The functionality of outdoor machinery relies heavily on the various components that make up its design. Familiarity with these elements not only aids in effective maintenance but also enhances the overall performance of the equipment. This section delves into the intricacies of essential parts and their interactions, providing a comprehensive overview for enthusiasts and professionals alike.

Recognizing each element’s role can significantly improve troubleshooting and repair efforts. By studying the arrangement and functionality of these components, users can gain insights into optimizing their equipment’s efficiency. Moreover, understanding how each part contributes to the machinery’s operation is vital for ensuring longevity and reliability in performance.

Through detailed exploration, this guide will assist users in identifying the various components, enabling them to tackle any challenges that may arise. Whether for routine maintenance or specific repairs, having a solid grasp of these mechanisms is crucial for any user looking to maximize the potential of their garden equipment.

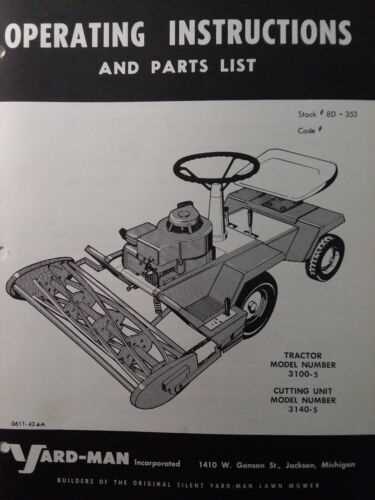

This section will provide a comprehensive overview of a specific type of outdoor equipment designed for grass maintenance. Understanding the various components of this machinery is essential for both novice users and experienced operators. This knowledge not only enhances the efficiency of the device but also facilitates effective troubleshooting and maintenance.

The following points will outline the key elements associated with the machinery:

- Introduction to the Equipment – Briefly explain the purpose and benefits of the equipment.

- Key Components – List the essential parts that make up the device.

- Functionality – Describe how each component contributes to the overall operation.

- Maintenance Tips – Provide guidelines for keeping the equipment in optimal condition.

- Common Issues – Identify frequent problems that users may encounter.

- Troubleshooting Steps – Offer solutions for resolving the identified issues.

- Replacement Parts – Discuss the availability and selection of spare components.

- Safety Precautions – Highlight necessary safety measures to follow during operation.

- Proper Usage Techniques – Share best practices for effective and safe usage.

- Storage Recommendations – Advise on how to store the equipment when not in use.

- Environmental Impact – Explore how the device can be environmentally friendly.

- Conclusion – Summarize the importance of understanding this machinery for enhanced user experience.

Essential Components of Lawn Mowers

Understanding the key elements of grass cutting machines is crucial for efficient maintenance and repair. Each component plays a significant role in ensuring optimal performance, longevity, and ease of use. Familiarity with these vital parts will help users troubleshoot issues and make informed decisions regarding repairs or upgrades.

The main components typically include:

- Engine: The heart of the machine, providing the necessary power to operate.

- Blade: Essential for cutting grass evenly and effectively.

- Deck: The housing that protects the internal parts while providing a platform for cutting.

- Wheels: Allow for mobility and maneuverability across various terrains.

- Handle: Facilitates control and navigation during operation.

Additionally, several other components contribute to the overall functionality:

- Fuel system: Supplies energy to the engine.

- Air filter: Keeps the engine clean by filtering out debris.

- Ignition system: Responsible for starting the engine.

- Transmission: Controls speed and direction.

Awareness of these crucial elements empowers users to ensure their machines operate smoothly and efficiently, ultimately leading to a more enjoyable experience.

Understanding the Cutting Mechanism

The cutting mechanism plays a crucial role in the efficiency and effectiveness of a grass maintenance tool. This system is designed to ensure that vegetation is trimmed accurately and evenly, contributing to a well-kept outdoor space. Understanding how this mechanism operates can help users maintain their equipment better and achieve optimal performance.

