Understanding the layout and structure of mechanical systems can be essential for maintaining and repairing outdoor tools. By studying various elements and their configurations, users can ensure efficient functionality and extend the lifespan of their machines. This section provides an insightful overview of how different mechanisms are organized and connected within a typical machine used for yard upkeep.

Exploring the relationship between different components will help you grasp the intricacies of the device, making it easier to troubleshoot and fix potential issues. The following information highlights the key sections and the role of each element, aiding both novice and experienced users in their maintenance tasks.

Classic Grass Cutting Machine Overview

The legacy of these timeless mechanical devices speaks to their durability and reliability, making them a staple in many households. Despite technological advancements, these traditional machines are still cherished for their straightforward operation and solid construction.

Key features of these machines include:

- Simple and effective engine design

- Robust build quality ensuring longevity

- Manually adjustable settings for different cutting heights

- Reliable drive mechanisms for consistent performance

With their proven track record, these machines continue to serve those who prefer a more hands-on approach to outdoor maintenance.

Identifying Key Components of Murray Mowers

Understanding the essential elements of a grass-cutting machine is crucial for its efficient operation and maintenance. These devices are composed of several interconnected mechanisms, each playing a vital role in ensuring the equipment runs smoothly and delivers the desired performance. Recognizing these fundamental parts allows users to troubleshoot issues effectively and keep the machine in good working order.

The engine serves as the powerhouse, driving the cutting mechanism and other mechanical systems. Attached to the engine is the fuel system, which supplies the necessary energy to keep the engine functioning. Additionally, a system of belts and pulleys helps transfer power from the engine to the blade, ensuring seamless operation.

The cutting blade, often located underneath the deck, is the primary component responsible for trimming the grass. The deck protects the blade and helps direct the cut material. Controls such as levers

Engine Parts and Their Functions

The internal components of small engines are critical to their overall performance and efficiency. Each element plays a vital role in maintaining the system’s functionality, ensuring that the machine operates smoothly and consistently under different conditions. Understanding the purpose and interaction of these components is key to maintaining and repairing the engine.

Key Components of the Engine

One of the essential components is the cylinder, which houses the piston. The piston moves up and down within the cylinder, creating the motion necessary for generating power. Another crucial part is the crankshaft, which converts the up-and-down motion of the piston into rotational energy. The flywheel helps regulate the engine’s speed, while the carburetor is

Understanding the Blade Assembly Mechanism

The blade assembly is a crucial component that ensures the efficiency of grass cutting. To comprehend how this system works, it is important to focus on how the cutting blade is connected and interacts with other elements, providing a smooth and balanced operation.

Blade Attachment and Mounting: The cutting element is securely fastened to a rotating spindle, which is powered by the engine. The connection must be tight to prevent wobbling, ensuring stability during rotation. Mounting bolts or fasteners play a key role in holding everything in place.

Balance and Sharpness: Maintaining a well-balanced blade is essential for efficient cutting and to avoid unnecessary wear on other components

Fuel System Breakdown and Maintenance

The fuel system plays a critical role in ensuring that the engine operates smoothly by delivering the necessary fuel mixture for combustion. Proper understanding of its components and regular upkeep can help avoid performance issues and prolong the engine’s lifespan.

Main Components of the Fuel System

- Fuel Tank: Stores fuel and ensures it is available for the system to function.

- Fuel Line: Transports the fuel from the tank to the engine.

- Fuel Filter: Removes impurities from the fuel to prevent damage to the engine.

- Carburetor:

Deck Structure and Adjustments

The framework of the cutting assembly plays a crucial role in the overall performance and efficiency of the machine. Understanding its components and the necessary adjustments can significantly enhance the cutting experience and prolong the lifespan of the equipment.

Key Components of the Framework

- Base Plate: Provides stability and supports other parts.

- Blade Housing: Encloses the cutting blade, ensuring safety during operation.

- Mounting Points: Connect various components, allowing for secure attachment.

- Adjustment Mechanisms: Enable users to modify height settings and blade positioning.

Adjustment Procedures

- Check the Level: Ensure the base is evenly positioned for optimal cutting.

- Adjust Blade Height: Use the adjustment mechanisms to set the desired cutting height.

- Inspect for Damage: Regularly check the housing and base for wear or cracks.

- Tighten Connections: Ensure all mounting points are securely fastened to avoid vibrations.

Troubleshooting Electrical Wiring Issues

When faced with electrical problems in machinery, it’s essential to methodically identify and resolve the issues. Understanding the basics of circuitry and connection points can greatly enhance the efficiency of your troubleshooting process. A systematic approach will help in pinpointing faults and ensuring that all components function correctly.

Start by inspecting the wiring for any visible signs of damage, such as fraying or exposed areas. Loose connections can also lead to intermittent issues, so ensure that all terminals are secure. Utilizing a multimeter can assist in checking for continuity and voltage at different points within the circuit.

