Understanding the different elements involved in cooling systems for beverages is essential for maintaining efficient operation and ensuring the longevity of the equipment. Each component plays a crucial role in the overall performance, and having a clear insight into their functionality can help in troubleshooting and replacement when needed.

In this section, we will delve into the primary elements of such systems, focusing on how each part contributes to the cooling process. By examining the essential units and their interconnections, you’ll gain a better understanding of how to maintain and repair these systems effectively.

Key highlights will cover the essential features of the system, providing practical advice on identifying common issues and selecting appropriate replacements for long-term reliability.

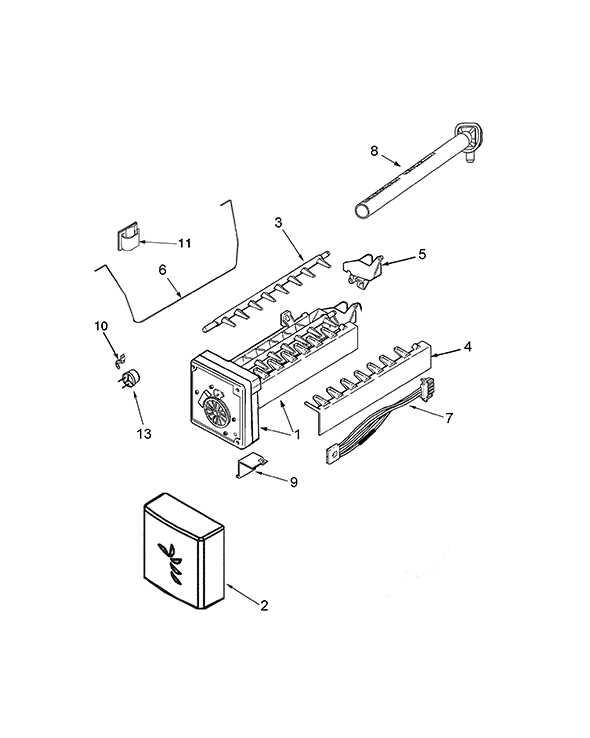

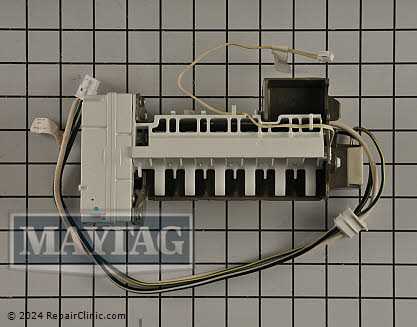

Overview of Maytag Ice Maker Components

Understanding the key elements of a cooling system designed to produce frozen water can help ensure its proper operation and maintenance. Each component plays a critical role in the process, ensuring efficient production and smooth functionality. In this section, we will explore the various functional units that work together to deliver consistent results.

Main Functional Elements

Several essential mechanisms are involved in the operation of these systems. They work in unison to manage the freezing process, ensuring that water is efficiently converted into solid form and stored. Below is a breakdown of the main components involved.

| Component | Description | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water Valve | Controls the flow of water into the system, ensuring the right amount is supplied for freezing. | ||||||||||||||