Key Components of the Cutting System

The cutting assembly comprises several essential components that work together harmoniously. Each part contributes to the overall functionality, enabling the tool to perform its task effectively.

| Component | Function |

|---|---|

| Blade | Responsible for cutting the grass at the desired height. |

| Deck | Houses the blade and provides a protective covering. |

| Drive System | Transfers power from the engine to the blade, allowing it to spin. |

| Height Adjustment | Allows users to set the cutting height according to preference. |

Importance of Maintenance

Regular maintenance of the cutting assembly is vital for ensuring optimal performance. This includes sharpening blades, cleaning the deck, and checking the drive system. By keeping these components in good condition, users can prolong the life of their equipment and achieve better results.

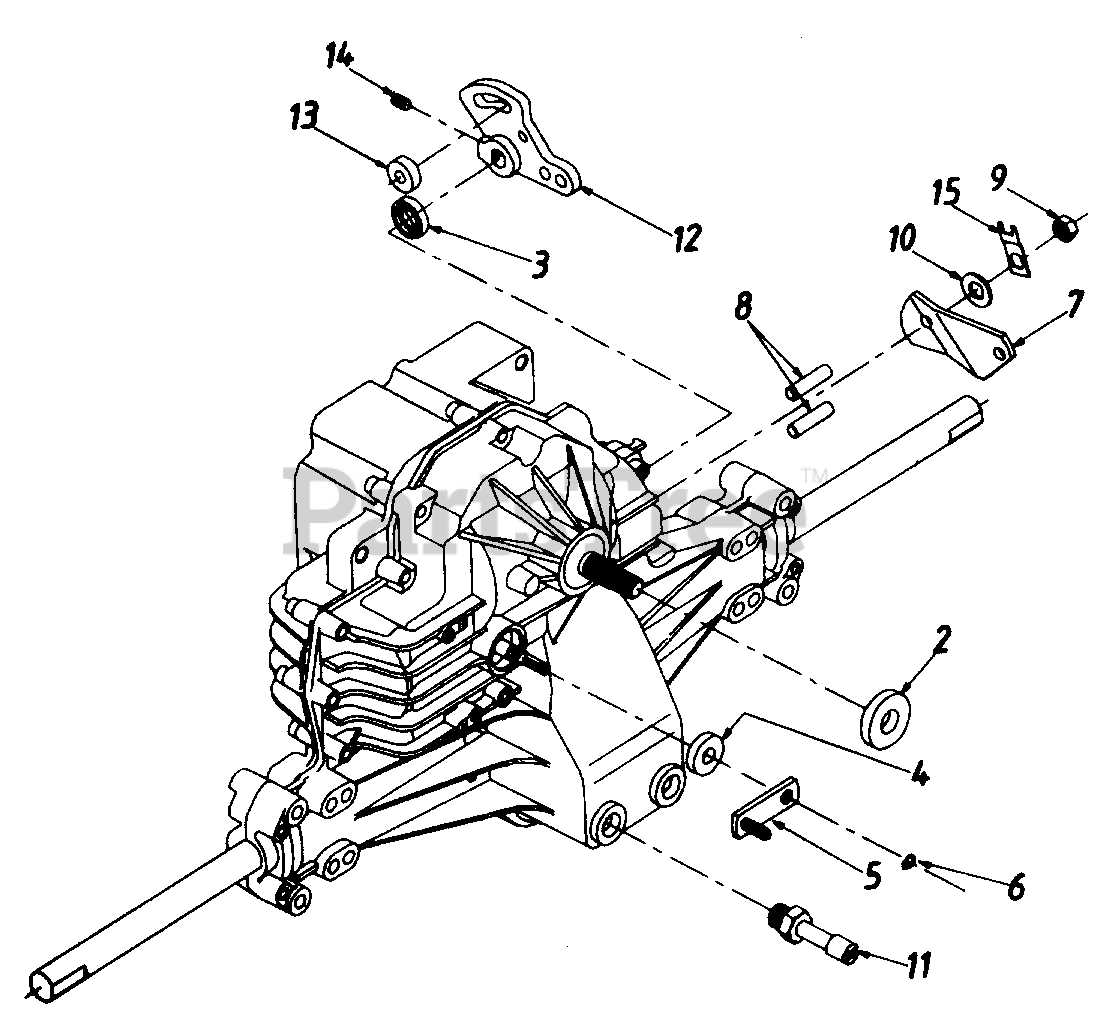

Identifying the Engine Parts

Understanding the components of a power unit is crucial for effective maintenance and troubleshooting. Familiarity with these elements allows users to recognize issues quickly and implement solutions to ensure optimal performance. This section will outline the key components typically found in such machinery.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix and are compressed for combustion. |

