Maintaining your outdoor machinery is essential for optimal performance and longevity. A clear visualization of its structure can enhance your ability to diagnose issues and carry out repairs efficiently. This guide aims to break down the intricate elements that make up your mowing device.

By familiarizing yourself with these components, you’ll not only improve your troubleshooting skills but also gain confidence in handling maintenance tasks. Knowing how each part interacts allows for a deeper understanding of the overall functionality, ensuring a smoother operation in your gardening endeavors.

In this exploration, we will delve into the essential aspects and illustrate the connections between various segments. This knowledge serves as the ultimate foundation for any homeowner or professional looking to enhance their lawn care experience.

Understanding Harry Lawnmower Components

Gaining insight into the various elements that comprise a grass cutting machine can significantly enhance its performance and longevity. Each component plays a critical role in the overall functionality, and understanding these roles helps in effective maintenance and troubleshooting.

Key Elements of the Machine

- Engine: The heart of the equipment, providing the necessary power to operate.

- Blade: The cutting tool that determines the quality of the cut and affects the appearance of the lawn.

- Deck: The housing that contains the blade and engine, impacting durability and efficiency.

- Wheels: Essential for maneuverability and stability during operation.

- Fuel System: Responsible for delivering energy to the engine, which can include the tank, lines, and filter.

Maintenance Considerations

- Regularly check the engine oil and replace it as necessary to ensure optimal performance.

- Inspect the blade for sharpness and damage, sharpening or replacing it as required.

- Clean the deck to prevent grass buildup, which can affect performance.

- Examine wheels for wear and ensure they are properly inflated for better handling.

- Monitor the fuel system for leaks and ensure filters are replaced periodically.

By understanding these critical components, operators can ensure their equipment runs smoothly and efficiently, providing the best results for lawn care tasks.

Key Parts of Harry Lawnmowers

This section explores the essential components that contribute to the efficient operation of a popular grass-cutting machine. Understanding these elements is crucial for maintenance and optimal performance.

Engine: The heart of the machine, responsible for providing the necessary power. Regular checks on its condition ensure smooth functioning.

Blades: These are the cutting tools that create a clean finish. Keeping them sharp is vital for effective grass trimming.

Deck: This sturdy housing holds the engine and blades, protecting them from debris. A well-maintained deck contributes to longevity.

Wheels: Essential for mobility, they allow for easy maneuvering across various terrains. Checking their condition ensures stability and control.

Fuel System: This includes the tank and carburetor, supplying energy to the engine. Proper maintenance here can prevent performance issues.

By delving into these components, users can ensure their machine remains in peak condition for years to come.

