In the realm of machinery, comprehending the arrangement and functionality of individual elements is crucial for efficient operation and maintenance. This section delves into the various components that make up a specific model of lawn care equipment, providing valuable insights into their organization and purpose. By grasping the relationships between these elements, users can enhance their understanding of how the machine functions as a whole.

Each part plays a significant role, contributing to the overall performance and reliability of the equipment. Whether it’s the engine, transmission, or other vital systems, knowing the configuration of these components can lead to more informed decisions regarding repairs and upgrades. Furthermore, this knowledge empowers users to troubleshoot issues effectively, ensuring optimal performance throughout the equipment’s lifecycle.

Through detailed exploration of the layout and interconnections of these elements, users will gain a deeper appreciation for the intricacies involved in the design and functionality of this machinery. Such an understanding is essential for both novice and experienced operators alike, facilitating better maintenance practices and ultimately extending the life of the equipment.

tags, with diverse topics: Kubota ZG227 Overview”>

tags, with diverse topics: Kubota ZG227 Overview”>

This section provides an insightful overview of a specific outdoor machinery model, focusing on its design and functionality. By exploring its key components, readers can gain a deeper understanding of how these elements work together to ensure optimal performance and reliability in various applications. The discussion will delve into the intricate details that make this machine efficient and effective in its operations.

Key Features and Benefits

The examined model boasts a variety of features that enhance its usability and efficiency. From a robust engine design to a user-friendly interface, each aspect contributes to a seamless operation. Additionally, the durability of its construction ensures long-term reliability, making it an ideal choice for both residential and commercial use. Highlighting these advantages will provide prospective users with a comprehensive understanding of what to expect.

Maintenance Considerations

Understanding maintenance requirements is crucial for the longevity of any machinery. Regular upkeep not only maximizes performance but also prevents potential issues from arising. This section will outline essential maintenance practices, including routine inspections and part replacements, ensuring users are well-informed about how to care for their equipment effectively.

Key Features of the ZG227

The model in question stands out in its category due to a blend of innovative design and practical functionality. Its construction emphasizes durability and ease of use, making it a valuable asset for various tasks. This section outlines the primary attributes that contribute to its effectiveness and popularity among users.

Exceptional Performance

Equipped with a robust engine, this model ensures powerful operation, enabling it to tackle challenging terrains and heavy workloads with ease. The following aspects highlight its performance capabilities:

- High horsepower rating for increased efficiency.

- Advanced cooling system to maintain optimal temperatures during prolonged use.

- Precision-engineered components for enhanced reliability.

User-Friendly Design

The thoughtful design of this model prioritizes user comfort and accessibility. Key design features include:

- Ergonomic seating for reduced operator fatigue.

- Intuitive controls for easy maneuverability.

- Compact dimensions for improved storage and transport.

