Ev

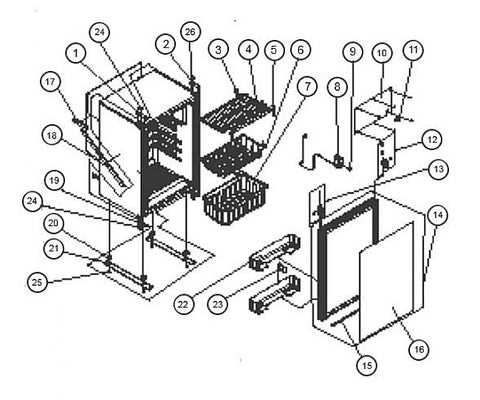

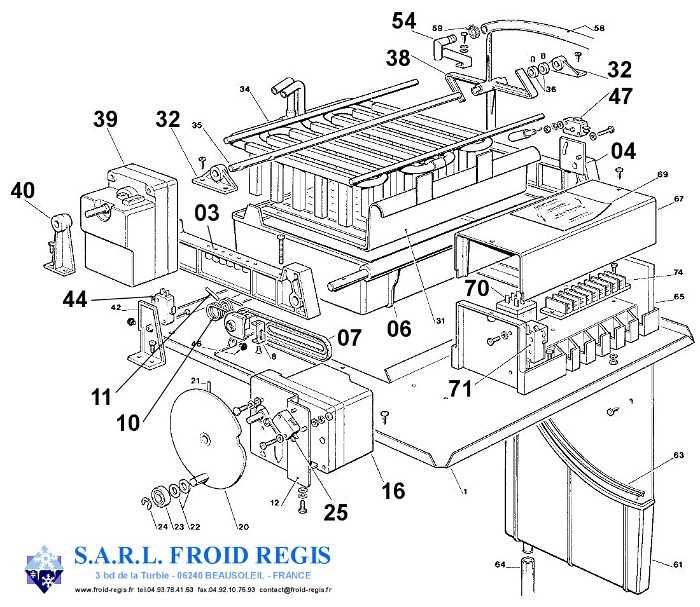

Comprehensive Breakdown of Ice Machine Diagrams

Understanding the internal mechanisms and structure of cooling devices requires a close examination of their individual components and the way they interact. A clear representation of these units in visual format can simplify the process of identifying issues or performing maintenance. These diagrams serve as valuable tools for both professionals and enthusiasts, offering a detailed look at how cooling systems operate.

Key Components and Their Functions

At the core of every cooling device are several essential elements that ensure optimal operation. Each part plays a unique role in maintaining functionality, from temperature regulation to water circulation. By analyzing the various sections, users can gain a deeper understanding of how each element contributes to the overall process, ensuring a steady performance.

Flow and Operation Sequence

The interaction between these parts follows a specific sequence designed to ensure efficiency. A well-constructed diagram highlights the flow of each stage, allowing technicians to easily follow and troubleshoot any interruptions. This level of detail empowers users to maintain systems, reduce downtime, and improve longevity.

