In the realm of outdoor maintenance, a comprehensive understanding of various machine elements is crucial for effective operation and maintenance. Whether you are a seasoned professional or a casual user, familiarity with the intricate layout and function of each component can enhance your overall experience. This section delves into the essential structures of a specific piece of lawn care machinery, shedding light on their roles and interconnections.

Identifying each segment allows for more efficient troubleshooting and repairs, ensuring that your equipment remains in optimal working condition. By grasping the relationship between different components, users can perform necessary adjustments and enhancements, ultimately leading to improved performance and longevity. Emphasizing the importance of a well-maintained machine, this discussion aims to equip you with the knowledge to navigate the complexities of your equipment with confidence.

Understanding Ryan Lawnaire IV Components

Grasping the functionality of the essential elements in a lawn care machine is crucial for effective maintenance and optimal performance. Each component plays a significant role in ensuring the equipment operates smoothly, making it vital to comprehend their individual purposes and interconnections.

Main Elements of the Equipment

- Engine: The power source that drives the entire unit, responsible for generating the necessary energy.

- Transmission: This mechanism transfers the power from the engine to the wheels, facilitating movement.

- Deck: The part of the machine that houses the cutting blades, designed for effective grass cutting.

- Wheels: Essential for mobility, allowing the device to navigate various terrains.

- Handle: Provides control and maneuverability, allowing the user to steer the equipment efficiently.

Importance of Each Component

- The engine is vital for starting and powering the device, directly affecting its efficiency.

- A well-functioning transmission ensures smooth operation and enhances the user experience.

- The deck’s design influences the quality of the cut and overall performance during use.

- Durable wheels contribute to stability and ease of movement across different surfaces.

- An ergonomic handle improves comfort and reduces fatigue during prolonged operation.

Understanding these core elements can lead to better upkeep practices and increased longevity of the machine. Each part must be regularly inspected and maintained to ensure seamless operation.

Key Parts of the Lawnaire IV

This section highlights the essential components of a specific turf maintenance machine, focusing on its functionality and design. Understanding these elements is crucial for effective operation and maintenance, ensuring optimal performance in various conditions.

- Engine: Powers the entire mechanism, providing the necessary energy for operation.

- Cutting Mechanism: Responsible for achieving the desired height and quality of grass. This element includes blades that must be kept sharp for efficiency.

- Chassis: The framework that supports all other components, offering stability and durability during use.

- Transmission: Facilitates the transfer of power from the engine to the wheels, enabling movement across different terrains.

- Fuel System: Comprises the tank and associated parts that ensure a steady supply of energy for the engine.

- Control Panel: The interface that allows the operator to manage settings and monitor performance metrics.

- Wheels: Designed for traction and maneuverability, essential for navigating various landscapes.

Each component plays a vital role in the overall effectiveness of the machine, making regular inspections and maintenance practices imperative for longevity and optimal functionality.

Functionality of Each Component

Understanding the role of various elements within a mechanical system is crucial for optimal performance and maintenance. Each component serves a specific purpose, contributing to the overall efficiency and effectiveness of the machinery. Below is a breakdown of the primary elements and their functions.

Main Elements

- Engine: The heart of the system, responsible for converting fuel into mechanical energy, enabling the machine to operate.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for controlled movement and speed adjustments.

- Control Mechanism: This element allows the operator to manage various functions, including speed, direction, and operational settings.

- Chassis: The framework that supports the structure and components, providing stability and strength during operation.

Supportive Components

- Wheels: Essential for mobility, enabling the system to navigate different terrains.

- Fuel System: Delivers fuel to the engine efficiently, ensuring optimal combustion and performance.

- Cooling System: Maintains the engine temperature, preventing overheating and ensuring longevity.

- Electrical System: Powers the various electronic components, including lights and control systems, enhancing functionality.

By comprehending the function of each component, operators can better maintain their equipment, ensuring it operates smoothly and efficiently over time.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your outdoor equipment. Regular attention not only enhances performance but also prevents potential issues that could lead to costly repairs. Implementing a few straightforward practices can ensure that your machinery remains in optimal condition for years to come.

Regular Inspections

Conducting frequent assessments of your equipment is crucial. Look for signs of wear and tear, and check fluid levels regularly. This proactive approach allows you to identify minor problems before they escalate into major malfunctions.

Cleaning and Storage

Keeping your machinery clean is vital for its longevity. After each use, remove debris and dirt to prevent buildup that can cause rust or corrosion. Additionally, proper storage in a sheltered environment protects it from harsh weather conditions, ensuring that all components function smoothly.

