In the world of outdoor maintenance, having a clear understanding of essential tools and their functionality can significantly enhance efficiency and performance. Each piece of equipment comprises various elements, each contributing to its overall effectiveness. This exploration delves into the intricacies of these components, shedding light on their roles and interactions.

When engaging in the upkeep of green spaces, recognizing how each segment operates is vital for optimal results. Whether it’s the mechanisms that drive movement or the systems that facilitate cutting, a comprehensive grasp of these elements empowers users to make informed decisions regarding maintenance and repairs.

Moreover, being familiar with the structure of these tools not only aids in troubleshooting potential issues but also enhances the overall experience of using them. By focusing on the individual elements and their collaborative functions, one can appreciate the artistry and engineering behind modern garden machinery.

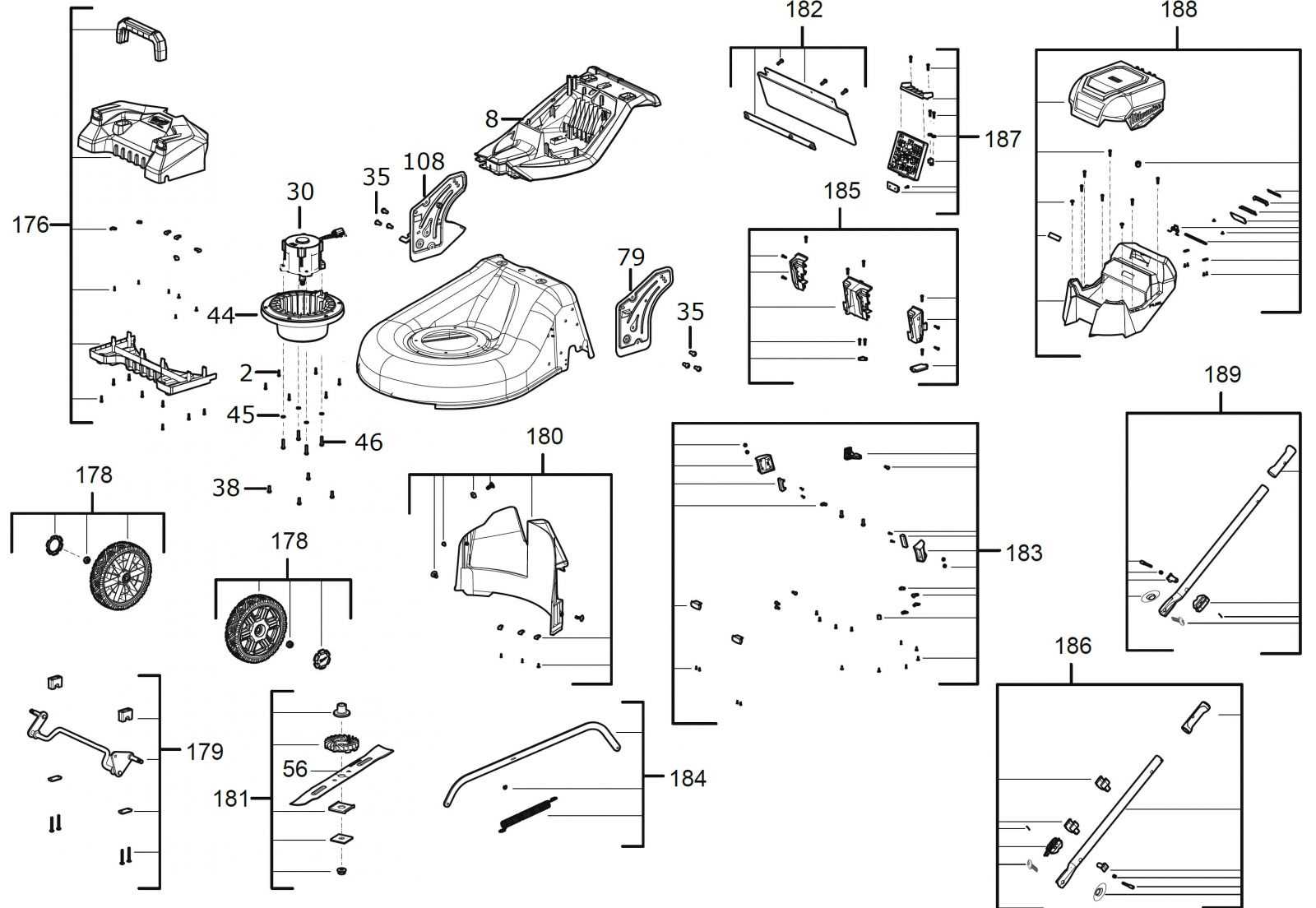

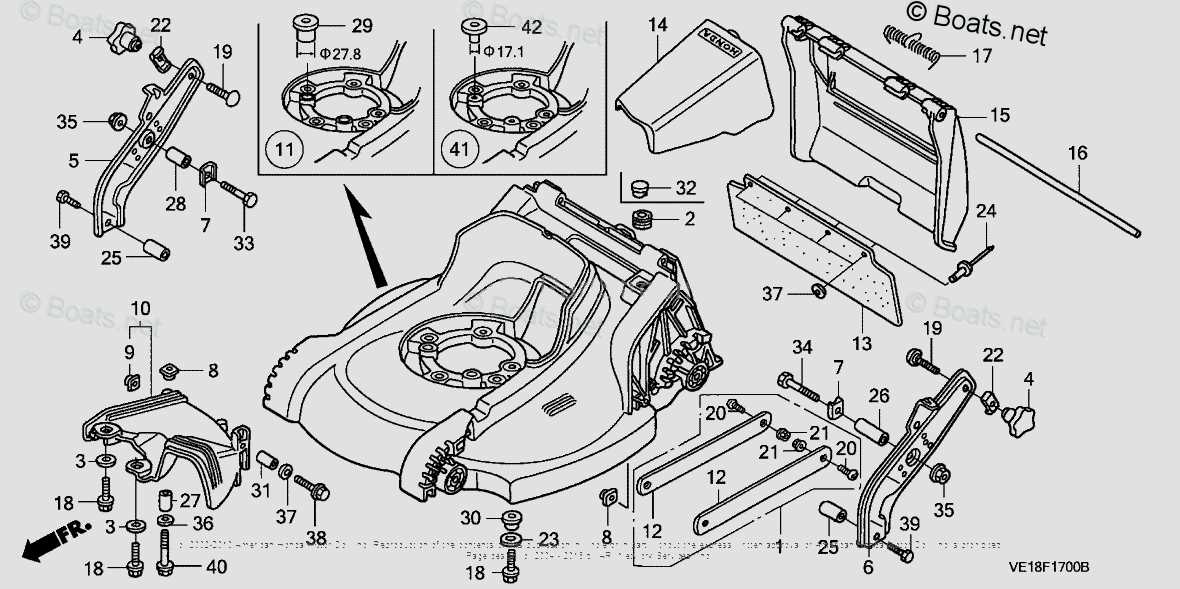

Understanding Lawn Mower Diagrams

Comprehending the layout of garden equipment is essential for effective maintenance and troubleshooting. Visual representations provide insights into the various components and their interactions, facilitating a better grasp of how everything works together to achieve optimal performance.

Key Components to Recognize

- Engine: The power source driving the machine.

- Blades: The essential tools for cutting grass.

- Chassis: The framework that houses all elements.

- Wheels: Provide mobility and support.

- Handle: Allows for steering and control.

Benefits of Familiarity

- Improved maintenance: Knowing where each part is located helps in routine checks and repairs.

- Enhanced troubleshooting: Understanding connections aids in identifying issues quickly.

- Informed upgrades: Awareness of components allows for smarter choices when enhancing equipment.

Overall, a solid understanding of the layout and function of each element empowers users to take better care of their tools and ensures a healthier, more vibrant outdoor space.

