When it comes to maintaining and ensuring the efficiency of equipment, having a clear layout of its essential elements is crucial. Identifying how these components are positioned and how they interact can simplify both routine upkeep and more involved repairs. This knowledge helps streamline the process, making it easier to address potential issues.

Recognizing the structure and configuration of various sections within a mechanical system allows users to better anticipate necessary adjustments. Whether you’re dealing with mechanical elements or intricate systems, a well-organized overview ensures that the right modifications are made with confidence and precision.

By understanding the arrangement of each individual piece, users can ensure that all operations run smoothly. This approach minimizes downtime and keeps the machinery functioning at optimal levels for longer periods.

Understanding Key Components of the Z121SKH-48

Grasping the essential elements of this machine is vital for ensuring optimal functionality and long-term maintenance. Each section is meticulously designed to perform a specific role, contributing to the overall efficiency and durability of the equipment. By exploring the major assemblies, you can gain a deeper understanding of how each part operates and supports the system’s performance.

Engine Assembly

The core of the machine’s performance lies in its power generation unit. This component ensures the engine’s energy is transferred efficiently to other areas, providing the necessary force for operation. Regular maintenance of the power unit is crucial to maintaining high output and avoiding mechanical issues.

Cutting Mechanism

This section is responsible for delivering precision and quality in every task. It consists of several elements that work in harmony to ensure a smooth and even cut. Understanding the connections and adjustments of these elements helps in optimizing the output and ensuring consistent performance.

How to Identify Engine Parts

Recognizing key components within the motor assembly is essential for maintenance and repair. Understanding the location and function of each element ensures that any issues can be quickly diagnosed and resolved. With careful attention to detail, even complex assemblies can be broken down into easily identifiable sections.

Examine the Layout: Start by observing the overall structure. The main units, such as the block, drive mechanism, and cooling system, are often visually distinct and provide a clear starting point for further identification.

Labeling and Schematics: Many systems feature visible markers or labels, aiding in the identification process. If available, reference visual aids that outline key areas to assist with distinguishing components.

Pay close attention to any unique shapes or configurations that could signal specialized parts. These variations can often be the fastest way to distinguish between different elements within the setup.

