In the realm of farming machinery, a comprehensive grasp of the various elements that constitute essential implements is crucial for effective operation and maintenance. Each piece of equipment serves a unique purpose, contributing to the overall efficiency and productivity of agricultural practices. A thorough exploration of these components allows users to optimize their machinery and ensure optimal performance.

Examining the intricate layout of these implements reveals how different elements interact and function together. This knowledge not only aids in troubleshooting and repairs but also enhances the operator’s ability to utilize the equipment effectively. By familiarizing oneself with the various components and their roles, one can significantly improve the longevity and functionality of their agricultural tools.

Furthermore, understanding the structure and arrangement of these elements is vital for making informed decisions regarding upgrades or replacements. Farmers and operators can better assess their needs and select appropriate enhancements by gaining insight into the underlying mechanics. This holistic approach ultimately leads to a more sustainable and efficient farming operation.

This section aims to provide a comprehensive overview of the essential components involved in agricultural tillage equipment. By breaking down the various elements, we can gain a clearer understanding of their functions and interrelationships, ensuring effective maintenance and operation.

| Component | Description | Function |

|---|---|---|

| Body | Main structure of the implement. | Houses other components and provides stability. |

| Cutting Edge | Sharp front edge of the tool. | Penetrates soil for effective tilling. |

| Shank | Vertical element connecting the body to the blade. | Supports the blade and facilitates depth adjustment. |

| Furrow Wheel | Wheel that guides the implement. | Maintains proper depth and direction. |

| Share | Replaceable point that digs into the soil. | Breaks up the soil for improved aeration. |

Understanding Plough Functionality

The essential mechanism of tillage equipment plays a crucial role in soil management and preparation for agricultural activities. This process involves several components working in harmony to achieve optimal results in the field.

At its core, this machinery is designed to turn over the top layer of soil, mixing organic matter and creating a conducive environment for crop growth. The effectiveness of this operation depends on various factors, including:

- Soil Type: Different soils respond uniquely to tillage, affecting the choice of equipment.

- Working Depth: The depth of operation significantly influences soil structure and health.

- Speed: The rate at which the machinery operates can alter the quality of soil disturbance.

Understanding these elements helps farmers optimize their agricultural practices. Furthermore, proper maintenance of each component ensures efficient functionality, ultimately contributing to enhanced crop yields and sustainable farming practices.

By comprehending the dynamics involved in soil cultivation, operators can make informed decisions about their equipment and techniques, leading to more effective land use and management.

Key Components of Kverneland Plough

The effectiveness of a soil-tilling implement relies heavily on its fundamental elements. Understanding these crucial components helps optimize performance, improve efficiency, and ensure longevity during agricultural tasks.

Essential Elements for Functionality

At the core of any effective tilling machine are its primary components that facilitate the breaking and turning of soil. These parts work in unison to create optimal conditions for planting, enhancing crop growth. The quality and design of these elements significantly impact the overall functionality of the implement.

Durability and Maintenance

Long-lasting performance hinges on the robustness of these critical components. Regular inspection and maintenance are vital to ensure that each piece functions correctly, preventing unnecessary wear and tear. Investing in high-quality materials and adhering to maintenance schedules can significantly extend the life of the machinery.

