In the realm of machinery and tools, comprehending the various elements that comprise a system is essential for effective operation and maintenance. Familiarity with these elements enhances the user experience and allows for troubleshooting when issues arise. This section delves into the intricate layout of components, providing valuable insights into their arrangement and functionality.

When engaging with technical illustrations, one can gain a clearer perspective on how each piece interacts within the larger assembly. Recognizing the significance of each segment empowers users to make informed decisions regarding repairs and enhancements. Moreover, having a detailed overview can assist in the identification of potential problems before they escalate.

Through this exploration, users are encouraged to familiarize themselves with the configuration of these crucial elements. By doing so, they can optimize the performance of their equipment, ensuring longevity and efficiency. Understanding the layout not only demystifies the machinery but also instills confidence in users as they navigate its features.

This section provides a comprehensive understanding of the essential elements that contribute to the functionality of the equipment. Each component plays a vital role in ensuring optimal performance and reliability, making it crucial for users to familiarize themselves with these parts.

- Heating Element: Responsible for generating the necessary heat, ensuring efficient cooking and baking processes.

- Control Panel: The interface through which users interact with the equipment, allowing for temperature adjustments and timing settings.

- Safety Features: Mechanisms designed to prevent overheating and ensure user safety during operation.

- Insulation: Material that minimizes heat loss, enhancing energy efficiency and maintaining consistent temperatures.

- Fan System: Distributes heat evenly throughout the cooking chamber, promoting uniform cooking results.

Understanding these core components is essential for effective usage and maintenance. Each part’s function is interconnected, contributing to the overall efficiency and effectiveness of the device.

Identifying Common Issues

Recognizing prevalent challenges is crucial for maintaining optimal functionality in various equipment. By understanding these typical problems, users can enhance performance and extend the lifespan of their devices.

1. Electrical Failures

One of the most frequent complications involves electrical systems. These may manifest in several ways:

- Poor connectivity or loose wiring

- Inconsistent power supply

- Faulty switches or circuits

To troubleshoot these issues, inspect connections, replace damaged components, and ensure that power sources are stable.

2. Mechanical Malfunctions

Another area that often presents difficulties is the mechanical aspect. Common indicators include:

- Unusual noises during operation

- Difficulty in movement or jamming

- Worn-out parts that require replacement

Regular maintenance, including lubrication and component checks, can help prevent these issues from arising.

