In the realm of outdoor upkeep, the functionality of your essential equipment relies heavily on the intricate assembly of its various elements. Each component plays a vital role in ensuring efficiency and effectiveness during use, making it crucial to comprehend how these parts interact.

Visualizing the layout of these integral elements can provide clarity and enhance your ability to maintain and repair your device. A detailed representation aids in identifying individual sections, streamlining the troubleshooting process, and facilitating smoother operation.

By exploring the arrangement of these crucial components, enthusiasts and professionals alike can ultimately enhance their understanding, leading to better care and performance of their outdoor tools. Let’s delve into the specifics and uncover the importance of each segment in achieving optimal functionality.

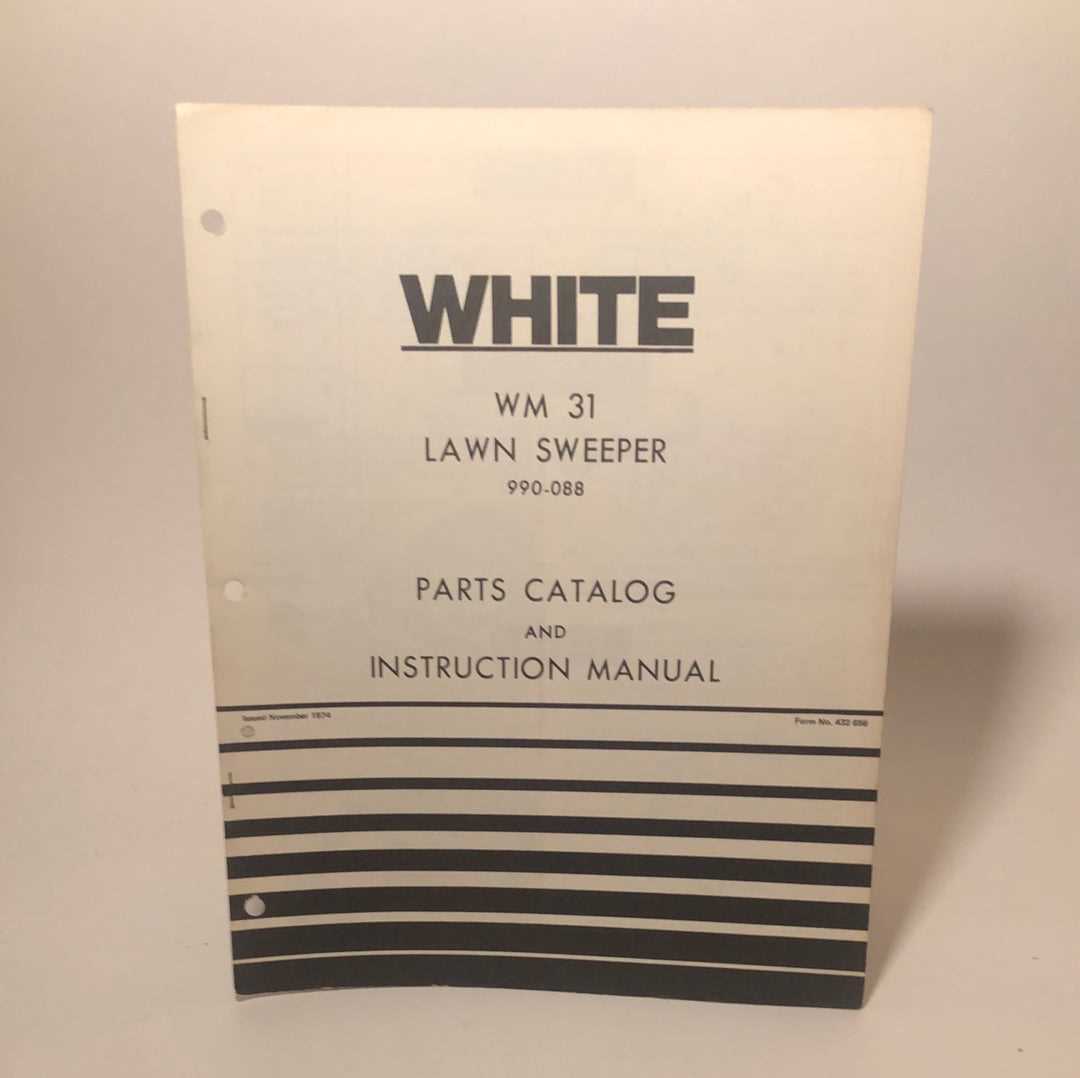

Lawn Sweeper Parts Overview

This section provides a comprehensive understanding of the various components that make up a turf-cleaning tool. Each element plays a crucial role in ensuring effective operation and optimal performance. By familiarizing yourself with these elements, you can enhance maintenance and troubleshooting efforts.

