The efficient functioning of any marine engine relies on a variety of integral components. Understanding these elements is crucial for maintenance and troubleshooting, ensuring that the equipment performs optimally in different water conditions. This section will delve into the essential parts that make up a specific model, offering insights into their arrangements and functions.

By exploring the configurations of these components, users can gain a clearer understanding of their interactions and the overall mechanics involved. This knowledge not only aids in proper upkeep but also empowers enthusiasts and professionals alike to identify potential issues before they escalate. Additionally, having a visual reference can significantly enhance the learning experience, allowing for easier navigation and comprehension of complex assemblies.

Whether you are a seasoned mariner or a newcomer to the world of marine engines, familiarizing yourself with the intricacies of these essential components will prove beneficial. Recognizing the significance of each part will help ensure that your engine operates smoothly, providing reliable performance on every journey.

1993 Mercury 40 HP Overview

This section provides a comprehensive look at a specific model of marine engine known for its reliability and performance on watercraft. Designed to cater to various boating needs, this unit combines efficiency with durability, making it a popular choice among boating enthusiasts. Understanding its key features and capabilities can enhance the overall experience for users and assist in maintenance practices.

Key Features

- Robust construction for long-lasting use

- Efficient fuel consumption for extended journeys

- Versatile compatibility with different boat types

- Accessible controls for ease of operation

- Effective cooling system to prevent overheating

Applications

- Ideal for recreational fishing trips

- Suitable for leisure cruising on lakes and rivers

- Used in small to medium-sized boats

- Preferred choice for water sports and activities

Key Components of Outboard Motor

Understanding the fundamental elements of a marine propulsion system is crucial for effective maintenance and operation. These systems consist of several key components, each playing a significant role in ensuring optimal performance and reliability while navigating water. Familiarity with these essential parts can aid in troubleshooting and enhance the overall experience on the water.

The engine serves as the heart of the system, converting fuel into mechanical energy to drive the vessel. A robust cooling mechanism is vital, preventing overheating and ensuring efficient operation during prolonged use. Additionally, the fuel delivery system is responsible for supplying the engine with the necessary fuel mixture, while the ignition system ignites the fuel to create power.

Moreover, the propulsion unit, which includes the propeller, is critical for thrust and maneuverability, allowing the vessel to move forward or change direction. The steering mechanism ensures precise handling, enabling the operator to navigate effectively. Regular inspection and maintenance of these components are essential for maintaining peak functionality and longevity.

Understanding Engine Specifications

When delving into the world of marine propulsion systems, it is essential to grasp the fundamental characteristics that define their performance and efficiency. These specifications encompass a range of parameters, including displacement, power output, and torque. Each of these elements plays a vital role in determining how well a motor functions in various conditions, impacting speed, handling, and fuel economy.

Displacement refers to the total volume of all the cylinders in the engine, affecting the amount of air and fuel that can be drawn in for combustion. A higher displacement often leads to increased power, enabling the vessel to achieve greater speeds and carry heavier loads.

Another crucial specification is power output, which indicates the engine’s ability to generate thrust. This measurement is typically expressed in horsepower and is directly related to how effectively the engine can perform under various operational scenarios. Additionally, the torque produced by the engine influences acceleration and the ability to maintain speed in challenging conditions, such as strong currents or rough waters.

Understanding these specifications allows boat owners and operators to make informed decisions when selecting or maintaining their marine engines, ensuring optimal performance and longevity in the water.

Common Issues with Mercury Outboards

Many boat engines can experience a range of problems that affect their performance and reliability. Identifying and addressing these issues is crucial for maintaining optimal functionality and extending the lifespan of the motor. Below are some typical challenges that users may encounter.

- Fuel Problems:

- Contaminated fuel can lead to starting difficulties and engine performance issues.

- Old or stale fuel may cause poor combustion and reduced power output.

- Electrical System Failures:

- Corroded connections can disrupt the flow of electricity, impacting ignition and starting.

- Faulty batteries or alternators may lead to inadequate power supply for the engine.

- Overheating:

- Blocked water intake can restrict cooling water flow, causing the engine to overheat.

- Malfunctioning thermostats may fail to regulate temperature properly.

- Gearbox and Propeller Issues:

- Damaged propellers can cause vibrations and inefficiencies in movement.

- Gearbox problems may result in difficulty shifting gears or unusual noises.

Addressing these common issues promptly can significantly enhance the engine’s performance and reliability, ensuring a more enjoyable experience on the water.

Identifying Essential Replacement Parts

When maintaining a marine propulsion system, understanding key components is crucial for ensuring optimal performance. Various elements play significant roles in the functionality of the engine, making it essential to recognize which ones require attention or replacement over time.

Key Components to Monitor

Several vital components contribute to the effective operation of a marine engine. Regular inspection of the ignition mechanism, fuel delivery system, and cooling elements can prevent potential failures. Each of these parts can exhibit signs of wear, necessitating timely replacement to maintain the system’s efficiency.

