When it comes to understanding how household appliances function, gaining insight into the structure and organization of their essential components is crucial. Knowing how different elements are assembled and interact with each other can help identify issues and maintain proper operation. This section will provide a detailed breakdown of critical elements within the appliance, offering a clear understanding of its internal layout.

Each individual piece within an appliance plays a unique role in ensuring the overall efficiency and performance. By understanding the function of these elements, troubleshooting and repairs can become more accessible, ultimately extending the appliance’s lifespan. Our goal is to offer a clear, easy-to-follow guide that explains how these components are arranged, ensuring that the information is both useful and practical.

Understanding the Key Components

In this section, we will explore the essential elements that make up a modern dishwasher system. These components work together to ensure efficient operation, from water intake to the final drying stage. Knowing how each part functions can help in troubleshooting and maintaining the system properly.

Water Distribution System

The water distribution system plays a crucial role in cleaning dishes. This section includes the spray arms and pumps, which circulate water through the appliance to remove food particles and debris effectively. Regular maintenance of these elements ensures the system runs smoothly and reduces the likelihood of breakdowns.

Control Panel and Sensors

The control panel and sensors are vital for regulating various functions such as temperature, wash cycles, and drying times. Sensors detect the load size, water level, and cleanliness, adjusting the process accordingly to optimize energy and water usage. Proper care of these components ensures reliable performance and longevity.

Main Control Board Functions and Features

The control unit plays a pivotal role in managing the overall operation of the appliance, ensuring that each component works in harmony. It is responsible for coordinating various tasks, including regulating cycles, monitoring sensors, and processing user inputs, to achieve optimal performance. This section outlines the essential functions and unique characteristics of the central control system, detailing how it interacts with other key modules to maintain efficiency and reliability.

One of the primary tasks of the control board is to interpret commands entered via the interface. This involves processing selections and adjusting settings according to user preferences. Additionally, the system continuously monitors operational statuses, ensuring that everything runs smoothly by automatically making adjustments where necessary.

Moreover, the control board is equipped with diagnostic capabilities, allowing it to detect potential issues and facilitate troubleshooting. By analyzing feedback from various sensors, the board can provide error codes that help identify specific problems, thus minimizing

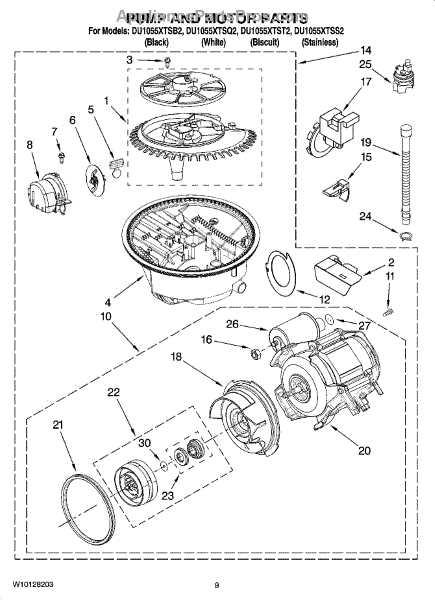

Motor Assembly Overview for Maytag Dishwashers

The motor assembly plays a critical role in ensuring efficient water circulation and draining during each wash cycle. Proper functioning of this component is essential for maintaining overall appliance performance and extending its lifespan.

Key elements of the motor assembly include various moving parts designed to pump water at different stages of the cycle. Understanding how these components work together can help in identifying potential issues and maintaining the unit efficiently.

- Water Pump: This section controls the movement of water throughout the cleaning and rinsing phases.

- Impeller: Helps direct water into the spray arms for effective dishwashing.

- Drain Pump: Assists in removing the used water from the unit after each cycle.

- Motor Housing: Encases and protects the motor from external elements, ensuring longevity.

By keeping the motor and its associated components in good condition,

Understanding the Drain Pump Mechanism

The drain pump is a critical component that helps remove water from the machine after each cycle. This process ensures that the appliance functions properly by draining out used water efficiently. A deeper understanding of this system can help with troubleshooting potential issues and maintaining smooth operation.

How the Drain Pump Works: The mechanism operates by creating a suction force, which pulls the water through specific pathways and out of the appliance. The pump is usually powered by an electric motor, allowing it to rotate and push water out through the drainage hose.

Common Issues: Over time, blockages or mechanical failures can disrupt the pump’s performance. Regular cleaning and inspection can prevent these problems, ensuring that the water is expelled quickly and effectively.

Detailed Look at the Heating Element

The heating component plays a crucial role in ensuring the appliance’s efficiency during the drying process. By converting electrical energy into heat, this element assists in drying items effectively and maintaining optimal performance.

Functionality and Importance

The heating element is designed to generate warmth, which is distributed evenly to remove moisture from the contents. Its reliable performance is key to achieving dry results, making it an essential feature in the overall system.

Signs of Wear and Maintenance

Over time, the heating unit may experience natural wear, which could affect its ability to produce sufficient warmth. Regular checks and proper maintenance ensure it continues to function effectively. If you notice any inconsistencies in drying performance, it’s important to assess the condition of this critical component.

Water Inlet Valve: Purpose and Replacement

The water inlet valve plays a crucial role in controlling the flow of water into the appliance, ensuring that it operates efficiently and effectively. This component acts as a gatekeeper, allowing water to enter when needed and shutting off when the required level is reached. Understanding its function is essential for proper maintenance and troubleshooting.

If you notice issues such as inadequate water supply or continuous leaking, it may indicate a malfunctioning valve. Replacement of this component is often necessary to restore the appliance’s performance. The process typically involves disconnecting the water supply, removing any securing screws, and replacing the old valve with a new one. Always ensure the power is turned off before beginning any repairs to prevent electrical hazards.