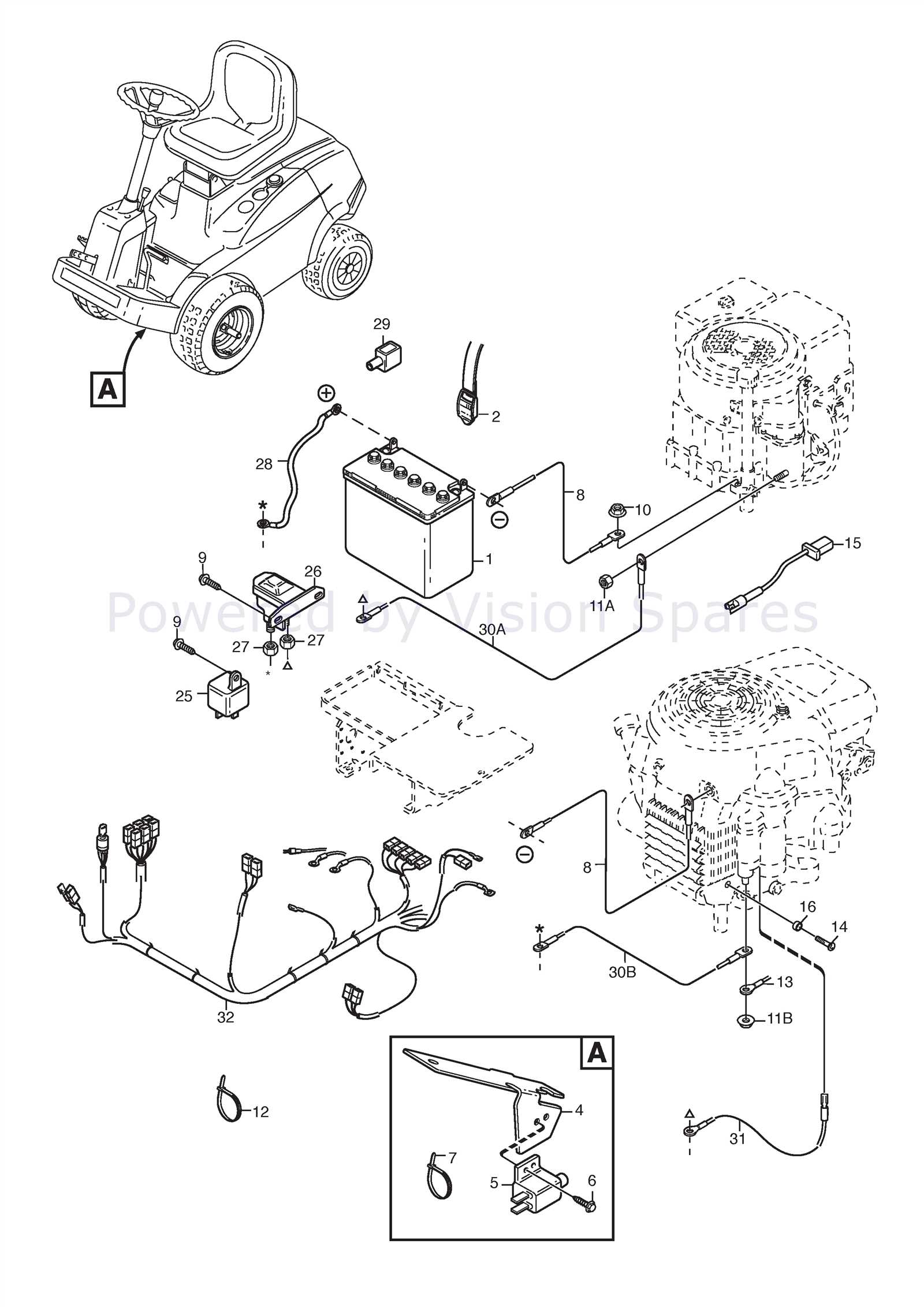

How to Read the Diagram

Understanding a schematic representation of components and their connections is crucial for effective troubleshooting and maintenance. This guide will help you interpret the various symbols and layouts commonly used in technical illustrations, enabling you to identify parts and their functionalities easily.

Key Elements to Recognize

When examining a visual representation, several essential elements need your attention. Each symbol represents a specific function, and recognizing these can significantly enhance your comprehension.

| Symbol | Description |

|---|---|

| Circle | Indicates a connection point or junction. |

| Arrow | Shows the direction of flow, whether it be electrical or fluid. |

| Line | Represents a pathway for energy or signals between components. |

| Square | Denotes a specific component, such as a relay or switch. |

Tips for Effective Interpretation

To navigate the representation successfully, start by familiarizing yourself with the legend or key, which usually accompanies the illustration. This will provide context for the symbols used. Additionally, trace the lines to understand how each component interacts within the system, allowing for a more comprehensive grasp of the overall setup.

Essential Tools for Repairs

Effective maintenance and troubleshooting require a specific set of instruments that can significantly streamline the repair process. Having the right equipment at hand not only facilitates efficient handling of issues but also ensures that tasks are completed with precision and safety. This section highlights the key tools necessary for effective repairs, focusing on their importance and functionality.

