In the realm of machinery, a comprehensive understanding of the individual elements that comprise a system is crucial for efficient operation and maintenance. By examining the intricate arrangement of these components, operators can enhance their knowledge of functionality and troubleshooting. This insight aids in ensuring longevity and reliability, ultimately optimizing performance.

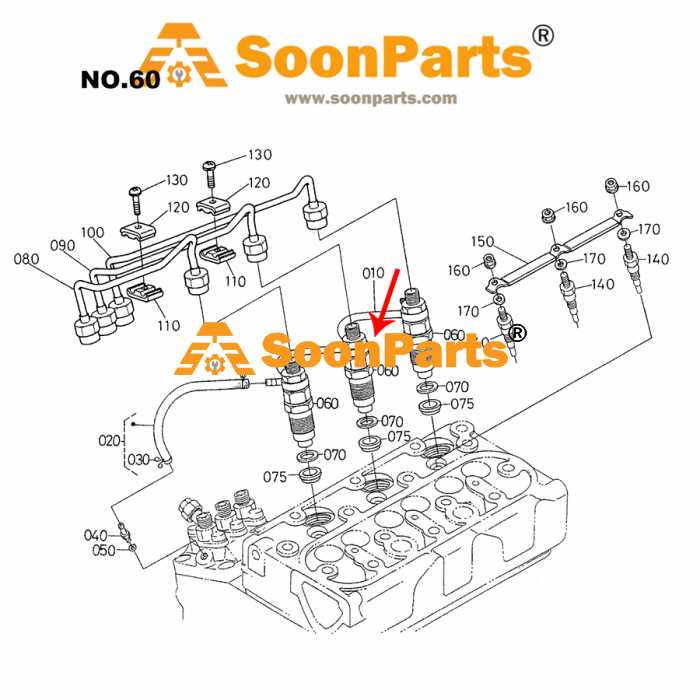

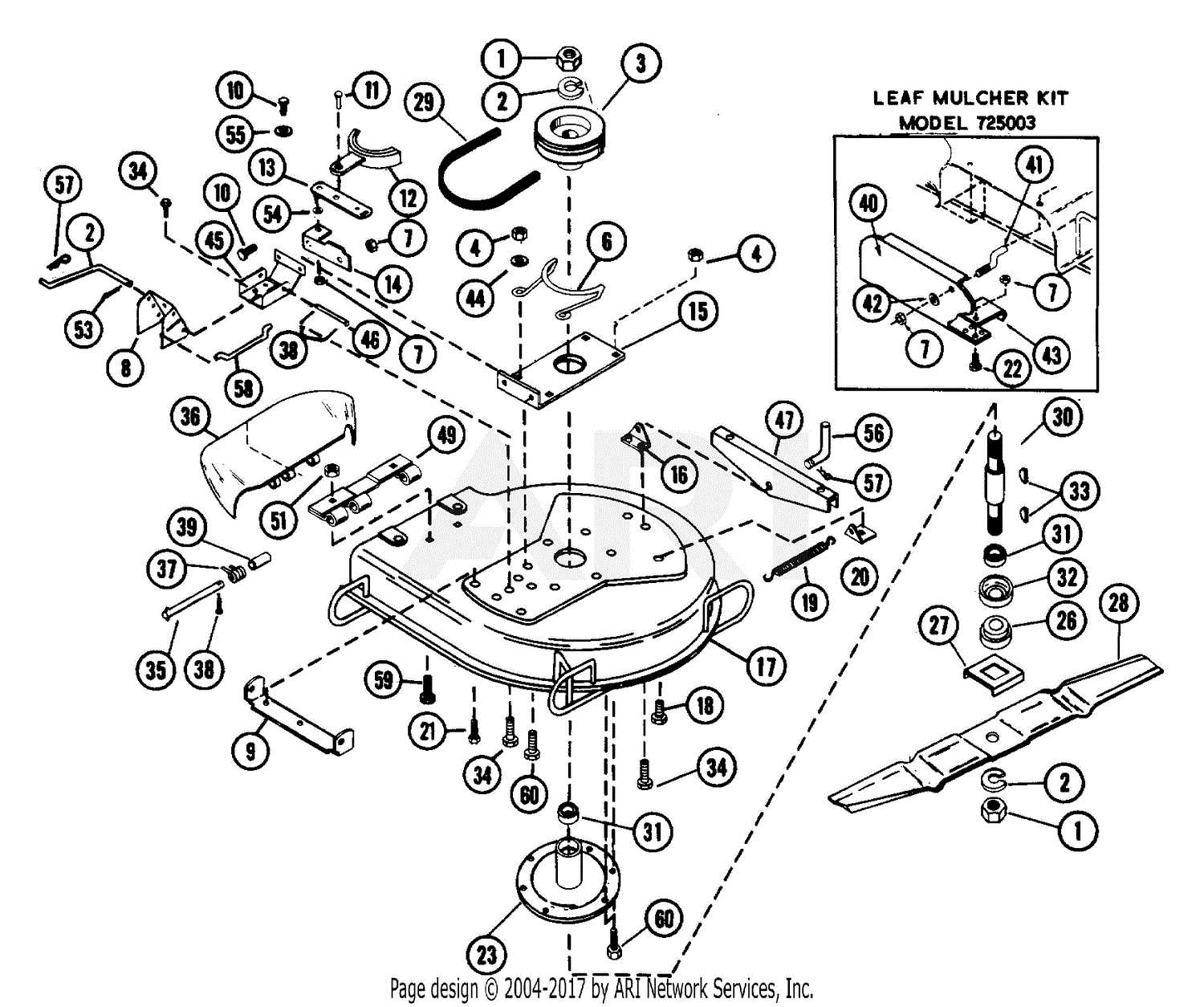

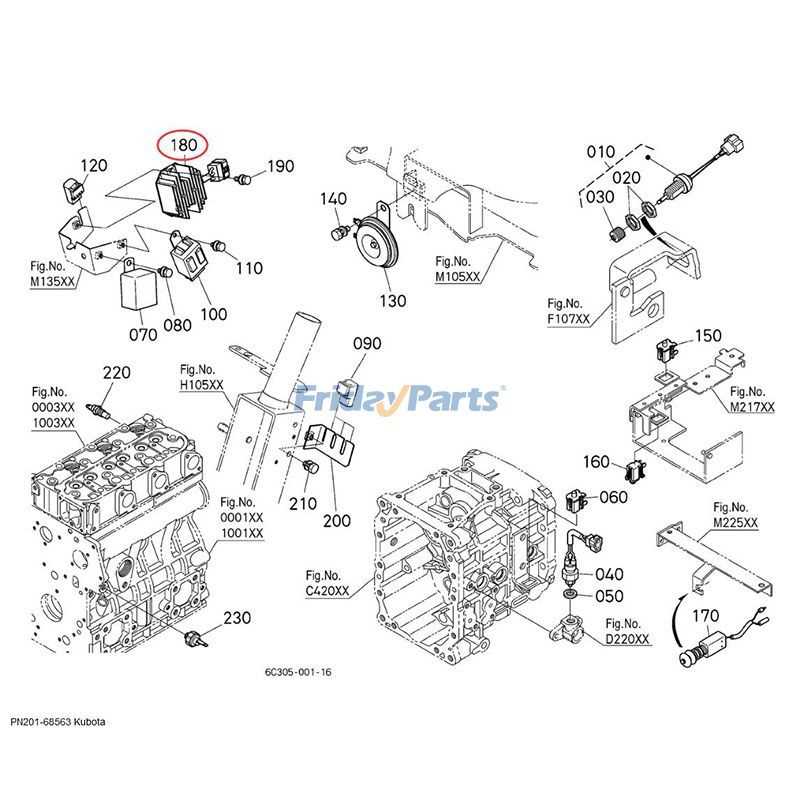

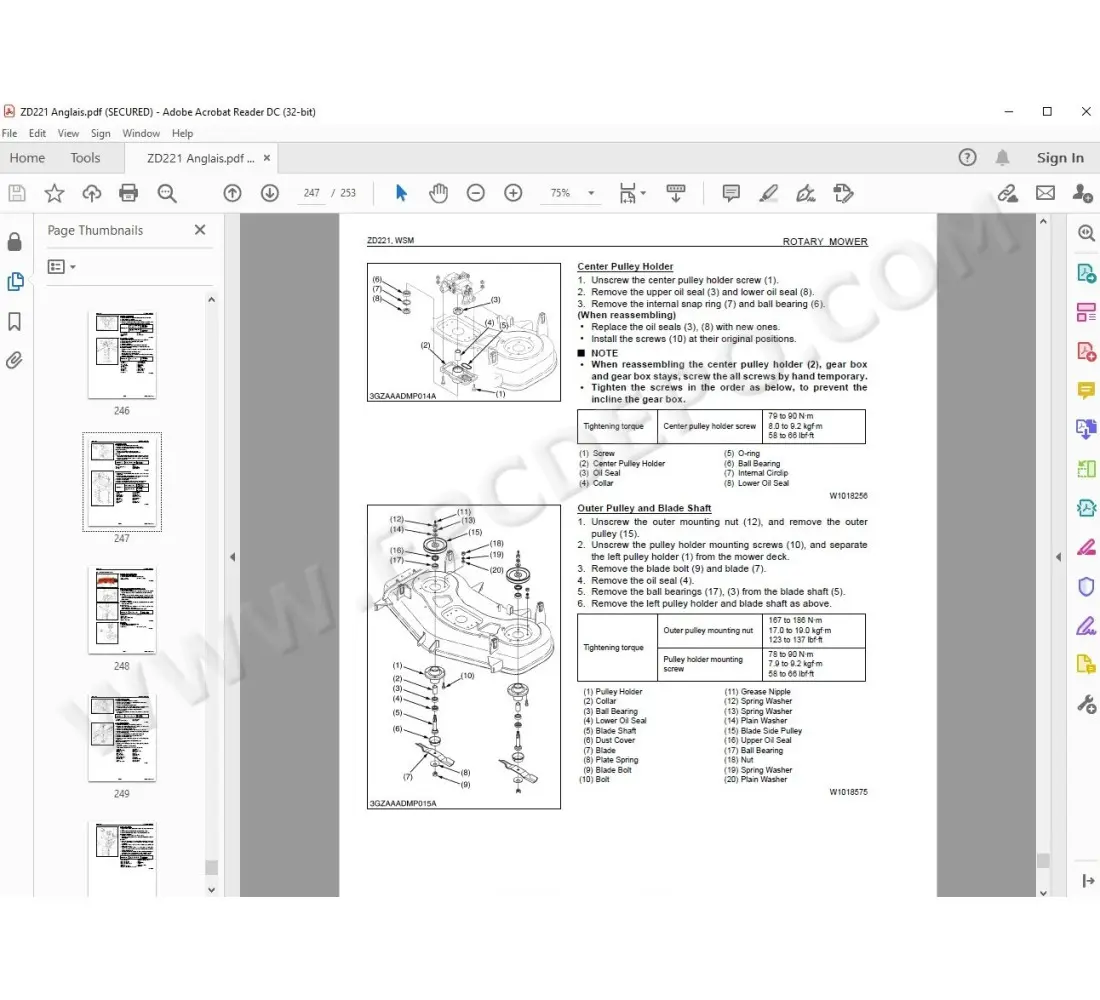

Visual representations of mechanical assemblies serve as essential tools for technicians and enthusiasts alike. They provide clarity on the relationships between various elements, making it easier to identify potential issues and plan for necessary replacements. Such illustrations are invaluable resources when embarking on repair projects or routine check-ups.

By familiarizing oneself with these layouts, users can cultivate a deeper appreciation for the engineering behind their machinery. This foundational knowledge not only facilitates informed decision-making but also fosters a proactive approach to maintenance. As a result, operators can keep their equipment running smoothly, minimizing downtime and maximizing efficiency.

This model is designed with several noteworthy attributes that enhance its performance and usability. Each feature contributes to an efficient operation, making it suitable for various tasks in different environments.

- Powerful Engine: Equipped with a robust engine that delivers exceptional power and torque, ensuring smooth operation even under challenging conditions.

- Advanced Transmission: Features a state-of-the-art transmission system, allowing for seamless gear shifts and enhanced control during operation.

- Exceptional Maneuverability: Compact design and tight turning radius enable easy navigation in confined spaces, making it ideal for residential and commercial properties.

- Durable Construction: Built with high-quality materials that ensure longevity and reliability, reducing the need for frequent repairs or replacements.

- User-Friendly Controls: Intuitive control layout simplifies operation, allowing users of all experience levels to handle the machine effectively.