| Piston | A cylindrical piece that moves up and down within the cylinder, creating pressure. |

| Crankshaft | A rotating shaft that converts the linear motion of the piston into rotational motion. |

| Spark Plug | Generates a spark to ignite the fuel-air mixture in the cylinder. |

| Air Filter | Prevents dirt and debris from entering the engine, ensuring clean airflow. |

| Fuel Tank | Stores the fuel required for engine operation. |

Importance of the Deck Assembly

The deck assembly is a crucial component in the functionality and efficiency of any cutting machine. It serves as the primary housing for the cutting mechanism, ensuring that the blades operate optimally. A well-designed deck contributes significantly to the overall performance, durability, and user experience of the equipment.

Key Functions of the Deck Assembly

This structure plays several vital roles in the operation of the machine:

- Provides structural integrity and stability during use.

- Facilitates the efficient discharge of clippings, preventing clogging.

- Houses the blades securely, ensuring safety and effectiveness.

Maintenance and Care

Regular maintenance of the deck assembly is essential for optimal performance. Neglecting this component can lead to reduced efficiency and potential damage to other parts. Key maintenance tasks include:

| Task | Frequency | Description |

|---|---|---|

| Cleaning | After each use | Remove grass clippings and debris to prevent rust and corrosion. |

| Inspection | Monthly | Check for wear and tear, ensuring all fasteners are secure. |

| Lubrication | Seasonally | Apply grease to moving parts to maintain smooth operation. |

Maintenance of the Fuel System

Ensuring optimal performance of a small engine requires regular care of its fuel system. This aspect is crucial for preventing issues that can hinder efficiency and reliability. Proper maintenance not only prolongs the lifespan of the equipment but also enhances its functionality.

Here are some essential steps to maintain the fuel system:

- Inspect Fuel Lines: Regularly check for any cracks, leaks, or wear on the fuel lines. Replace any damaged components to prevent fuel loss.

- Clean the Fuel Filter: A clogged filter can restrict fuel flow. Clean or replace the fuel filter periodically to ensure smooth operation.

- Check Fuel Quality: Use fresh fuel and avoid using old or contaminated gasoline, as it can lead to performance issues.

- Inspect the Carburetor: Keep the carburetor clean and free from debris. Periodically remove it for a thorough cleaning to prevent blockages.

- Drain Old Fuel: If the equipment will be unused for an extended period, drain the fuel to prevent gumming and corrosion within the system.

Following these maintenance practices will help maintain the efficiency and reliability of your equipment’s fuel system.

How to Replace Blades Safely

Replacing the cutting components of your equipment is crucial for maintaining optimal performance and ensuring a clean finish on your turf. This task, while straightforward, requires careful attention to detail to avoid injury and guarantee the longevity of the device.

Before starting the replacement process, ensure the machine is powered off and completely cool. This step is vital to prevent accidental activation during the procedure. Gather the necessary tools, such as wrenches, safety gloves, and protective eyewear. Having everything prepared beforehand will make the task smoother.