Role of the Detergent Dispenser in Operation

The detergent dispenser plays a crucial role in the functioning of cleaning appliances, ensuring that the appropriate amount of cleaning agent is released at the right time during the washing cycle. Its design and operation are essential for achieving optimal cleaning results, enhancing the overall efficiency of the machine.

This component is typically located in an easily accessible area, allowing users to load detergent and rinse agents conveniently. The dispenser is engineered to dispense the correct dosage of cleaning solution, which is vital for maintaining the appliance’s performance and preventing any residue buildup. Proper functioning of the detergent dispenser directly influences the cleanliness of the items being washed.

| Function | Description |

|---|---|

| Dosage Control | Regulates the amount of detergent released during each wash cycle. |

| Timing Mechanism | Ensures that detergent is dispensed at the optimal time for maximum effectiveness. |

| Compatibility | Designed to work with various types of cleaning agents, including liquid and powder formulations. |

Regular maintenance of the detergent dispenser is recommended to prevent clogs and ensure consistent performance. Users should periodically check for any signs of wear or damage and clean the compartment to guarantee efficient operation. By understanding the significance of this component, users can improve the cleaning results and extend the lifespan of their appliances.

Upper and Lower Rack Components Explained

The functionality of dishwashing machines relies heavily on the design and arrangement of the upper and lower racks. These essential elements are engineered to accommodate a variety of dishware and utensils, ensuring thorough cleaning while optimizing space. Understanding the components of these racks can enhance the user experience and improve maintenance practices.

Upper Rack Components

The upper rack is primarily designed for delicate items, providing a secure place for glassware, small plates, and bowls. Here are some key features:

- Adjustable Tines: These can be repositioned to create space for larger items or to optimize the arrangement for specific types of dishware.

- Flip-Down Shelves: These shelves allow for additional storage options for items like cups and small bowls, maximizing the use of available space.

- Spray Arm: Positioned above the upper rack, this component ensures that water reaches all areas effectively for optimal cleaning.

Lower Rack Components

The lower rack is tailored for larger and heavier items, such as pots, pans, and dinner plates. Its design incorporates several important elements:

- Heavy-Duty Tines: These provide support for larger dishware, ensuring stability during the wash cycle.

- Extra-Height Options: Some models feature adjustable height settings to accommodate tall pots and pans without compromising washing efficiency.

- Lower Spray Arm: This component works in conjunction with the upper spray arm to deliver a thorough clean, reaching all items on the lower rack.

Inspecting and Replacing the Door Latch

The door latch plays a crucial role in ensuring that your appliance operates safely and efficiently. Over time, wear and tear can lead to malfunctions, making it essential to regularly check and, if necessary, replace this component. Proper maintenance of the door latch not only enhances the performance of your appliance but also prevents potential safety hazards.

Inspection Process

Begin by visually examining the door latch for any signs of damage, such as cracks or misalignment. Check if the latch engages smoothly and securely when the door is closed. If you notice any irregularities, it’s advisable to perform a more thorough assessment by removing the outer panel of the appliance. This allows you to inspect the internal mechanisms connected to the latch.

Replacement Steps

If the inspection reveals that the latch is indeed faulty, follow these steps to replace it. First, disconnect the appliance from the power source to ensure safety. Next, remove the screws securing the door panel to gain access to the latch assembly. Carefully detach the old latch and replace it with a new one, making sure it is properly aligned. Finally, reassemble the door panel, secure all screws, and reconnect the power. Testing the door operation will confirm that the new latch functions correctly.

Importance of the Float Switch in Dishwashers

The float switch plays a crucial role in the functioning of dishwashing appliances by regulating water levels during cycles. This component ensures that the machine does not overflow, maintaining the efficiency and safety of the operation. By monitoring the water level, the float switch contributes significantly to the overall performance and longevity of the appliance.

How the Float Switch Works

This device operates based on the principle of buoyancy. As water fills the appliance, the float rises, triggering the switch to monitor and control the water level. When the desired level is reached, the float switch signals the inlet valve to stop water flow, preventing any potential leaks or spills. This automatic regulation not only protects the appliance but also enhances user convenience.

Common Issues Related to the Float Switch

Like any other component, the float switch can experience issues over time. Common problems include sticking or malfunctioning switches, which can lead to improper water levels and inefficient cleaning cycles. Regular maintenance and inspection of this part are essential to ensure the smooth operation of the dishwasher.

| Common Issues | Symptoms | Possible Solutions |

|---|---|---|

| Stuck Float | Water overflow | Clean or replace the float switch |

| Faulty Switch | Inconsistent water levels | Inspect wiring and connections |

| Blockages | Improper drainage | Clear debris from the float mechanism |

Cleaning and Maintaining the Spray Arms

Regular upkeep of the spray mechanisms is essential for ensuring optimal performance in dishwashing appliances. These components play a crucial role in distributing water effectively, and keeping them clean helps achieve spotless results. Neglecting maintenance can lead to clogs and reduced efficiency, making it important to incorporate cleaning into your routine.

Here are some steps to follow for proper cleaning and maintenance:

- Remove the spray arms from the appliance.

- Rinse the spray arms under warm water to remove any food particles or debris.

- Inspect the spray nozzles for blockages. If necessary, use a toothpick or a small brush to clear any obstructions.

- Soak the spray arms in a mixture of warm water and mild detergent for about 15-30 minutes.

- Scrub the arms gently with a soft sponge or cloth to remove any stubborn grime.

- Rinse thoroughly under running water to ensure all soap residue is gone.

- Reattach the spray arms securely to their original positions.

In addition to regular cleaning, it’s important to check the spray arms for signs of wear or damage. If you notice any cracks or significant degradation, replacing the components will help maintain the appliance’s performance and efficiency.