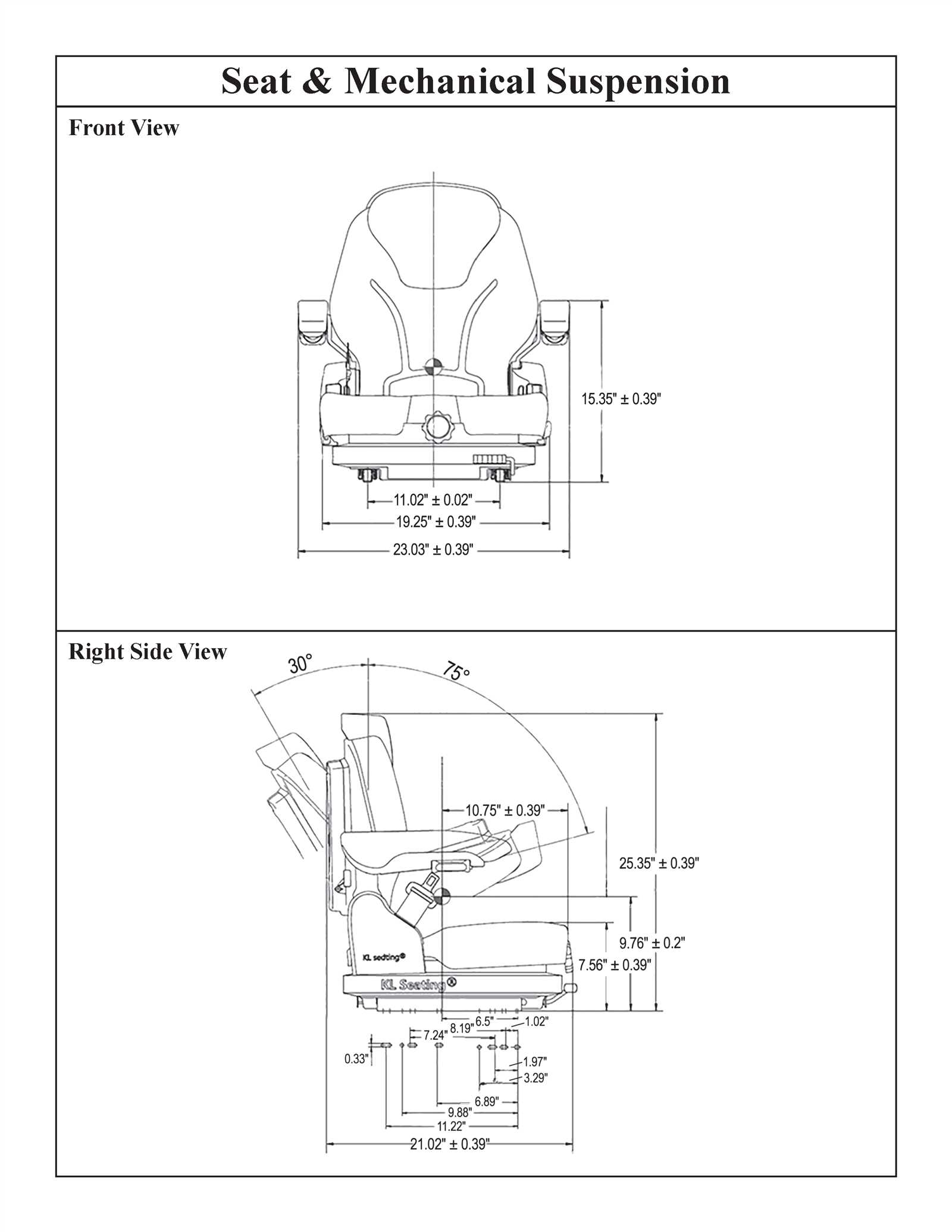

- Comfortable Operator Station: Ergonomically designed seat and controls provide comfort for extended use, minimizing fatigue during long working hours.

These features collectively enhance the versatility and efficiency of this model, making it a preferred choice for various applications.