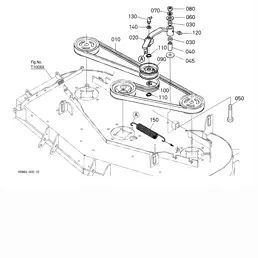

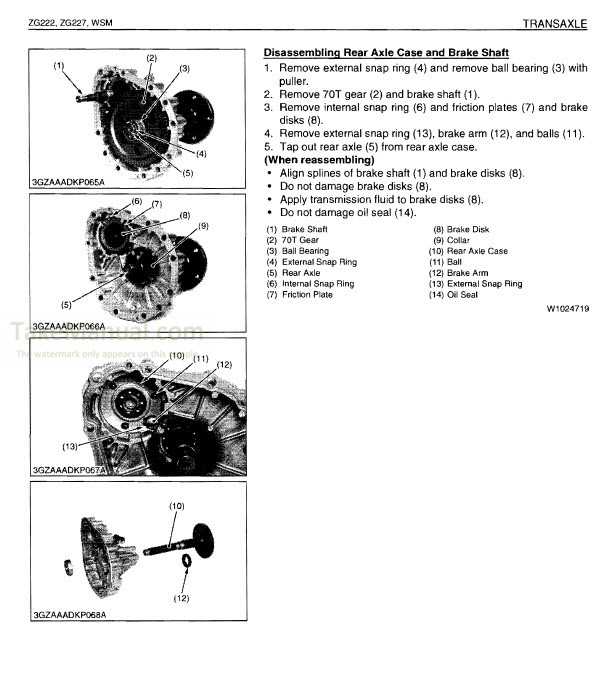

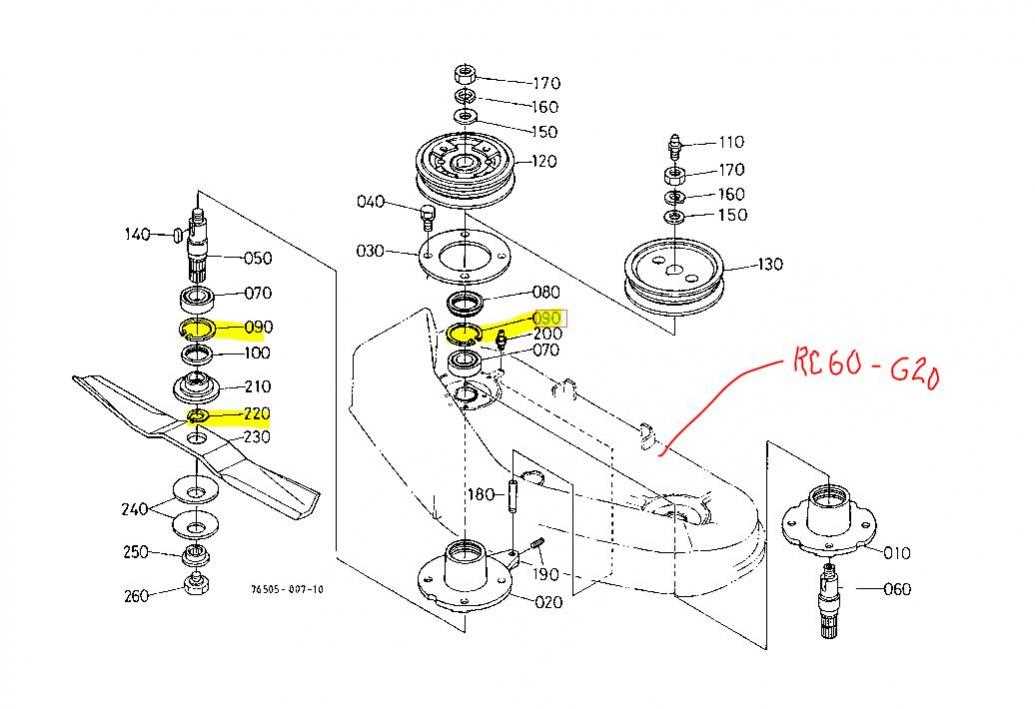

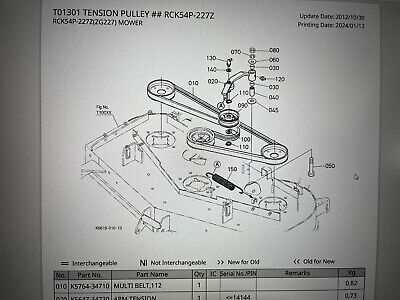

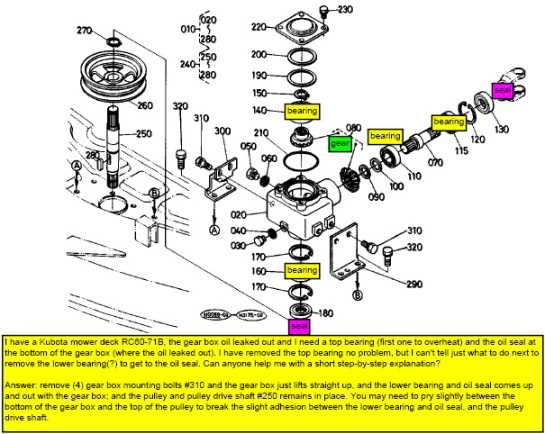

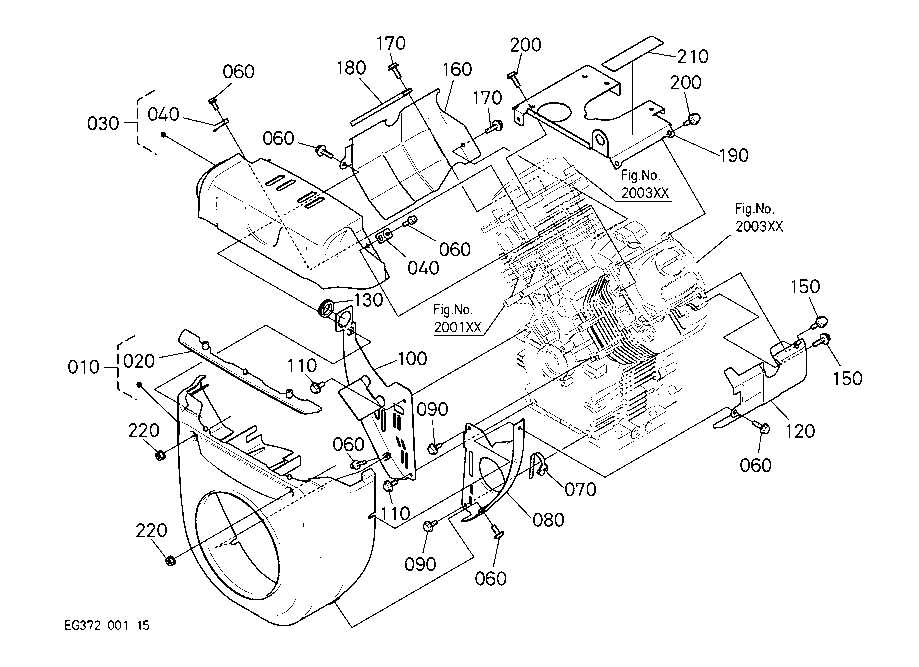

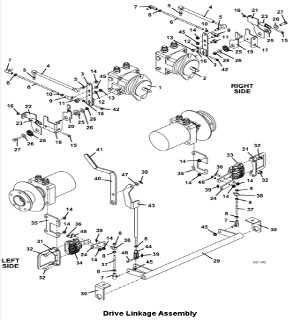

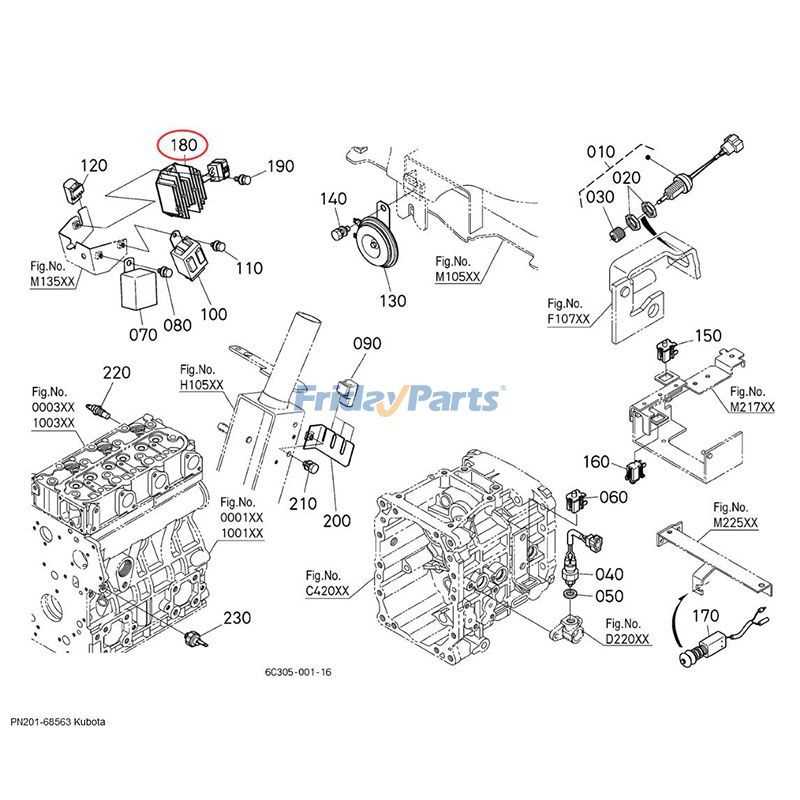

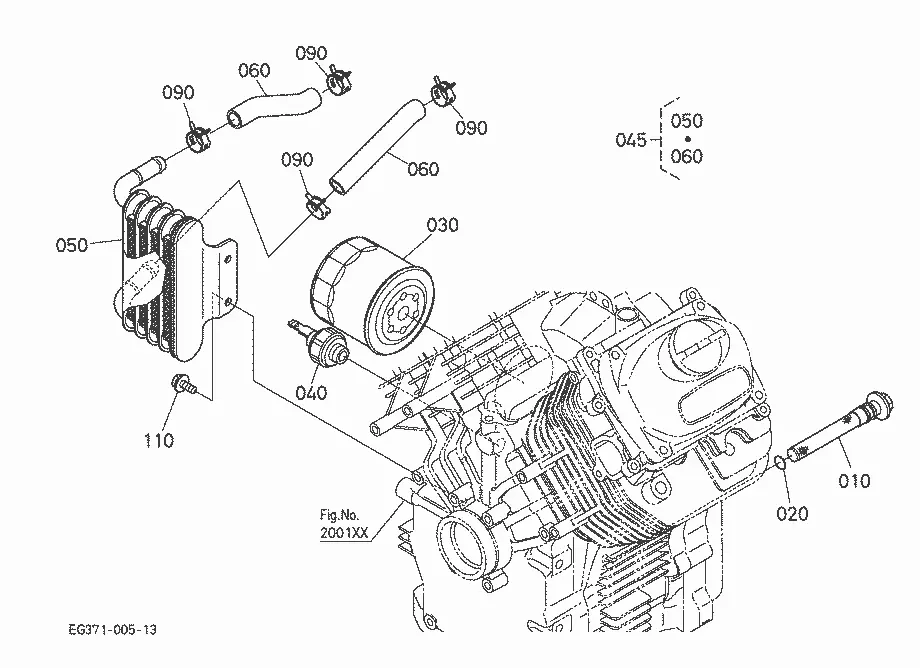

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear overview of individual elements and their relationships within a system, facilitating a better understanding of the overall structure.

Enhanced Understanding

Having a detailed illustration helps users identify each component’s location and function. This clarity is essential for effective troubleshooting and ensures that repairs can be conducted swiftly and accurately.

Streamlined Maintenance

Using visual aids for component reference promotes organized and systematic upkeep. Key benefits include:

- Reduction of errors during assembly or disassembly.

- Improved efficiency in locating specific elements when needed.

- Facilitation of communication between technicians and service personnel.

In summary, well-crafted visuals of machine components serve as invaluable tools that enhance operational efficiency and reduce downtime during maintenance tasks.

Understanding Components and Their Functions