Choosing Quality Alternatives

When sourcing replacements, prioritizing quality is essential. Selecting durable and reliable options can significantly enhance performance and longevity. Additionally, seeking guidance from trusted resources can assist in making informed decisions regarding the best components for your needs.

Benefits of Regular Maintenance

Routine care for your marine engine is essential for optimal performance and longevity. Consistent attention to maintenance tasks not only enhances efficiency but also helps identify potential issues before they escalate into significant problems. This proactive approach ensures that your equipment operates smoothly, providing peace of mind during your adventures on the water.

Enhanced Performance

Regular upkeep can significantly improve the functioning of your engine. By addressing minor issues promptly, you can ensure that your engine runs at its best, leading to:

- Improved fuel efficiency

- Smoother operation

- Faster response times

Cost Savings

Investing in routine maintenance can save you money in the long run. By preventing major repairs through early detection, you can avoid costly fixes. Key benefits include:

- Lower repair costs

- Extended lifespan of components

- Minimized downtime during outings

Where to Find Spare Parts

Locating components for your marine engine can be straightforward with the right resources. Many options are available to help you acquire the necessary items, ensuring your vessel operates smoothly. By exploring various channels, you can identify the most suitable solutions for your requirements.

Here are some effective methods to find the necessary components:

| Source | Description |

|---|---|

| Authorized Dealers | Visit official distributors that specialize in marine equipment. They often have a comprehensive inventory of components and can offer expert advice. |

| Online Retailers | Numerous websites specialize in marine supplies, providing a wide selection of components. Ensure to verify the credibility of the retailer before making a purchase. |

| Local Marine Shops | Check nearby stores that sell boating supplies. Staff members may assist you in finding what you need or ordering it for you. |

| Salvage Yards | Explore salvage yards that focus on marine vessels. You can often find used components at lower prices, but ensure they are in good condition. |

| Online Marketplaces | Platforms like eBay or Craigslist may have listings for various components. However, it’s essential to communicate with the seller to confirm the item’s condition. |