Common Issues and Solutions

When operating outdoor maintenance equipment, users may encounter various challenges that can affect performance and efficiency. Identifying these common difficulties and implementing appropriate remedies can enhance the longevity and functionality of the machine.

| Issue | Description | Solution |

|---|---|---|

| Engine Not Starting | The motor fails to ignite or run, leading to operational delays. | Check the fuel level and ensure the spark plug is clean and properly connected. |

| Uneven Cutting | The cutting mechanism produces an inconsistent result across the surface. | Inspect the blades for sharpness and ensure they are adjusted to the correct height. |

| Excessive Vibration | Unusual shaking during operation can indicate mechanical issues. | Examine all fasteners and components for wear and ensure they are securely attached. |

| Overheating | Components may become excessively hot, potentially leading to damage. | Ensure proper airflow around the engine and check for clogged filters or debris. |

| Battery Drain | Frequent need for recharging can signal electrical system problems. | Inspect the battery connections for corrosion and ensure all electrical components are functioning properly. |

How to Identify Replacement Parts

When seeking to replace components in any machinery, understanding how to accurately recognize the necessary items is crucial for effective maintenance and repair. This process involves several steps that ensure you obtain the right elements tailored to your specific equipment needs.

Assessing Compatibility

Start by evaluating the specifications of your device. This includes examining the model number and any identifying features that can help narrow down the options. Pay attention to the manufacturer’s guidelines, which often provide valuable information on suitable substitutes. This will assist in ensuring that the components you select will function correctly within the existing framework.

Consulting Resource Materials

Utilize manuals and online resources to find detailed descriptions and images of the required items. Reference guides often include diagrams and lists that can facilitate the identification process. Engaging with online forums and communities can also provide insights from other users who have faced similar challenges, offering recommendations based on their experiences.

Assembly and Disassembly Instructions

This section provides essential guidance for the proper assembly and disassembly of the equipment. Following these steps ensures safe handling and efficient operation, as well as facilitates necessary maintenance and repairs.

Before beginning, ensure you have the required tools at hand and work in a well-lit environment. Adhere to safety protocols to avoid any accidents during the process.

Assembly Steps

- Begin by laying out all components to ensure nothing is missing.

- Identify the main unit and connect it to the base securely.

- Attach any additional elements, such as handles or trays, as specified in the assembly instructions.

- Ensure all connections are tight and double-check for stability.

Disassembly Steps

- Unplug the unit from the power source before starting disassembly.

- Carefully remove any accessories or attachments.

- Loosen the connections between the main unit and the base using the appropriate tools.

- Take apart the components in reverse order of assembly, ensuring to keep screws and small parts organized.

After completing the assembly or disassembly, inspect all components for any wear or damage. Proper handling will prolong the life of the equipment and maintain optimal performance.

Importance of Regular Inspections

Conducting routine evaluations of equipment and machinery is crucial for ensuring optimal performance and longevity. These assessments help identify potential issues before they escalate into more significant problems, thereby minimizing downtime and repair costs.

Frequent examinations not only enhance safety but also improve efficiency by ensuring that all components are functioning correctly. When operators regularly check for wear and tear, they can address minor concerns proactively, which ultimately leads to a more reliable operation.

Moreover, regular inspections play a vital role in maintaining compliance with safety regulations and standards. Adhering to these guidelines protects both personnel and equipment, fostering a safer working environment. By prioritizing these evaluations, organizations can enhance their operational integrity and reduce the likelihood of accidents.