In the realm of machinery, a comprehensive grasp of various elements and their specific roles is crucial for optimal performance. Each component plays a vital part in the overall functionality, contributing to the efficiency and reliability of the equipment. By examining these elements, operators and technicians can enhance their maintenance strategies and troubleshoot potential issues more effectively.

Key Elements and Their Roles

- Engine: The heart of the machine, responsible for converting fuel into mechanical energy.

- Transmission: Facilitates the transfer of power from the engine to the wheels, ensuring smooth operation.

- Cutting Deck: The component responsible for grass trimming, designed to provide a clean and even cut.

- Wheels and Tires: Essential for mobility, providing traction and stability on various terrains.

Maintenance Considerations

Regular upkeep of these elements is vital for maintaining optimal performance. Proper care and timely replacement of worn components can significantly extend the lifespan of the machinery. Operators should be familiar with:

- Inspecting fluid levels and filters regularly.

- Checking for wear and tear on the cutting deck.

- Ensuring tire pressure is within the recommended range.

- Keeping the engine clean to prevent overheating.

How to Read the Diagram

Understanding visual representations of mechanical components is crucial for effective maintenance and repair. This section will guide you through interpreting these illustrations, enabling you to identify various elements and their relationships within the system.

Begin by familiarizing yourself with the layout. Typically, these illustrations are organized in a way that groups related elements together, making it easier to comprehend the assembly. Look for labels that indicate different components and their functions.

Next, pay attention to the symbols and notations. Each symbol represents a specific part or function, and understanding these can provide insights into how each element interacts within the system. Take note of any legends or keys provided, as they will clarify the meanings of various icons.

Finally, follow the connections. Arrows and lines often indicate how components are linked. Trace these pathways to gain a clearer picture of how the entire assembly operates. This understanding will enhance your ability to troubleshoot issues and perform maintenance effectively.

Common Issues with ZG227 Parts

When working with equipment components, various challenges can arise that affect performance and efficiency. Understanding these potential issues is essential for effective maintenance and operation. Common concerns include wear and tear, compatibility problems, and insufficient maintenance practices that can lead to significant downtime.

Wear and Tear

Over time, the constant use of machinery can lead to deterioration of crucial elements. Signs of wear may include decreased performance and unusual noises. Regular inspections are vital to identifying these issues early and replacing worn components promptly.

