The exploration of intricate layouts within various systems offers valuable insights into their functionality and design. By visualizing these configurations, we can enhance our comprehension of how individual elements interact to form cohesive units. This knowledge is crucial for anyone involved in the maintenance or innovation of technological solutions.

In-depth examination of these illustrations reveals the relationships between different units, enabling more efficient troubleshooting and optimization. Through systematic analysis, one can identify areas for improvement and potential upgrades, ultimately leading to superior performance.

Moreover, understanding these configurations not only aids in practical applications but also sparks creativity in design. By delving into the specifics, engineers and enthusiasts alike can push the boundaries of what is possible, fostering advancements in the field.

Understanding Green Machine Components

This section aims to explore the essential elements that contribute to the functionality and efficiency of eco-friendly equipment. By breaking down these components, we can appreciate their roles and the synergy between them.

Key Elements

- Power Systems

- Control Units

- Structural Framework

- Transmission Mechanisms

Functionality and Efficiency

- Power Systems generate and distribute energy effectively.

- Control Units manage operations and ensure precision.

- Structural Framework provides stability and support.

- Transmission Mechanisms facilitate movement and functionality.

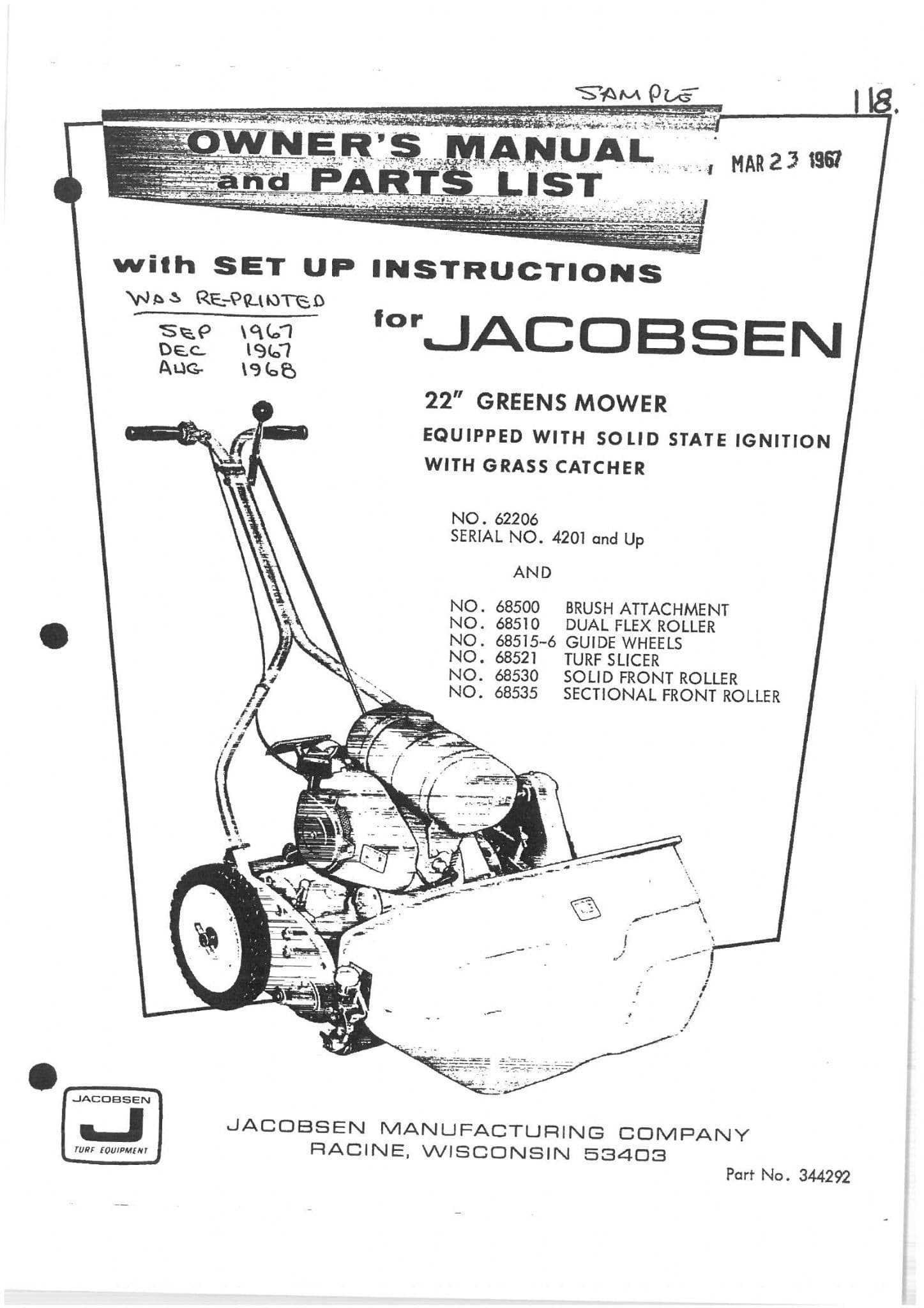

Importance of Diagrams in Machinery

Visual representations play a crucial role in understanding complex systems. They provide clarity and enhance communication among engineers, technicians, and operators, ensuring that everyone is on the same page when it comes to functionality and maintenance.

