The internal structure of complex equipment can often seem overwhelming, with various systems working together to ensure optimal performance. Understanding how these elements interact is crucial for maintaining operational efficiency and longevity. This guide provides a detailed overview of key elements within one such machine, breaking down its essential components for a clearer perspective on how each part plays a role in its overall function.

Key systems within such equipment are designed to work seamlessly, ensuring that every component functions harmoniously. Whether you’re handling maintenance or seeking to improve functionality, a comprehensive understanding of these elements can streamline troubleshooting and enhance operational precision.

In this article, we will delve into the individual elements of this machinery, examining their roles and importance within the broader system. By the end, you will have a clearer understanding of how these components interconnect, helping you make informed decisions regarding maintenance and repair.

Comprehensive Overview of Kubota ZD1211 Parts

In this section, we will provide a detailed exploration of the various components and assemblies that make up this model. Each section of the machine plays a crucial role in ensuring its smooth operation and overall performance. By understanding how these elements work together, users can maintain and service the equipment efficiently.

Engine and Transmission Components

The engine and transmission are central to the

Key Components of the Kubota ZD1211 Mower

The mower in question is built to provide exceptional performance and durability through its carefully designed components. These elements work together to ensure smooth operation, effective cutting, and long-lasting use. Each part is engineered to optimize functionality, making the machine efficient for various mowing tasks.

Engine and Power System

The power source of the machine plays a crucial role in delivering consistent energy to drive both the cutting system and mobility. This component is designed to handle heavy workloads, ensuring reliable output even in demanding conditions. Alongside it, the cooling and filtration systems support optimal performance by maintaining ideal operating conditions.

How to Identify Different Components in a Lawn Care Machine

Understanding how to distinguish various elements in a lawn care machine is essential for proper maintenance and repair. By recognizing key structures and their functions, you can ensure the device operates efficiently and address any potential issues before they escalate.

Engine Section: The engine, often located at the core, powers the entire system. Identifying the main motor block, fuel lines, and filters is vital for performing regular checkups and ensuring smooth operation.

Cutting Mechanism: The blades, along with the deck housing, make up the critical cutting apparatus. Noticing wear and tear on these components helps maintain clean and precise mowing results.

Transmission and Steering: This area includes various control rods and hydraulic systems, which allow for movement and direction changes. Recognizing leaks or damage here can prevent performance issues.

Maintenance Tips for Kubota ZD1211 Parts

Regular upkeep of your equipment’s components ensures long-lasting performance and reduces the risk of unexpected breakdowns. By implementing a consistent care routine, you can extend the lifespan of essential mechanisms, keeping them in optimal condition for years to come.

- Inspect all moving elements regularly for signs of wear or damage. Early detection of issues can prevent more significant problems from developing.

- Lubricate bearings, joints, and other critical points as per the manufacturer’s recommendations to maintain smooth operation.

- Ensure that all fasteners are securely tightened. Loose screws or bolts can cause instability or excessive vibration during use.

- Keep filters clean and replace them as needed. Clogged filters can strain the system and reduce efficiency.