| How Ice Makers Function in Refrigerators

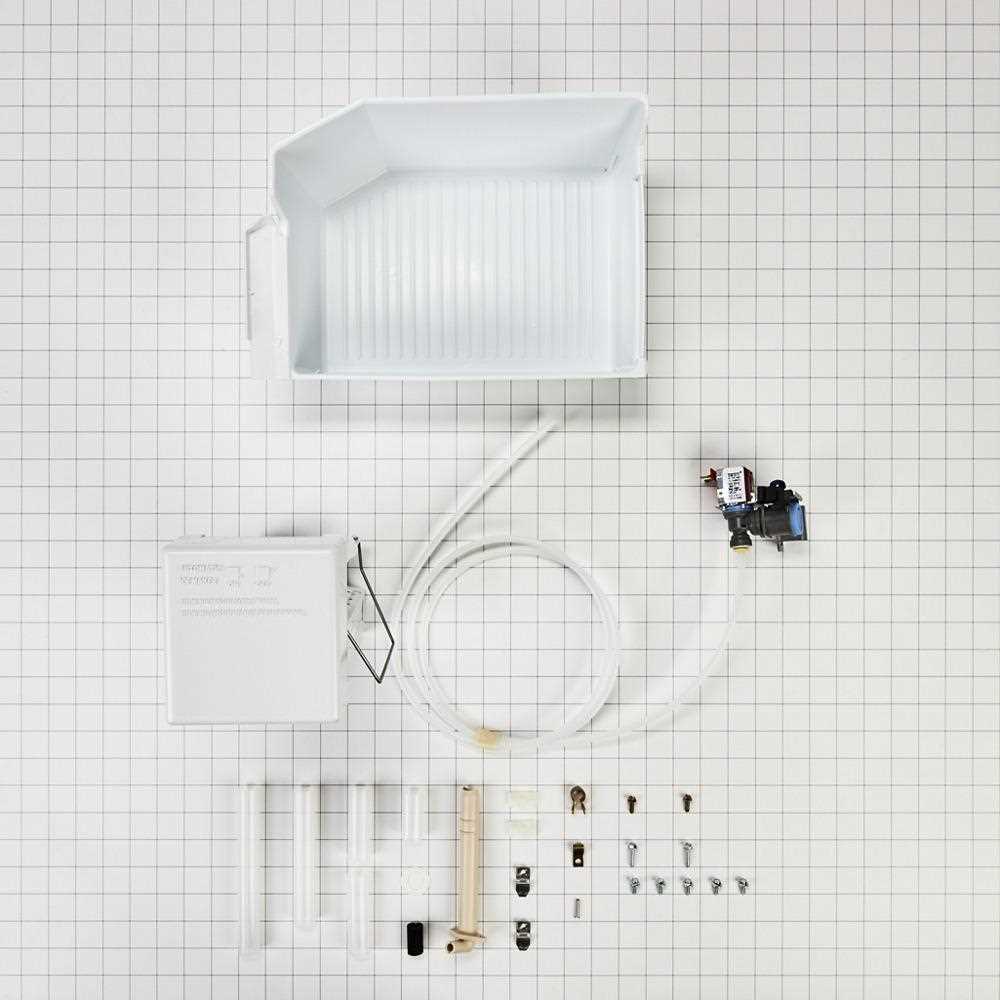

The process of producing frozen cubes within cooling appliances involves a series of carefully coordinated actions. These units operate automatically, providing convenience by generating and storing frozen elements without the need for manual intervention. Understanding their functionality can enhance users’ appreciation of this common feature. Initially, the system fills a designated compartment with water, which is then subjected to a chilling process. A thermostat monitors the temperature, ensuring that the liquid transforms into solid form. Once the appropriate conditions are met, a mechanism activates to release the frozen cubes from their compartment. Additionally, the unit often includes a reservoir for excess liquid, which ensures a continuous supply for future cycles. Regular maintenance, such as cleaning and checking for clogs, is essential for optimal performance. By recognizing the underlying principles of these systems, users can troubleshoot common issues and maintain their efficiency. Key Parts of a Maytag Ice MakerUnderstanding the essential components of an ice-producing appliance is crucial for ensuring its effective operation. Each element plays a significant role in the overall functionality, from water supply to the freezing mechanism. Familiarity with these components can help users troubleshoot issues and maintain optimal performance. Water Inlet Valve: This device regulates the flow of water into the system. It opens to allow water to fill the reservoir, ensuring a consistent supply for production. Evaporator: The evaporator is responsible for freezing the water into solid form. It absorbs heat from the water, facilitating the transition from liquid to solid. Compressor: The compressor circulates refrigerant through the system, maintaining the necessary temperature for effective freezing. It plays a vital role in the cooling process. Ice Harvesting Mechanism: This component aids in releasing the frozen cubes into the storage bin. It typically consists of a motor and a series of levers that work together to ensure smooth operation. Control Module: The control module manages the various functions of the system, including the timing of freezing and harvesting cycles. It ensures that the appliance operates efficiently and responds to user settings. By gaining insights into these critical components, users can enhance their understanding of how the appliance functions and address potential issues more effectively. Common Issues with Ice Maker MechanismsUnderstanding the frequent challenges associated with these appliances can significantly enhance their performance and reliability. Various malfunctions may occur due to mechanical failures, electrical issues, or even external factors that impede their efficient operation. Identifying these common problems can help users troubleshoot effectively and ensure a steady supply of frozen cubes. Mechanical FailuresMechanical components are vital for proper functionality. Over time, wear and tear may lead to dysfunction. Key elements such as motors, gears, and levers can become misaligned or damaged, resulting in the inability to produce the desired output. Regular maintenance is essential to prevent such issues from arising. Electrical ProblemsElectrical malfunctions often disrupt the power supply, hindering the overall operation of these units. Faulty wiring, blown fuses, or defective switches may contribute to inadequate performance. Ensuring that all electrical connections are secure and free of damage is crucial for optimal functionality.