Next, secure the

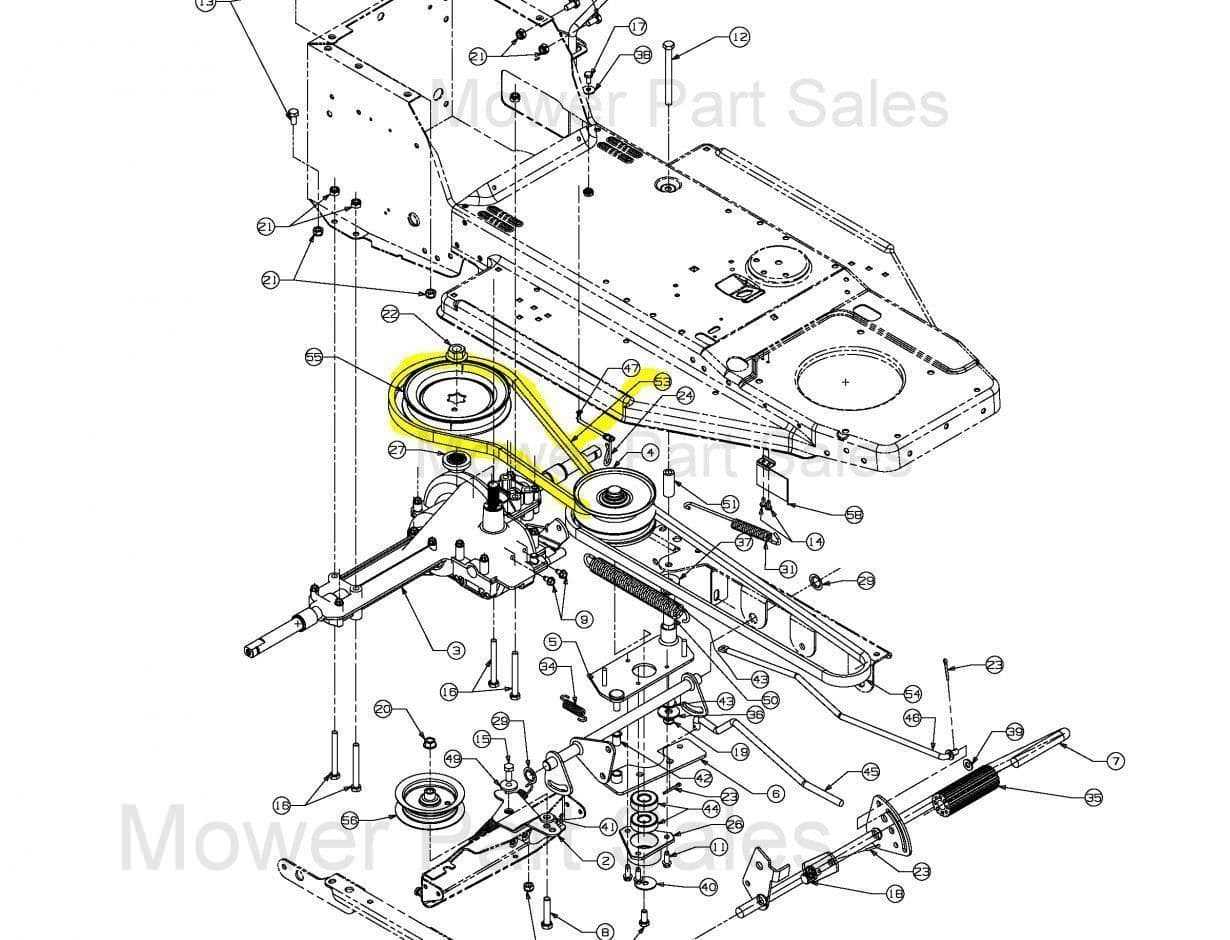

Overview of Drive System Components

The drive system plays a crucial role in the overall functionality of garden machinery, enabling efficient operation and optimal performance. Understanding the various elements involved in this mechanism is essential for maintaining and troubleshooting the equipment effectively.

The primary components of the drive system include the transmission, belts, and pulleys, each contributing to the seamless transfer of power from the engine to the wheels. The transmission regulates the speed and torque, allowing for smooth operation on different terrains. Belts serve as the flexible link, transferring motion between pulleys while absorbing shocks during operation.

Pulleys, strategically positioned within the system, facilitate the movement of belts and help maintain the appropriate tension. Additionally, various bearings and bushings support these components, ensuring minimal friction and wear during use. Regular inspection and maintenance of these parts are vital to prolonging the life of the machinery and enhancing its performance.

Wiring and Electrical Connections Explained

This section provides a comprehensive overview of the electrical systems and wiring components found in outdoor machinery. Understanding these connections is essential for proper maintenance and troubleshooting. Knowledge of how electricity flows through various components can help users ensure their equipment operates efficiently and safely.

Understanding Electrical Components

Various electrical components play a crucial role in the functionality of outdoor equipment. Below are key elements to familiarize yourself with:

- Battery: Supplies the necessary power to start the engine.