If a specific component is malfunctioning, refer to the corresponding schematic for guidance. This will help you understand how each part interacts within the system. Pay special attention to switches and relays, as these are common culprits in electrical failures.

For persistent problems, consider consulting with a professional who can provide additional insight or assistance. Regular maintenance and checks can prevent many wiring issues from arising in the first place, ensuring smooth operation of your equipment.

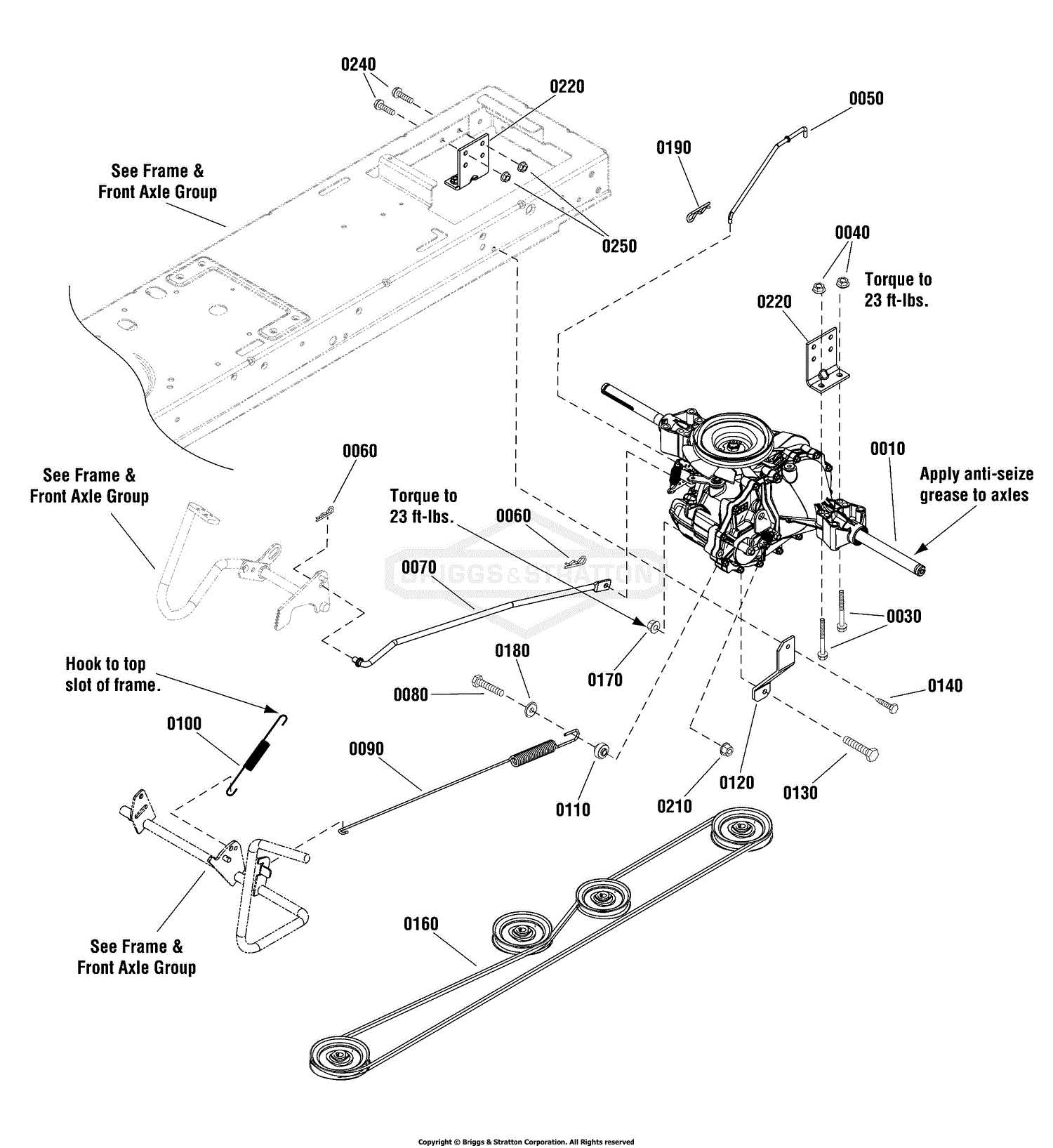

Transmission and Drive System Explained

The transmission and drive mechanism play a crucial role in the functionality of outdoor machinery. This system is responsible for transferring power from the engine to the wheels, ensuring efficient movement and operation. Understanding the components and their interactions can help users maintain and troubleshoot their equipment effectively.

Transmission Types typically include manual and automatic variations. Each type has its unique characteristics, offering different levels of control and responsiveness. Manual transmissions provide users with the ability to select gears based on the terrain and workload, while automatic systems adjust gears automatically, simplifying operation.