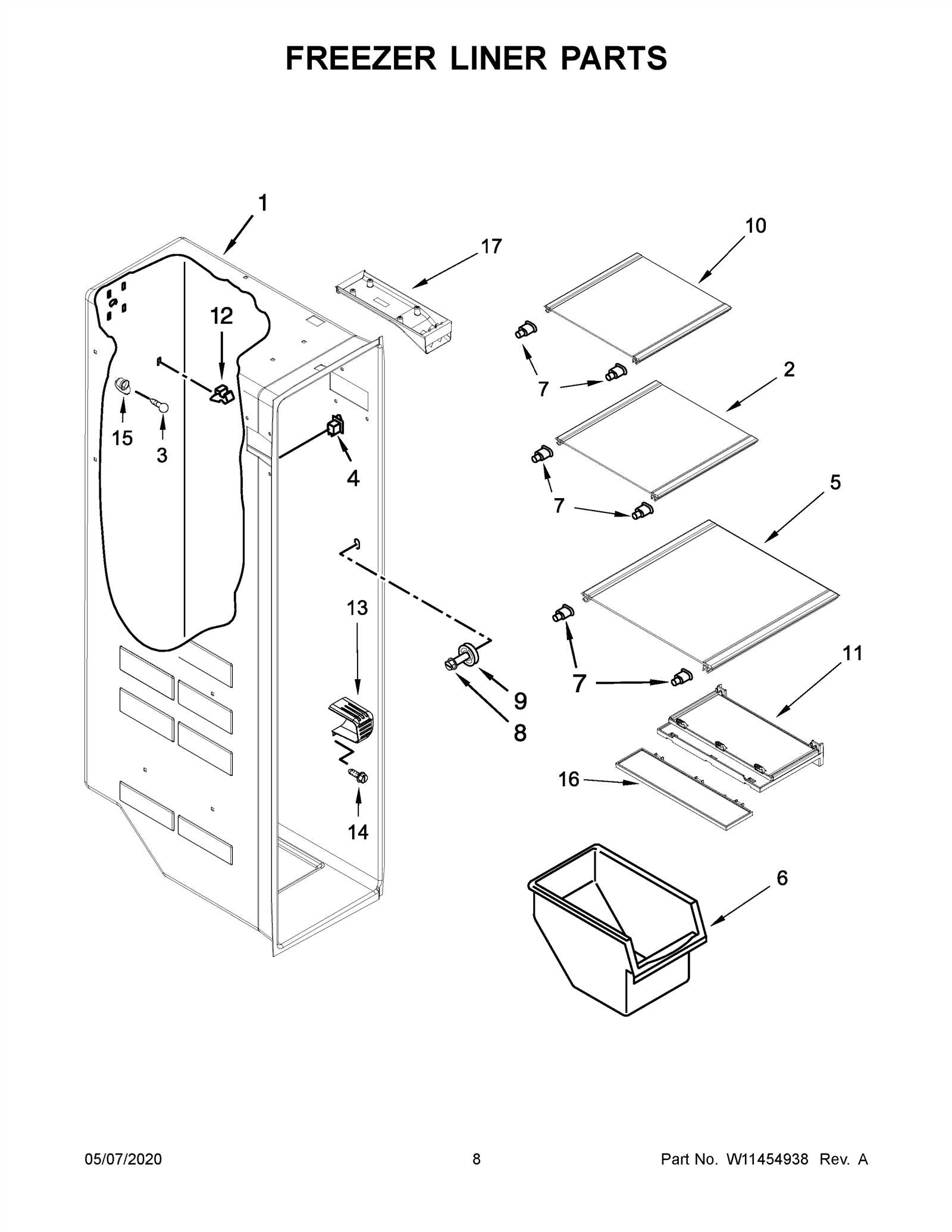

Replacing the Ice Tray in Maytag ModelsMaintaining optimal performance in your freezing appliance often requires replacing specific components. One crucial element that may need attention is the container responsible for shaping frozen blocks. When this component becomes damaged or inefficient, it can lead to inadequate production of frozen blocks. To begin the replacement process, ensure that the appliance is unplugged to guarantee safety. Locate the compartment housing the container and carefully remove any covering or insulation. Once exposed, detach the existing container by following the manufacturer’s guidelines. It is essential to handle this component delicately to avoid damaging surrounding parts. After removing the old container, compare it with the new one to confirm compatibility. Installation of the new container should follow the reverse steps of removal. Secure it in place, ensuring that it fits snugly within its housing. Finally, restore any coverings or insulation before plugging the appliance back in to resume normal operation. By replacing the container efficiently, you can restore the functionality of your freezing appliance, ensuring it operates smoothly and continues to provide you with quality frozen products. Maintenance Tips for Long-Lasting PerformanceEnsuring optimal functionality of your appliance requires regular care and attention. By implementing a few simple practices, you can extend its lifespan and enhance its efficiency. This section outlines effective strategies to keep your unit running smoothly, preventing common issues that may arise over time. Regular Cleaning and Inspection