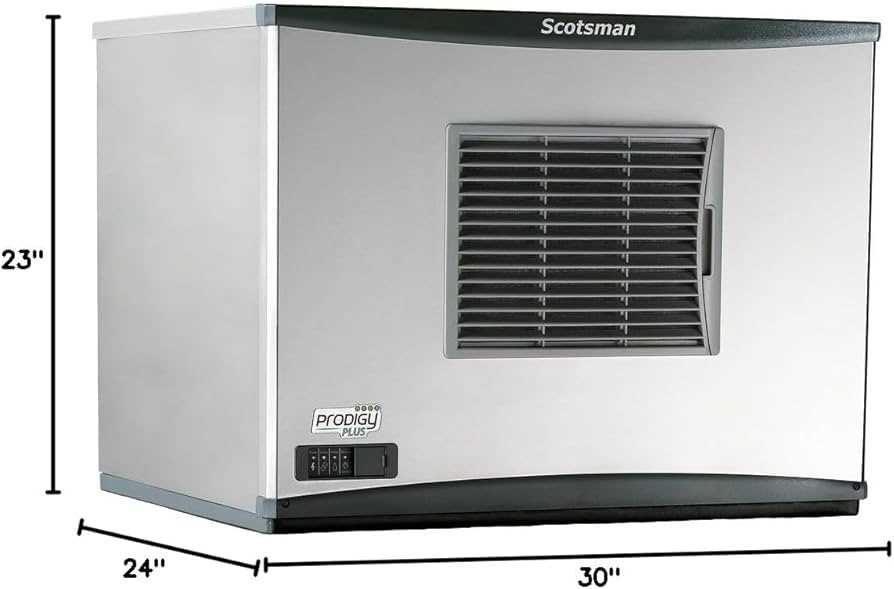

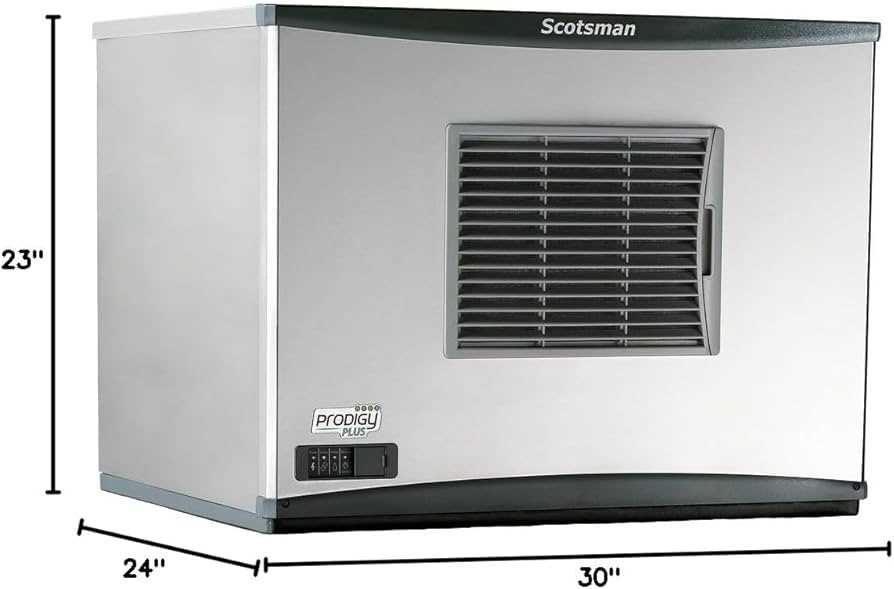

How Scotsman Ice Makers Operate

Understanding the process behind advanced refrigeration systems involves exploring how water is transformed into solid crystals using efficient cooling mechanisms. These devices are designed to manage temperature regulation and water flow, ensuring a consistent cycle of freezing and harvesting without manual intervention. By combining mechanical precision with smart controls, they provide a reliable and seamless way to generate frozen cubes for various uses.

Key Cooling Mechanisms

The operation begins with a cooling system that drops the temperature within a specialized chamber. As water flows over a chilled surface, it gradually solidifies into small, uniform pieces. This process is carefully controlled by sensors that monitor temperature and water levels, ensuring the system remains efficient and energy-conscious.

Harvesting and Recycle Processes

Once the freezing phase is complete, the solidified blocks are released through a warming process that loosens them from the surface. Afterward, the device resets itself, preparing for the next cycle. Any excess water is redirected back into the system, minimizing waste and maintaining high productivity.

Diagnosing Issues in Scotsman Prodigy Units

Identifying problems in advanced refrigeration units requires a systematic approach to troubleshooting. Understanding common symptoms and their potential causes can significantly reduce downtime and enhance operational efficiency. Proper diagnostic techniques not only aid in pinpointing the issues but also provide insights into preventive measures that can be taken to avoid future malfunctions.

Common Symptoms and Their Causes

Units may exhibit various signs of malfunction, including unusual noises, inconsistent production levels, or failure to start. Unusual sounds could indicate mechanical wear or misalignment of components. Inconsistent output levels may stem from insufficient refrigerant, compromised seals, or electronic control failures. A failure to initiate operations often results from electrical issues or sensor malfunctions.

Troubleshooting Steps

Begin the diagnostic process by conducting a thorough visual inspection. Check for leaks, corrosion, or loose connections that may affect functionality. Next, utilize testing tools to measure electrical components and ensure they are operating within specified ranges. If problems persist, refer to the unit’s service manual for detailed specifications and troubleshooting procedures. Regular maintenance and periodic checks can help mitigate issues and prolong the lifespan of the equipment.

Repairing Common Ice Machine Problems

Understanding the typical issues that can arise with refrigeration devices is crucial for efficient maintenance and longevity. Users may encounter a range of malfunctions, from inadequate freezing to abnormal noise levels. This section will explore several prevalent challenges and offer guidance on troubleshooting and resolution.

Identifying Insufficient Cooling

A frequent complaint involves the lack of proper freezing capability. This can be attributed to various factors, including blocked air vents, insufficient refrigerant levels, or malfunctioning components. Begin by examining airflow and ensuring that vents are unobstructed. If the airflow appears normal, consider checking the refrigerant charge and verifying that the compressor is functioning correctly.

