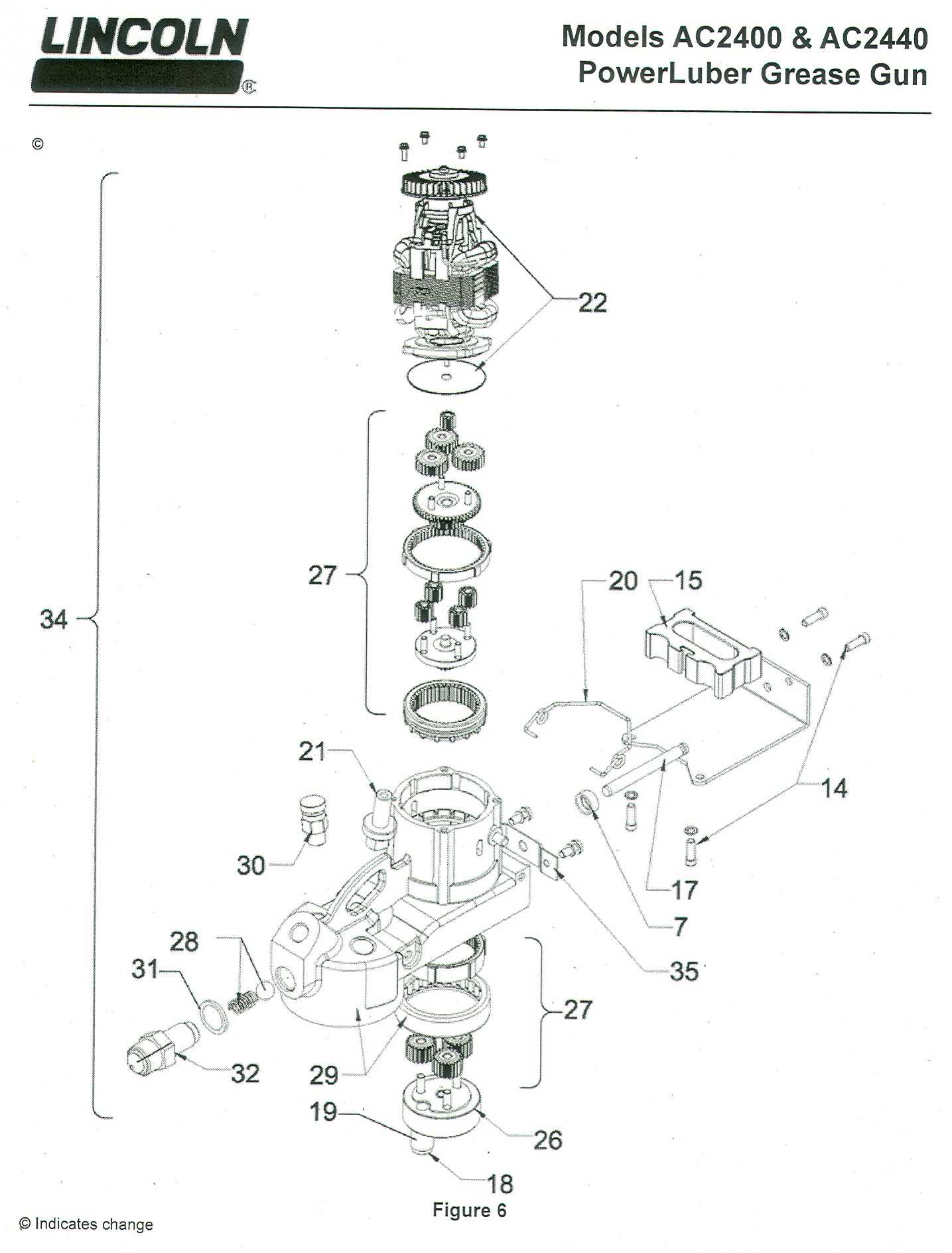

In any complex equipment, the arrangement and identification of individual elements play a crucial role in ensuring smooth functionality and effective maintenance. Each component within the system has its specific place and purpose, contributing to the overall performance. By studying the structure and placement of these elements, users can better navigate repair processes and routine upkeep, ensuring longevity and reliability of the machinery.

Familiarizing oneself with the internal layout helps in identifying critical connections and mechanisms. This knowledge provides insight into how different sections of the system interact with each other. Detailed visualization and proper categorization of these elements greatly facilitate troubleshooting and the replacement of malfunctioning parts, which is key to keeping the machine in optimal working condition.

Advanced Overview of the Power Arc 4000 Machine

In this section, we delve into a comprehensive overview of the sophisticated machinery known for its robust capabilities in industrial settings. This equipment stands out for its high-performance attributes, designed to handle various tasks with efficiency and precision.

