In the realm of transportation and logistics, the reliability of support structures plays a crucial role in ensuring safe and efficient operations. These systems are designed to provide stability and ease of movement, which are vital for various applications, especially in the heavy-duty sector. A thorough understanding of the key elements involved can greatly enhance functionality and performance.

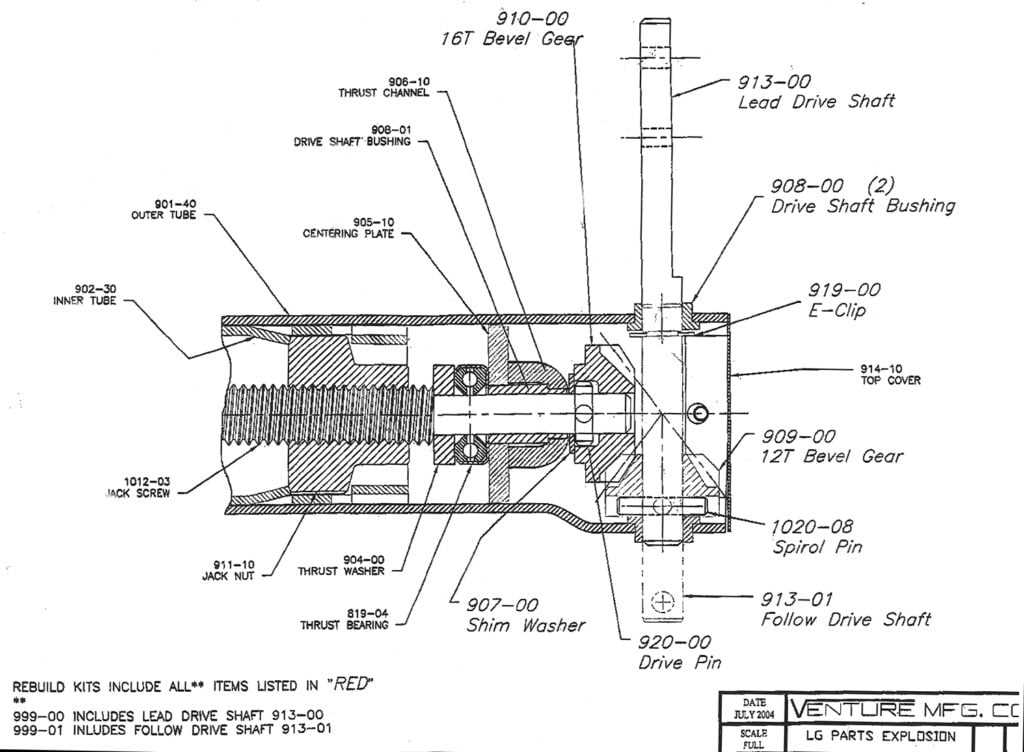

Exploring the different elements that contribute to these mechanisms reveals their intricate design and functionality. Each component is engineered to work in harmony, providing the necessary support and stability required for optimal performance. This knowledge is invaluable for anyone involved in maintenance, repair, or improvement of these essential systems.

Delving into the specifics of each component not only aids in troubleshooting and repairs but also empowers users to make informed decisions when selecting replacement items or upgrades. By familiarizing oneself with these essential elements, one can ensure that the entire system operates at peak efficiency, promoting safety and reliability in various operational contexts.

This section provides a comprehensive overview of the essential components that support the weight and stability of a specific type of vehicle used for transporting goods. Understanding the construction and function of these elements is crucial for anyone involved in the maintenance or operation of such vehicles.

1. The Importance of Stability

Maintaining stability is vital for safe transportation. Key features include:

- Preventing tipping during loading and unloading

- Ensuring balance while on the road

- Reducing wear on tires and suspension

2. Key Components Overview

This section highlights the main components involved in the structure, including:

- Support frame

- Adjustable legs

- Mounting brackets

- Locking mechanisms

Key Components of Landing Gear

The functionality and stability of a vehicle during stationary and motion phases depend on several crucial elements. Understanding these essential components is vital for ensuring the overall safety and performance of the structure. Each part plays a specific role in facilitating effective operation, especially when maneuvering over various terrains.

Wheels are fundamental components that provide support and mobility. They are designed to withstand significant weight while ensuring smooth movement. A well-engineered wheel system enhances traction and maneuverability, contributing to efficient navigation.

Support Legs are another critical feature, designed to sustain the weight of the vehicle when stationary. These structures provide stability, preventing unwanted tilting or shifting. Their robust construction ensures durability under various conditions.

Braking Mechanism plays an integral role in controlling movement. Effective brakes allow for smooth stopping and contribute to the safety of the overall system. Regular maintenance of this system is essential for reliable performance.