Addressing Excessive Noise

Another common issue is excessive operational noise, which may signal underlying problems. Noisy equipment can stem from loose or damaged elements, such as the fan or compressor. Inspecting these parts for wear and securing any loose connections can often mitigate the disturbance. In cases of persistent noise, consulting a professional for a thorough examination is advisable.

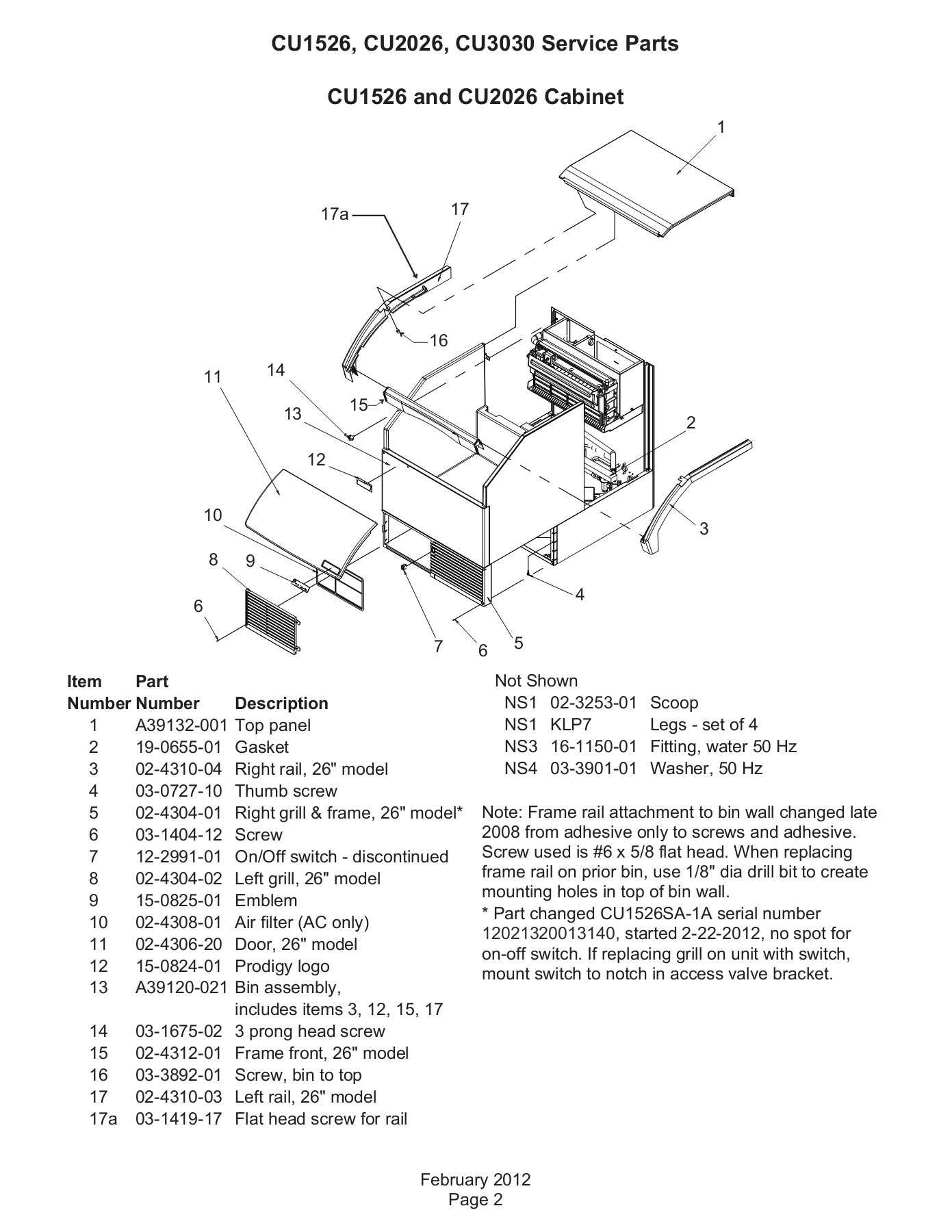

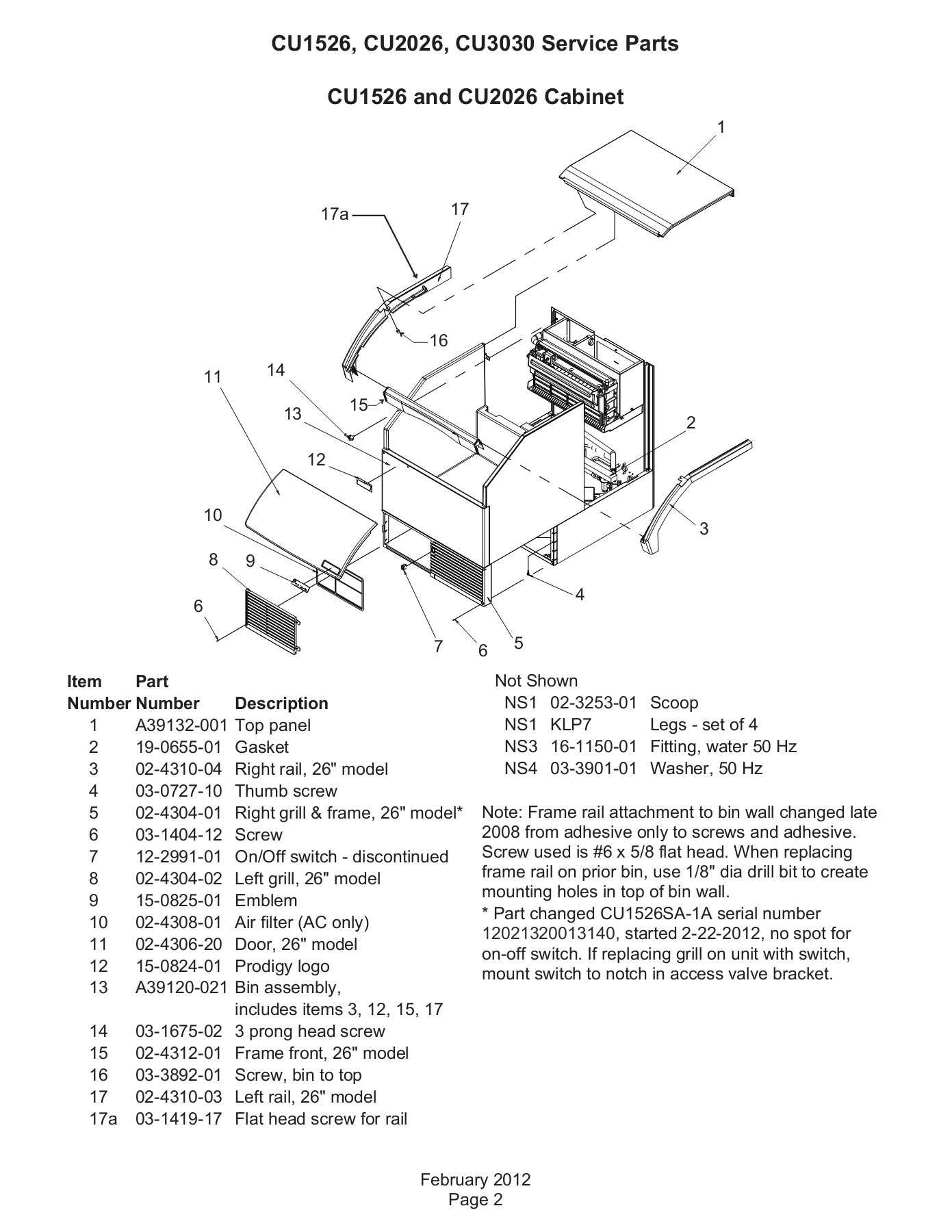

