In the world of outdoor machinery, familiarity with the various elements that comprise a specific model can greatly enhance both maintenance and performance. By gaining insights into the individual pieces, users can ensure optimal functionality and longevity of their equipment. This understanding empowers operators to tackle repairs with confidence and precision.

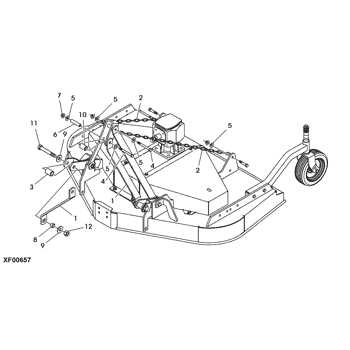

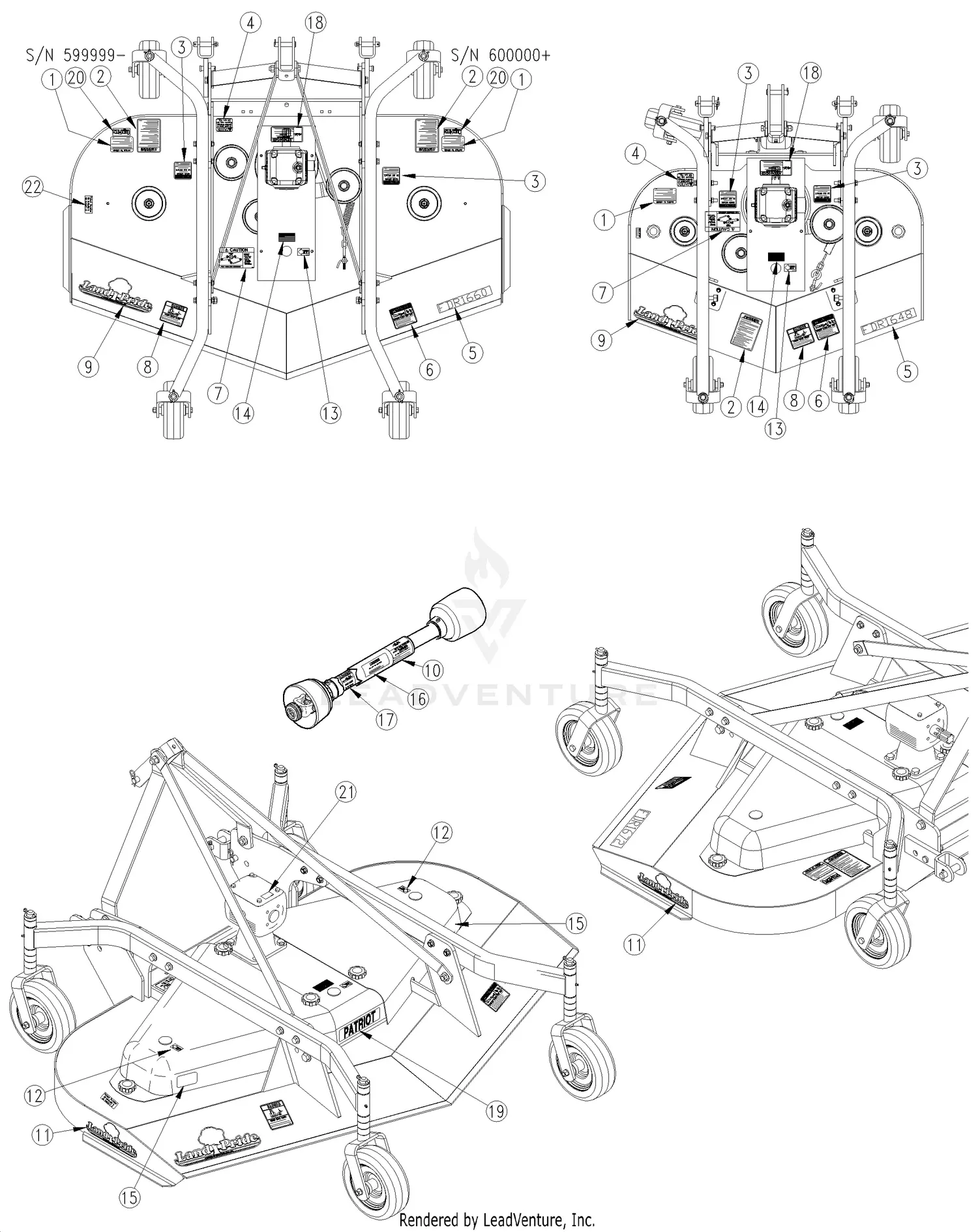

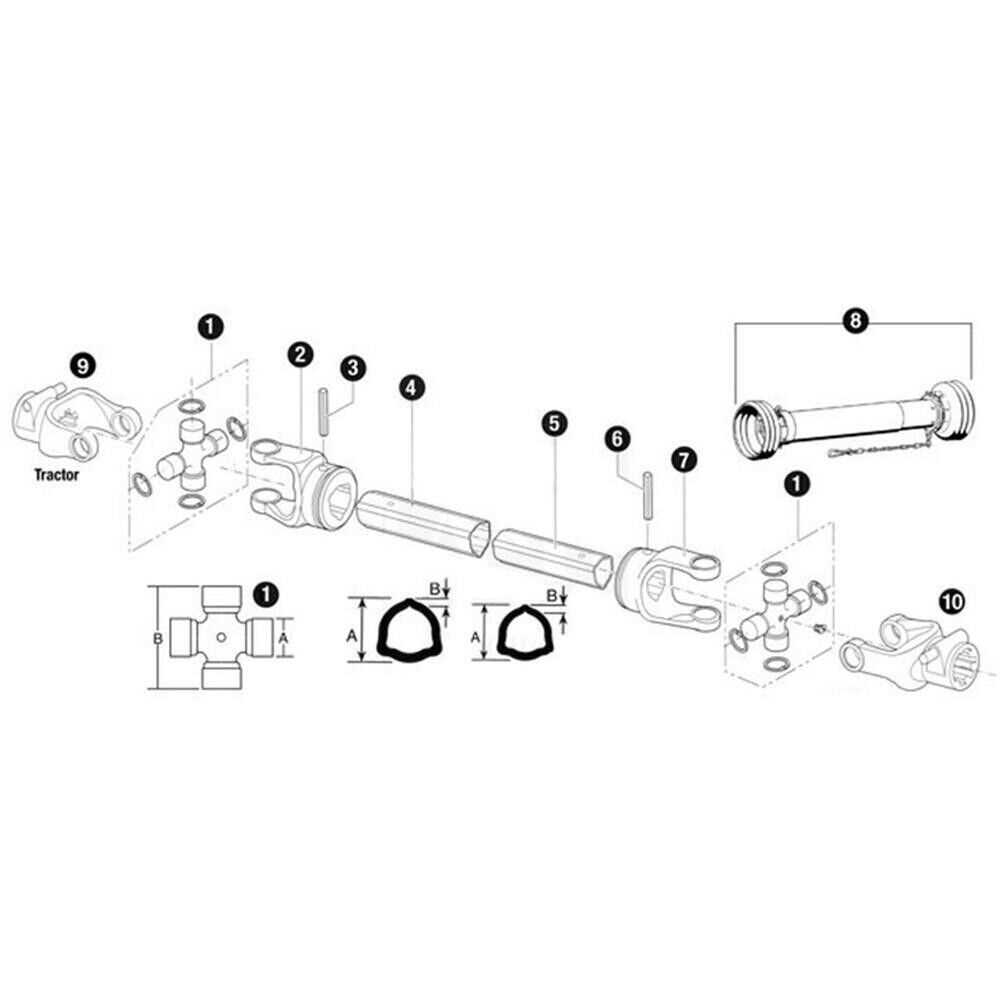

Visualization of the assembly plays a crucial role in identifying how each component interacts within the larger system. With a clear representation, it becomes easier to diagnose issues, source replacements, and perform upgrades. This knowledge not only simplifies the repair process but also enhances overall efficiency.

Furthermore, having access to a comprehensive overview of the construction aids in understanding the technology behind the machinery. Aspects such as wear and tear, compatibility with other parts, and upgrades become clearer. This exploration opens doors to improved operational techniques and informed decision-making for any user invested in their outdoor equipment.