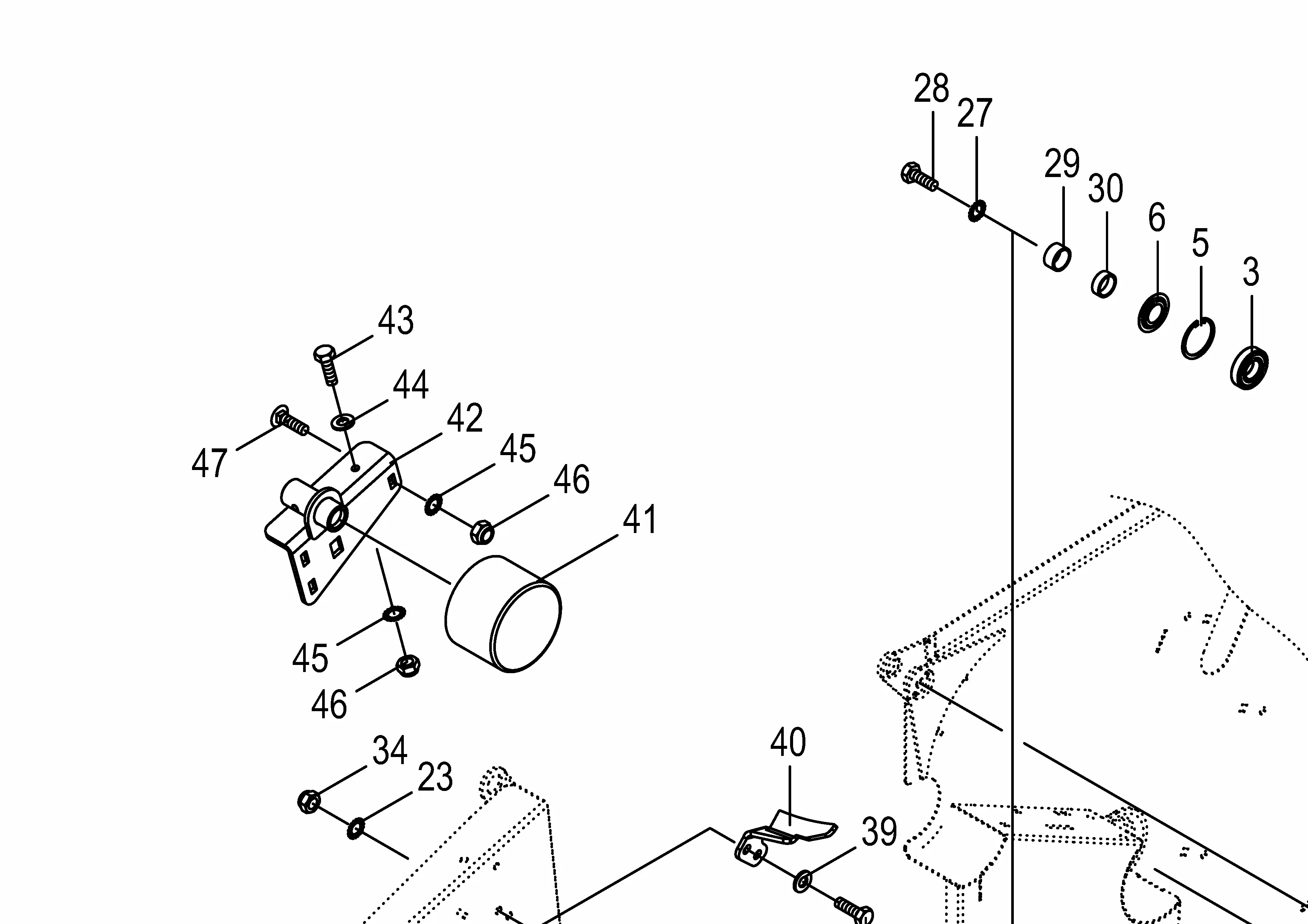

Parts Diagram Overview

This section provides a comprehensive understanding of the components involved in the machine’s structure. By exploring the various elements, users can gain insights into the assembly and functionality of the equipment.

Understanding the layout of these components is crucial for effective maintenance and troubleshooting. The illustration serves as a visual guide, highlighting the interrelationships between different sections and their respective roles. Here are some key aspects to consider:

- Component Identification: Recognizing each element allows for easier replacement and repairs.

- Assembly Insights: Knowledge of how parts fit together aids in reassembly after service.

- Maintenance Tips: Familiarity with the configuration can enhance upkeep routines and prolong equipment life.

In summary, this overview equips users with essential information to navigate the intricate network of components efficiently, ensuring optimal operation of the equipment.

Where to Purchase Replacement Parts

Finding quality components for your equipment can enhance its performance and longevity. Whether you are seeking items for routine maintenance or specific repairs, knowing where to acquire these essentials is crucial for any owner. Various sources offer a range of options, ensuring you can find what you need conveniently and efficiently.

Authorized Dealers

One of the most reliable avenues is through authorized dealers. These establishments provide genuine items that meet the manufacturer’s specifications, guaranteeing compatibility and durability. In addition, authorized dealers often have knowledgeable staff who can assist in identifying the correct items for your machine.

Online Retailers

The internet offers a vast selection of options, making it easy to locate specific components. Websites specializing in machinery supplies typically feature extensive inventories and detailed descriptions. Online shopping allows for convenient comparison of prices and availability, making it an excellent choice for those who prefer a hassle-free purchasing experience.

Benefits of Genuine Parts

Utilizing authentic components is essential for ensuring optimal performance and longevity of equipment. High-quality replacements offer numerous advantages that enhance functionality and safety. By choosing original items, users can avoid potential issues related to compatibility and reliability.

- Quality Assurance: Genuine components are manufactured to meet strict standards, ensuring they perform as intended.

- Enhanced Performance: Authentic items are designed specifically for your machine, contributing to better efficiency and effectiveness.

- Durability: Original parts are often more robust and resistant to wear and tear, leading to a longer lifespan.

- Warranty Protection: Many manufacturers offer warranties on their genuine components, providing peace of mind in case of defects.

- Safety: Using original items minimizes the risk of malfunction, which can lead to accidents and costly repairs.

In conclusion, opting for authentic components not only supports the longevity of your equipment but also ensures a reliable and safe operation. It is a wise investment that pays off in the long run.

Frequently Asked Questions About Parts

This section addresses common inquiries regarding components and their functionality in various machinery. Understanding these elements can significantly enhance your operational experience and ensure optimal performance. Below are some frequently asked questions that cover essential aspects and troubleshooting tips related to these crucial elements.

What Should I Consider When Replacing Components?

When looking to swap out any item, it’s vital to evaluate compatibility with your equipment model. Always refer to the specifications outlined by the manufacturer. Additionally, examining the quality of replacement options can prevent future complications and ensure durability.

How Can I Identify Specific Elements in My Equipment?

To pinpoint the right components, consulting a reliable reference source is essential. Manufacturer manuals often provide valuable insights and visual guides to aid in identification. Moreover, online forums and community groups can be beneficial for shared experiences and recommendations from fellow users.