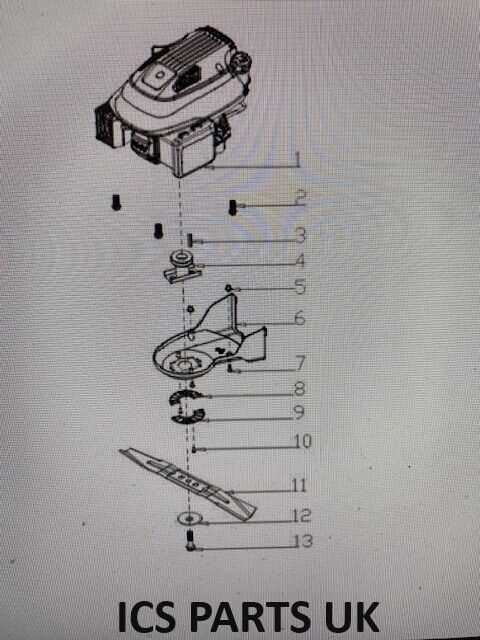

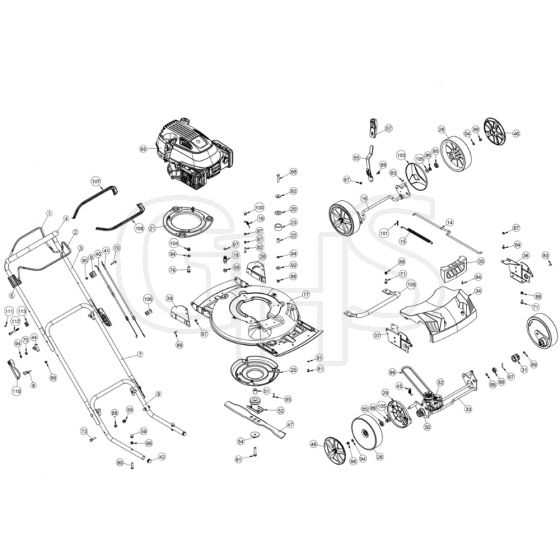

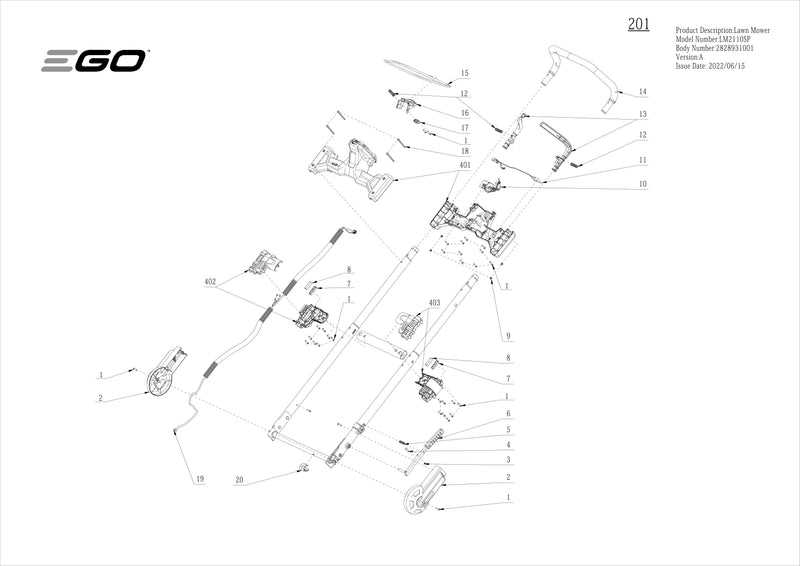

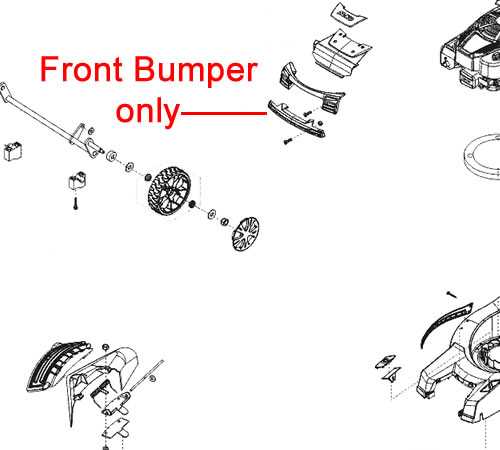

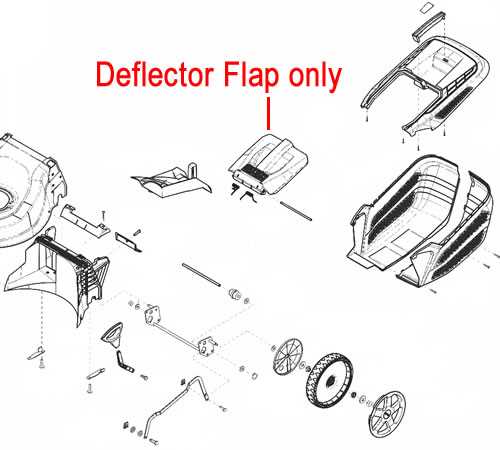

How to Read a Parts Diagram

Understanding a visual representation of components is crucial for effective maintenance and repairs. This overview will guide you through the essential elements and techniques to make the most of these illustrations.

Identify Key Elements

Begin by familiarizing yourself with the symbols and labels used in the illustration. Each element typically represents a specific component, often accompanied by a reference number that correlates to a list of items. This enables you to pinpoint exactly what you need for your task.

Follow the Flow

Pay attention to how the components connect and interact with each other. Understanding the relationships between parts can help you troubleshoot issues and ensure that replacements are executed smoothly, enhancing overall functionality.

Importance of Accurate Diagrams

Clear and precise visual representations play a crucial role in understanding complex machinery. They serve as essential tools for both novice users and seasoned professionals, ensuring efficient maintenance and repairs.

Here are several reasons why accuracy in these visuals is vital:

- Enhanced Understanding: Well-crafted illustrations simplify complicated components, making it easier to identify and locate specific elements.

- Effective Communication: Clear visuals foster better collaboration among technicians and users, minimizing misunderstandings during discussions.

- Time Efficiency: Accurate representations reduce the time spent searching for parts, allowing for quicker repairs and maintenance.