- Check

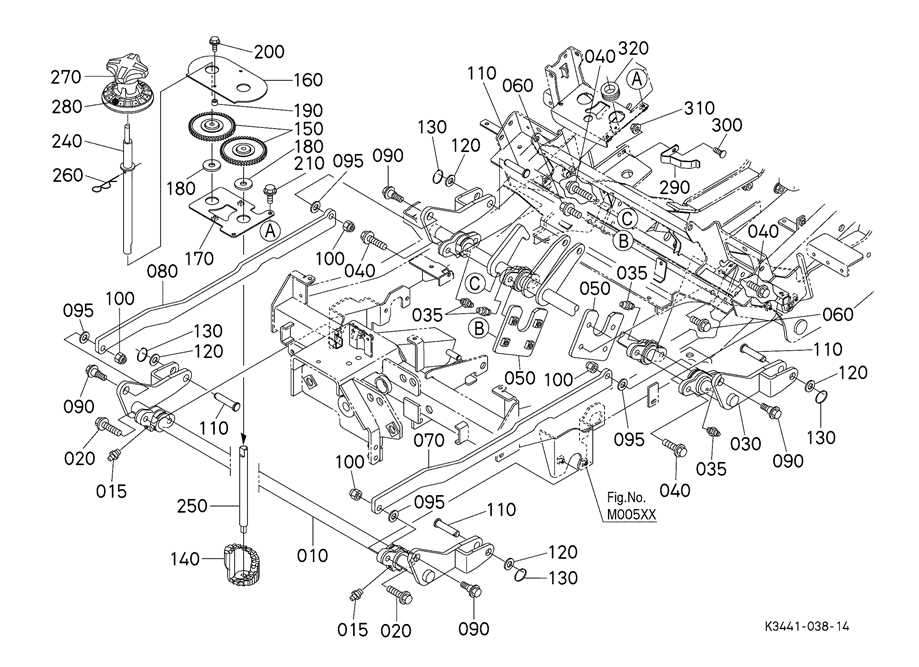

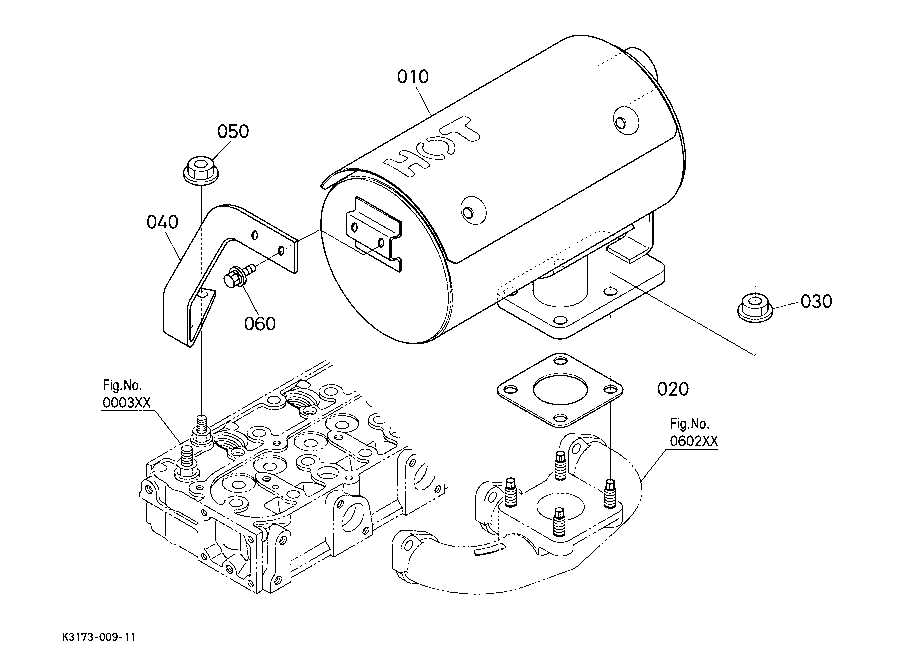

Understanding the Kubota ZD1211 Engine Assembly

The engine assembly of this model is a complex system composed of various interconnected components that work together to ensure smooth and efficient operation. By gaining insight into the layout and function of these parts, users can better maintain and troubleshoot the machinery, ensuring longevity and performance.

Key components within the engine assembly include essential systems responsible for power generation, cooling, and fuel management. Each part plays a crucial role in keeping the engine running optimally, contributing to the overall reliability and efficiency of the equipment.

Component Function Engine Block Houses the main internal moving parts of Transmission and Drive System Breakdown

