In the realm of heavy machinery, a comprehensive understanding of the various elements that make up these powerful machines is crucial for effective maintenance and operation. Each component plays a significant role in ensuring that the equipment runs smoothly and efficiently. Familiarity with these parts enables operators and technicians to troubleshoot issues promptly, minimizing downtime.

Visual representation of these components serves as an invaluable tool for both novice and experienced users alike. By examining the layout and relationship between different elements, one can delve into the intricacies of machine functionality. This knowledge is not only essential for repairs but also enhances overall operational proficiency.

Moreover, having access to clear illustrations helps in identifying replacement needs and understanding how each section contributes to the ultimate performance of the machinery. Such resources empower users to make informed decisions, ensuring longevity and reliability in their equipment.

Kubota X1100C Overview

This segment provides a comprehensive look at a versatile utility vehicle designed for various applications. Known for its durability and performance, it caters to both agricultural and recreational needs, making it an essential asset in diverse environments.

Engine Performance: Equipped with a powerful engine, this vehicle ensures efficient operation, enabling users to tackle tough tasks with ease. Its robust powertrain contributes to excellent torque and acceleration.

Design and Comfort: The layout emphasizes user comfort, featuring an ergonomic seating arrangement and intuitive controls. This design allows operators to maintain productivity during extended use.

Versatility: With multiple attachment options, this model adapts seamlessly to various roles, from hauling materials to maneuvering through challenging terrains, showcasing its ultimate flexibility.

Importance of Parts Diagrams

Visual representations of components play a crucial role in maintenance and repair tasks. They provide clarity and understanding, making it easier to identify specific elements and their functions within a machine.

Here are some key reasons why these visual guides are essential:

- Enhanced Clarity: Simplifies complex assemblies, allowing for easier identification of individual components.

- Improved Efficiency: Speeds up repair processes by guiding technicians directly to the parts in need of attention.

- Accurate Troubleshooting: Aids in diagnosing issues by visually connecting symptoms to the relevant components.

- Streamlined Ordering: Helps in correctly identifying the required pieces for replacements, reducing errors.

- Training Tool: Serves as an educational resource for new technicians, enhancing their understanding of the machinery.

In summary, these visual guides are invaluable for anyone involved in machinery maintenance, contributing significantly to effective and efficient repairs.

Key Components of Kubota X1100C

This section delves into the essential elements that make up the robust machinery, emphasizing their roles and functionalities. Understanding these components is crucial for optimal performance and maintenance.

Engine: The powerhouse of the vehicle, the engine delivers the necessary horsepower and torque, ensuring reliable operation across various terrains. Its design focuses on efficiency and durability, contributing to long-term reliability.

Transmission: This element facilitates the transfer of power from the engine to the wheels, allowing for smooth acceleration and deceleration. The advanced transmission system enhances maneuverability, making it suitable for both work and recreational purposes.

Chassis: The structural framework provides stability and support to all other components. Its robust construction ensures that the vehicle can withstand heavy loads and challenging conditions without compromising safety.

Suspension: The suspension system is crucial for absorbing shocks and ensuring a comfortable ride. It allows for better traction and control, particularly in uneven terrain, enhancing the overall driving experience.

Braking System: A reliable braking system is vital for safety. It provides the necessary stopping power, ensuring that the vehicle can respond quickly in various situations, enhancing overall control.

Electrical System: This system powers all electronic components, including lights, controls, and instrumentation. A well-designed electrical system is essential for functionality and user convenience.

By familiarizing yourself with these key components, you can ensure the longevity and efficiency of your machinery, maximizing its potential in various applications.

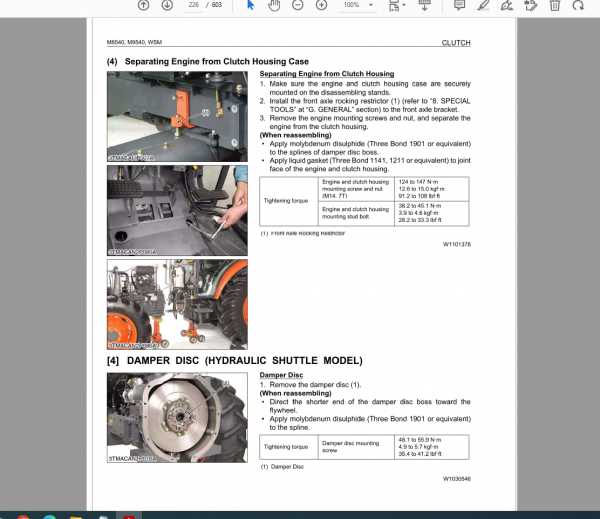

Understanding the Parts Diagram

The visual representation of components serves as a vital tool for understanding how machinery functions. By analyzing these illustrations, users can gain insights into the arrangement and interconnectivity of various elements, facilitating better maintenance and repair practices.

Components Overview

Each section of the illustration typically highlights specific features, allowing for easy identification. Users can pinpoint individual pieces, understanding their role within the larger system.

Utilizing the Visual Guide

To effectively navigate the visual guide, it is essential to correlate the labeled items with physical components. This approach not only aids in troubleshooting but also enhances overall efficiency during repairs. Familiarity with these visuals empowers users to tackle mechanical issues with confidence.

Common Issues and Solutions

When operating heavy machinery, users may encounter various challenges that can hinder performance. Understanding these common problems and their respective solutions is essential for maintaining efficiency and longevity. This section highlights typical issues faced during operation, along with practical remedies to address them.

Engine Overheating: One frequent concern is overheating, which can result from low coolant levels or a faulty thermostat. Regularly checking fluid levels and ensuring the cooling system is functioning properly can prevent this issue. If overheating persists, inspecting the radiator for blockages is advisable.