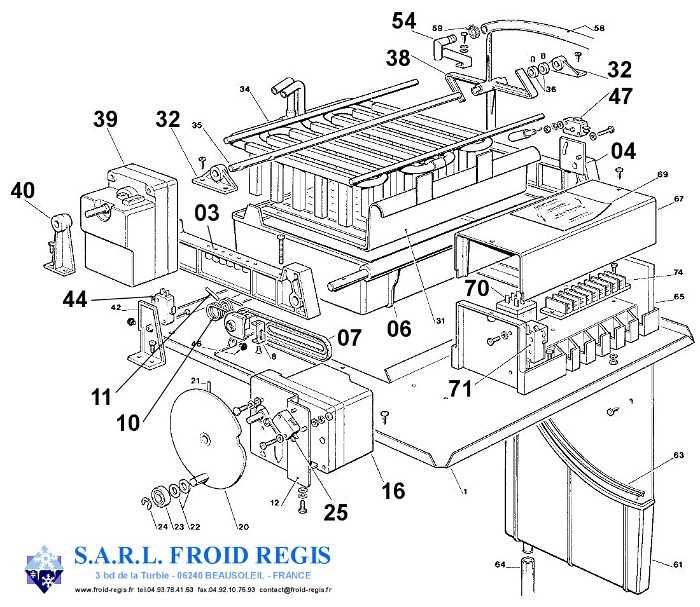

Identifying Scotsman Prodigy Ice Machine Parts

Understanding the components of a specific refrigeration unit is essential for effective maintenance and troubleshooting. Familiarity with each element enhances operational efficiency and can prevent costly repairs. This section provides insights into recognizing and distinguishing various elements that contribute to the overall functionality of these cooling systems.