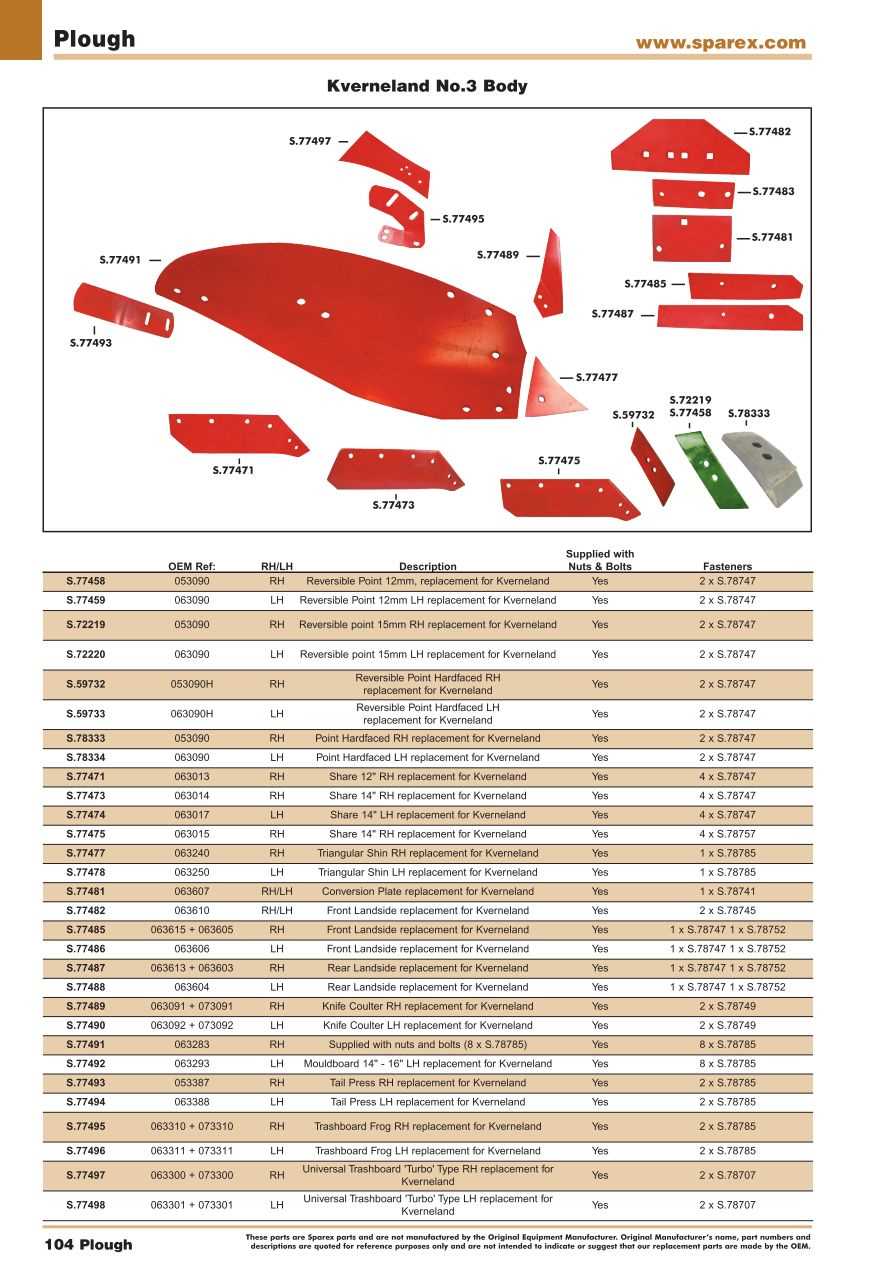

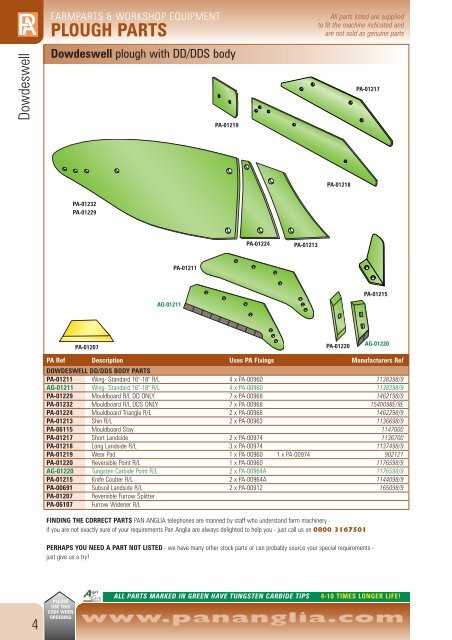

Importance of Accurate Diagrams

Precise visual representations play a crucial role in the effective maintenance and operation of agricultural machinery. They serve as essential guides, providing users with the necessary information to understand the components and their interactions. Such clarity helps in minimizing errors during repairs or adjustments, ensuring optimal performance of the equipment.

