine

Among the essential parts are the cylinders, where fuel and air mix and combust to produce energy. The piston moves within the cylinder, converting the explosive energy into mechanical motion. The movement is transferred through the crankshaft, which transforms linear motion into rotational force.

Supporting Systems

In addition to the core components, several supporting systems are critical for smooth operation. The cooling system prevents overheating, while the lubrication system reduces friction between moving parts, ensuring efficiency and minimizing wear. Understanding these interconnected systems is crucial for maintaining optimal engine performance.

Importance of Parts Diagrams

Visual representations of components are essential tools in various industries, serving as guides for maintenance, assembly, and troubleshooting. They provide a clear view of how different elements fit together and function, which is crucial for effective operations.

Understanding these visuals is beneficial for several reasons:

- Enhanced Clarity: They break down complex systems into understandable parts, making it easier for technicians and operators to identify and locate specific items.

- Improved Efficiency: Quick reference to these illustrations helps streamline repair and maintenance processes, reducing downtime and enhancing productivity.

- Effective Communication: They serve as a common language among team members, facilitating discussions and ensuring everyone is on the same page regarding repairs or modifications.

Moreover, familiarity with these illustrations can lead to:

- Fewer Errors: Clear visuals minimize the risk of mistakes during assembly or repairs.

- Cost Savings: Efficient troubleshooting can prevent unnecessary expenditures on parts and labor.

- Safety: Understanding how components work together can help avoid accidents and ensure safer operations.

In summary, visual guides play a crucial role in the effective management and operation of machinery, enhancing both productivity and safety in various environments.

Common Replacement Parts for WG752

When maintaining engines, certain components frequently require attention due to wear and tear. Understanding these essential elements can help ensure optimal performance and longevity.

Filters play a crucial role in keeping fluids clean. Regularly replacing the oil, fuel, and air filters is vital for maintaining engine efficiency.

Gaskets and seals are essential for preventing leaks. Over time, these can degrade, leading to performance issues and potential damage.

Belts are key for powering various accessories. Regular checks and timely replacements can prevent unexpected breakdowns.

Spark plugs are fundamental for ignition. Keeping them in good condition ensures smooth starts and efficient fuel consumption.

By staying informed about these critical components, one can effectively manage engine upkeep and enhance overall functionality.

Locating a Parts Diagram Online

Finding an illustration that details the components of a machine can be crucial for maintenance and repair. Such resources often provide valuable visual aids that enhance understanding of how various elements fit together and function. The process can be simplified by knowing where to search and what keywords to utilize.

Start your search by visiting manufacturer websites, as they often host technical documentation. Additionally, consider exploring specialized forums and communities dedicated to machinery enthusiasts, where members frequently share links to useful resources. Using the right search terms can significantly increase the chances of uncovering the information you need.

Moreover, online marketplaces and retailers might also offer comprehensive guides along with their products. Checking social media platforms for groups focused on repair can lead to helpful suggestions and shared resources. Persistence in exploring multiple avenues will ultimately yield the best results in your search.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures that you receive products designed specifically for your machinery. These items often provide enhanced durability and reliability, significantly reducing the likelihood of future issues.

Quality Assurance: OEM components undergo rigorous testing and quality control, ensuring they meet high performance standards. This results in better functionality and longevity.

Perfect Fit: Designed to match the original specifications, these parts offer a seamless fit, minimizing the risk of installation errors and operational inefficiencies.

Manufacturer Support: Using these components typically grants access to manufacturer warranties and support, providing peace of mind regarding your investment.

Performance Consistency: OEM items are engineered to work harmoniously with your equipment, ensuring optimal performance and maintaining its value over time.

Maintenance Tips for WG752 Engine

Ensuring the longevity and efficiency of an engine requires regular care and attention. Proper upkeep not only enhances performance but also prevents unexpected breakdowns. Here are some essential tips to maintain optimal functionality.

Regular Checks

- Inspect oil levels frequently and change it according to the manufacturer’s recommendations.

- Monitor coolant levels and ensure the cooling system is free of leaks.

- Examine air filters regularly and clean or replace them as necessary to promote airflow.

Cleaning and Lubrication

- Keep the exterior clean to prevent dirt and debris accumulation that can cause overheating.

- Lubricate moving parts to minimize friction and wear over time.

- Check and tighten belts and hoses to ensure they are in good condition and functioning properly.

By following these maintenance tips, you can help ensure that your engine runs smoothly and efficiently for years to come.