Compatibility Issues

When replacing components, ensuring compatibility with existing systems is critical. Mismatched elements can lead to malfunctions or reduced efficiency. It is advisable to consult the manufacturer’s specifications before purchasing replacements to avoid complications.

| Issue | Symptoms | Solution |

|---|---|---|

| Wear | Reduced efficiency, unusual sounds | Regular inspections and timely replacements |

| Compatibility | Frequent malfunctions, inefficiency | Consult manufacturer specifications |

| Maintenance | Increased breakdowns, operational delays | Implement a regular maintenance schedule |

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your equipment involves regular upkeep and attention to detail. By following a consistent maintenance routine, you can prevent issues and enhance efficiency, ultimately extending the life of your machinery. This section outlines essential practices that contribute to the durability and reliability of your equipment.

Regular Inspections

Conducting frequent inspections is vital for identifying potential problems before they escalate. Look for signs of wear, leaks, or unusual sounds. Pay attention to critical components and ensure they are functioning properly. Keeping a maintenance log can also help track any issues that arise and the steps taken to address them.

Proper Cleaning

Maintaining cleanliness is crucial for optimal operation. Debris and dirt accumulation can lead to overheating and inefficient performance. Regularly clean external surfaces and ensure that air filters are free of obstructions. Additionally, follow manufacturer recommendations for internal cleaning procedures to avoid damaging sensitive parts.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Check oil levels | Every 50 hours | Replace if necessary |

| Inspect blades | Weekly | Sharpen as needed |

| Clean air filters | Monthly | Replace if damaged |

| Examine tires | Every 100 hours | Check for wear and proper inflation |

Finding Replacement Parts Easily

Locating suitable components for your equipment can often be a daunting task, especially when dealing with complex machinery. Understanding the layout and specifications of the various elements can simplify the process significantly. This guide will provide insight into how to efficiently find the necessary items for your maintenance needs.

Utilizing a well-organized reference can streamline your search, allowing for quicker identification of the components you require. Below is a structured overview to assist you in navigating the available options:

| Component Type | Description | Model Compatibility |

|---|---|---|

| Engine Assembly | Main power unit responsible for operation. | Various models |

| Blade Set | Cutting blades for effective trimming. | Compatible with similar designs |

| Wheel Assemblies | Complete units for mobility and stability. | Various sizes available |

| Electrical Components | Wiring and connectors for power distribution. | Check compatibility |

| Transmission Parts | Elements that control power transfer. | Specific models |

By using the above reference and consulting reliable suppliers, you can enhance your ability to obtain the necessary components, ensuring that your machinery remains in optimal working condition.

Upgrades for Improved Performance

Enhancing the efficiency and effectiveness of lawn maintenance equipment can significantly boost productivity and prolong its lifespan. By implementing various modifications, operators can achieve superior results while minimizing wear and tear on essential components. This section explores several upgrades that can lead to improved performance in machinery used for turf care.

One of the most effective ways to enhance overall functionality is by upgrading the cutting mechanism. An improved blade design can ensure cleaner cuts and a better finish, reducing the need for frequent maintenance. Additionally, the incorporation of high-quality filters and fluids can optimize engine performance and fuel efficiency.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Cutting Blades | Replace standard blades with advanced high-performance blades. | Provides cleaner cuts and enhances grass health. |

| Engine Filters | Install premium air and fuel filters to improve airflow and fuel delivery. | Boosts engine efficiency and longevity. |

| Tires | Upgrade to specialized turf tires for better traction. | Improves maneuverability and reduces turf damage. |

| Suspension System | Enhance the suspension system for improved ride quality. | Reduces operator fatigue during prolonged use. |

Investing in these enhancements not only improves performance but also contributes to the overall durability of the equipment. Operators can enjoy a more efficient and effective mowing experience, ensuring that their machines operate at optimal levels for years to come.

Customer Reviews and Feedback

This section focuses on the opinions and experiences shared by users regarding their experiences with the equipment. Customer insights play a crucial role in understanding the performance, durability, and overall satisfaction with various components. Feedback gathered from users helps potential buyers make informed decisions and enhances the product’s reputation in the market.

User Experiences

Many users have reported positive experiences with their machinery, noting its reliability and efficiency in handling various tasks. The ease of operation and maintenance has been highlighted, making it a preferred choice among homeowners and professionals alike. Reviews often mention the superior build quality and the effectiveness of the equipment in diverse conditions.

While feedback is predominantly favorable, some users have suggested areas for improvement. Common concerns include the availability of replacement components and the responsiveness of customer support. Addressing these issues could significantly enhance user satisfaction and strengthen brand loyalty.