Moreover, well-crafted illustrations contribute to enhanced training and onboarding processes for new operators. By presenting complex information in a clear and accessible manner, these visuals facilitate quicker comprehension and retention of critical details. This can lead to increased efficiency and reduced downtime in agricultural operations.

| Benefits | Explanation |

|---|---|

| Enhanced Understanding | Clear visuals help users grasp the functionality of components. |

| Improved Efficiency | Minimized errors lead to faster repairs and operations. |

| Better Training | New operators learn quicker through visual aids. |

Common Issues with Plough Parts

Various challenges can arise with the components of soil cultivation equipment, impacting their performance and efficiency. Identifying these problems early can help in maintaining optimal functionality and prolonging the lifespan of the machinery.

Wear and Tear

Wear and tear is a frequent concern, especially in high-stress environments. Components can experience fatigue due to continuous use, leading to diminished performance. Regular inspections can aid in detecting signs of deterioration early, allowing for timely replacements or repairs.

Improper Adjustments

Improper adjustments can significantly affect the equipment’s effectiveness. If the settings are not calibrated correctly, it can lead to uneven soil handling or inadequate depth control. Maintaining accurate settings ensures consistent operation and optimal results in soil preparation.

Identifying Each Part’s Role

Understanding the function of each component in agricultural equipment is essential for optimizing its performance and maintenance. Every element plays a distinct role in the overall operation, contributing to efficiency and effectiveness in farming practices.

Essential Components and Their Functions

Cutting Edge: The leading edge is responsible for slicing through soil, enabling deeper penetration. Its sharpness and durability directly affect the quality of the tillage.

Body Frame: This structure provides stability and support to all attached elements. Its robustness ensures that the implement withstands the stresses of operation, enhancing longevity.

Supportive Elements

Adjustable Skids: These assist in maintaining the desired depth during operation, allowing for precise adjustments according to soil conditions.

Hitch Assembly: This connection mechanism links the implement to the tractor, ensuring efficient power transfer and maneuverability across fields.

Maintenance Tips for Longevity

Ensuring the durability of agricultural equipment requires regular attention and care. By implementing proper upkeep practices, one can significantly extend the life of machinery and enhance its performance. The following guidelines will help maintain optimal functioning and prevent premature wear and tear.

Regular Inspections

Conducting consistent assessments of machinery is vital. Look for signs of wear, loose components, and any unusual noises during operation.

- Check for rust or corrosion on metal surfaces.

- Inspect all moving parts for proper lubrication.

- Ensure that fasteners and bolts are secure and not loose.

Proper Storage

Storing equipment correctly protects it from environmental factors that can cause damage.

- Keep machinery in a dry and sheltered area.

- Use protective covers to shield from dust and moisture.

- Avoid leaving equipment exposed to extreme weather conditions.

How to Read a Parts Diagram

Understanding an illustration of components is essential for effective maintenance and repair. Such visuals serve as a valuable guide, providing a clear representation of individual elements and their relationships within a system. By familiarizing yourself with these visuals, you can enhance your comprehension and facilitate efficient troubleshooting.

Here are some key aspects to consider when examining an illustration of components:

- Symbols and Labels: Pay attention to the symbols used, as they often represent specific elements. Labels may include part numbers, names, or other identifiers that help you recognize each component.

- Arrangement: Note how the elements are organized. The layout usually reflects their physical relationships, indicating which parts connect or interact with one another.

- Reference Numbers: Look for reference numbers associated with each part. These can be crucial when ordering replacements or identifying specific items in a catalog.

- Legend: If available, consult the legend or key. This section often clarifies the meanings of various symbols, enhancing your understanding of the entire illustration.

By following these guidelines, you can effectively navigate an illustration of components and ensure you have the necessary information for successful maintenance and repairs.

Tools Needed for Plough Repairs

Maintaining and fixing agricultural equipment requires a specific set of tools to ensure efficient operation and longevity. Having the right instruments on hand is crucial for completing repairs effectively and safely.