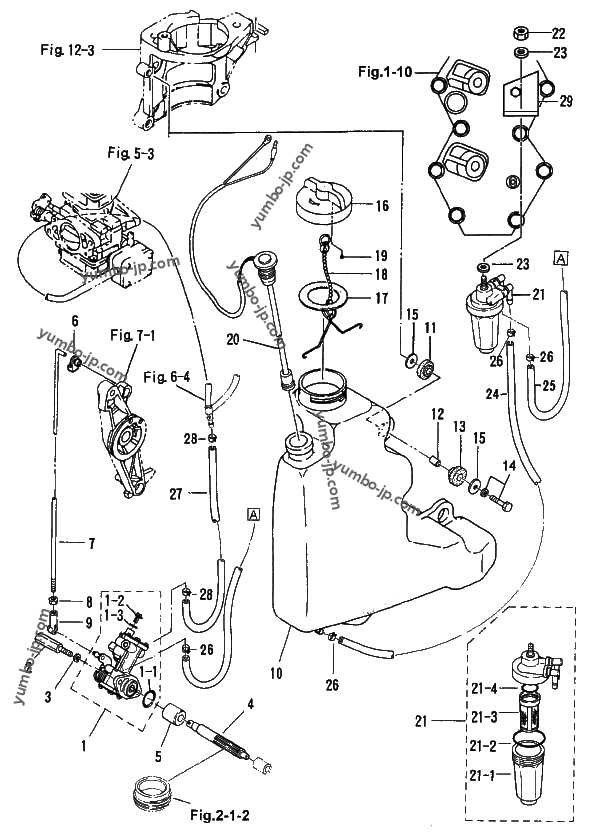

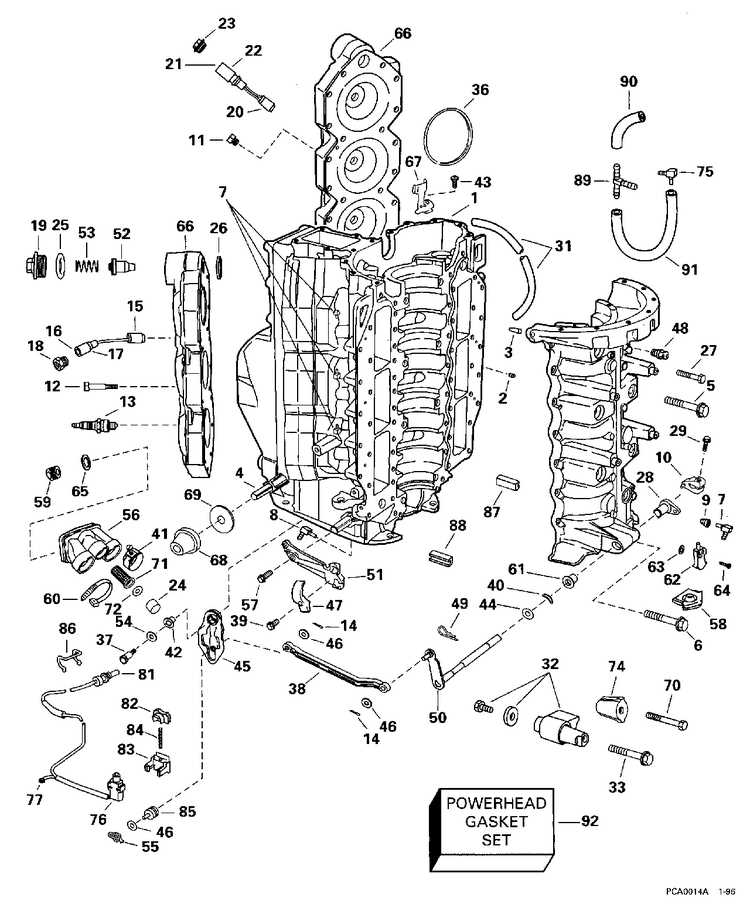

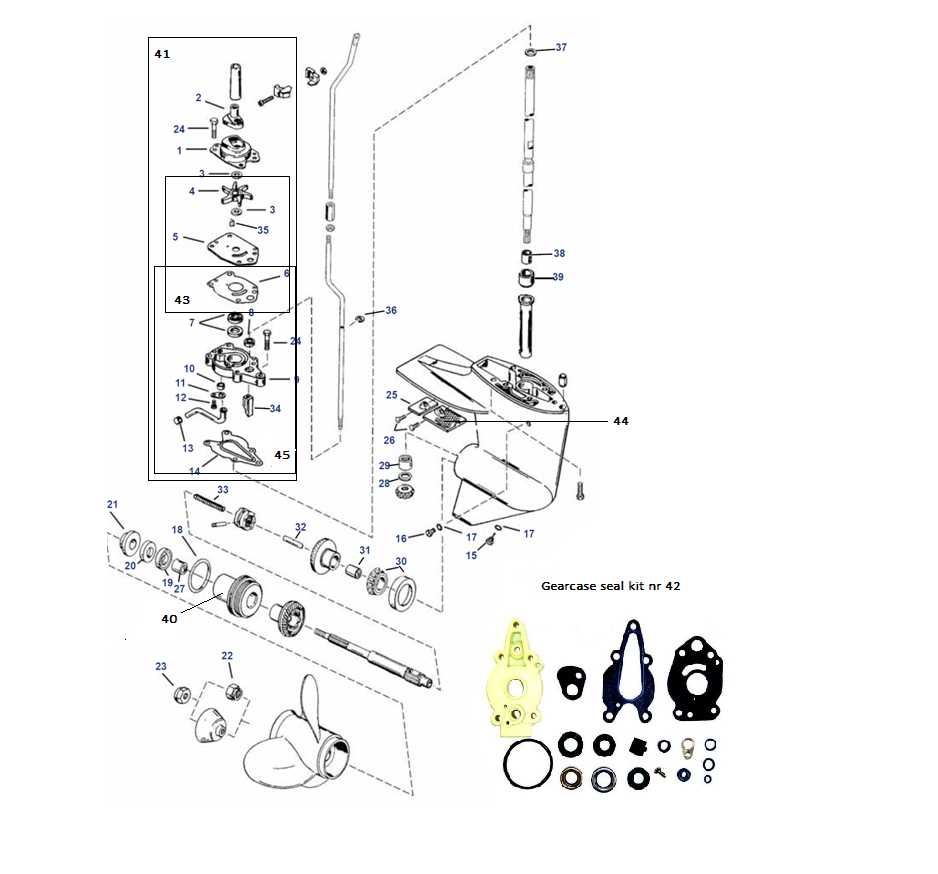

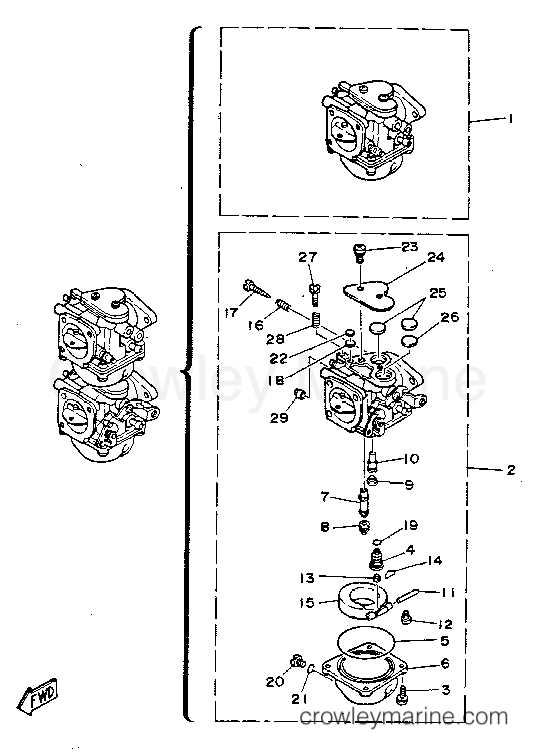