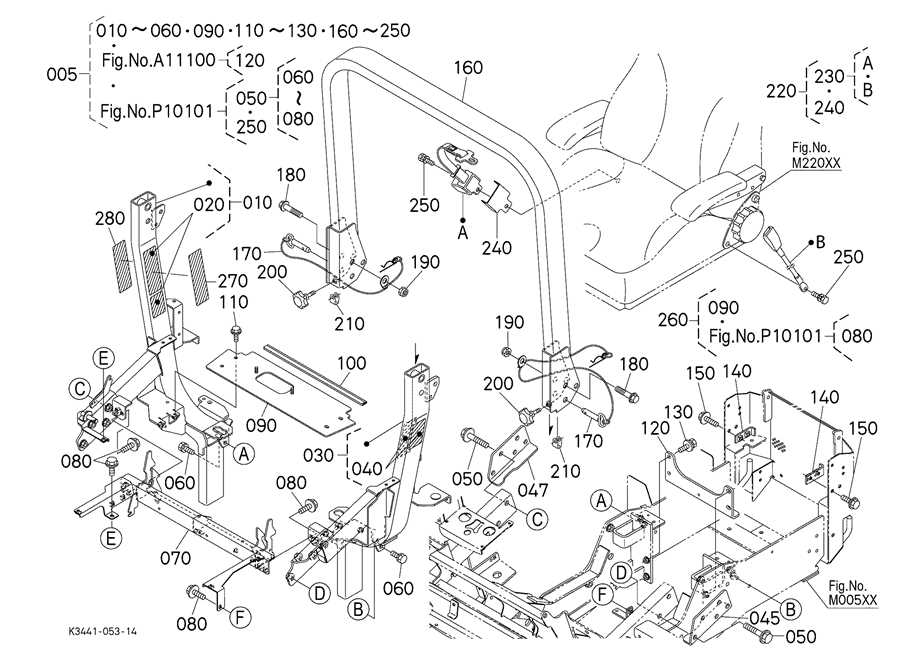

The transmission and drive system play a crucial role in the overall functionality of machinery, facilitating the transfer of power from the engine to the wheels or blades. Understanding the components and their arrangement is essential for effective maintenance and troubleshooting. This section delves into the various elements involved in this system, outlining their functions and interconnections.

Component Description Function Transmission A system of gears and shafts Modulates engine power and torque Drive Shaft A rod that transmits power Connects the transmission to the wheels Differential A gear assembly Distributes torque to the wheels Clutch A device that engages and disengages power Allows for smooth gear transitions Final Drive A mechanism that further reduces speed Increases torque to the wheels Each component within this assembly works in concert to ensure efficient operation, enabling the machine to perform various tasks effectively. Regular inspection and maintenance of these parts are vital to prevent failures and extend the lifespan of the equipment.

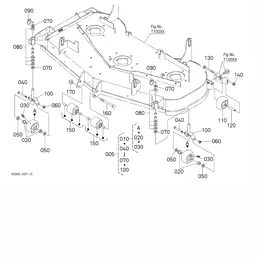

Blade System Overview for Kubota ZD1211

The cutting mechanism of a riding mower is crucial for achieving precise and effective grass management. This section delves into the essential components and functionalities that constitute the blade assembly, ensuring optimal performance and durability during operation.

At the heart of the cutting system are the blades, designed to deliver a clean cut while maintaining efficiency. Understanding the configuration and operation of these components is key to ensuring a well-maintained mowing experience. Key aspects include:

- Blade Type: Various designs are available, each suited for different types of grass and terrain.

- Blade Length: Optimal length ensures effective coverage and reduces the need for multiple passes.

- Material Quality: High-grade materials enhance durability and resistance to wear and tear.

In addition to the blades themselves, several supporting components contribute to the overall functionality:

- Spindles: These connect the blades to the mower deck and facilitate rotation.

- Belt System: A reliable belt system transmits power from the engine to the blades, ensuring smooth operation.

- Deck Design: The mower deck’s shape influences airflow and cutting efficiency.

Regular maintenance and proper adjustments to these elements are essential for preserving the performance and lifespan of the cutting system. Routine checks and replacements, when necessary, contribute to a consistent mowing experience.