Essential Hand Tools: A variety of hand tools are indispensable for any repair job. Wrenches, screwdrivers, and pliers are among the most commonly used. Each tool plays a vital role in loosening or tightening components, making them necessary for adjustments and replacements.

Power Tools: In addition to hand tools, power tools can greatly enhance repair efficiency. Drills, grinders, and impact wrenches facilitate quicker work and allow for more complex tasks to be accomplished with ease.

Safety Gear: Protecting oneself during repairs is paramount. Wearing gloves, safety glasses, and durable clothing helps prevent injuries while handling tools and equipment. It is important to prioritize safety to avoid accidents during the maintenance process.

Diagnostic Equipment: For troubleshooting, having diagnostic tools is beneficial. Multimeters and pressure gauges assist in identifying issues, ensuring that repairs are made based on accurate assessments.

Overall, being equipped with the proper tools not only streamlines the repair process but also contributes to the overall effectiveness and reliability of agricultural machinery.

Replacement Parts: What to Consider

When it comes to maintaining agricultural equipment, the selection of appropriate components is crucial for ensuring optimal performance and longevity. Understanding the key factors involved in choosing suitable replacements can significantly impact productivity and reduce downtime.

Quality Assurance: Prioritizing high-quality materials is essential. Components manufactured from durable materials tend to offer better resistance to wear and tear, thereby enhancing overall functionality.

Compatibility: Ensuring that the replacements are compatible with existing machinery is vital. Mismatched components can lead to inefficient operation or even damage to the equipment.

Cost Considerations: While affordability is important, it should not come at the expense of quality. Striking a balance between cost and reliability will yield better long-term results.

Manufacturer Reputation: Opting for parts from reputable manufacturers often guarantees higher standards of quality and support. Researching the reputation of different suppliers can provide valuable insights.

Maintenance and Support: Consider whether the supplier offers adequate support and resources for maintenance. Having access to guidance can assist in the proper installation and care of the components.

Impact of Quality Parts on Performance

The effectiveness of agricultural machinery is significantly influenced by the caliber of its components. High-quality elements ensure that the equipment operates smoothly and efficiently, which is crucial for achieving optimal results in farming tasks. Reliable components contribute to overall durability, reducing the likelihood of malfunctions and enhancing productivity.

Superior materials and meticulous craftsmanship can lead to improved functionality and longevity of the equipment. When every element is designed to meet rigorous standards, the entire system benefits from enhanced precision and performance. This not only maximizes the yield but also minimizes maintenance costs over time.

Furthermore, investing in quality ensures that the machinery can withstand various operating conditions, offering greater versatility and adaptability. This adaptability is essential for farmers who face differing soil types and weather conditions. Thus, the integration of top-tier components ultimately plays a vital role in the effectiveness of agricultural operations.

Where to Find Kverneland Parts

Locating essential components for agricultural equipment can be a straightforward process when you know where to look. Various avenues are available to ensure you can find the necessary items to maintain and enhance your machinery’s performance.

Authorized Dealers and Distributors

One of the most reliable sources for obtaining replacement components is through official dealers. They provide genuine items and often offer expert advice on selection and installation.

- Check the manufacturer’s website for a list of authorized dealers.

- Visit local agricultural machinery showrooms that represent the brand.

- Contact dealers directly for specific inquiries or to place orders.

Online Marketplaces and Retailers

The digital marketplace has become an invaluable resource for finding agricultural equipment components. Numerous online platforms specialize in these items, often featuring a wide selection.

- Search for reputable websites that specialize in agricultural machinery parts.

- Explore auction sites for second-hand options that may be more affordable.

- Utilize comparison tools to find the best prices and shipping options.

FAQs About Plough Parts

This section addresses common inquiries related to the components used in tillage equipment. Understanding these elements can enhance the efficiency and longevity of agricultural machinery.

Common Questions

- What are the main components of a tilling machine?

- How can I identify worn-out elements?

- What maintenance practices are recommended for longevity?

Replacement and Repair

- Where can I find suitable replacements?

- How do I know when to repair instead of replacing?

- What tools are needed for installation and maintenance?