Key Components Overview

Each cooling apparatus consists of several integral components, each serving a unique purpose. The primary structure typically includes a condenser, responsible for expelling heat, and an evaporator, which absorbs heat from the surroundings. Additionally, a compressor plays a crucial role in circulating refrigerant throughout the system. Understanding these fundamental elements will aid in diagnosing issues effectively.

Locating Essential Elements

To facilitate maintenance, it is vital to locate and identify critical components accurately. Look for the water reservoir, which collects excess liquid, and the control panel, where operational settings are adjusted. Knowing the position and function of these elements is key to ensuring smooth operation and extending the lifespan of the unit.

Maintaining Optimal Performance of Ice Makers

Ensuring the highest level of efficiency in refrigeration units requires regular upkeep and attention. Proper maintenance practices not only prolong the lifespan of the equipment but also enhance its output quality. By adhering to a systematic maintenance routine, operators can prevent common issues and ensure that their units run smoothly.

Key maintenance tasks include thorough cleaning, regular inspection, and timely replacement of any worn components. Additionally, monitoring the surrounding environment and addressing any potential obstructions can significantly impact performance. Here are some essential guidelines:

| Maintenance Task |

Frequency |

Purpose |

| Cleaning Condenser Coils |

Every 3 months |

Improves heat exchange efficiency |

| Inspecting Water Filters |

Monthly |

Ensures clean water supply and prevents clogs |

| Checking Drainage System |

Every 6 months |

Prevents water buildup and potential leaks |

| Testing Electrical Connections |

Annually |

Ensures safe and reliable operation |

| Replacing Worn Components |

As needed |

Maintains overall functionality |

Implementing these practices will not only maintain optimal functionality but also enhance the quality of the product generated. Regular attention to these details allows for smoother operations and a more reliable outcome in the long run.

Troubleshooting Scotsman Prodigy Ice Production

Addressing issues related to the production of frozen cubes can be challenging but essential for maintaining operational efficiency. Understanding the common problems and their solutions can greatly enhance performance and extend the lifespan of the equipment. This guide aims to provide insights into diagnosing and resolving these prevalent complications.

Common Issues and Solutions

One frequent complication involves insufficient output. This can stem from several factors, including low water supply, blocked filters, or improper temperature settings. Ensuring that the water supply is adequate and clean is crucial. Regularly inspecting and replacing filters can prevent obstructions that hinder performance. Additionally, verifying the settings on the thermostat is vital to maintain optimal functioning.

Maintenance Tips

Routine maintenance is critical in preventing potential disruptions. Regularly cleaning the interior and exterior components can significantly reduce the likelihood of malfunctions. It’s advisable to schedule professional servicing periodically to address any hidden issues that may not be immediately apparent. Keeping a maintenance log can help track any repairs or adjustments made over time, further aiding in the troubleshooting process.

Prolonging the Life of Your Ice Machine

Ensuring the longevity of your refrigeration unit is essential for maintaining consistent performance and minimizing costly repairs. By implementing a series of preventive measures, you can significantly extend its lifespan and enhance its efficiency. This approach not only saves money but also improves the quality of the output.

Regular Maintenance: Consistent upkeep is crucial. Schedule routine check-ups and cleanings to remove any build-up of debris or mineral deposits. This helps in maintaining optimal functionality and prevents the risk of malfunctions.

Temperature Control: Keeping the unit at an appropriate temperature is vital. Avoid extreme fluctuations and ensure that it operates within the recommended range. This practice helps reduce stress on components and enhances overall performance.

Water Quality: The quality of the liquid used directly impacts the efficiency and durability of your appliance. Use filtered or distilled water to prevent mineral accumulation and reduce wear on internal parts.

Proper Ventilation: Ensure that the area around your refrigeration unit is well-ventilated. Adequate airflow prevents overheating and allows for efficient operation. Avoid placing the unit in confined spaces where heat can build up.

Monitoring Performance: Keep an eye on the performance indicators of your unit. If you notice any unusual sounds or a decline in efficiency, address these issues immediately to prevent further damage.

By adopting these practices, you can create a conducive environment for your refrigeration unit to thrive, ultimately leading to enhanced reliability and a longer operational life.

|