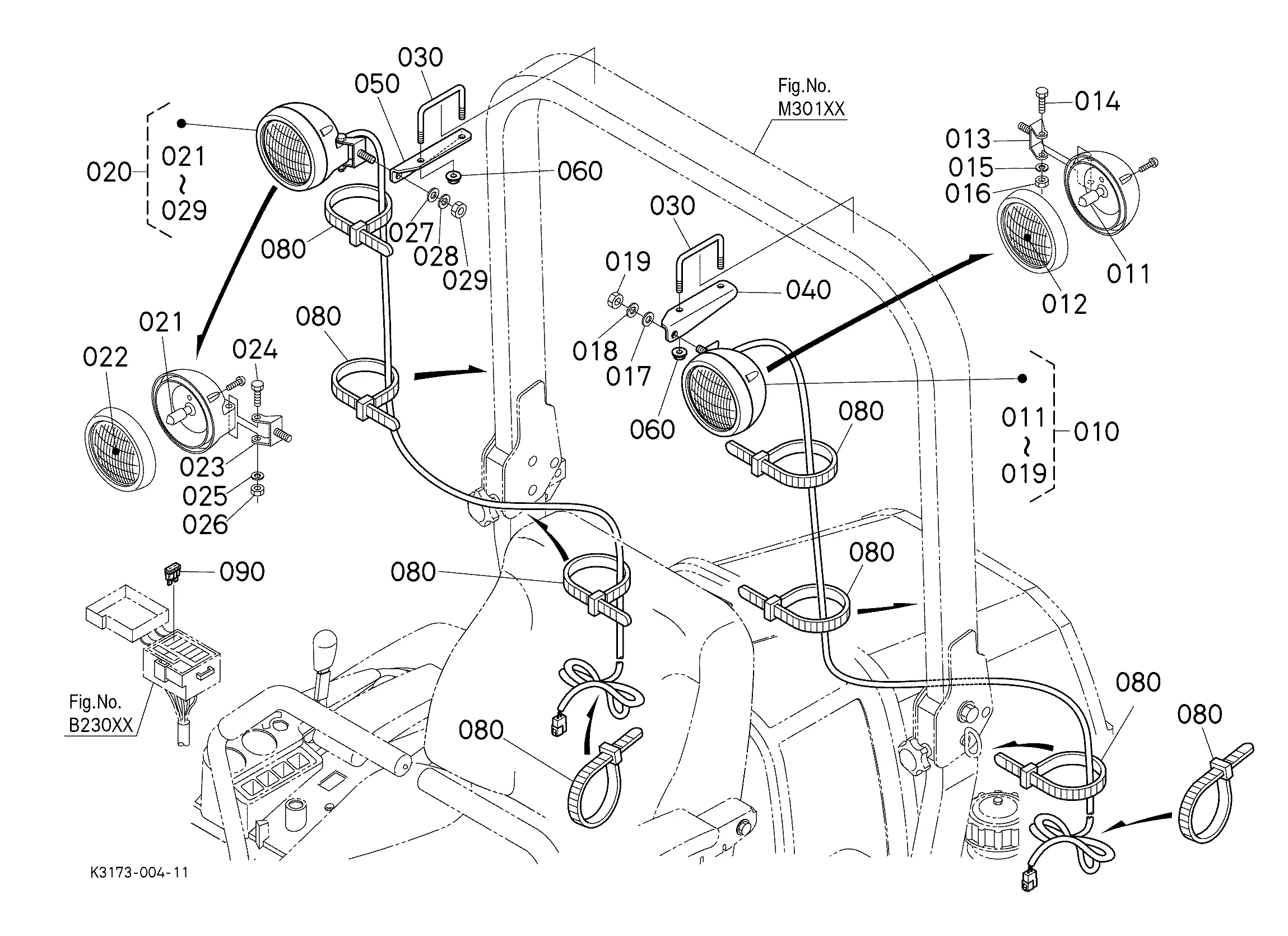

Electrical Parts of the Kubota ZD1211 Explained

The electrical system of a modern machinery unit plays a crucial role in ensuring optimal performance and functionality. Understanding the various components that comprise this system is essential for effective maintenance and troubleshooting. This section will delve into the key electrical elements that contribute to the efficient operation of the machine, highlighting their purposes and interconnections.

Key Electrical Components

Among the vital elements of the electrical system are the starter motor, battery, and wiring harness. The starter motor is responsible for initiating the engine’s operation, while the battery provides the necessary electrical energy to power various systems. The wiring harness acts as a network, facilitating communication and power distribution between different components. Each part must function correctly to maintain the overall efficiency of the equipment.

Control and Safety Systems

In addition to the primary electrical components, control units and safety systems are integral to the machine’s operation. The control unit regulates various functions, ensuring the equipment operates within specified parameters. Safety systems, such as fuses and relays, protect against electrical failures and prevent damage. Understanding these systems is essential for maintaining the longevity and reliability of the equipment.