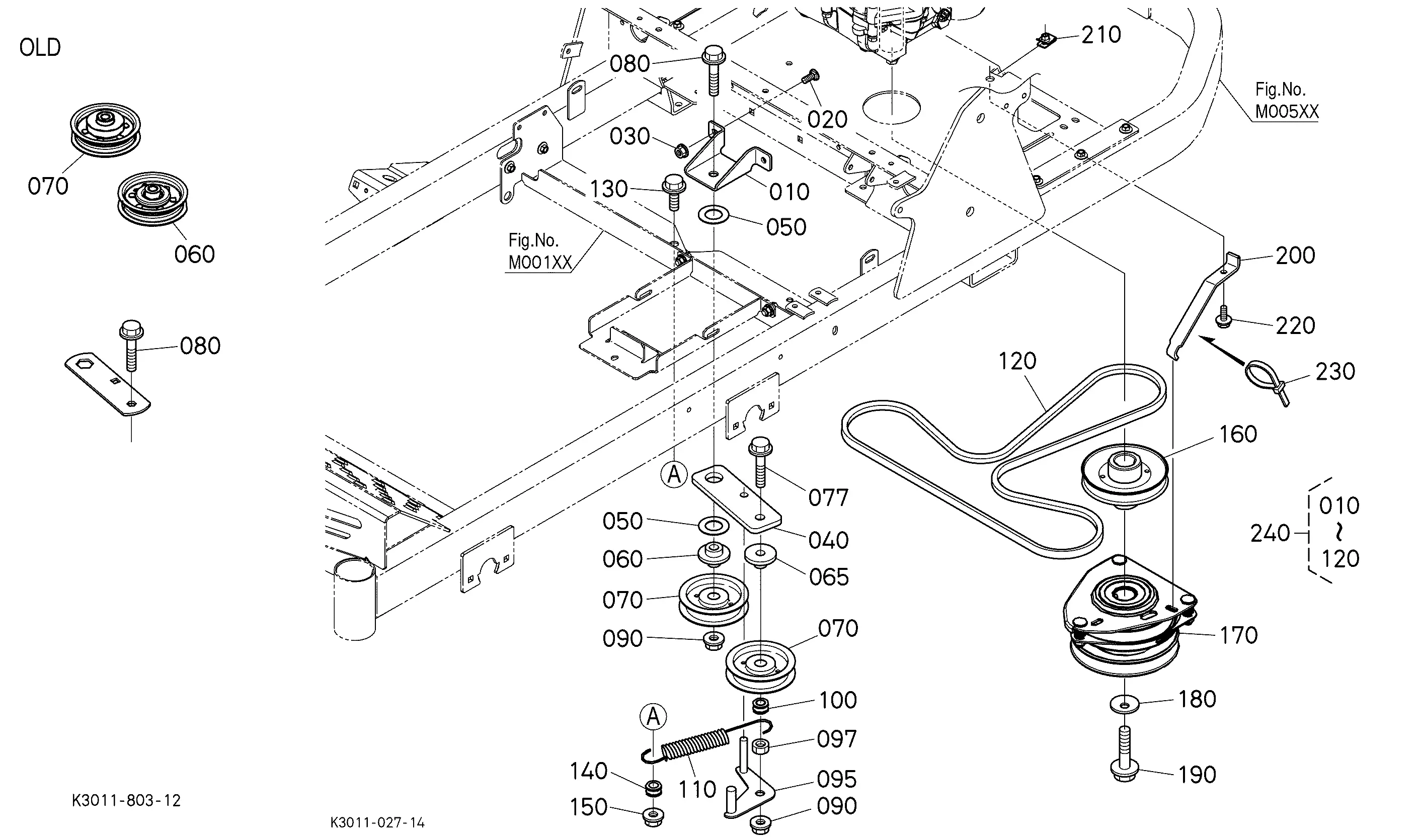

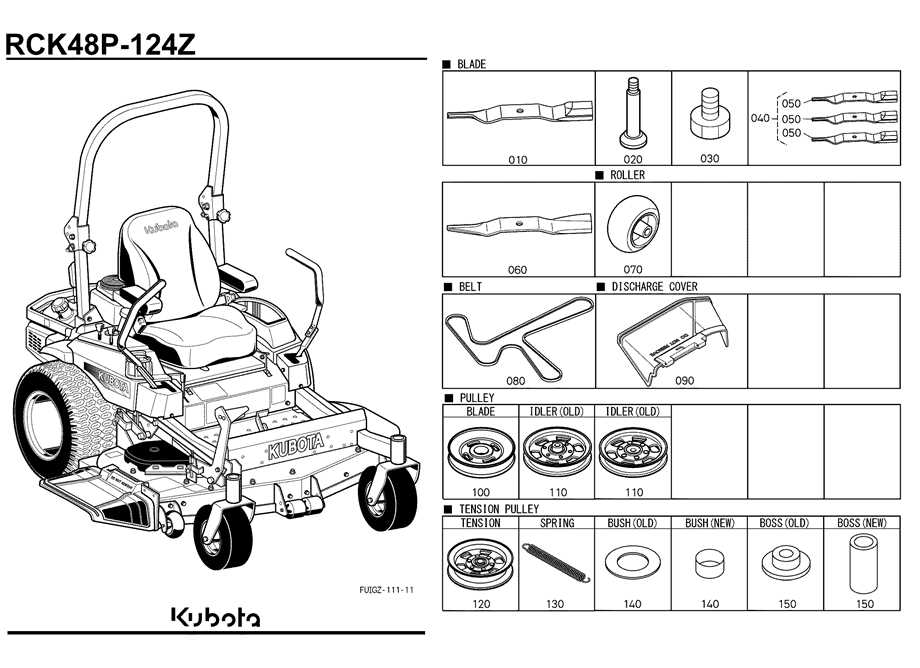

Exploring the Mower Deck Structure

The cutting system plays a vital role in the overall performance of a riding lawn machine. Understanding its construction helps in maintaining smooth and efficient operation. This section delves into the main components, highlighting the physical arrangement and functionality of the various elements that work together to provide an even trim across a range of terrains.

Key components such as blades, spindles, and belts are essential to the functioning of this setup. Their alignment and integration ensure optimal grass-cutting efficiency. Regular checks and maintenance of these parts are crucial to keep the system running smoothly over time.

In addition to the cutting mechanism, the deck housing itself offers protection and support to the entire structure. It is designed to withstand external impacts while enabling the machine to work under various conditions. Ensuring the integrity of this framework is critical for both safety and durability.