Essential Components

The primary elements include the collection mechanism, which gathers debris, and the frame that supports the entire structure. Other key parts include the wheels, which facilitate movement, and the drive system, ensuring smooth functionality.

Maintenance and Care

Regular inspection of these components is vital. Lubrication of moving parts and replacement of worn-out elements can significantly prolong the lifespan of your tool, keeping it efficient and reliable.

Understanding Lawn Sweeper Functionality

The mechanism designed for collecting debris from grassy areas operates through a series of coordinated components that ensure efficiency and ease of use. At its core, this equipment employs a rotating system to gather organic material while maintaining the integrity of the underlying surface.

Key elements include the collection bin, which plays a crucial role in retaining the gathered waste, and the brushes that facilitate the cleaning process. By utilizing a combination of motion and collection, this device effectively minimizes the effort required for yard maintenance.

To achieve the ultimate performance, regular maintenance and understanding of the individual components are essential. Familiarity with how these elements interact can enhance the overall effectiveness of the tool, ensuring that users can keep their outdoor spaces pristine with minimal hassle.

Common Components of Lawn Sweepers

Understanding the essential elements of these yard maintenance tools is crucial for effective operation and maintenance. Each component plays a significant role in ensuring efficient collection of debris and leaves, enhancing the overall functionality.

Key Elements

Among the primary features are the collection bag, which holds gathered materials, and the brush system, responsible for agitating and lifting debris. These parts work in tandem to optimize the performance and ensure thorough cleaning.

Additional Features

Another notable component is the frame, providing structural integrity and stability during use. Additionally, an adjustable hitch allows compatibility with various towing vehicles, enhancing versatility in yard care tasks.