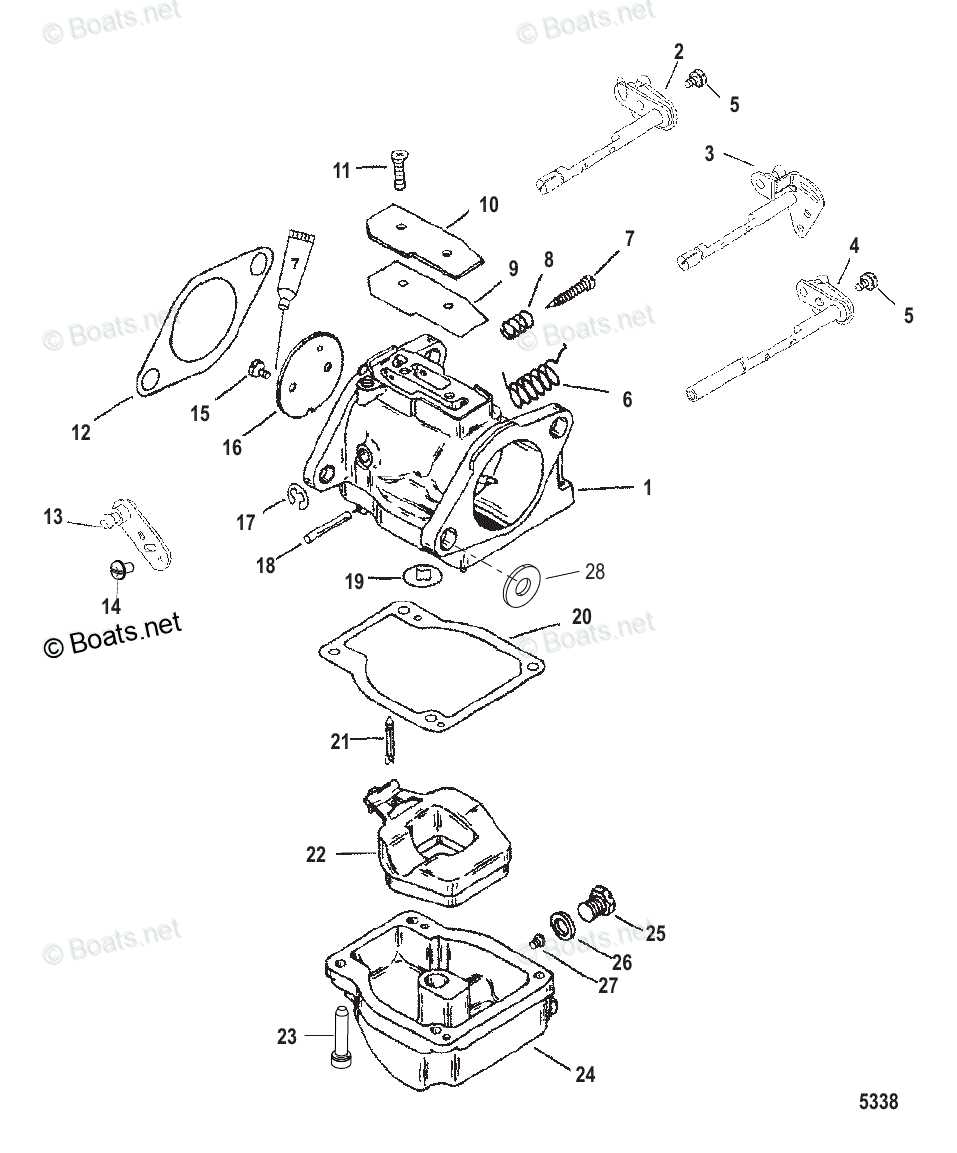

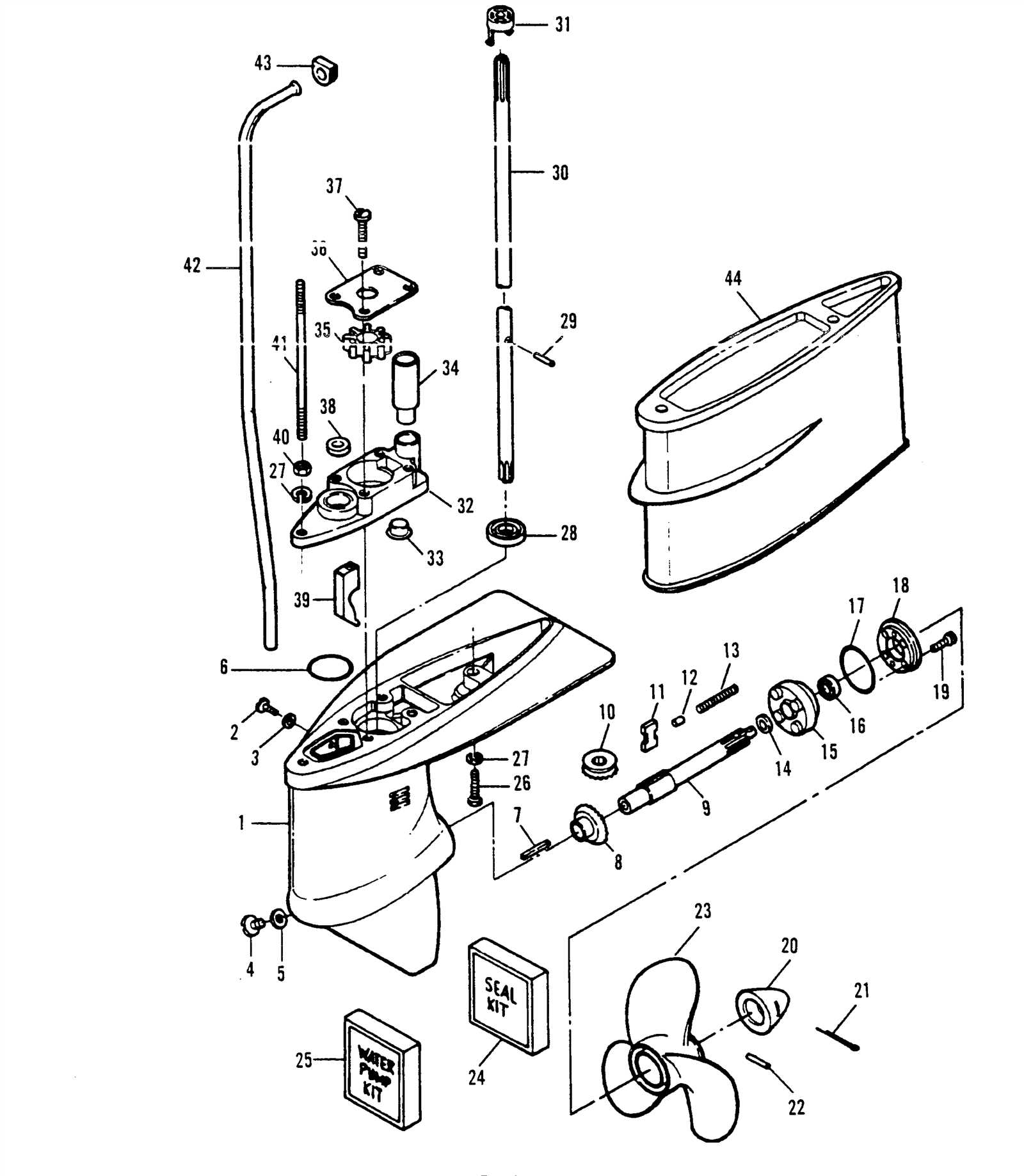

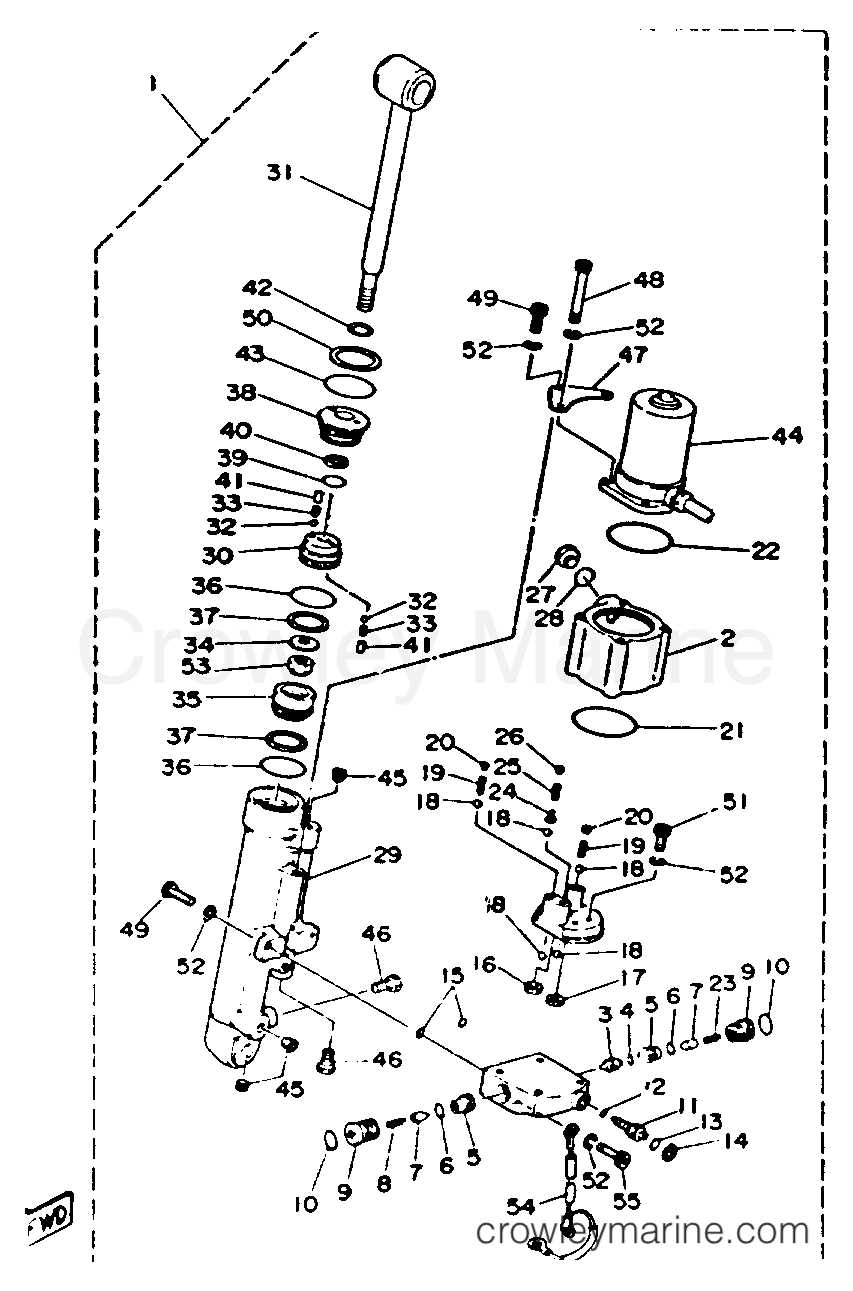

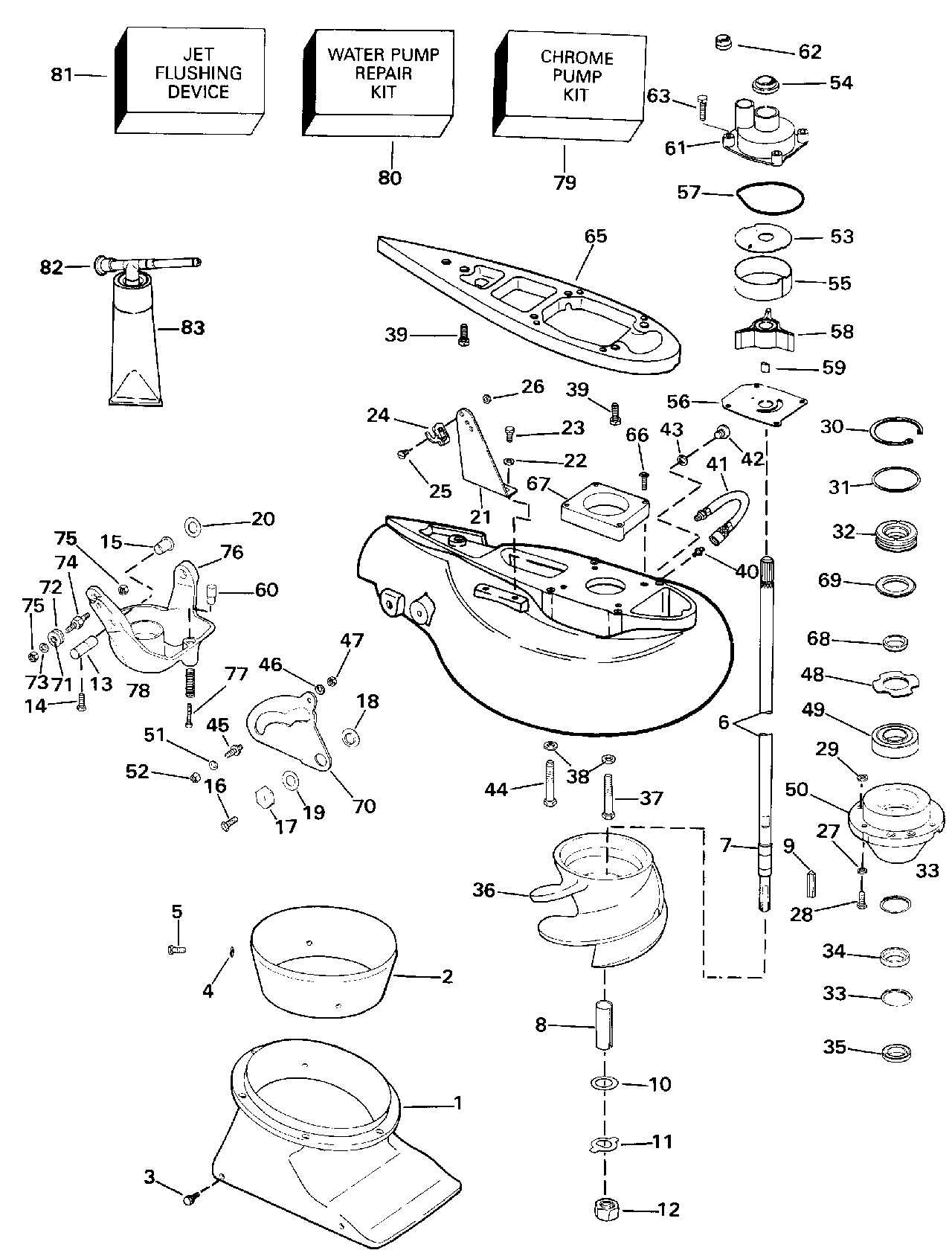