Guide to Blade Assembly Maintenance

Maintaining the cutting system is crucial to ensure efficient performance and longevity. Regular upkeep helps prevent issues that may arise from wear and tear, and ensures a smooth cutting experience. This guide offers essential steps to keep the blades functioning properly.

Regular Cleaning and Inspection

Begin by routinely cleaning the cutting system after each use. Debris can accumulate around the blades, affecting their efficiency. Inspect for any signs of damage such as cracks, dullness, or misalignment, and address them promptly.

- Clear debris from the blades and surrounding areas.

- Check for visible wear or damage.

- Ensure that blades are securely fastened and not loose.

Sharpening and Balancing

Sharpening the blades

Tips for Locating Electrical Components

Identifying electrical systems in mechanical equipment can be challenging, especially when faced with intricate layouts and multiple circuits. Understanding how to locate these essential parts can save time and effort during maintenance or upgrades. By focusing on specific clues within the machinery and utilizing common inspection methods, you can efficiently find what you need without unnecessary complications.

Check Visible Wiring Routes

One of the simplest ways to locate electrical components is to follow the visible wiring paths. These often lead directly to major units such as switches, sensors, and connections. Pay attention to how the wires are bundled and routed to uncover where different parts are likely positioned. This method can help you trace connections quickly, even in complex setups.

Use Manufacturer Guidelines

Referencing general guidelines provided by the equipment manufacturer is another reliable way to locate electrical elements. Thes

Fuel System Breakdown and Troubleshooting

The functionality of the fuel delivery system is crucial for the efficient operation of any engine. Understanding its components and potential issues can significantly enhance performance and reliability. This section delves into the intricate workings of the fuel system and outlines common problems along with their solutions.

Key elements of this system include the fuel tank, pump, filter, and injectors. Each component plays a vital role in ensuring that fuel is delivered efficiently to the engine. Identifying issues such as clogs, leaks, or pump failures can prevent significant performance degradation and costly repairs.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Clogged Fuel Filter | Poor acceleration, engine sputtering | Replace the filter, check for debris in the fuel system |

| Fuel Pump Failure | No fuel delivery, engine won’t start | Test pump pressure, replace pump if necessary |

| Leaking Fuel Lines | Visible fuel stains, strong fuel odor | Inspect lines for cracks, replace damaged sections |

| Injector Issues | Engine misfires, rough idle | Clean or replace injectors, check wiring connections |

Regular maintenance and timely troubleshooting of the fuel system can prevent serious complications and enhance the overall lifespan of the engine. By addressing these issues promptly, operators can ensure optimal performance and reliability.

Essential Parts for Hydraulic Systems

Hydraulic systems play a crucial role in the functionality of various machinery, relying on specific components to ensure optimal performance and efficiency. Understanding the key elements involved in these systems is vital for maintenance and troubleshooting.

Below is a table outlining the fundamental components that contribute to the effectiveness of hydraulic systems:

| Component | Description |

|---|---|

| Hydraulic Pump | The device that converts mechanical energy into hydraulic energy, generating flow and pressure within the system. |

| Actuator | A mechanism that converts hydraulic energy back into mechanical energy, facilitating movement or force application. |

| Hydraulic Fluid | The medium used to transmit power through the system, which also helps with lubrication and cooling. |

| Valves | Devices that control the flow and pressure of the hydraulic fluid, allowing for precise operation of the system. |

| Reservoir | A container that stores hydraulic fluid, providing a supply for the system and allowing for expansion during operation. |

| Filters | Elements that remove contaminants from the hydraulic fluid, ensuring the longevity and reliability of the system. |

Inspecting Steering Mechanism Elements

Understanding the components of the steering system is crucial for maintaining optimal functionality and ensuring safety. Regular examination of these elements can help identify potential issues before they escalate, leading to more efficient repairs and enhanced performance.

Key elements to inspect include:

- Steering Wheel: Check for any looseness or irregularities that may indicate wear.

- Steering Column: Inspect for damage or misalignment, which can affect control.

- Linkage: Ensure all joints are tight and free of corrosion.

- Steering Gear: Look for signs of leakage and verify that it operates smoothly.

- Ball Joints: Examine for play and ensure proper lubrication.

Following a systematic approach to inspecting these components can help ensure a reliable steering mechanism. Utilize the following checklist to guide your inspection:

- Visually assess each component for any visible signs of wear or damage.

- Test the functionality of the steering wheel and gear while stationary and in motion.