Routine cleaning is essential to avoid buildup that can impair functionality. Make it a habit to remove any debris and dust from the unit’s exterior and accessible components. Additionally, inspect the internal mechanisms periodically for any signs of wear or malfunction. Early detection of potential issues can save time and costs associated with repairs. Optimal Temperature SettingsSetting the appropriate temperature is crucial for efficient operation. Avoid extremes; instead, maintain a balanced setting that ensures consistent performance. This not only helps in maintaining quality but also minimizes energy consumption, contributing to both environmental sustainability and cost-effectiveness. Thermostats and Temperature Control in Ice Makers

Effective regulation of temperature is crucial in any freezing appliance, as it ensures optimal functionality and prolongs the lifespan of the unit. The components responsible for monitoring and adjusting temperatures play a significant role in maintaining the desired conditions. Understanding these elements can enhance performance and efficiency. Role of ThermostatsThermostats serve as essential devices that monitor the ambient temperature within the unit. When the temperature deviates from the set threshold, these sensors trigger the cooling mechanism, ensuring that the internal environment remains stable. This precise control helps prevent the formation of undesirable conditions that could affect the quality of the frozen products. Temperature Adjustment MechanismsVarious mechanisms are utilized to achieve accurate temperature control. Mechanical devices often feature adjustable dials, allowing users to set their preferred levels. In contrast, digital systems provide more advanced options, such as programmable settings and real-time monitoring. Understanding the differences between these mechanisms can aid in selecting the most suitable option for specific needs. How to Clean and Maintain Ice Dispensers