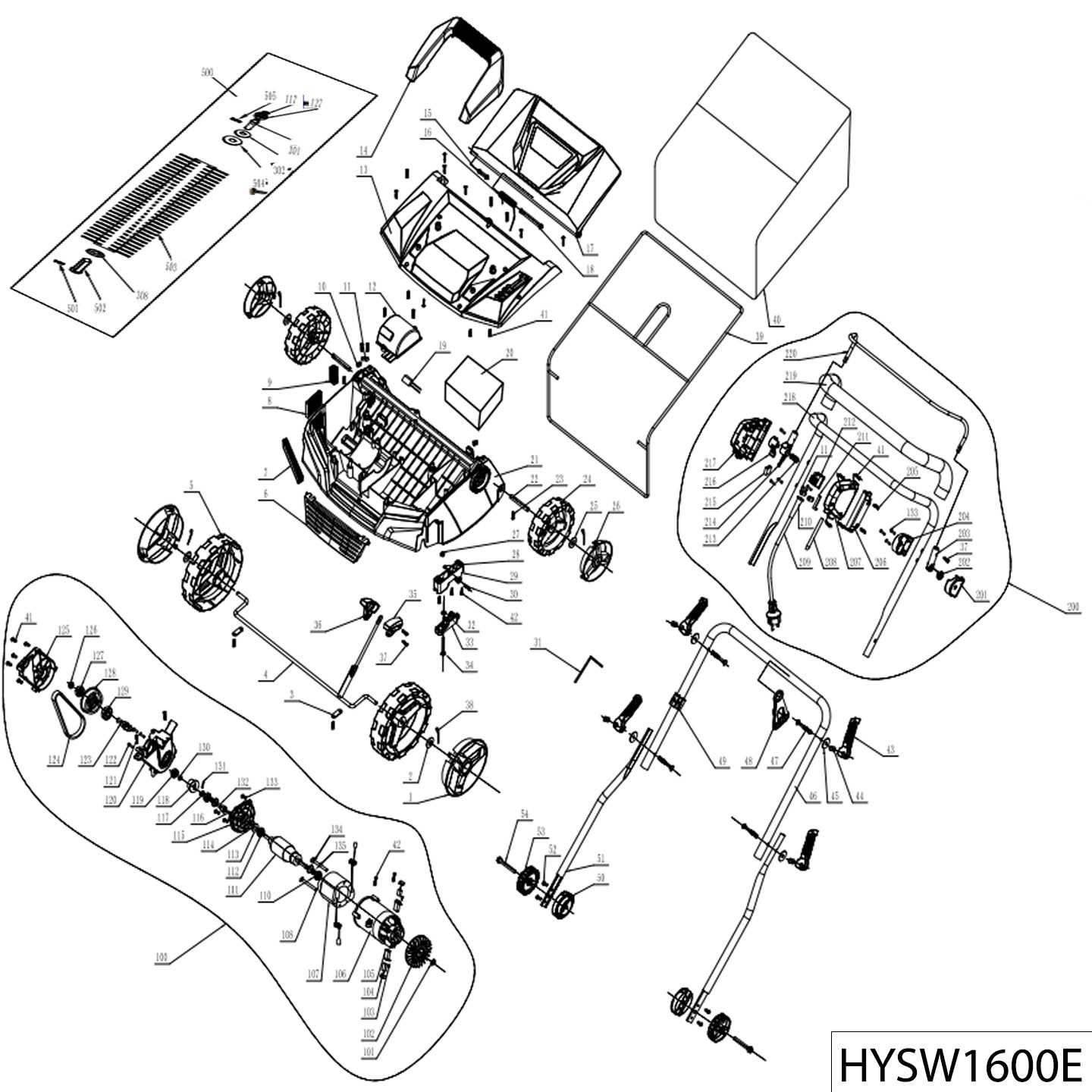

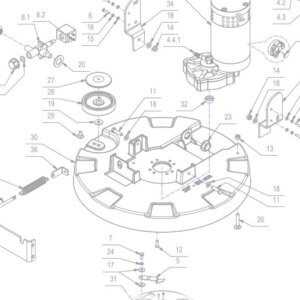

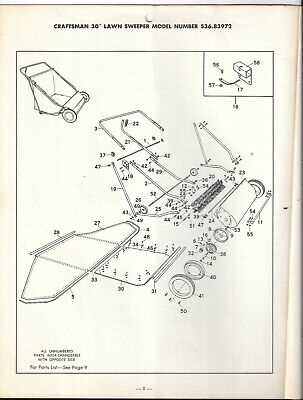

How to Read a Parts Diagram

Understanding an assembly illustration is crucial for effective maintenance and repairs. These visual guides offer a clear representation of components and their arrangements, making it easier to identify and replace parts when necessary.

Key Elements to Focus On

- Labels: Pay attention to the annotations that indicate specific items.

- Numbering: Look for sequential numbers that correlate with a list of parts.

- Shapes and Connections: Observe how items are connected and their respective shapes for proper identification.

Steps to Follow

- Start by familiarizing yourself with the entire layout.

- Identify the labels and corresponding numbers.

- Note any special symbols that indicate specific functions or conditions.

- Cross-reference with the parts list to ensure accuracy.