Essential Components of Lawn Mowers

Every machine designed for maintaining grassy areas is built upon a series of fundamental elements, each playing a crucial role in its overall functionality. Understanding these vital components helps in grasping how the equipment operates efficiently and effectively.

Engine is the powerhouse of the equipment, converting fuel into mechanical energy. Different models may utilize gasoline or electric systems, affecting performance and maintenance.

Blades are responsible for cutting the grass to the desired height. Their sharpness and design significantly influence the quality of the cut and overall appearance of the terrain.

Deck houses the blades and serves as the foundation of the device. Its shape and material can impact durability and maneuverability while ensuring the safety of users.

Wheels are essential for mobility, enabling smooth navigation across various surfaces. The size and tread pattern contribute to stability and traction during operation.

Handle provides control and steering, allowing users to guide the machine with ease. Ergonomic designs enhance comfort, especially during extended usage.

Fuel System includes components like the tank and carburetor, ensuring a steady supply of energy to the engine. Regular maintenance of this system is vital for optimal performance.

By familiarizing oneself with these integral elements, one can better appreciate the technology behind efficient grass management and enhance their overall experience with the equipment.

How to Read a Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. These illustrations provide a clear overview of the structure and function of various elements, allowing users to navigate and comprehend complex systems with ease.

First, familiarize yourself with the symbols and notations used in the illustration. Each icon typically represents a specific component or action, and recognizing these symbols is crucial for accurate interpretation. Pay close attention to any accompanying labels or legends, as they often provide valuable information regarding sizes, materials, or connections.

Next, observe the arrangement of elements. The layout can indicate relationships and sequences, guiding you through the assembly or disassembly process. Identifying how parts are interconnected helps in understanding their functionality within the entire system.

Finally, cross-reference the illustration with written instructions or manuals when available. This can enhance your comprehension and provide context that might be lacking in the visual alone. With practice, interpreting these representations will become a more intuitive skill, making your repair or maintenance tasks more efficient.

Common Parts and Their Functions

Understanding the key components of a grass-cutting machine is essential for effective maintenance and operation. Each element plays a crucial role in ensuring that the equipment runs smoothly and efficiently. Below is a list of frequently found components along with their specific functions.

- Engine: The power source that drives the entire machine, converting fuel into mechanical energy.

- Blade: The cutting implement responsible for trimming grass to the desired height.

- Deck: The housing that encases the blade and protects the user from debris.

- Wheels: Provide mobility and allow the equipment to traverse various terrains.

- Handle: The grip that enables the user to control and maneuver the machine with ease.

In addition to these main components, several other elements contribute to the overall functionality:

- Throttle Control: Regulates the engine speed, allowing for adjustments based on cutting conditions.

- Grass Catcher: Collects clippings during operation for easy disposal.

- Starter System: Facilitates the ignition of the engine, making it ready for use.

- Fuel Tank: Holds the necessary liquid for the engine’s operation.

- Chassis: The framework that supports all other components, ensuring structural integrity.

Familiarity with these essential elements can greatly enhance the user’s experience and prolong the lifespan of the equipment.

Maintenance Tips for Key Components

Proper upkeep of essential machinery elements is vital for ensuring optimal performance and longevity. Regular attention to these components can prevent costly repairs and improve efficiency. Below are some practical suggestions to keep your equipment running smoothly.

Regular Inspections

Frequent evaluations of critical elements can help identify potential issues before they escalate. Consider the following:

- Check for wear and tear on belts and cables.

- Inspect blades for sharpness and damage.

- Ensure that the fuel system is clean and free of debris.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is essential for functionality. Here are some steps to follow:

- Clean the exterior and interior surfaces to remove grass clippings and dirt.

- Apply lubricant to moving parts to reduce friction.

- Clear out air filters to promote better airflow.

By following these maintenance tips, you can enhance the reliability and efficiency of your equipment, ensuring it remains in top condition for years to come.

Identifying Replacement Parts Easily

Understanding how to pinpoint the necessary components for your equipment can save you time and frustration. By familiarizing yourself with the essential elements and their functions, you can streamline the process of locating suitable alternatives when repairs are needed. This guide will provide you with practical tips for quick identification, ensuring you make informed decisions.