Diagnosing Common Issues

Identifying prevalent problems in machinery requires a systematic approach. By observing symptoms and analyzing potential causes, one can efficiently determine the underlying issues affecting performance.

Typical Symptoms

- Unusual noises during operation

- Inconsistent power delivery

- Overheating components

- Difficulty starting the engine

Steps to Diagnose

- Check fluid levels and quality.

- Inspect belts and hoses for wear.

- Listen for abnormal sounds and vibrations.

- Test electrical connections and battery health.

- Consult the maintenance manual for troubleshooting tips.

Tools Needed for Repairs

When it comes to performing maintenance or fixing equipment, having the right instruments is crucial for efficiency and safety. Proper tools not only ensure that tasks are completed effectively but also help prevent damage to components. Below is a comprehensive list of essential items that will aid in various repair processes.

Essential Hand Tools

- Wrenches (various sizes)

- Screwdrivers (flat and Phillips)

- Pliers (needle-nose and standard)

- Socket set

- Torque wrench

Specialized Equipment

- Multimeter for electrical diagnostics

- Oil filter wrench

- Jack stands for safe lifting

- Diagnostic scanner for troubleshooting

- Cleaning supplies (rags, brushes)

Equipping yourself with these tools will not only facilitate repairs but also enhance your overall understanding of the machinery. Proper maintenance can extend the life of the equipment and improve its performance, making these tools a valuable investment for any repair enthusiast.

Assembly Instructions from Diagrams

Understanding assembly instructions through visual representations is essential for achieving a successful build. These illustrations provide a clear guide to the components and their arrangement, facilitating a more efficient assembly process. By interpreting these visual aids, users can gain insights into the relationships between various elements and the steps required for proper installation.

To begin the assembly, carefully analyze the visual representation, noting the orientation and positioning of each component. It is crucial to follow the sequence indicated in the guide, as this ensures that all parts fit together seamlessly. Make use of any labels or numbers provided to identify specific pieces, which will help streamline the construction process.

As you proceed, periodically verify that each component is correctly placed according to the visual guide. This practice not only helps in preventing errors but also allows for a more organized workspace. Should any discrepancies arise, refer back to the illustrations for clarification, ensuring that all parts are assembled as intended.

Once the assembly is complete, take a moment to review the entire structure against the visual reference. This final check can reveal any missed steps or misalignments, allowing for adjustments before the final operation. By adhering to the instructions provided in the visual format, the assembly process becomes more manageable and efficient, leading to a successful outcome.

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visual aids simplify the identification of components, making it easier to locate specific items in a complex assembly.

Key Symbols and Labels

Familiarize yourself with the common symbols and labels used in these visuals. Each icon typically represents a specific element, while numbers often correspond to a parts list, ensuring clarity when ordering or replacing items.

Interpreting Relationships

Pay attention to the connections between various elements. Lines and arrows usually indicate how components interact or fit together. This understanding is essential for ensuring proper assembly and functionality.

Where to Buy Replacement Parts

Finding the right components for machinery can be a crucial task, especially when maintenance is required. It’s essential to know where to source high-quality replacements to ensure optimal performance and longevity of your equipment.

Online Retailers

- Check major e-commerce platforms for a wide variety of options.

- Look for specialized websites that focus on machinery components.

- Read customer reviews to gauge product reliability and seller trustworthiness.

Local Dealers

- Visit authorized dealerships that provide genuine replacements.

- Inquire about warranty and support services available with purchases.

- Consider local repair shops that might have a selection of reliable components.

Customer Reviews on WG752 Parts

This section explores the feedback and experiences shared by users regarding essential components of a specific engine model. Customers often provide insights into durability, performance, and compatibility, helping others make informed decisions.

Quality and Reliability: Many users emphasize the importance of high-quality components, noting that reliable parts significantly enhance overall performance and longevity. One reviewer stated, “Investing in top-notch components made all the difference in my engine’s efficiency.”

Ease of Installation: Several comments highlight the straightforward installation process. A user remarked, “The components fit perfectly and were easy to install, saving me time and frustration.”

Value for Money: Cost-effectiveness is a recurring theme. Many customers agree that while some parts may come at a premium, their longevity justifies the expense. One satisfied customer mentioned, “I initially hesitated due to the price, but the durability has proven it was worth every penny.”

Overall Satisfaction: The consensus among users reflects a high level of satisfaction, with many expressing a willingness to recommend these components to others. A typical comment read, “I’ve had a fantastic experience and would definitely buy again.”