- Prevention of Errors: Detailed illustrations help prevent mistakes by providing precise guidance on assembly and disassembly processes.

- Training Aid: High-quality visuals serve as valuable resources for training new users, offering a clear reference for learning about machinery.

In conclusion, the significance of reliable visuals cannot be overstated, as they fundamentally enhance the overall experience of working with mechanical equipment.

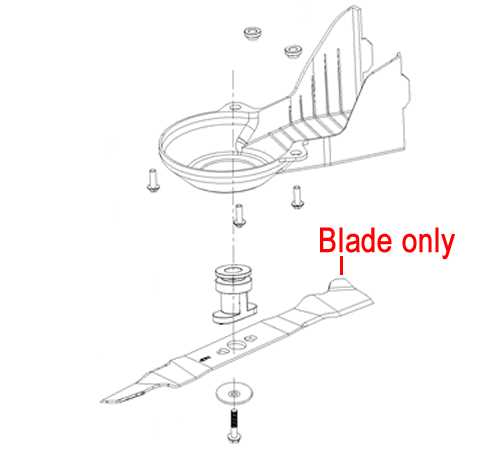

Common Replacement Parts Explained

Understanding the various components of outdoor maintenance equipment is essential for efficient operation and longevity. Over time, certain elements may wear out or require upgrading to ensure optimal performance. This section will outline some of the most frequently replaced components, highlighting their roles and the importance of timely replacements.

| Component | Description | Signs of Wear |

|---|---|---|

| Blades | Sharp edges that cut through grass efficiently. | Dullness, chipping, or uneven cuts. |

| Filters | Prevent dirt and debris from entering the engine. | Reduced airflow or increased engine strain. |

| Belts | Transfer power from the engine to moving parts. | Cracking, fraying, or slipping. |

| Spark Plugs | Ignite the fuel-air mixture for combustion. | Difficulty starting, rough idling. |

| Batteries | Power the electric components and ignition. | Slow starts, dim lights, or corrosion. |

Troubleshooting Lawn Mower Issues

When dealing with challenges in maintaining your outdoor equipment, identifying the root cause of the problem is crucial. Common difficulties can arise from various factors, including mechanical failures, fuel issues, or electrical malfunctions. Understanding these elements will help you restore functionality effectively.

Engine Won’t Start: If your machine is unresponsive, check the fuel level and ensure it is fresh. A clogged air filter may also impede operation, so inspect and replace it if necessary. Additionally, examine the spark plug for any signs of wear or damage.

Uneven Cutting: Inconsistent performance while trimming grass can often be attributed to dull blades or improper height settings. Regular sharpening and adjusting the cutting height can improve results significantly.

Excessive Vibration: If you notice unusual shaking during use, inspect for loose components or unbalanced blades. Tightening screws and ensuring blades are properly aligned can mitigate this issue.

Overheating: A machine that becomes too hot may indicate an oil deficiency or blockages in the cooling system. Check the oil level and clean any debris that might be obstructing airflow.

By systematically addressing these potential problems, you can enhance the performance and longevity of your outdoor equipment, ensuring it operates smoothly throughout the seasons.

Maintaining Your Lawnmower’s Efficiency

Ensuring optimal performance of your grass-cutting machine requires regular attention and care. This not only prolongs its lifespan but also enhances its effectiveness, saving you time and effort. A few simple practices can go a long way in maintaining functionality.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil to keep the engine running smoothly. |

| Blade Sharpening | Every season | Sharpen blades for a clean cut and reduced strain. |

| Filter Cleaning | Monthly | Clean or replace air filters to improve airflow. |

| Fuel Check | Before use | Ensure fresh fuel is available for efficient operation. |

By following these guidelines, you can delve deeper into the care of your equipment, ensuring it delivers ultimate performance every time you use it.

Where to Find Replacement Parts

Locating the necessary components for your equipment can seem daunting, but there are numerous avenues to explore. Whether you prefer shopping online or visiting local retailers, understanding where to search can save you time and ensure you find the right items to keep your machinery running smoothly.

Online Resources

The internet is a treasure trove of information and options. Numerous websites specialize in supplying components, offering detailed catalogs and diagrams to help you identify what you need. Additionally, online marketplaces often have listings from various sellers, allowing you to compare prices and find the best deals. Always ensure you are purchasing from reputable sources to guarantee quality.