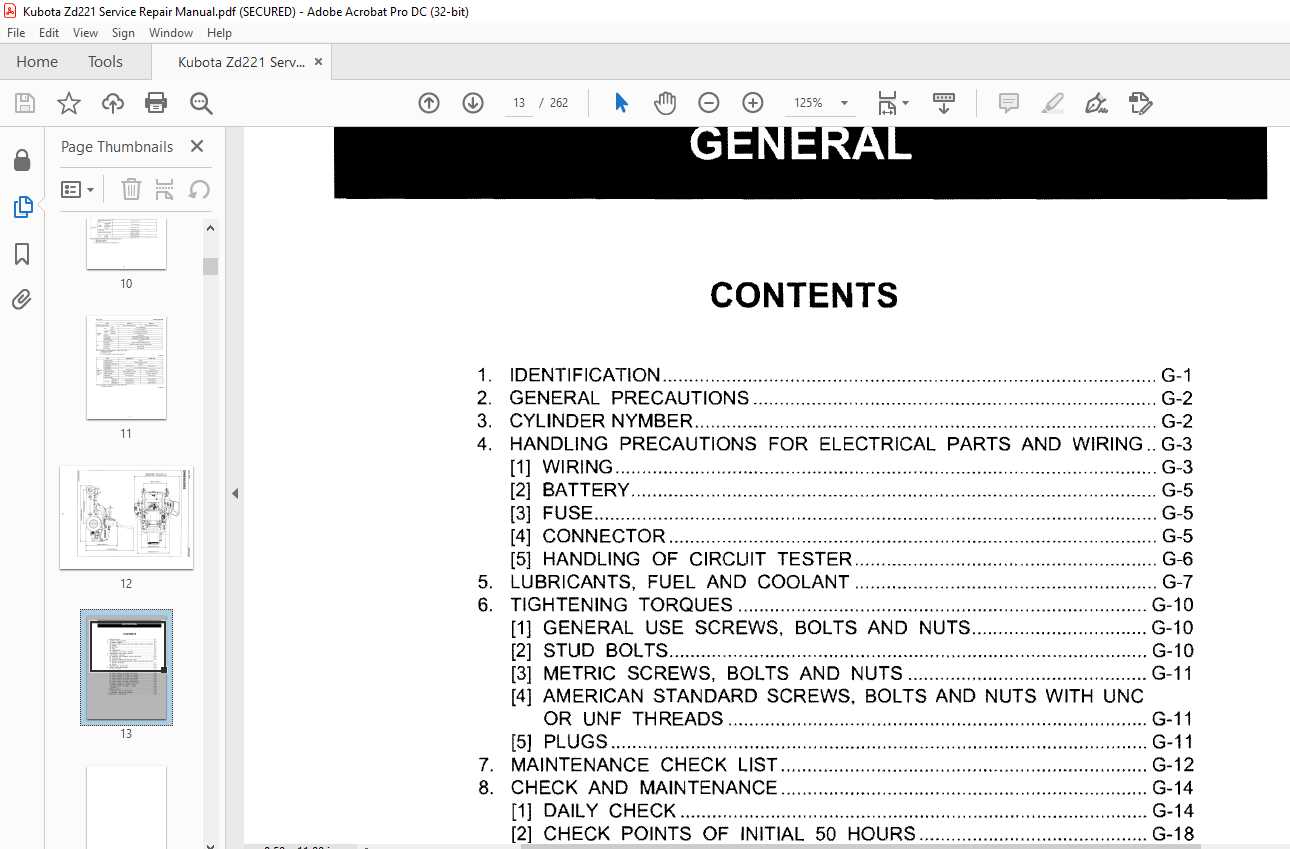

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for efficient maintenance and repairs. Visual representations provide users with a clear insight into the various elements that make up a device, aiding in the identification and replacement of necessary items. These illustrations serve as essential tools for technicians and users alike, ensuring proper functionality and longevity of equipment.

Enhanced Efficiency in Maintenance

Visual aids significantly streamline the upkeep process. By offering a comprehensive overview, they allow users to quickly locate specific elements and understand their interrelationships. This efficiency reduces downtime, enabling users to focus on other critical tasks without the frustration of searching for components.

Facilitating Accurate Repairs

When issues arise, having a visual guide assists in diagnosing problems accurately. Users can refer to the illustrations to pinpoint faulty components, ensuring that repairs are conducted precisely. This accuracy minimizes the risk of further damage and enhances the overall reliability of the machinery, ultimately leading to improved performance.