- Ignition System: Responsible for igniting the fuel-air mixture.

- Switches: Control the power flow to different parts of the machinery.

- Wires: Conduct electricity between components, ensuring seamless operation.

Common Wiring Issues

Being aware of typical wiring problems can aid in diagnosing issues effectively. Here are some common concerns:

- Loose Connections: Can cause intermittent power loss.

- Frayed Wires: May lead to shorts and potential equipment failure.

- Corroded Terminals: Impede electrical flow and reduce performance.

- Incorrect Wiring: Can result in malfunctioning components or safety hazards.

Regular inspections and maintenance of electrical connections are vital to prolonging the lifespan of outdoor machinery and ensuring optimal performance.

Common Troubleshooting Techniques

When facing issues with outdoor equipment, employing effective diagnostic methods can significantly streamline the repair process. Understanding how to identify and resolve common problems is essential for maintaining functionality and efficiency. Below are several techniques to assist in troubleshooting typical challenges encountered with garden machinery.

Visual Inspection

Start by conducting a thorough visual examination of the equipment. Look for signs of wear, damage, or loose connections. Pay attention to any abnormal components that may indicate underlying issues. This initial step can often reveal problems that require immediate attention.

Systematic Testing

Utilize a systematic approach to test different functionalities. Begin with the basic operations and progress to more complex functions. Checking fuel levels, battery condition, and electrical connections can help isolate the source of malfunction. If necessary, consult the user manual for specific troubleshooting steps related to the equipment.

Choosing the Right Replacement Parts

Selecting appropriate components for your gardening equipment is essential for maintaining optimal performance and extending its lifespan. Ensuring compatibility and quality will not only enhance functionality but also promote safety during operation.

When it comes to acquiring suitable replacements, consider the following factors:

- Compatibility: Always check that the component fits your specific model. Refer to the user manual or manufacturer’s website for detailed specifications.

- Quality: Opt for high-quality replacements to ensure durability. Genuine components or reputable aftermarket options are recommended.

- Reviews: Look for user feedback regarding the component’s performance. Ratings can provide insights into the reliability and effectiveness of the part.

- Warranty: Consider whether the replacement comes with a warranty. A guarantee can offer peace of mind regarding the product’s longevity.

By taking these aspects into account, you can make informed decisions that enhance the efficiency and safety of your gardening tasks.

DIY Repair Tips for Lawn Mowers

Maintaining your outdoor equipment can enhance its longevity and performance. Engaging in basic repairs can save you time and money while ensuring that your machinery operates efficiently. Here are some essential tips for tackling common issues effectively.

Routine Maintenance

Regular upkeep is crucial for preventing larger problems. Follow these steps:

- Check the oil level and change it periodically.

- Inspect and clean the air filter to ensure proper airflow.

- Sharpen or replace blades to maintain cutting efficiency.

- Examine belts and cables for signs of wear and replace as needed.

Troubleshooting Common Issues

Addressing common operational problems can often be done with simple adjustments:

- If your machine won’t start, ensure the fuel is fresh and the spark plug is clean.

- For uneven cutting, check the blade height settings and adjust accordingly.

- If overheating occurs, inspect the cooling fins and clean any debris.

Where to Find Parts Diagrams Online

Finding detailed illustrations for various equipment can be crucial for effective maintenance and repair. Several online resources provide comprehensive visual guides that assist users in identifying components and their specifications. These resources help streamline the process of troubleshooting and ensure that the correct elements are sourced for replacements.

Official Manufacturer Websites

One of the most reliable sources for visual guides is the official websites of manufacturers. These platforms often offer downloadable resources that include precise drawings and detailed information about each component. Users can easily navigate through sections dedicated to specific models and access user manuals, which typically contain clear visual references.

Online Forums and Community Groups

Engaging with online communities can also yield valuable information. Many forums dedicated to equipment enthusiasts allow users to share resources, including illustrations. Members often post links to useful sites or even upload their own diagrams. Participating in these discussions can provide insights from other users’ experiences, enhancing the knowledge base for maintaining and repairing equipment.