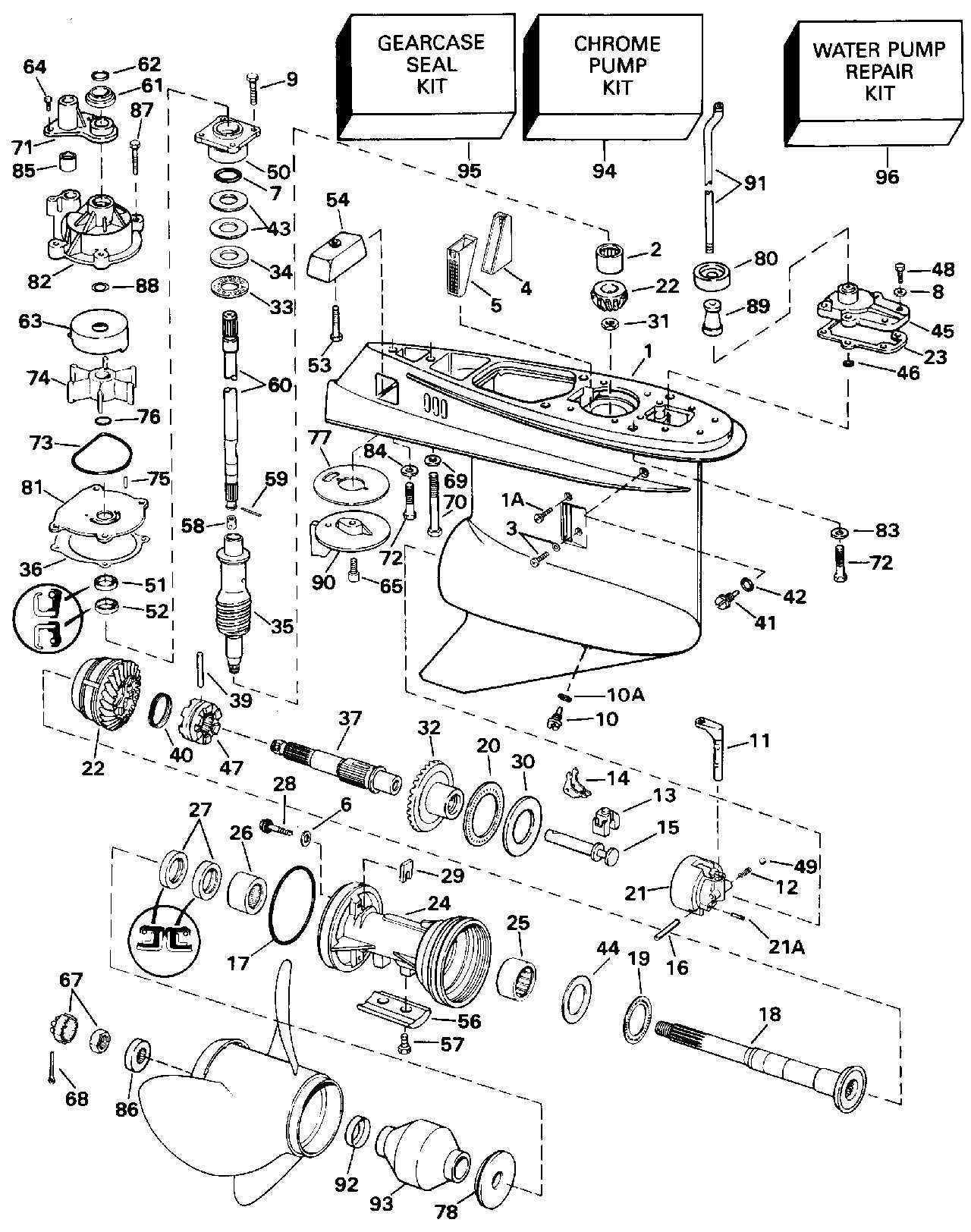

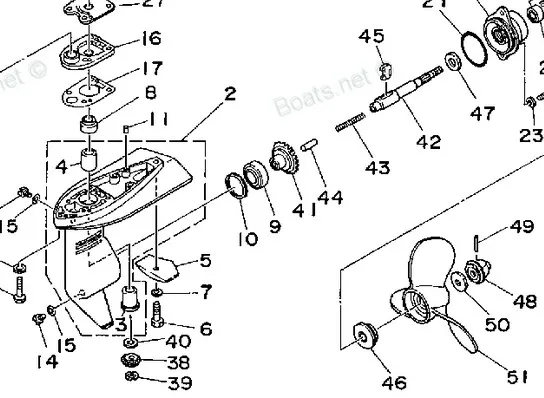

Diagrams for Easy Reference

Visual representations are invaluable tools for understanding the components and assembly of various equipment. By utilizing these illustrations, users can quickly locate and identify specific elements, facilitating more efficient maintenance and repairs. This section aims to provide clear and accessible resources that enhance the user experience.