Local Retail Stores

Your nearby hardware or home improvement store can be an excellent resource. Many of these retailers stock a range of components for various types of equipment. Furthermore, knowledgeable staff can assist you in finding the right items and may even offer insights into compatible alternatives. It’s also beneficial to check if they can order specific components that might not be in stock.

Tips for DIY Repairs

Undertaking repairs on your machinery can be a rewarding experience that saves time and money. With the right approach and knowledge, you can enhance your skills while ensuring your equipment operates smoothly. Below are some valuable suggestions to guide you through your repair journey.

Preparation is Key

Before diving into any maintenance task, make sure to gather all necessary tools and materials. A well-organized workspace minimizes distractions and increases efficiency. Here’s a checklist of essential items:

| Tool | Purpose |

|---|---|

| Wrenches | Tightening and loosening bolts |

| Screwdrivers | Adjusting screws and components |

| Pliers | Gripping and bending materials |

| Safety goggles | Protecting eyes during repairs |

Follow the Manual

Utilizing the manufacturer’s guide is crucial for understanding specific mechanisms. This resource often includes troubleshooting tips and detailed instructions that can ultimately prevent costly mistakes.

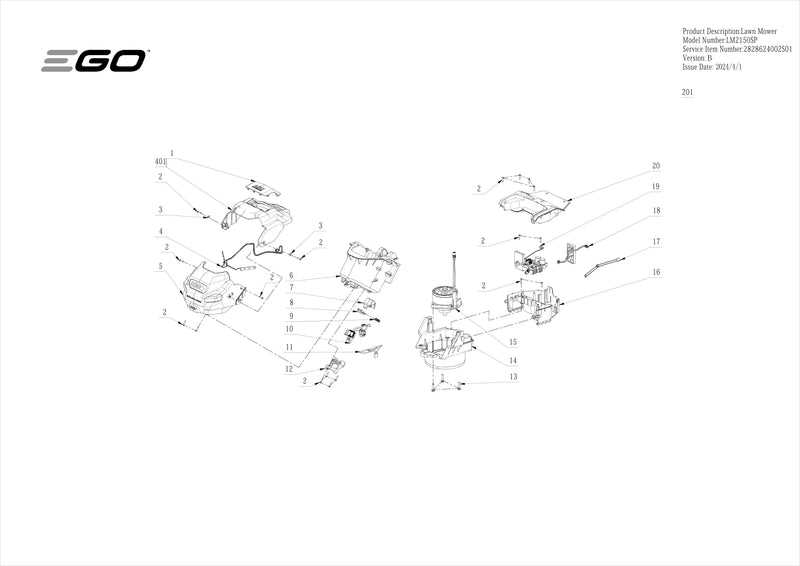

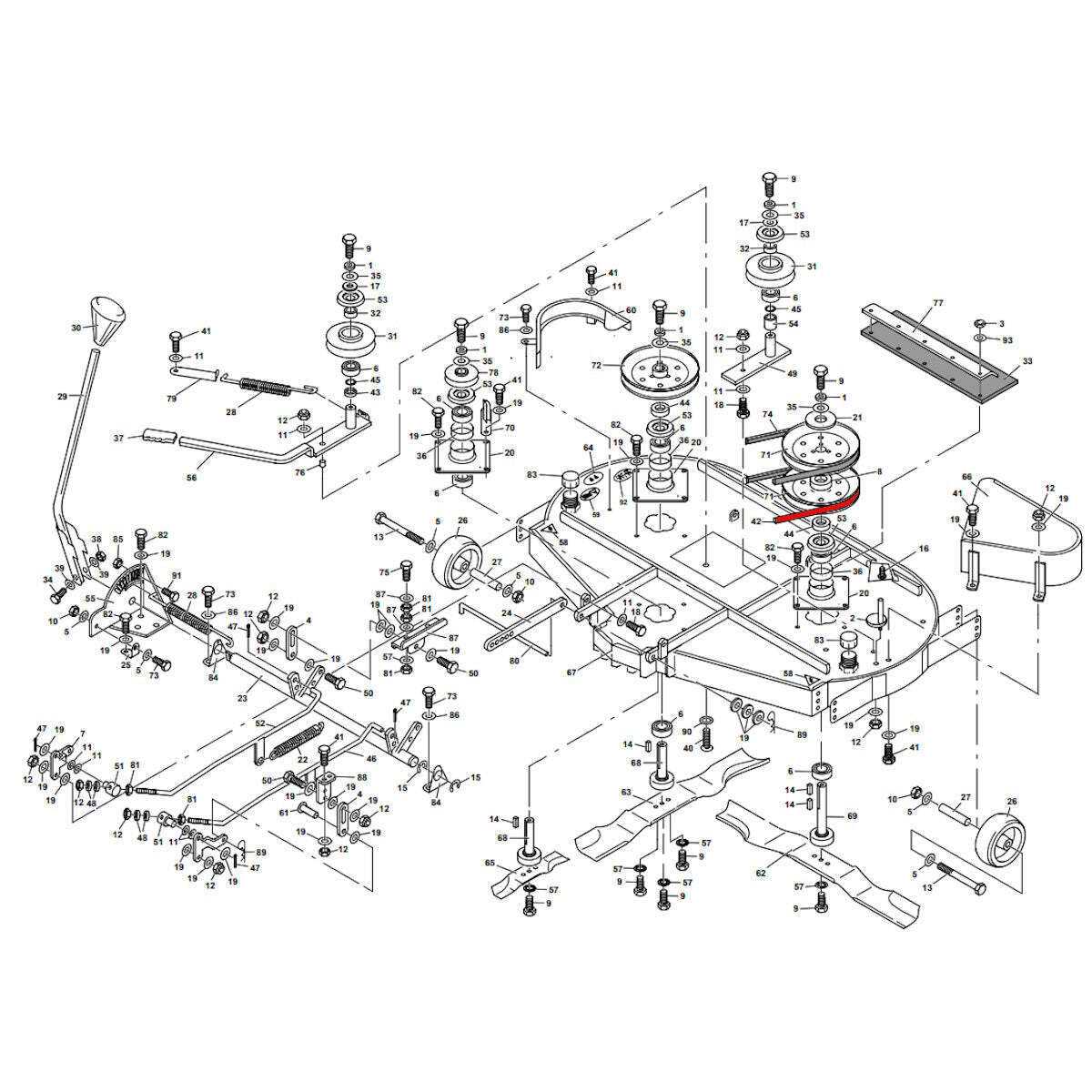

Understanding Lawn Mower Assembly

Assembling outdoor cutting equipment requires a clear comprehension of its various components and how they interconnect to function effectively. Each element plays a crucial role in the overall performance and reliability of the machine.

The core structure includes the frame, which serves as the foundation, supporting all other features. Understanding how these pieces fit together is essential for maintenance and repairs, ensuring optimal operation and longevity.

In addition to the main body, other vital components include the engine, blades, and transmission systems. Each of these parts contributes uniquely to the equipment’s capabilities, highlighting the importance of a thorough grasp of their functions and relationships.