Poor Fuel Efficiency: Reduced fuel efficiency can often be traced back to clogged filters or improper tire pressure. Replacing air and fuel filters regularly and maintaining optimal tire inflation can significantly enhance performance and reduce operational costs.

Electrical Failures: Electrical problems, such as dead batteries or faulty wiring, can lead to unexpected breakdowns. Regularly inspecting battery connections and keeping terminals clean can help avoid these issues. Additionally, using a multimeter to test electrical components can identify potential faults before they escalate.

Hydraulic System Leaks: Leaks in the hydraulic system can affect performance and safety. Regular inspections for signs of wear on hoses and connections, along with timely replacements, can mitigate this risk. Using the correct hydraulic fluid and maintaining proper levels are also crucial.

Transmission Problems: Difficulty in shifting gears may indicate issues with the transmission fluid or internal components. Checking fluid levels and ensuring that the right type of fluid is used can often resolve these issues. If problems persist, consulting a professional technician may be necessary.

Where to Find Replacement Parts

When it comes to maintaining machinery, sourcing the right components is crucial for optimal performance. Whether you’re looking to upgrade or repair, knowing where to locate quality items can save time and ensure longevity. There are various avenues available for acquiring the necessary elements, each with its own advantages.

Authorized Dealers

One of the most reliable sources for high-quality components is through authorized dealerships. These establishments offer genuine items that are specifically designed for your equipment. Additionally, they often provide expert guidance on compatibility and installation. Engaging with these professionals can also yield access to exclusive promotions or service packages.

Online Marketplaces

The digital landscape offers a plethora of options for procuring replacement items. Numerous websites specialize in machinery components, providing a wide selection at competitive prices. Customer reviews can be invaluable in assessing the reliability of the vendor, while comprehensive search filters simplify the process of finding the exact part you need. Always verify the credibility of the site to avoid potential pitfalls.

In conclusion, whether opting for local dealers or online platforms, ensuring the authenticity and quality of the components is essential for maintaining the efficiency of your equipment.

Maintenance Tips for Kubota X1100C

Regular upkeep is essential for ensuring the longevity and optimal performance of your machinery. By following a consistent maintenance routine, you can prevent unexpected breakdowns and enhance efficiency. This section outlines key practices to keep your equipment running smoothly.

Begin with routine inspections of critical components, including the engine, transmission, and hydraulic systems. Check fluid levels frequently and replace any fluids that appear contaminated or below recommended levels. Cleaning or replacing filters at specified intervals is also crucial to maintain proper functioning.

Pay attention to the condition of tires, ensuring they are properly inflated and free from damage. Regularly examine the belts and hoses for signs of wear, and replace them as necessary to avoid potential failures. Keeping the exterior clean will also help prevent rust and deterioration.

Follow the manufacturer’s guidelines for scheduled services, which may include tasks such as oil changes, coolant checks, and brake inspections. Documenting all maintenance activities can provide valuable insights into performance trends and help identify recurring issues.

Lastly, consider the environment in which the equipment operates. Harsh conditions may require more frequent checks and maintenance. Being proactive in your approach will contribute to a reliable and efficient machine for years to come.

Comparing Parts with Other Models

Understanding the components of one model can significantly enhance the knowledge of similar machines. By analyzing the similarities and differences among various models, operators can make informed decisions about maintenance, repairs, and upgrades. This comparative approach not only helps in identifying compatible elements but also assists in recognizing unique features that might be beneficial for specific tasks.

When examining different machines, it’s essential to focus on key systems such as the drivetrain, electrical assembly, and hydraulic components. These areas often reveal shared designs that may simplify repairs or replacements. Additionally, comparing dimensions and specifications can uncover alternative options that enhance performance or improve efficiency.

Furthermore, reviewing user experiences and feedback on various models provides insights into which components are more durable or effective. This information can guide potential buyers in selecting machinery that meets their needs while ensuring access to reliable replacements when necessary. Ultimately, a thorough comparison fosters a deeper understanding of the equipment and promotes smarter purchasing choices.

Upgrades and Modifications

Enhancing the performance and functionality of your vehicle can significantly improve its utility and longevity. Various upgrades and modifications can be implemented to tailor the machine to better suit your specific needs, whether for work or recreational use. This section explores potential enhancements that can optimize efficiency and elevate the overall experience.

Consider the following upgrades:

- Engine Performance: Upgrading the engine components can lead to increased power and better fuel efficiency. Options include improved air filters, exhaust systems, and tuning kits.

- Suspension Enhancements: Upgrading the suspension can provide better handling and ride quality, especially in rough terrains. Consider options like heavy-duty shock absorbers or lift kits.

- Tire and Wheel Modifications: Changing the tires to ones better suited for specific environments can enhance traction and stability. Additionally, larger wheels can improve ground clearance.

- Lighting Systems: Installing high-intensity LED lights can improve visibility during night operations and in adverse weather conditions.

- Cab Accessories: Enhancing the interior with upgraded seating, storage solutions, or advanced technology can improve comfort and usability.

Each modification should be carefully considered to ensure compatibility with your machine’s specifications and intended use. Always consult with a professional or refer to manufacturer guidelines when implementing these upgrades.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can significantly enhance the performance and longevity of machinery. These high-quality items are specifically designed to meet the exact specifications and standards set by the manufacturer, ensuring optimal compatibility and reliability.

Enhanced Durability

OEM components are crafted with superior materials and precise engineering, resulting in enhanced durability. This reliability translates into reduced maintenance costs and fewer repairs, allowing equipment to operate smoothly for longer periods.

Improved Performance

When original parts are used, they help maintain the intended performance levels of the machinery. This not only maximizes efficiency but also ensures that the equipment operates as intended, delivering the best results for users.