Understanding the FDR1672 Components

The intricate assembly of agricultural machinery plays a crucial role in enhancing efficiency and productivity. Each element within this system is designed to work in harmony, ensuring optimal performance in various tasks. Recognizing how these components interact and contribute to the overall functionality is essential for effective operation and maintenance.

Key Elements within this configuration include mechanical parts, which facilitate movement, and electrical systems that provide control and power. Understanding the functionality of each segment helps operators identify potential issues and optimize performance. Regular examination and maintenance of these components not only prolong their lifespan but also enhance the overall efficiency of the machinery.

Additionally, being familiar with specific functionalities aids in troubleshooting. For instance, knowing how a particular element influences the overall operation can lead to quicker resolutions when problems arise. This knowledge empowers users to take proactive measures, ensuring that their equipment remains in peak condition.

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual representations provide a clear breakdown of components, aiding in the identification and procurement of necessary items. Familiarity with the layout and symbols used can significantly enhance your ability to work with various systems.

Key Elements of Technical Illustrations

- Labels: Each item is typically marked with a reference number or letter, which corresponds to a list of components.

- Legend: A legend or key may explain symbols used in the visual, such as specific types of fasteners or materials.

- Sections: Diagrams may be divided into sections, allowing for focused examination of particular areas.

Steps to Interpret the Visuals

- Identify the overall layout and structure.

- Locate the reference numbers for specific components.

- Consult the accompanying list to find detailed information on each item.

- Use the legend to understand any symbols or color coding present.

- Cross-reference with the manual or repair guides as needed for context.

By following these guidelines, you will enhance your proficiency in navigating technical visuals, leading to more efficient repairs and part replacements.

Common Issues with FDR1672 Parts

When it comes to maintenance and functionality, certain components of equipment can frequently encounter challenges. Identifying these common issues can help users manage their machinery more effectively, ensuring longevity and optimal performance. Understanding the typical problems associated with these elements is essential for timely repairs and replacements.

Wear and Tear

Over time, various components can experience significant wear and tear due to regular use. This degradation can manifest in decreased efficiency or even complete failure. Regular inspections are crucial to identify signs of deterioration early. Indicators such as unusual noises, vibrations, or decreased output often signal the need for immediate attention.