Utilizing Resourceful Guides

Many manufacturers offer comprehensive manuals that include descriptions and images of the various components. These resources are invaluable for helping you recognize the specific elements you may need to replace. By consulting these guides, you can gain insights into the layout and function of each component, facilitating easier identification.

Consulting Online Forums and Communities

Online platforms and discussion groups can serve as excellent venues for advice and troubleshooting. Engaging with fellow enthusiasts or professionals can provide you with firsthand experiences and tips for identifying the right components. Make use of these resources to broaden your knowledge and connect with others who share similar interests.

Safety Features in Mower Design

In modern outdoor equipment, the emphasis on safety is paramount. Engineers incorporate various protective elements to ensure the user operates the device with minimal risk. These innovations not only enhance the overall experience but also contribute to a more secure working environment.

Blade Brake System: One of the most critical features is the blade brake system, which stops the cutting mechanism almost instantly when the user releases the handle. This quick response is essential for preventing accidents and injuries.

Operator Presence Control: Another important aspect is the operator presence control. This mechanism ensures that the equipment will not function unless the user maintains proper contact with the control handles, reducing the chance of unintentional activation.

Safety Guards: Additionally, safety guards are strategically placed around moving parts to prevent accidental contact. These shields help keep the user safe while allowing for efficient operation.

Ergonomic Design: Ergonomics also play a crucial role in safety. Devices designed with user comfort in mind help reduce fatigue, allowing for better control and handling during use.

By integrating these features, manufacturers prioritize user protection and contribute to a safer outdoor maintenance experience.

Electrical Systems Overview in Mowers

The electrical components of outdoor equipment play a crucial role in ensuring efficient operation and ease of use. These systems are designed to provide power and control mechanisms that enhance functionality, safety, and user experience. Understanding these elements is essential for maintenance and troubleshooting.

Power Supply: At the heart of the electrical framework is the power supply, which can be either battery-operated or corded. Battery systems offer portability, while corded versions provide continuous energy without the need for recharging.

Control Mechanisms: Various control systems are integrated to allow users to operate the machinery effectively. This includes switches, sensors, and electronic speed controllers that help regulate performance and ensure responsiveness to user inputs.

Safety Features: Safety is paramount, and electrical systems are equipped with features such as emergency shut-off switches and blade brake mechanisms. These elements work together to minimize risks during operation, providing peace of mind to users.

Maintenance Considerations: Regular maintenance of electrical systems is vital to prolonging the life of the equipment. This involves checking connections, replacing worn-out components, and ensuring that all systems are functioning as intended to prevent malfunctions.

In summary, the electrical systems in outdoor equipment are essential for optimal operation, user safety, and overall performance. Understanding their components and functions allows users to make informed decisions regarding maintenance and operation.

Types of Mower Engines Explained

Understanding the various types of engines used in cutting equipment is crucial for selecting the right model for your needs. Each engine type offers unique advantages and considerations, influencing performance, maintenance, and fuel efficiency.

-

Gasoline Engines:

These are the most common type found in cutting tools. They typically provide strong power and are suitable for larger areas. However, they require regular maintenance and fuel management.

-

Electric Motors:

Electric variants are becoming increasingly popular due to their quiet operation and reduced emissions. They are ideal for smaller yards and require less maintenance, though they may have limited power and runtime.

-

Battery-Powered Engines:

Similar to electric motors, battery-powered systems offer the convenience of portability without the need for cords. Advances in battery technology have improved their power and longevity, making them suitable for moderate tasks.

-

Diesel Engines:

These engines are typically used in commercial-grade equipment, providing exceptional durability and fuel efficiency. They are ideal for extensive or heavy-duty tasks, but they can be more expensive and require specific maintenance practices.

When choosing an engine, consider the size of the area to be maintained, frequency of use, and personal preferences regarding maintenance and environmental impact. Each type has its own set of characteristics that can significantly affect the overall experience of usage.