Effective schematics allow for quick identification of components and their relationships, streamlining troubleshooting processes and facilitating repairs. By using these illustrations, individuals can delve into the intricacies of the system, making it easier to grasp the ultimate structure and operation.

Moreover, such visual aids serve as valuable training tools, enabling newcomers to familiarize themselves with the equipment efficiently. In essence, these representations are not merely decorative; they are essential for the smooth operation and longevity of any intricate assembly.

Key Parts of Green Machines

This section explores essential components that contribute to the efficiency and effectiveness of eco-friendly devices. Understanding these elements is crucial for maximizing their functionality and performance in sustainable operations.

Core Components

Engines serve as the heart of these systems, providing the necessary power while minimizing environmental impact. Advanced technologies ensure that these power sources operate at optimal efficiency, reducing waste and enhancing sustainability.

Support Structures

Frameworks and chassis play vital roles in stability and durability. These elements are designed to withstand various conditions while supporting the intricate mechanisms that drive innovation in environmentally responsible technologies.

How to Read Machine Diagrams

Understanding technical illustrations is essential for effectively navigating and maintaining complex equipment. These representations convey crucial information about components, their relationships, and functions, enabling users to grasp the system’s structure and operation.

Identifying Key Symbols

Every illustration utilizes specific symbols to represent various elements. Familiarizing yourself with these icons is vital; consult a legend or key to decipher meanings, ensuring accurate interpretation.

Interpreting Connections and Flow

Pay attention to the lines and arrows that indicate connections between elements. These pathways illustrate the flow of energy or materials, which is crucial for understanding how the system operates as a whole.

Common Issues with Machine Parts

When it comes to mechanical components, various challenges can arise that hinder performance and efficiency. Identifying these problems early can save time and resources, ensuring that equipment operates smoothly. This section explores typical complications encountered in the realm of industrial hardware.

Wear and Tear: Over time, constant use leads to natural deterioration of components. This can manifest as reduced functionality or even complete failure if not addressed promptly. Regular maintenance is crucial to mitigate this issue.

Misalignment: Improper installation or shifting due to vibrations can cause parts to become misaligned. This not only affects performance but can also lead to additional stress and damage over time. Routine inspections can help identify and correct misalignments before they escalate.

Corrosion: Exposure to moisture and harsh environments can result in rust and degradation of metal components. Implementing protective coatings and regular cleaning can extend the lifespan of these elements and prevent failure.

Contamination: Foreign substances, such as dirt or debris, can compromise the integrity of various components. Ensuring that systems are properly sealed and employing effective filtration can help maintain cleanliness and functionality.

Improper Lubrication: Insufficient or excessive lubrication can cause friction or lead to overheating. Finding the right balance and using appropriate lubricants is essential for optimal performance.

Addressing these common challenges through proactive measures and routine checks can significantly enhance the reliability and longevity of mechanical systems, ensuring efficient operations across various applications.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. Implementing proper upkeep practices can significantly extend the lifespan of components and enhance overall performance. By following a few essential guidelines, you can prevent premature wear and tear while optimizing functionality.

1. Regular Inspection: Conduct routine checks to identify any signs of wear or damage. Early detection of issues can prevent more significant problems down the line.

2. Lubrication: Properly lubricate moving elements to reduce friction and minimize wear. Choose high-quality lubricants suitable for specific applications.

3. Cleaning: Keep surfaces free of debris and contaminants. Regular cleaning prevents buildup that can hinder performance and cause corrosion.

4. Temperature Control: Monitor operating temperatures to prevent overheating. Ensure adequate cooling mechanisms are in place to maintain optimal conditions.

5. Follow Manufacturer Guidelines: Adhere to the recommendations provided by the manufacturer for maintenance schedules and procedures. This ensures that all practices align with the intended use.

6. Proper Storage: When not in use, store equipment in a controlled environment. This helps protect it from environmental factors that may cause deterioration.

7. Training and Awareness: Ensure that all operators are adequately trained on maintenance practices. Knowledgeable users are key to preventing misuse and maintaining equipment in top condition.