Key Features and Functionalities

Delving deeper into its operational prowess, this apparatus integrates cutting-edge technologies that facilitate seamless execution of diverse operations. Its innovative design ensures optimal functionality across different environments, making it a preferred choice among professionals seeking reliability and versatility.

| 1. | Advanced Control Interface | A sophisticated control interface enhances user experience and operational control. |

| 2. | Durable Construction | Constructed from durable materials, ensuring longevity and resilience in demanding conditions. |

| 3. | Integrated Safety Features | Equipped with integrated safety features to ensure operator protection and equipment longevity. |

This overview highlights the multifaceted capabilities of this cutting-edge equipment, emphasizing its role as a pivotal tool in modern industrial applications. Its seamless integration of technology and durability sets a benchmark in the realm of industrial machinery.

Key Components of the Arc Welder

The structure of a welding device consists of several vital elements that ensure smooth operation and high efficiency. Each component has a specific role in the welding process, contributing to both safety and performance. Understanding these elements is crucial for proper maintenance and repair, as well as for achieving optimal results in various welding tasks.

Electrode Holder and Work Clamp

The electrode holder and work clamp are essential for completing the electrical circuit. The holder secures the consumable rod, while the clamp attaches to the metal surface, allowing current to flow. Both of these components must be checked regularly to ensure firm connections and prevent overheating.

Transformer and Cooling System

The transformer is responsible for converting the incoming electrical supply to a usable output for the welding process. Meanwhile, the cooling system ensures the internal parts remain at safe operating temperatures, protecting the unit from overheating. Proper maintenance of both is vital for ensuring long-lasting performance.

Understanding the Electrical System Layout

Exploring the arrangement of the electrical components is crucial for grasping how a welder operates effectively. This framework facilitates seamless interaction between various parts, ensuring optimal performance and safety during welding tasks. Familiarity with this layout can enhance troubleshooting and maintenance efforts, providing insights into potential issues and their resolutions.

Key Components and Their Functions

The primary elements in the electrical configuration include the transformer, rectifier, and control circuitry. Each component plays a vital role in converting and regulating the electrical current, thereby impacting the overall functionality. Understanding how these parts interconnect allows for a more thorough comprehension of the welding machine’s operation.

Safety Considerations

Breakdown of the Control Panel Functions

The control panel serves as the central hub for managing various operational features of the equipment. Understanding its components and their functionalities is crucial for optimal performance and efficient use. Each element plays a significant role in controlling settings and monitoring the system’s status, making it essential for users to familiarize themselves with this interface.

Key Components

Among the primary elements are the power switch, which activates the system, and the display screen that provides real-time feedback on performance metrics. Additionally, there are various knobs and buttons designed to adjust settings such as voltage and current levels, allowing for precise control over the operation.

Indicator Lights and Safety Features

Indicator lights are also vital; they offer immediate visual cues regarding the equipment’s operational status. Safety features, including emergency shut-off controls, are integrated to prevent accidents and ensure user protection. Understanding these functions can enhance safety and efficiency, making it easier to troubleshoot any issues that arise.

Cooling System Parts and Their Role

The effectiveness of a welding machine largely depends on its ability to maintain optimal operating temperatures. A well-functioning cooling mechanism is crucial for preventing overheating, ensuring longevity, and promoting reliable performance. Understanding the components of this system and their functions is essential for effective maintenance and troubleshooting.

Key Components of the Cooling Mechanism

The cooling assembly consists of several critical elements. Pumps circulate coolant, while heat exchangers dissipate excess heat. Fans enhance airflow, ensuring that the machine remains at a manageable temperature. Each component plays a vital role in sustaining the operational efficiency of the device.

Importance of Maintenance

Regular inspection and maintenance of the cooling system components can significantly prolong the life of the equipment. Keeping these elements clean and functional prevents blockages and failures, allowing for uninterrupted operation. A well-maintained cooling mechanism is the ultimate safeguard against overheating.

Detailed Look at the Engine Assembly

The engine assembly serves as the heart of any machine, translating fuel into mechanical energy. Understanding its components and how they interact is crucial for maintenance and performance optimization. This section will explore the various elements that comprise the engine assembly, shedding light on their functions and significance.

Key Components of the Engine Assembly

- Cylinder Block: The core structure housing the cylinders and providing support for other components.

- Pistons: These move up and down within the cylinders, converting pressure from combustion into mechanical work.

- Crankshaft: A vital part that transforms the linear motion of the pistons into rotational motion.

- Camshaft: Responsible for opening and closing the engine’s valves at the right moments.

- Valves: Control the intake of air and fuel as well as the expulsion of exhaust gases.

- Timing Belt/Chain: Ensures the synchronization between the crankshaft and camshaft.

Assembly Process Overview

The assembly of the engine involves precise coordination of each component. Here’s a brief outline of the process:

- Begin with the cylinder block, ensuring all surfaces are clean and free from debris.

- Install the pistons into their respective cylinders, using proper lubrication.

- Attach the crankshaft, ensuring it is securely fastened and aligned.

- Set up the camshaft in conjunction with the timing mechanism.