Understanding Component Functions

In any machinery, comprehending the role of each component is vital for effective operation and maintenance. This knowledge not only enhances performance but also aids in identifying issues quickly. By breaking down the various elements, users can better appreciate how each piece contributes to the overall functionality of the equipment.

Components in these systems can be categorized based on their functions:

- Power Transmission: These parts are responsible for converting energy into motion, ensuring that power is effectively delivered to the necessary areas.

- Control Systems: This group regulates operations, allowing the user to manage speed, direction, and other critical parameters.

- Support Structures: These elements provide stability and support, ensuring that all moving parts operate smoothly and remain aligned.

- Hydraulic Components: Key to various mechanical functions, these parts utilize fluid power to facilitate movement and force.

Recognizing the function of each category helps users troubleshoot problems and maintain their equipment more effectively. When issues arise, identifying the malfunctioning component is simplified by understanding the role of each part.

Moreover, regular checks and maintenance of these components can prevent significant breakdowns, prolonging the lifespan of the machinery. Knowledge about each element’s function empowers users to engage in proactive maintenance strategies.

Common Issues and Solutions

This section addresses frequent challenges encountered with this specific type of equipment and offers effective resolutions. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their machines.

1. Engine Starting Difficulties

One of the most prevalent issues faced by users is difficulty in starting the engine. This can stem from various factors, including fuel supply problems or electrical system failures.

- Check the fuel level and ensure that it is clean and uncontaminated.

- Inspect the battery connections for corrosion and secure fit.

- Examine the ignition system components for wear or damage.

2. Overheating Problems

Another common challenge is the overheating of the engine. This can lead to severe damage if not addressed promptly.

- Ensure that the coolant level is adequate and that there are no leaks in the system.

- Clean the radiator and air filters to allow proper airflow.

- Monitor the operation of the thermostat and replace it if malfunctioning.

By regularly checking these aspects, users can minimize downtime and maintain the efficiency of their equipment.

Replacement Parts Availability

When it comes to maintaining your outdoor machinery, ensuring the accessibility of high-quality components is essential for optimal performance. The availability of suitable replacements contributes significantly to extending the lifespan and efficiency of your equipment. This section explores the options and resources available for acquiring these essential elements.

Sources for Quality Components

Numerous suppliers offer an extensive selection of reliable components for various types of machinery. Authorized dealers provide original equipment that meets specific performance standards. Additionally, many online retailers and specialty stores cater to a wide array of models, often featuring competitive pricing and convenient shipping options.

Aftermarket Alternatives

In addition to original equipment, aftermarket options are available that may offer a cost-effective solution without compromising quality. Many reputable manufacturers produce compatible components designed to meet or exceed original specifications. Researching these alternatives can provide a balance between affordability and reliability, ensuring that your machinery remains in peak condition.

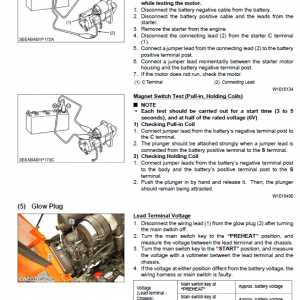

How to Read Diagrams

Understanding visual representations is essential for effective maintenance and repair tasks. These illustrations convey vital information about components and their interconnections, allowing users to grasp the overall structure and function of the equipment. By familiarizing yourself with the various symbols and notations used, you can enhance your ability to interpret these visuals accurately.

1. Familiarize Yourself with Symbols: Each illustration contains specific symbols that represent different elements. Take time to learn what these symbols mean; this knowledge will aid in deciphering the connections and functions of each part.

2. Follow the Flow: Visuals often depict the flow of processes or connections. Observe how lines and arrows guide your understanding, showing relationships and sequences. This can help in troubleshooting issues effectively.

3. Refer to a Legend: Many illustrations include a legend or key that explains the symbols used. Always check this section as it provides crucial context and can clarify any confusion regarding the notations.

4. Practice Regularly: The more you engage with these visuals, the better you will become at reading them. Practice with different types of representations to strengthen your skills and confidence.

By applying these strategies, you can develop a comprehensive understanding of technical visuals, making your repair and maintenance tasks more efficient.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your machinery requires regular upkeep and attention to detail. By following specific maintenance practices, you can significantly extend the lifespan of your equipment and enhance its performance. This section outlines essential tips to keep your machine in optimal condition, reducing the risk of breakdowns and costly repairs.