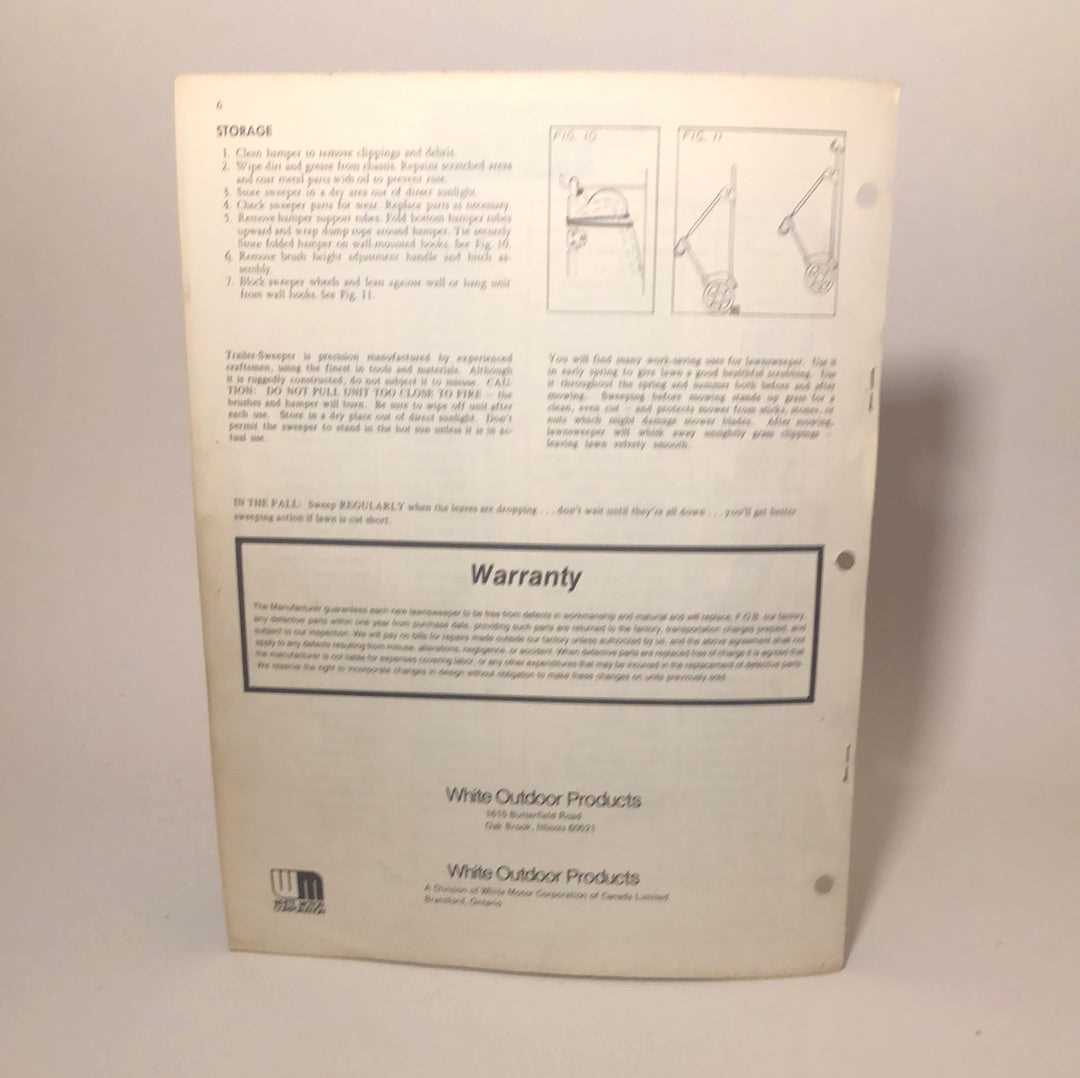

Maintenance Tips for Lawn Sweepers

Proper upkeep of your outdoor cleaning equipment ensures longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents unexpected breakdowns and costly repairs. Following a few simple guidelines can make a significant difference in the lifespan and functionality of your machinery.

1. Regular Inspection: Frequently examine your device for any signs of wear or damage. Pay attention to belts, brushes, and wheels, ensuring everything operates smoothly.

2. Cleaning: After each use, remove debris and buildup from all surfaces. A clean machine operates more effectively and reduces the risk of rust or corrosion.

3. Lubrication: Periodically apply lubricant to moving parts to minimize friction and wear. This will enhance performance and extend the life of critical components.

4. Storage: Keep your equipment in a dry, sheltered area to protect it from the elements. Proper storage prevents rust and deterioration.

5. Follow Manufacturer Guidelines: Always refer to the user manual for specific maintenance recommendations and intervals. Adhering to these instructions is crucial for achieving the best results.

By implementing these practices, you can ensure that your outdoor cleaning apparatus remains efficient and reliable for years to come.

Identifying Wear and Tear Signs

Understanding the indicators of deterioration is essential for maintaining your outdoor equipment effectively. Regular inspection can help you recognize when components are becoming less efficient or showing signs of damage. By being proactive, you can prolong the lifespan of your machinery and ensure optimal performance.

Common Indicators

Several telltale signs can signal that parts need attention. Look for excessive wear on surfaces that frequently come into contact with debris. Scratches, dents, or cracks may indicate that these elements are reaching the end of their functional life. Additionally, unusual noises during operation often point to misalignment or damage within the assembly.