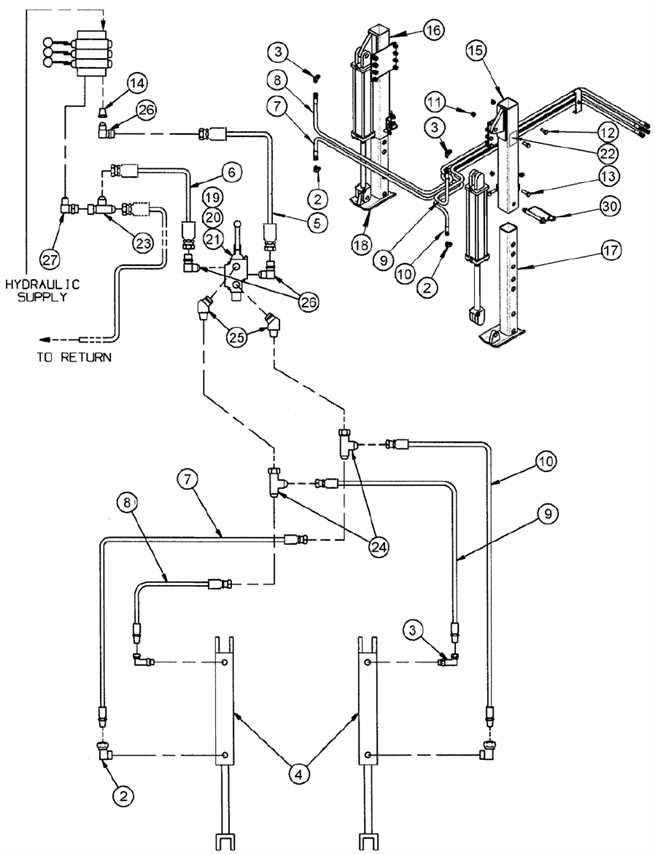

Hydraulic Systems are vital for operating the various functions of the assembly, including raising and lowering mechanisms. This system ensures that adjustments can be made quickly and efficiently, enhancing usability.

Each of these components works in unison to enhance the overall performance and safety of the vehicle, making their understanding essential for operators and maintenance personnel alike.

Functionality of Each Part

The various components of a support system play crucial roles in ensuring stability and maneuverability. Understanding the function of each element is essential for optimal performance and maintenance.

Support Frame: This is the foundation that provides overall strength and stability. It ensures that all components work in harmony, allowing for safe operation during use.

Wheels: The wheels facilitate movement, enabling easy transportation. They are designed to bear heavy loads while providing smooth navigation over various surfaces.

Locking Mechanism: This feature secures the assembly in place, preventing unintended movement. A reliable locking system enhances safety and stability, particularly when stationary.

Adjustment Handle: This element allows for easy height modification, ensuring compatibility with different vehicles. It enables users to achieve the desired position for effective utilization.

Shock Absorbers: These components minimize vibrations and impact during movement. They enhance comfort and protect the integrity of the entire system by absorbing shocks.

Brake System: This system is vital for controlling speed and ensuring safety during operation. Effective brakes allow for precise stopping, contributing to overall stability.

Common Issues with Landing Gear

In the realm of vehicle support systems, several frequent challenges can arise that may affect stability and performance. Understanding these issues is crucial for maintaining optimal functionality and ensuring safe operations.

1. Misalignment Problems

One of the primary concerns involves misalignment, which can lead to uneven weight distribution. This issue may cause excessive wear and tear on the structure, potentially resulting in failure during use.

2. Wear and Tear

Over time, components may experience deterioration due to regular use. This natural process can result in reduced efficiency and may require replacement or repair to ensure continued safety.

| Issue | Description | Potential Solutions |

|---|---|---|

| Misalignment | Uneven weight distribution affecting stability. | Regular inspections and adjustments. |

| Wear and Tear | Deterioration of components over time. | Timely replacements and maintenance. |

| Corrosion | Rust and deterioration due to exposure. | Protective coatings and regular cleaning. |

| Hydraulic Failures | Issues with fluid leaks or pressure loss. | Inspect seals and replace faulty components. |

Maintenance Tips for Longevity

Proper upkeep of your towing equipment is essential for ensuring durability and optimal performance. Regular maintenance not only enhances functionality but also extends the lifespan of your apparatus, preventing costly repairs and replacements. Here are some key practices to consider for long-term reliability.

Regular Inspections

Conducting frequent assessments of your equipment helps identify wear and tear before they become major issues. Pay attention to the following:

- Check for rust or corrosion.

- Inspect for loose connections and bolts.

- Examine moving components for signs of damage or excessive friction.

Lubrication

Keeping your equipment properly lubricated is crucial for smooth operation. Regularly apply suitable lubricants to:

- All pivot points to minimize friction.

- Chains or cables to ensure smooth movement.

- Bearings to reduce wear over time.

By adhering to these maintenance tips, you can enhance the longevity of your towing equipment, ensuring it remains reliable for all your hauling needs.

Choosing the Right Replacement Parts

When it comes to maintaining equipment used for transport, selecting appropriate components is essential for ensuring optimal functionality and safety. The process involves understanding various specifications and compatibility to avoid any issues that may arise during operation.