- Finally, install the valves and cover to complete the assembly.

Understanding these elements and their roles can significantly enhance one’s ability to troubleshoot issues and perform effective maintenance on the assembly.

Fuel System Components and Connections

The fuel system is crucial for the efficient operation of any machine, ensuring a steady supply of the necessary energy source for combustion. Understanding its various elements and their interconnections is essential for maintaining optimal performance and troubleshooting potential issues.

Key elements of the fuel system include the fuel tank, which stores the energy source, and the fuel pump, responsible for transferring the fuel to the engine. The fuel filter plays a vital role in removing impurities, while the fuel lines facilitate the flow between these components, ensuring a seamless supply.

Connections within the system must be secure to prevent leaks and maintain pressure. This involves using connectors and clamps that withstand varying temperatures and pressures. Regular inspection of these connections is crucial for safe and efficient operation.

In summary, the functionality of the fuel system relies on the proper interaction of its components. Familiarity with these parts and their connections is essential for anyone involved in maintenance or repair tasks.

Maintenance of the Power Output Sections

Regular upkeep of the energy delivery components is crucial for ensuring optimal performance and longevity. Neglecting these sections can lead to inefficiencies and potential failures. Proper maintenance not only enhances functionality but also contributes to safety during operation.

Routine Inspection

Frequent examinations of the output elements should be conducted to identify wear or damage. Check connections for corrosion and ensure that all components are securely fastened. Addressing minor issues promptly can prevent costly repairs later.

Cleaning and Lubrication

Maintaining cleanliness in the output sections is vital. Dust and debris can hinder performance. Use appropriate cleaning agents and lubricants as specified in the manual to ensure smooth operation. Regular maintenance will ultimately extend the lifespan of the equipment.

Commonly Replaced Parts in Arc 4000

In many welding machines, certain components tend to wear out over time, leading to the need for replacement. Understanding which elements are frequently changed can enhance maintenance efforts and extend the machine’s lifespan. This section highlights the essential items that often require attention and replacement in these devices.

Electrode Holder: This component is crucial for holding the electrode securely. Over time, it can degrade, leading to poor performance.

Ground Clamp: A reliable ground connection is vital for safety and efficiency. The ground clamp can become worn, impacting the overall function.

Insulation Liners: These protect internal components from heat and damage. They may need to be replaced as they degrade with use.

Circuit Boards: Essential for the machine’s operation, circuit boards can fail due to electrical surges or age, necessitating replacement.

Cooling Fans: Proper ventilation is necessary to prevent overheating. Fans can wear out, affecting cooling efficiency.

Regular maintenance and timely replacements of these components can significantly improve performance and durability, ensuring optimal operation.

Troubleshooting the Ignition Mechanism

Understanding and diagnosing issues with the ignition system is crucial for ensuring optimal performance of your equipment. Common problems can arise due to a variety of factors, and identifying these can help restore functionality quickly and efficiently.

Common Symptoms

When the ignition system malfunctions, you may notice several telltale signs. Here are some of the most frequent indicators:

| Symptom | Possible Cause |

|---|---|

| No spark | Faulty ignition coil |

| Intermittent spark | Worn ignition cables |

| Difficulty starting | Defective starter switch |

| Erratic performance | Contaminated fuel |

Troubleshooting Steps

To effectively address ignition-related problems, follow these steps:

- Inspect the ignition coil for any signs of damage or wear.

- Examine all connections and wiring for corrosion or loose fittings.

- Test the ignition switch to ensure it is functioning properly.

- Check the fuel supply and filter for obstructions.

Accessories and Attachments Compatibility

Understanding the compatibility of various accessories and attachments is essential for maximizing the functionality of your welding equipment. Ensuring that you select the right components can enhance performance and improve the overall user experience.

Key Accessories

- Electrode holders

- Ground clamps

- Gas hoses

- Welding helmets

Attachment Types

- Spool guns

- TIG torches

- Wire feeders

When choosing attachments, always consult compatibility charts to ensure optimal operation and safety.

How to Read a Parts Diagram Effectively

Understanding an illustration that outlines components can significantly enhance your repair and maintenance skills. Familiarity with symbols, labels, and their relationships will facilitate your ability to locate specific items and comprehend their functions. This knowledge is essential for ensuring proper assembly and troubleshooting.

Start by identifying the key elements in the visual representation. Look for a legend or key that explains the symbols used; this will provide clarity on what each symbol signifies. Pay attention to the layout, as it often follows a logical order that mirrors the assembly process.

Next, examine the connections between the different parts. Arrows or lines may indicate how components interact or are positioned relative to one another. Understanding these relationships is crucial for effective repairs. Take notes or highlight areas that require special attention during the reassembly process.

Finally, practice by referencing the illustration while working on the actual components. This hands-on approach will reinforce your understanding and build confidence. With time and experience, interpreting such visuals will become an intuitive skill.