Maintenance Tips

Regular maintenance can mitigate many issues associated with wear. Inspecting components for any signs of fatigue or damage after each use can help catch problems early. Moreover, keeping moving parts clean and lubricated reduces friction, ultimately enhancing their durability and performance.

Choosing Replacement Parts Wisely

When it comes to maintaining outdoor equipment, selecting suitable components is crucial for optimal performance and longevity. Understanding the intricacies of these elements can significantly impact functionality and efficiency. Making informed choices helps in avoiding unnecessary expenses and ensures reliable operation.

Researching Quality Options is the first step in this process. Look for reputable manufacturers and suppliers known for their durability and reliability. High-quality alternatives may have a higher upfront cost but often save money in the long run through decreased maintenance and replacement frequency.

Compatibility is another vital consideration. Always verify that the chosen component fits seamlessly with your existing machinery. Mismatched items can lead to further issues, affecting performance and potentially causing damage. Consult the user manual or seek expert advice when in doubt.

Furthermore, evaluating warranties can provide peace of mind. Components backed by solid guarantees often indicate a manufacturer’s confidence in their product. This assurance can be a deciding factor when faced with multiple options.

Lastly, reading customer reviews can offer valuable insights into the experiences of others. Feedback from fellow users can highlight both the strengths and weaknesses of specific choices, guiding you towards the most effective solutions.

Tools Needed for Assembly and Repair

Proper assembly and maintenance of your equipment require a specific set of tools. Having the right instruments on hand not only ensures efficiency but also enhances safety and precision during the process. Below are the essential tools that will facilitate both assembly and repair tasks.

Essential Tools

- Screwdrivers: A set of both flat-head and Phillips screwdrivers is crucial for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets will help in securing bolts and nuts.

- Pliers: Needle-nose and slip-joint pliers can be used for gripping, twisting, and cutting tasks.

- Hammer: A rubber mallet is ideal for gently tapping components into place without damaging them.

- Measuring Tape: Accurate measurements are essential for ensuring proper fit and alignment.

Additional Accessories

- Lubricants: Keep various lubricants handy to reduce friction and wear on moving parts.

- Cleaning Supplies: Rags and brushes are important for keeping components clean before assembly.

- Safety Gear: Always wear gloves and goggles to protect yourself during assembly and repairs.

Frequently Asked Questions on Parts

This section addresses common inquiries related to components and their functionalities. Understanding these elements can significantly enhance your experience and maintenance efforts.

Common Inquiries

| Question | Answer |

|---|---|

| What are the essential components for optimal performance? | Key elements include the collection system, driving mechanism, and adjustment features that work together to ensure efficiency. |

| How can I identify worn-out components? | Look for signs of wear, such as reduced efficiency or unusual noises, which indicate the need for replacement. |

Maintenance Tips

Regular checks and cleaning can prolong the lifespan of these essential elements. It’s advisable to consult the manual for specific care instructions.

Upgrading Your Lawn Sweeper Equipment

Enhancing your outdoor maintenance tools can significantly improve efficiency and performance. By focusing on key upgrades, you can ensure your equipment operates at its peak, making the chore of yard upkeep much simpler and more effective.

Choosing Quality Components

Investing in high-quality elements is crucial for durability and functionality. Look for robust materials and reputable brands that offer reliability and longevity in their offerings, ultimately providing a better return on investment.

Incorporating Advanced Features

Modern enhancements, such as ergonomic designs and innovative technology, can transform the user experience. Features like adjustable heights and improved collection systems will ultimately streamline your tasks, allowing for a more productive maintenance routine.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety is of utmost importance. Proper precautions not only protect the individual performing the work but also safeguard the equipment and surrounding environment. Awareness of potential hazards and adherence to safety guidelines are essential for a successful repair experience.

Always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear, to mitigate risks associated with sharp tools or moving parts. Before starting any maintenance, disconnect power sources and ensure that all components are secure to prevent accidental activation.

Maintain a clean workspace to avoid tripping hazards and keep tools organized. If working with chemicals or lubricants, follow manufacturer instructions and use them in well-ventilated areas. Taking these steps can significantly reduce the likelihood of accidents during repair tasks.

Lastly, consider having a buddy system in place, especially when handling heavy components. Having someone nearby can provide immediate assistance in case of an emergency, making repairs safer and more efficient.