Start by assessing the specific requirements of your machinery. This includes evaluating the load capacity, material quality, and design features of the components. Choosing replacements that closely match the original specifications will help maintain performance standards and extend the lifespan of your equipment.

| Criteria | Considerations |

|---|---|

| Material | Durability and resistance to wear |

| Compatibility | Fit with existing systems and other components |

| Manufacturer | Reputation and warranty offered |

| Cost | Balance between quality and affordability |

In conclusion, thorough research and careful consideration are crucial when selecting components for your equipment. By focusing on quality and compatibility, you can ensure efficient and reliable performance for your operations.

Installation Process Overview

This section outlines the key steps involved in setting up the necessary components for effective support systems. A clear understanding of the installation procedure is essential for ensuring optimal functionality and safety.

The installation process generally involves several critical stages, including preparation, assembly, and adjustment. Each step requires careful attention to detail and adherence to guidelines to achieve a successful outcome.

| Step | Description |

|---|---|

| Preparation | Gather all required tools and components, ensuring everything is in good condition. |

| Assembly | Follow the outlined instructions to connect the various elements securely. |

| Adjustment | Make necessary modifications to ensure everything functions smoothly and safely. |

| Testing | Perform checks to confirm that the setup meets all operational standards. |

Safety Considerations During Use

Ensuring safety during operation is crucial to prevent accidents and injuries. Understanding the equipment’s functionality and adhering to recommended practices can significantly enhance the overall safety of any maneuver.

Prior to engaging in any activity, it is essential to inspect the apparatus thoroughly. Look for signs of wear or damage, and verify that all components are functioning properly. Regular maintenance plays a vital role in ensuring reliability.

It is also important to follow proper procedures when handling the equipment. Familiarize yourself with the operating instructions and adhere to weight limits. Utilizing appropriate protective gear can further safeguard against potential hazards.

Finally, maintaining awareness of your surroundings is essential. Ensure the area is clear of obstacles and that bystanders are at a safe distance to minimize the risk of accidents. Adopting these practices fosters a safer working environment.

Comparing Different Gear Types

When evaluating various mechanisms for support systems, it’s crucial to understand the characteristics and functionalities of each type. Different configurations can significantly influence the stability and ease of use in various applications. This analysis aims to highlight the distinctions and advantages of alternative systems, aiding users in making informed decisions based on their specific needs.

Hydraulic vs. Manual Systems

Hydraulic mechanisms are known for their efficiency and ability to handle heavy loads with minimal effort. These systems often allow for quick adjustments and are favored in demanding environments. In contrast, manual configurations rely on physical strength and may require more time for operation. While manual systems are typically more straightforward and less expensive, they can be less practical for frequent adjustments.

Single vs. Double Axle Configurations

Single axle setups are generally lighter and easier to maneuver, making them suitable for smaller applications. However, they may lack the stability required for heavier loads. On the other hand, double axle configurations provide enhanced support and balance, distributing weight more evenly. This can be particularly advantageous in larger setups where safety and stability are paramount.

Resources for Further Learning

Expanding your knowledge on the various components and mechanisms associated with mobile structures is essential for enhancing both performance and maintenance. Numerous resources are available to deepen your understanding and improve your skills in this area. From online platforms to literature, a wealth of information awaits those eager to learn.

Online Courses and Tutorials

Many websites offer courses that cover the essentials of structural components, including their functions and maintenance practices. Interactive tutorials can provide hands-on experience, making it easier to grasp complex concepts. Websites like Coursera, Udemy, and Khan Academy offer a variety of relevant courses tailored to different skill levels.

Books and Manuals

Comprehensive literature is another valuable resource. Books focusing on mechanical systems, maintenance manuals, and engineering principles can provide in-depth knowledge. Local libraries and bookstores often have sections dedicated to mechanics and engineering that can be highly beneficial for further study.

FAQs About Landing Gear Systems

This section addresses common inquiries regarding support structures for trailers, aiming to clarify their functionality and maintenance. Understanding these components is crucial for ensuring safe and efficient operation.

What are the main functions of support systems?

Support systems are designed to provide stability when stationary and facilitate smooth movement during transport. They play a vital role in distributing weight and enhancing overall safety.

How do I know if my support structure needs maintenance?

Regular inspections are essential. Signs of wear, unusual noises during operation, or difficulty in adjusting height may indicate the need for maintenance or replacement of components.

Can I perform repairs on my own?

Basic maintenance tasks, such as lubrication and tightening bolts, can often be handled independently. However, more complex repairs should be carried out by a professional to ensure safety and compliance with regulations.

What materials are commonly used in these systems?

Most structures are constructed from durable materials such as steel or aluminum, chosen for their strength and resistance to corrosion. These materials ensure longevity and reliable performance in various conditions.

How often should I inspect my equipment?

It is advisable to conduct inspections at least once a year or more frequently if the equipment is used extensively. Regular checks help identify potential issues before they escalate, ensuring safe operation.