By integrating these strategies into your routine, you can promote longevity and reliability, ensuring that your equipment remains effective for years to come.

Tools Needed for Repairs

Having the right equipment is essential for effective maintenance and restoration tasks. Various instruments facilitate precision and efficiency, ensuring that each job is completed to the highest standard. Understanding which tools are necessary can significantly enhance the repair process, making it smoother and more productive.

Essential Hand Tools

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for any repair job. These instruments allow for precise adjustments and assembly, making them indispensable in tackling minor and major tasks alike.

Power Equipment

For more complex repairs, power tools like drills and saws can greatly expedite the process. Utilizing these machines not only saves time but also provides the ability to handle tougher materials and intricate designs with ease.

Identifying Components by Function

Understanding the various elements within a system is crucial for efficient operation and maintenance. Each component serves a unique purpose, contributing to the overall functionality. By recognizing these roles, one can enhance performance and troubleshoot issues effectively.

Core Elements

Primary elements typically include power sources, control units, and output mechanisms. Each plays a distinct role, from initiating action to executing tasks, ensuring seamless interaction throughout the entire setup.

Supporting Components

Supportive elements, such as connectors and sensors, facilitate communication and enhance efficiency. Their proper identification and understanding enable a comprehensive grasp of how the system operates, ultimately leading to improved functionality.

Comparing Diagrams Across Models

Understanding the variations in schematics among different designs is crucial for effective analysis and maintenance. By examining these visual representations, one can uncover unique features and functions specific to each model, aiding in both troubleshooting and enhancement.

Each representation serves as a vital tool for engineers and technicians, facilitating a deeper grasp of the operational mechanisms involved. When contrasting the layouts, one may notice how certain elements are positioned or connected differently, reflecting the distinct engineering choices made during development.

Furthermore, identifying patterns and discrepancies across various models can lead to insights into best practices and innovations in design. This comparative approach not only enhances understanding but also promotes continuous improvement in future iterations.

Impact of Quality Parts on Performance

The caliber of components significantly influences overall functionality and efficiency in any system. High-quality elements ensure reliability, reduce wear, and enhance the lifespan of the entire setup. This ultimately translates to smoother operations and less downtime, which is critical in maintaining productivity.

Durability and Longevity

Investing in superior components leads to enhanced durability, meaning fewer replacements and repairs over time. Quality materials withstand stress and environmental factors, resulting in consistent performance. Reliability becomes a hallmark, allowing users to trust their equipment for prolonged periods.

Efficiency and Performance

When top-tier components are employed, systems operate at optimal levels, showcasing increased efficiency. This not only boosts productivity but also minimizes energy consumption. Consequently, users experience a reduction in operational costs, reinforcing the importance of selecting the right elements.

Innovations in Green Machine Design

The evolution of eco-friendly technology has led to significant advancements in the realm of sustainable equipment design. These innovations focus on enhancing efficiency while minimizing environmental impact, demonstrating a commitment to a cleaner future. This section explores the latest breakthroughs that are reshaping industries through responsible engineering practices.

Energy Efficiency is at the forefront of modern development. New systems integrate smart sensors and automation to optimize power consumption, reducing waste and enhancing overall productivity. These improvements not only contribute to lower operational costs but also align with global sustainability goals.

Material Innovations play a crucial role in this transformation. The adoption of biodegradable and recyclable materials in construction leads to a significant reduction in carbon footprint. Engineers are now exploring composite materials that offer durability while being less harmful to the environment, ensuring longevity without compromising eco-friendliness.

Modular Design is another trend gaining traction. By creating components that can be easily upgraded or replaced, manufacturers reduce the need for complete replacements, extending the life cycle of products. This approach promotes a circular economy, where resources are reused and waste is minimized.

Finally, renewable energy integration is revolutionizing the way we power our systems. The incorporation of solar panels, wind turbines, and other renewable sources allows for self-sufficiency, further reducing reliance on fossil fuels. These advancements represent a significant step towards a more sustainable and responsible future.

Resources for Further Learning

Exploring advanced topics in mechanical systems can greatly enhance your understanding and skills. Numerous resources are available to help you dive deeper into this field, providing valuable insights and practical knowledge.

Online Courses

- Coursera: Offers various courses on engineering principles.

- edX: Features programs from top universities focusing on design and functionality.

- Udacity: Provides nano-degrees in related areas of study.

Books and Publications

- Mechanics of Materials by Ferdinand P. Beer

- Engineering Mechanics: Dynamics by J.L. Meriam

- Fundamentals of Thermodynamics by Richard E. Sonntag