- Check the tightness of all fasteners and connections.

- Monitor for unusual noises while operating the steering system.

- Replace any worn or damaged parts promptly to maintain system integrity.

By regularly evaluating these components, you can prolong the lifespan of the steering system and enhance overall vehicle performance.

Overview of the Transmission Components

The transmission system is a crucial aspect of any machinery, playing a significant role in power transfer and performance. Understanding its components helps in maintaining optimal functionality and enhancing overall efficiency.

Key elements of the transmission assembly include the gearbox, which facilitates gear shifting and ensures that the engine’s power is effectively utilized. The clutch mechanism is another essential component, allowing for smooth engagement and disengagement of power flow between the engine and wheels.

Additionally, various linkages and actuators work in harmony to control the operation of the transmission. Gear selectors enable the operator to choose the appropriate gear ratio, while drive shafts transmit torque to the wheels. Proper knowledge of these components is vital for troubleshooting and performing maintenance tasks effectively.

Brake System Part Identification

The brake system is a crucial component in any vehicle, ensuring safe and reliable stopping capabilities. Understanding the various elements that make up this system is essential for effective maintenance and troubleshooting. This section provides an overview of the key components involved in the braking mechanism, aiding in their identification and function.

Below are the primary components commonly found in a brake system:

- Brake Pads: These friction materials press against the rotors to slow down the vehicle.

- Brake Rotors: Circular discs that provide a surface for the brake pads to clamp down on, converting kinetic energy into thermal energy.

- Calipers: These housings hold the brake pads and house the pistons that apply pressure to the pads.

- Brake Lines: Hoses that carry brake fluid from the master cylinder to the calipers.

- Master Cylinder: The component that generates hydraulic pressure in the brake fluid.

- Brake Fluid: The hydraulic fluid used to transmit force in the braking system.

Each of these components plays a vital role in the overall functionality of the brake system. Regular inspection and maintenance can help ensure optimal performance and longevity.

Best Practices for Belt System Repair

Maintaining the efficiency of a belt system is crucial for optimal performance. Understanding the fundamentals of repair can prevent potential issues and extend the lifespan of the components. Below are some essential guidelines to consider when addressing repairs.

- Regular Inspection: Frequently examine the belt for signs of wear, fraying, or damage. Early detection of problems can prevent more severe failures.

- Proper Tensioning: Ensure that the belt is adequately tensioned. A belt that is too loose may slip, while one that is too tight can lead to premature wear.

- Use Quality Components: Always opt for high-quality replacement parts. Using inferior materials can compromise the entire system’s integrity.

- Follow Manufacturer Guidelines: Adhere to the recommended specifications for installation and adjustment. This ensures compatibility and optimal performance.

- Document Repairs: Keep a record of all maintenance and repairs performed. This documentation can help identify recurring issues and inform future maintenance strategies.

By implementing these best practices, you can enhance the reliability and longevity of the belt system, ensuring that it functions smoothly and efficiently.

Understanding the Safety Features Layout

This section aims to elucidate the arrangement of safety mechanisms that enhance operational security in machinery. A clear understanding of these features is crucial for users to ensure safe handling and effective maintenance.

The layout of safety elements typically includes critical components designed to prevent accidents and promote user protection. These may consist of emergency stop switches, safety guards, and various sensors that monitor operational conditions.

By familiarizing oneself with the positioning and functionality of these safety features, operators can better respond to potential hazards and ensure a safer working environment. It is essential to regularly inspect these components to maintain their effectiveness and reliability.

Choosing Replacement Parts for Tires

When it comes to maintaining the efficiency and safety of your machinery, selecting the right components for tires is essential. The appropriate replacements ensure optimal performance and prolong the lifespan of your equipment. Understanding the different options available can greatly enhance your decision-making process.

Firstly, it is crucial to consider the specifications of your current tires. Look for dimensions, tread patterns, and load ratings that match your requirements. Consulting the equipment’s manual can provide valuable insights into the suitable choices.

Additionally, assess the terrain and conditions where your machinery operates. Different environments demand specific tire features, such as enhanced grip for uneven surfaces or durability for harsh weather. Evaluating these factors will help you make an informed selection that aligns with your operational needs.

Lastly, consider the manufacturer’s reputation and warranty offered on the replacement items. Opting for reputable brands can offer peace of mind, as they are often associated with quality and reliability. Researching customer reviews and recommendations can guide you towards the best options available in the market.