Basic Hand Tools

Hand tools are indispensable for any repair task. These tools allow for direct manipulation of components and can often solve problems without the need for specialized equipment. Here is a summary of essential hand tools:

| Tool | Description |

|---|---|

| Screwdriver Set | Variety of sizes and types for different screws. |

| Pliers | For gripping, twisting, and cutting wires or components. |

| Wrench Set | Useful for tightening or loosening nuts and bolts. |

| Utility Knife | For cutting various materials during repairs. |

Power Tools

In addition to hand tools, power tools enhance efficiency, especially in more demanding tasks. These devices provide increased torque and speed, making them invaluable for specific repair needs. Below are some common power tools used in repair work:

| Tool | Description |

|---|---|

| Drill | Used for creating holes or driving screws quickly. |

| Impact Driver | Excellent for driving screws into tough materials. |

| Angle Grinder | Versatile tool for cutting, grinding, and polishing. |

| Saw | For cutting wood, metal, or plastic with precision. |

Maintenance Tips for Longevity

To ensure the durability and efficiency of your equipment, regular upkeep is essential. Implementing a structured maintenance routine can significantly extend the lifespan of your device, preventing unexpected failures and costly repairs.

- Regular Cleaning: Keep surfaces free from debris and contaminants. Dust and residue can accumulate and affect performance.

- Check Connections: Periodically inspect all connections to ensure they are secure and free from corrosion. Loose or damaged connections can lead to operational issues.

- Lubrication: Apply appropriate lubricants to moving parts to minimize friction and wear. Consult the manufacturer’s guidelines for recommended products.

- Temperature Monitoring: Ensure that your device operates within the recommended temperature range. Overheating can cause premature failure.

- Component Inspection: Routinely check for any signs of wear or damage on critical components. Early detection can prevent more severe problems later.

By following these suggestions, users can enhance the performance and extend the service life of their equipment, ensuring reliable operation for years to come.

Replacing Worn-Out Parts

Over time, components in machinery can wear down, affecting performance and efficiency. Addressing these issues promptly can extend the life of the equipment and improve overall functionality. This section will outline the process and considerations for swapping out aged components, ensuring a smoother operation and minimizing downtime.

Identifying Worn Components

Recognizing which elements require replacement is crucial. Common signs of wear include:

- Unusual noises during operation

- Decreased performance or efficiency

- Visible damage, such as cracks or breaks

- Increased vibrations or instability

Regular inspections can help catch these issues early. It is advisable to keep a maintenance log to track performance changes over time.

Replacement Process

Once worn components are identified, follow these steps for replacement:

- Gather the necessary tools and new components.

- Power down the machinery and ensure safety protocols are followed.

- Carefully remove the old components, taking note of their placement.

- Install the new components, ensuring a secure fit.

- Conduct tests to confirm proper operation.

By systematically addressing worn components, operators can maintain optimal performance and reduce the likelihood of unexpected failures.

Understanding Wiring and Connections

Comprehending the intricacies of electrical connections is essential for anyone working with complex appliances. Effective wiring ensures that each component communicates efficiently, minimizing the risk of malfunctions. Proper understanding of these connections can greatly enhance both the performance and safety of the device.

Connections involve various elements, including wires, terminals, and connectors, which work together to create a seamless flow of electricity. Each wire serves a specific purpose, whether it is for power delivery, signal transmission, or grounding. Recognizing the role of each connection allows for easier troubleshooting and maintenance.

It is also important to pay attention to the color coding of wires, as it provides vital information about their function. Familiarizing oneself with common wiring standards can facilitate smoother repairs and upgrades. Additionally, using the correct tools and following safety protocols during installation will prevent potential hazards and ensure longevity.

Safety Precautions During Repairs

When undertaking maintenance on any equipment, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure that individuals can work effectively without exposing themselves or others to unnecessary risks. Adhering to established safety guidelines creates a secure environment, allowing for thorough and efficient repairs.

Personal Protective Equipment

Utilizing personal protective equipment (PPE) is essential for safeguarding against potential hazards. Always wear appropriate gear such as gloves, goggles, and masks to protect against debris, chemicals, and other harmful substances. Ensure that clothing is suitable for the task and minimizes the risk of entanglement in moving parts.

Work Environment Safety

Maintaining a clean and organized workspace is vital for effective repairs. Eliminate clutter to reduce the risk of trips and falls. Ensure that all tools are in good condition and properly stored when not in use. Additionally, verify that the area is well-ventilated and adequately illuminated to enhance visibility and comfort during the repair process.