Regular upkeep of your dispensing unit is essential to ensure optimal performance and hygiene. Neglecting this aspect can lead to unwanted buildup and potential malfunctions, affecting the quality of the product served. Implementing a consistent cleaning routine not only enhances functionality but also prolongs the life of the appliance. Cleaning ProcedureBegin by disconnecting the device from the power source to ensure safety. Remove any remaining items within the compartment. Use a mixture of warm water and mild detergent to wipe down all accessible surfaces. Pay special attention to the interior and any crevices where debris may accumulate. Rinse thoroughly with clean water and dry with a soft cloth to prevent moisture buildup. Maintenance TipsTo maintain the unit effectively, inspect it regularly for signs of wear or damage. Check seals and gaskets for leaks and replace them as necessary. Additionally, consider using a specialized cleaning solution designed for this type of equipment every few months to help eliminate mineral deposits and other residues. Regular maintenance will ensure the longevity of your appliance and consistent quality of the dispensed product. Identifying Faulty Valves in Ice MakersRecognizing malfunctioning components in refrigeration appliances is essential for maintaining their efficiency. One critical element that can affect overall performance is the valve system. Understanding how to diagnose issues related to these mechanisms can prevent further complications and ensure optimal functioning. When assessing these mechanisms, several indicators may suggest that they are not operating correctly. Look for signs such as irregular water flow, unusual noises, or even leaks around the appliance. Careful observation of these symptoms can provide valuable insights into potential problems. To confirm suspicions, a thorough inspection of the valve assembly is necessary. This includes checking for blockages, ensuring seals are intact, and testing for proper electrical connectivity. Utilizing a multimeter can assist in verifying whether the electrical components are functioning as intended. Proper maintenance and timely identification of these issues can significantly extend the lifespan of the equipment. Electrical Components Crucial for Ice ProductionIn the realm of frozen water production, various electrical elements play a vital role in ensuring efficiency and effectiveness. These components work in harmony to facilitate the transformation of liquid into solid, creating the desired product. Understanding the functions and interactions of these essential parts can greatly enhance the performance of the system. One of the key players in this process is the thermostat, which regulates temperature and ensures that the freezing mechanism operates at optimal levels. Additionally, the water valve serves as a gateway, controlling the flow of liquid into the freezing chamber. This careful management of resources is essential for producing high-quality results. Another crucial element is the motor, responsible for driving various mechanisms within the unit. This component ensures that all moving parts function smoothly, contributing to the overall efficiency of the operation. Lastly, electrical connections and wiring facilitate communication between these components, allowing for coordinated actions that are vital for successful output. Finding the Right Replacement Parts for Maytag UnitsWhen it comes to maintaining household appliances, ensuring that each component functions optimally is essential for overall performance. Understanding how to locate the appropriate components can significantly enhance the longevity and efficiency of your device. This section aims to guide you in identifying and acquiring the necessary replacements for your appliance. Identifying Essential Components

Before searching for replacements, it’s crucial to determine which components require attention. Common signs of malfunction may include:

Where to Find Quality ReplacementsThere are several reliable sources to explore when looking for suitable replacements:

By following these guidelines, you can efficiently navigate the process of sourcing the right components, ensuring that your appliance remains in top-notch condition. DIY Troubleshooting for Malfunctioning Ice MakersExperiencing issues with your cooling unit can be frustrating, but many common problems can be resolved without professional assistance. Understanding the fundamentals of how these appliances function allows homeowners to identify and fix malfunctions effectively. This guide outlines simple steps to diagnose and address frequent issues that may arise. Identifying Common Issues

Start by observing any unusual signs. If the device isn’t producing frozen cubes, check the water supply. Ensure that the valve is open and not obstructed. Additionally, inspect the electrical connections to confirm that everything is secure and functioning. Look for any visible blockages that could hinder the process. Performing Basic MaintenanceRegular upkeep is essential for optimal performance. Clean the components regularly to prevent buildup, which can lead to inefficiency. If you encounter persistent issues, consider resetting the unit according to the manufacturer’s instructions. This can often resolve minor glitches that affect functionality. |