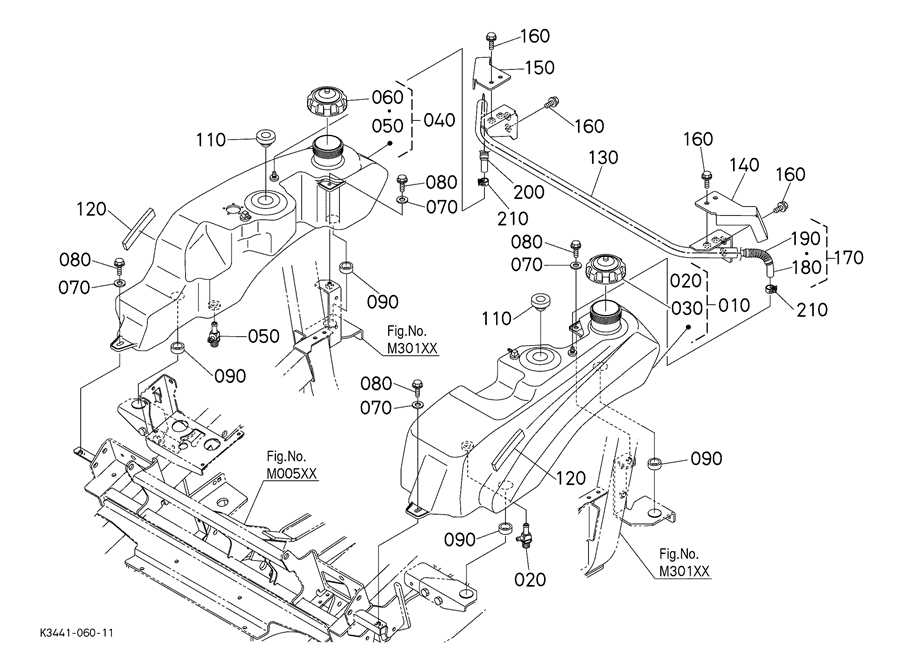

Fuel System Components of Kubota ZD1211

The fuel delivery system is crucial for the optimal functioning of any machinery. It ensures that the engine receives the correct amount of fuel necessary for combustion, thereby maintaining performance and efficiency. This section delves into the essential elements that comprise the fuel mechanism in a specific mower model, highlighting their roles and interconnections.

Key Elements of the Fuel Delivery Mechanism

At the heart of the fuel system is the fuel tank, which stores the liquid energy source. Attached to this component is the fuel pump, responsible for transporting fuel from the tank to the engine. This pump operates by creating a vacuum that draws the fuel, ensuring a steady supply to maintain engine power.

Filtration and Regulation

Another critical part of this system is the fuel filter, which safeguards the engine from contaminants that could lead to wear or damage. By trapping debris and particles, the filter helps prolong the life of the engine. Additionally, the fuel injector plays a vital role in regulating the flow of fuel into the combustion chamber, atomizing it for efficient burning and enhancing overall performance.

Understanding these components provides insight into the intricacies of the fuel system and its significance in ensuring smooth operation and longevity of the machinery.

How to Order Genuine Kubota ZD1211 Parts

Acquiring authentic components for your machinery is crucial for maintaining its performance and longevity. This process ensures that you receive high-quality items designed specifically for your equipment, thereby optimizing its efficiency and functionality. Here are the steps you can take to order these genuine items.

- Identify Required Components:

Before placing an order, it’s essential to determine the exact components you need. Refer to your equipment’s manual for a list of necessary items and specifications.

- Locate Authorized Dealers:

Find authorized distributors or retailers that specialize in genuine items. You can typically find this information on the manufacturer’s website or by contacting their customer service.

- Check Availability:

Once you’ve located a dealer, inquire about the availability of the specific items you need. It’s advisable to confirm that the components are in stock to avoid delays in your order.

- Provide Accurate Information:

When placing your order, ensure that you provide precise details such as model numbers and descriptions of the components. This accuracy helps avoid any potential mix-ups.

- Review Order Confirmation:

After submitting your order, review the confirmation provided by the dealer. Check that all details are correct, including pricing and shipping information.

- Follow Up:

If you don’t receive your order within the expected timeframe, don’t hesitate to contact the dealer for updates. Keeping track of your order ensures timely delivery.

By following these steps, you can efficiently acquire the authentic components needed for your equipment, ensuring optimal performance and reliability.

Frequently Replaced Parts in Kubota ZD1211

In the maintenance of any lawn care machinery, certain components tend to require replacement more often than others. Understanding which elements commonly wear out can help owners anticipate repairs and ensure their equipment operates efficiently. Regularly monitoring these components can prevent unexpected breakdowns and prolong the lifespan of the machine.

Belts are crucial for the transmission of power from the engine to the blades. Due to constant tension and movement, they may fray or break over time, necessitating periodic replacement.

Blades themselves are essential for achieving a clean cut. Regular use can dull or damage these cutting edges, making them less effective and requiring frequent sharpening or replacement to maintain optimal performance.

Filters, including air and fuel types, play a vital role in keeping the engine running smoothly. Clogged filters can restrict airflow or fuel delivery, leading to decreased performance. Regular inspections and timely replacements are essential for maintaining engine health.

Wheels and tires can wear down due to various factors, including terrain and usage patterns. Regular checks for tread wear and proper inflation can help ensure safety and stability during operation.

By keeping an eye on these commonly replaced elements, operators can enhance the performance and reliability of their machinery, ultimately leading to more efficient lawn maintenance.