Cutting Deck: Structure and Purpose

The cutting deck serves as a fundamental component of a grass trimming machine, playing a crucial role in achieving an even and efficient cut. Its design and construction influence both performance and user experience, ensuring that the task is executed effectively.

Key aspects of the cutting deck include:

- Material Composition: Typically made from durable metals or high-quality plastics, the choice of materials affects longevity and weight.

- Shape and Size: Various shapes are optimized for different types of terrain, impacting maneuverability and cutting efficiency.

- Blade Configuration: The arrangement of blades within the deck is designed to maximize cutting power and ensure a clean finish.

- Height Adjustment Mechanism: This feature allows users to set the cutting height according to specific grass types and preferences.

- Ventilation Design: Proper airflow within the deck enhances cutting performance and prevents clumping.

The purpose of the cutting deck extends beyond mere aesthetics. Its primary functions include:

- Providing a stable platform for the blades to operate.

- Ensuring efficient grass collection and disposal.

- Facilitating easy navigation over varying landscapes.

- Enhancing overall machine stability and control.

Understanding the structure and function of the cutting deck is essential for users aiming to maintain their equipment and achieve optimal performance. A well-designed deck not only improves cutting quality but also contributes to the overall efficiency of the entire machine.

Wheels and Chassis: A Closer Look

The fundamental components of any outdoor maintenance equipment play a crucial role in its overall performance and functionality. Understanding these elements helps in appreciating their design and significance in achieving optimal results. This section will explore the construction and features that contribute to the efficiency and ease of use of these essential mechanisms.

Importance of Wheels

The wheels are not just mere accessories; they serve as the primary point of contact with the ground, influencing mobility and stability. Durability and traction are vital attributes, ensuring smooth navigation across various terrains. High-quality materials enhance longevity, while thoughtful tread patterns optimize grip, making it easier to maneuver in challenging conditions.

Chassis Design and Function

The chassis acts as the backbone of the entire structure, providing support and housing for other vital elements. A well-engineered frame contributes to the overall stability and balance of the equipment. Lightweight yet robust designs allow for easy handling without compromising strength. Additionally, the layout of the chassis can significantly affect the user experience, facilitating better control and operation.

Understanding the Fuel System Layout

The fuel system is a critical component that ensures the proper operation of any engine. It is designed to deliver a precise mixture of fuel and air to the combustion chamber, facilitating efficient performance and optimal power output. Understanding this layout can help diagnose issues and maintain the machine effectively.

Key Components of the Fuel System

Several essential elements work together within this system. Fuel tank stores the fuel, while the fuel pump transfers it to the engine. The fuel filter plays a vital role in ensuring that any impurities are removed before the fuel reaches the engine, protecting it from potential damage. Carburetors or fuel injectors then mix the fuel with air, creating the ideal ratio for combustion.

Importance of Regular Maintenance

Routine checks and maintenance of the fuel system can significantly enhance the performance and longevity of the engine. Regularly replacing the fuel filter and inspecting the fuel lines for leaks can prevent many common issues. Ensuring that the fuel remains clean and free from contaminants is crucial for the efficient operation of the entire system.

Importance of the Blade Assembly

The blade assembly is a critical component that significantly influences the performance and efficiency of outdoor maintenance equipment. It plays a vital role in achieving a clean and even cut, ensuring that the grass or vegetation is trimmed effectively. The precision of this assembly directly impacts the overall health and appearance of the landscape.

High-quality blades enhance the cutting process, reducing the effort required from the machine and prolonging its lifespan. A well-maintained assembly not only improves the aesthetics of the area but also supports the growth of healthy grass by minimizing damage during the cutting process. Regular inspection and replacement of the blades are essential to maintain optimal performance and to avoid unnecessary wear on the entire unit.

In summary, the blade assembly is indispensable for achieving outstanding results in outdoor maintenance. Investing in quality and proper maintenance of this component is essential for anyone looking to ensure their equipment operates at peak efficiency and delivers professional-grade results.