Regular Inspections

Conducting frequent inspections is crucial for identifying potential issues before they escalate. Examine all components for signs of wear, leaks, or corrosion. Pay close attention to belts, filters, and fluid levels, and replace any parts that show deterioration. Regular check-ups can help maintain efficiency and prevent unexpected failures.

Proper Cleaning

Keeping your equipment clean is vital for its longevity. Accumulated dirt and debris can lead to overheating and mechanical failures. Schedule routine cleanings to remove buildup from surfaces and ensure ventilation systems are clear. Utilize appropriate cleaning agents and methods to avoid damaging sensitive components.

Where to Find Original Parts

Locating authentic components for your equipment is crucial for maintaining optimal performance and longevity. Understanding where to acquire these essential elements ensures that you are investing in quality that aligns with your machinery’s specifications.

One of the most reliable sources for genuine items is the manufacturer’s official dealership network. These authorized vendors not only provide high-quality options but also offer expert guidance on installation and compatibility. Furthermore, visiting the official website of the manufacturer can lead you to trusted suppliers who maintain an extensive inventory.

Another valuable resource is specialized online platforms that focus on offering certified items. These websites often feature a user-friendly interface that allows you to search for specific components quickly. Look for platforms that guarantee the authenticity of their products and provide customer reviews to aid in your decision-making.

Additionally, consider joining forums or community groups related to your machinery. Enthusiasts and professionals often share insights on where to find reputable sources for original components. Engaging in these discussions can also lead to recommendations for local retailers who stock the items you need.

Lastly, keeping an eye on seasonal sales and promotions at authorized dealers can provide excellent opportunities to purchase essential components at a reduced cost. Regularly checking these outlets can result in significant savings while ensuring you receive top-notch quality.

Aftermarket Options to Consider

When maintaining or upgrading your outdoor machinery, exploring alternatives can yield numerous benefits. Aftermarket solutions often provide comparable quality and performance at a more accessible price point. This can be particularly advantageous for owners seeking cost-effective methods to enhance functionality.

Compatibility is a crucial factor when selecting replacements. Many aftermarket manufacturers design components that seamlessly integrate with existing systems, ensuring optimal performance. Additionally, some options may even offer improved durability, enhancing the lifespan of your equipment.

Another consideration is availability. Aftermarket products can often be found more easily than original components, particularly for older models. This accessibility can reduce downtime and help you get your machinery back in operation swiftly.

Lastly, don’t overlook the warranty and support options provided by aftermarket suppliers. Many reputable manufacturers offer guarantees on their products, providing peace of mind and assurance of quality. By carefully evaluating these factors, you can make informed choices that best suit your machinery needs.

Benefits of Regular Maintenance

Regular upkeep of machinery is crucial for ensuring optimal performance and longevity. Routine servicing helps in identifying potential issues before they escalate, ultimately saving time and resources. Maintaining equipment not only enhances its efficiency but also minimizes the risk of unexpected breakdowns, allowing for smoother operations.

Consistent maintenance extends the lifespan of the machinery, as it prevents wear and tear from accumulating over time. This proactive approach can lead to significant cost savings, as repairs can be planned and budgeted rather than occurring suddenly. Additionally, well-maintained equipment often operates more efficiently, contributing to reduced fuel consumption and lower operational costs.

Furthermore, adhering to a regular maintenance schedule promotes safety. Ensuring that all components are in good working order minimizes the risk of accidents, protecting both operators and the surrounding environment. By investing in regular maintenance, owners can enjoy peace of mind, knowing their machinery is reliable and safe to use.

Customer Reviews and Experiences

This section highlights the feedback and experiences shared by users regarding their machinery. It provides insights into the performance, reliability, and overall satisfaction of operators who have utilized various components and features.

Positive Feedback

- Many users express appreciation for the exceptional durability of the equipment, noting its ability to withstand rigorous conditions.

- Several operators commend the ease of use, highlighting how straightforward controls contribute to a more efficient workflow.

- Customers frequently mention the responsive customer service, making parts replacement and inquiries hassle-free.

Areas for Improvement

- Some reviews indicate a desire for enhanced accessibility to specific components during maintenance.

- Users have pointed out that while the equipment performs well, certain features could benefit from modern upgrades.

- Feedback also suggests that clearer documentation for troubleshooting would further enhance user experience.