Drive Systems may involve several configurations, such as rear-wheel drive or front-wheel drive, influencing maneuverability and stability. The choice of drive system often impacts the overall performance and handling of the machinery, making it essential to select the right type for specific applications.

Replacing Worn-Out Belts and Pulleys

Regular maintenance of your equipment is crucial for optimal performance. One key aspect is ensuring that all moving components, such as belts and pulleys, are in good condition. Over time, these elements may wear down, affecting the overall efficiency and functionality.

Identifying the signs of wear is essential. Look for the following indications:

- Cracks or fraying on the belts

- Unusual noises during operation

- Slipping or loss of power

- Visible damage to pulleys

Once you’ve recognized worn components, follow these steps for replacement:

- Gather necessary tools, including a wrench set and replacement belts and pulleys.

- Disconnect the power source to ensure safety during the process.

- Remove the cover or casing to access the internal components.

- Carefully take out the old belts and pulleys, noting their arrangement for proper reinstallation.

- Install the new belts and pulleys, ensuring they are aligned correctly and securely fastened.

- Replace the cover or casing, and reconnect the power source.

- Test the equipment to confirm everything is functioning smoothly.

Regularly checking and replacing worn elements not only prolongs the lifespan of your equipment but also enhances its performance. Stay proactive to avoid unexpected breakdowns and ensure efficient operation.

Proper Care for the Cutting Deck

Maintaining the cutting deck of your equipment is essential for optimal performance and longevity. Proper care not only enhances the efficiency of the device but also ensures a clean and precise cut, contributing to a healthier appearance for your green spaces.

Here are some important steps to consider for effective maintenance:

- Regular Cleaning: Remove grass clippings and debris after each use to prevent buildup that can lead to corrosion.

- Inspect for Damage: Regularly check for cracks, dents, or other signs of wear that may affect performance.

- Sharpen Blades: Keep blades sharp to ensure a clean cut. Dull blades can damage the grass and create uneven surfaces.

- Lubricate Moving Parts: Apply appropriate lubricants to joints and pivot points to reduce friction and prevent wear.

- Check Fasteners: Periodically tighten screws and bolts to ensure that all components are securely attached.

By following these maintenance practices, you can enhance the efficiency and durability of your equipment, ensuring it operates effectively throughout its lifespan.

Restoring the Throttle and Control Linkages

Reviving the throttle and control mechanisms is crucial for ensuring optimal performance of your equipment. These components play a significant role in regulating power and responsiveness, making their restoration an essential task for enthusiasts and operators alike.

To effectively restore these systems, follow these steps:

- Assessment: Begin by evaluating the current condition of the throttle and control linkages. Look for signs of wear, damage, or corrosion that may affect functionality.

- Disassembly: Carefully disassemble the linkages to access all components. Take note of the arrangement for easy reassembly.

- Cleaning: Use a suitable solvent to clean each part thoroughly. Remove any dirt, grime, or buildup that could hinder movement.

- Inspection: Examine each component for signs of damage or excessive wear. Replace any broken or severely worn parts to maintain proper operation.

- Lubrication: Apply a light coat of lubricant to all moving parts to ensure smooth operation. Be careful not to over-lubricate, as excess can attract dirt.

- Reassembly: Reassemble the components according to your initial notes. Ensure that all linkages are connected properly for seamless operation.

- Testing: Once reassembled, conduct a test run to ensure everything functions as intended. Adjust as necessary for optimal performance.

By following these guidelines, you can successfully restore the throttle and control linkages, enhancing the efficiency and responsiveness of your machinery.

Common Upgrades for Old Murray Mowers

Enhancing the performance and efficiency of vintage grass cutters can significantly improve their usability and lifespan. Various modifications can be made to ensure these machines operate more smoothly and effectively, catering to the needs of modern users.

Below are some popular enhancements that can be implemented:

- Engine Tune-Up: Regular maintenance of the engine can lead to improved fuel efficiency and power output. This may include changing the spark plugs, air filters, and oil.

- Blade Replacement: Upgrading to high-quality blades can provide a cleaner cut, reducing the time spent on maintenance and improving the overall appearance of the yard.

- Deck Modification: Modifying the deck can improve airflow and cutting performance, allowing for better grass discharge and reduced clumping.

- Wheel Upgrades: Replacing old wheels with larger or more durable options can enhance maneuverability and stability on uneven terrain.

- Fuel System Enhancement: Upgrading the fuel system, such as installing a new carburetor, can optimize engine performance and ensure smoother operation.

- Lighting Installation: Adding lights can make it easier to operate the equipment in low-light conditions, extending its usability.

These upgrades not only enhance functionality but also contribute to a more enjoyable experience when using vintage equipment. Regular attention to these areas can lead to significant improvements in both performance and efficiency.