By delving into the assembly process, users can identify potential issues and enhance their ability to manage upkeep effectively, ultimately improving the equipment’s lifespan and performance.

Safety Precautions for Maintenance

Proper upkeep of machinery is essential for optimal performance and longevity. However, it is crucial to prioritize safety during maintenance tasks to prevent accidents and injuries. Following specific guidelines can help ensure a secure working environment.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear.

- Ensure that the equipment is powered off and disconnected from any power source before beginning work.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Keep the workspace organized and free from clutter to prevent tripping hazards.

Additional Recommendations

- Read the manufacturer’s manual for specific safety instructions related to your machinery.

- Use tools that are suitable for the task to minimize the risk of injury.

- Never attempt to perform maintenance alone; always have someone nearby in case of emergencies.

- Dispose of any waste materials according to local regulations to maintain a safe environment.

Choosing the Right Tools for Repairs

Selecting the appropriate equipment for maintenance tasks is crucial for ensuring efficiency and effectiveness. The right instruments not only facilitate smooth operations but also enhance safety and prolong the life of the machinery.

Before embarking on any repair project, consider the following key factors:

- Type of Repair: Identify the specific issue that needs addressing. This will guide your choice of tools.

- Quality of Tools: Invest in durable and reliable equipment to avoid frequent replacements.

- Ergonomics: Choose tools that are comfortable to hold and easy to maneuver to reduce fatigue during repairs.

- Safety Features: Ensure tools have necessary safety measures to protect yourself while working.

Here are some essential tools to consider for various tasks:

- Wrenches: Useful for tightening and loosening bolts and nuts.

- Screwdrivers: Available in various sizes and types for different screw heads.

- Socket Sets: Ideal for fasteners in tight spaces.

- Multimeters: Essential for electrical diagnostics.

- Pliers: Versatile for gripping, bending, and cutting.

By thoughtfully selecting your tools based on these criteria, you can enhance your repair experience and achieve successful outcomes.