Compatibility and Fit

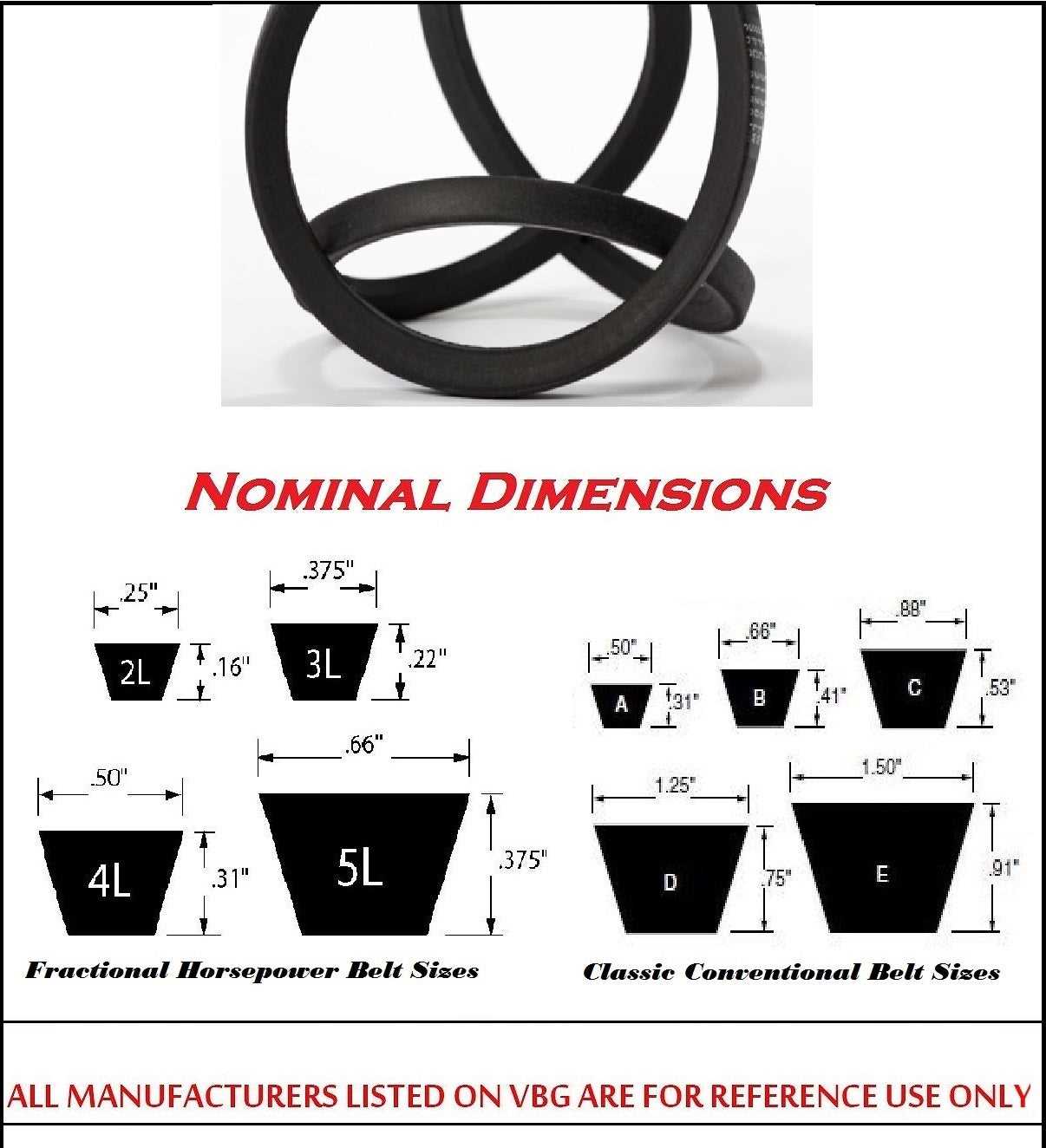

Another prevalent issue involves the compatibility of replacement elements. Using components that do not fit correctly can lead to malfunctions or damage to the overall system. Ensuring that replacements meet the necessary specifications is vital to maintaining operational integrity. Always refer to the manufacturer’s guidelines to confirm compatibility before purchasing new items.

Maintenance Tips for Land Pride Equipment

Regular upkeep of your machinery is crucial for optimal performance and longevity. Implementing a structured maintenance routine can prevent unexpected breakdowns and ensure your equipment operates at its peak efficiency.

1. Regular Inspections: Conduct thorough checks of all components to identify wear and tear early. Focus on critical parts such as blades, belts, and hydraulics.

2. Cleaning: Keep the machinery clean to prevent dirt and debris from causing damage. Use appropriate cleaning agents that won’t harm the equipment’s surfaces.

3. Lubrication: Apply suitable lubricants to moving parts regularly. This reduces friction and prolongs the life of the machinery.

4. Follow Manufacturer Guidelines: Adhere to the recommended service intervals and procedures provided in the user manual. This ensures compliance and helps maintain warranties.

5. Seasonal Preparation: Prepare your equipment for seasonal use by checking fluids, filters, and functionality before heavy usage periods.

6. Proper Storage: Store machinery in a sheltered area to protect it from the elements. Use covers to prevent dust accumulation and rust.

Identifying Parts for Replacement

When it comes to maintaining machinery, recognizing components that require substitution is essential for optimal performance. This process involves a careful assessment to ensure that the correct items are selected, which can significantly affect the functionality and longevity of the equipment.

Understanding the assembly is the first step. Familiarity with how each segment interacts with others allows for quicker identification of issues. It’s advisable to have access to a detailed visual reference, which can serve as a guide to locate specific elements needing attention.

Another crucial aspect is considering compatibility. Not all pieces are interchangeable; thus, verifying specifications and manufacturer recommendations is vital to avoid further complications. Regular inspections and documentation of wear can aid in anticipating which components might need replacement in the near future.

Finally, keeping an organized inventory of components on hand can streamline the replacement process. Having readily available parts minimizes downtime and enhances overall efficiency in maintenance tasks. Prioritizing this practice will contribute to a smoother operation and reduced operational disruptions.

Where to Purchase FDR1672 Parts

Finding the right components for your equipment is crucial for optimal performance. Various options are available to ensure you acquire the necessary elements effectively and efficiently.