Comparing with Other Models

This section provides a thorough examination of various equipment from the same category, highlighting their features and specifications. By analyzing similarities and differences, users can gain insights into which option best meets their needs. Understanding the nuances between models helps in making an informed decision, especially when considering functionality, durability, and performance metrics.

Feature Overview

Each model comes with distinct characteristics that cater to different requirements. The table below summarizes key attributes, allowing for an easy comparison:

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Heating Capacity | 150,000 BTU | 125,000 BTU | 175,000 BTU |

| Material Quality | Stainless Steel | Aluminum | Stainless Steel |

| Control System | Digital | Analog | Digital |

| Energy Efficiency | High | Moderate | High |

User Experience

Feedback from users often sheds light on practical performance in various settings. While some may prefer the streamlined features of certain options, others might favor robust durability or ease of use. This subjective evaluation can play a significant role in selecting the right equipment for specific tasks.

Resources for Further Assistance

For those seeking additional support and insights regarding equipment maintenance and repairs, a variety of resources are available. Whether you are looking for technical manuals, community forums, or expert advice, these options can significantly enhance your understanding and skills.

Online Manuals and Guides

Comprehensive manuals often provide detailed information about operation and troubleshooting. They can serve as valuable references during maintenance tasks.

| Resource Type | Description | Access Link |

|---|---|---|

| User Manuals | Official documents containing specifications and usage instructions. | View Manuals |

| Maintenance Guides | Step-by-step instructions for routine upkeep and repairs. | Explore Guides |

Community Support

Engaging with online communities can offer practical insights and solutions from experienced users. Participating in discussions can foster learning and problem-solving.

| Platform | Description | Access Link |

|---|---|---|

| Forums | Discussion boards for sharing tips and experiences. | Join Forum |

| Social Media Groups | Groups dedicated to specific topics or equipment where members can ask questions and share knowledge. | Find Groups |

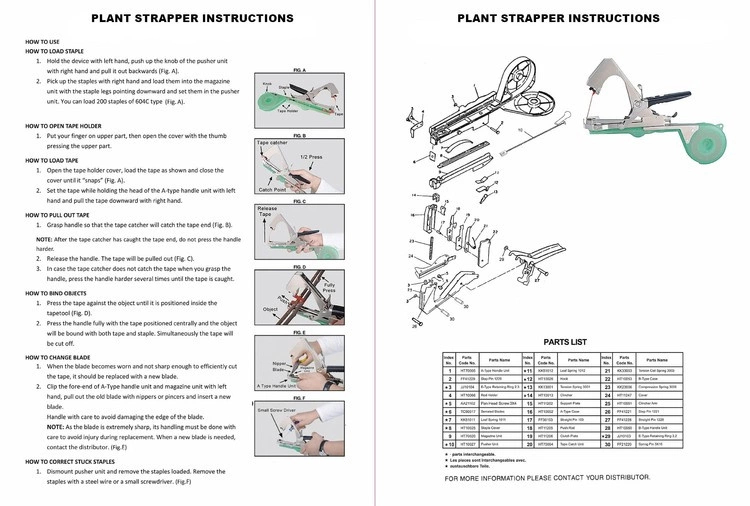

Gathering Replacement Parts

When it comes to maintaining or refurbishing equipment, acquiring the necessary components is crucial for ensuring optimal performance. Whether you are undertaking repairs or enhancing functionality, identifying and sourcing the correct items can make all the difference in the outcome of your project. This process requires careful consideration of compatibility, quality, and availability to ensure that the new elements fit seamlessly into your existing setup.

Identifying Compatible Components

Before seeking replacements, it is essential to determine which specific elements need to be substituted. Consult the manufacturer’s specifications or any available reference materials to pinpoint the exact requirements. This may include dimensions, material types, and operational parameters. Understanding these factors will help streamline the selection process and prevent potential issues during installation.

Where to Source Quality Items

Finding reliable sources for your needed components can be achieved through various channels. Local suppliers often carry essential items, while online marketplaces provide a broader selection. Always prioritize vendors with positive reviews and a history of delivering high-quality products. Additionally, exploring surplus or second-hand options can yield valuable finds, especially for rare or discontinued items.