Online Retailers offer a vast selection of items. Websites specializing in machinery supplies often have an extensive inventory, making it easy to browse and compare options.

Local Dealers can provide personalized assistance. Visiting a nearby store allows you to ask questions and receive expert advice tailored to your specific needs.

Manufacturer’s Website is another reliable source. Purchasing directly ensures authenticity and compatibility, often accompanied by warranty support.

Consider checking forums and community groups dedicated to equipment maintenance. Fellow enthusiasts often share recommendations on where to find the best deals and trusted sellers.

Impact of Worn Components on Performance

The efficiency and effectiveness of machinery can be significantly affected by the condition of its internal elements. When components experience wear and tear, their functionality diminishes, leading to a cascade of issues that impact overall operation.

Key areas where degradation can influence performance include:

- Operational Efficiency: Deteriorated parts may result in increased friction and resistance, causing machinery to work harder and consume more energy.

- Accuracy: Components that are not in optimal condition can lead to misalignments, affecting precision in tasks such as cutting or drilling.

- Safety: Worn elements can compromise the safety of operations, increasing the risk of malfunction or accidents.

- Longevity: Neglecting worn components can lead to further damage, ultimately reducing the lifespan of the entire system.

Regular maintenance and timely replacement of compromised elements are essential to preserving performance and preventing costly downtimes. Recognizing the signs of wear early can mitigate potential issues and enhance the reliability of machinery.

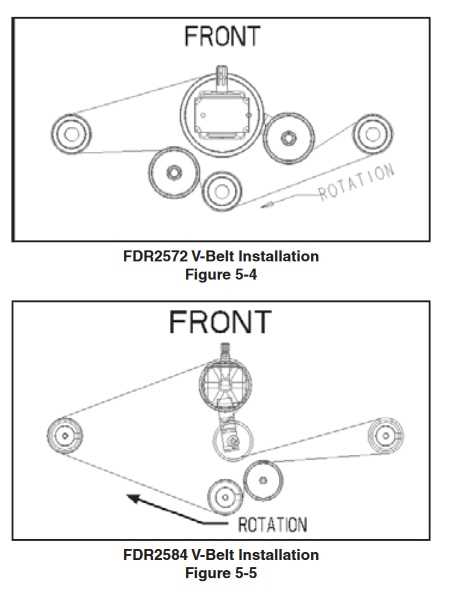

Assembly Guidelines for FDR1672

This section provides essential instructions for effectively piecing together components for optimal performance. Proper assembly is crucial to ensure functionality and longevity of the equipment.

Preparation: Before beginning the assembly process, gather all necessary tools and materials. Ensure that the workspace is clean and organized to prevent any loss of components.

Component Inspection: Examine each individual piece for any signs of damage or wear. It’s vital to address any issues before assembly to avoid complications during operation.

Assembly Steps: Follow the sequence outlined in the accompanying guide closely. Begin with the base structure, then progressively attach additional elements as specified. Utilize appropriate fasteners and tools to secure each connection.

Alignment: Ensure all components are properly aligned during assembly. Misalignment can lead to operational inefficiencies or potential breakdowns.

Final Checks: After the assembly is complete, perform a thorough inspection. Verify that all connections are secure and that there are no loose parts. It is advisable to conduct a preliminary test to ensure everything functions as intended.

Comparing Land Pride Models

This section explores various models from a well-known brand, highlighting their features, specifications, and differences. By examining these variations, users can make informed decisions based on their specific needs and preferences.

Each model offers unique capabilities, catering to diverse applications in agriculture and landscaping. Understanding these distinctions enables users to choose the most suitable equipment for their tasks.

Additionally, performance, durability, and ease of use are critical factors when comparing these options. Evaluating these elements helps potential buyers select machinery that aligns with their operational goals.

Frequently Asked Questions About FDR1672

This section addresses common inquiries regarding the specific model, providing clarity and insights into various aspects that users often seek. Below, we explore essential topics that can help enhance understanding and usability.

General Queries

- What is the primary function of this model?

- How does it compare to similar products?

- What are the most common issues users face?

Maintenance and Support

- How often should regular upkeep be performed?

- Where can I find replacement components?

- What resources are available for troubleshooting?