Types of Illustrations

- Exploded Views: Offer a detailed perspective of each component and how they fit together.

- Schematic Drawings: Simplify the electrical connections and flow within the system.

- Labelled Images: Highlight key parts, making it easier to identify and understand their functions.

Benefits of Using Visual Aids

- Improved Understanding: Clear visuals help users grasp complex setups.

- Time Efficiency: Quick reference to diagrams saves time during troubleshooting.

- Enhanced Learning: New users can easily learn about the equipment through visual cues.

How to Read Parts Diagrams

Understanding assembly illustrations is crucial for effective maintenance and repair tasks. These visuals provide a clear overview of components, their arrangement, and interactions within a system. By mastering the interpretation of these illustrations, you can efficiently identify needed items and navigate repair procedures with confidence.

Here are some key elements to consider when examining assembly illustrations:

- Symbols and Labels: Each component typically has unique symbols or labels that correspond to specific items. Familiarize yourself with these to quickly identify parts.

- Numbering System: Often, illustrations will feature a numbering system that correlates with a parts list. This allows for easy cross-referencing between the visual and the accompanying documentation.

- Section Views: Pay attention to section views that show internal details of assemblies. These views can provide insights into how parts fit together and function as a whole.

- Color Coding: Some diagrams use color coding to differentiate between various systems or components. Recognizing these color codes can help streamline your understanding.

By carefully analyzing these aspects, you can develop a comprehensive understanding of the components and their relationships within the system. This knowledge is essential for effective repairs and maintenance.

Tips for Ordering Correct Parts

Ensuring you acquire the right components for your marine engine is crucial for optimal performance and longevity. Navigating the selection process can be daunting, but following a few guidelines can streamline your experience and lead to successful purchases.

Here are some essential recommendations:

| Tip | Description |

|---|---|

| Identify Model Information | Gather specific details regarding the engine’s model and serial number to facilitate accurate searches. |

| Use Reliable Sources | Purchase from reputable dealers or manufacturers to guarantee the authenticity of the components. |

| Compare Prices | Review multiple sources to find competitive pricing and avoid overspending on necessary items. |

| Consult with Experts | Engage with knowledgeable professionals for advice on selecting the appropriate components for your needs. |

| Review Return Policies | Understand the return procedures in case the wrong items are ordered, providing peace of mind with your purchase. |

Installation Guidelines for New Parts

When integrating fresh components into your marine engine, it’s essential to adhere to specific procedures to ensure optimal performance and longevity. Proper installation not only enhances functionality but also minimizes the risk of damage to both the new elements and the existing systems. This section outlines critical steps and considerations for achieving a successful integration.

Preparation Steps

Before beginning the installation, gather all necessary tools and components. Inspect each item to confirm that it is free from defects and compatible with your system. Familiarize yourself with the installation manual, if available, to understand the specifics of each component’s placement and attachment.

Installation Process

Follow these steps to effectively install the new components:

| Step | Action |

|---|---|

| 1 | Disconnect the power source to ensure safety. |

| 2 | Remove any existing components that may obstruct access. |

| 3 | Position the new component in the designated area, ensuring proper alignment. |

| 4 | Secure the component using the appropriate fasteners, avoiding over-tightening. |

| 5 | Reassemble any removed components and reconnect the power source. |

| 6 | Conduct a thorough test to verify functionality and check for leaks. |

By following these guidelines, you can achieve a smooth installation process, ensuring that your marine engine operates at its best.

Safety Precautions for Repairs

When undertaking maintenance or restoration of marine engines, it is essential to prioritize safety. Proper precautions ensure not only personal well-being but also the integrity of the equipment. Adhering to safety guidelines minimizes the risk of accidents and injuries during the repair process.

Use Personal Protective Equipment

Always equip yourself with appropriate personal protective gear. This includes gloves to shield your hands from sharp objects and harmful substances, safety goggles to protect your eyes from debris, and sturdy footwear to prevent slips and falls. Having a well-stocked first aid kit nearby is also advisable.

Work in a Ventilated Area

Ensure that your workspace is well-ventilated to avoid inhaling harmful fumes and vapors. Proper airflow reduces the risk of respiratory issues and allows for a safer working environment. If necessary, use fans or ventilation systems to maintain air quality.

Remember: Prioritizing safety not only protects you but also enhances the quality of your work. Always follow manufacturer guidelines and consult professionals when in doubt.

Performance Upgrades for 1993 Models

Enhancing the efficiency and power of earlier engine models can significantly improve overall performance on the water. Various modifications and upgrades can be implemented to achieve better speed, acceleration, and fuel efficiency. This section explores some effective strategies and components that can elevate performance levels.

Engine Modifications

- Carburetor Tuning: Adjusting the carburetor can optimize fuel delivery, resulting in improved throttle response and acceleration.

- Exhaust System Upgrades: Upgrading the exhaust system can enhance airflow, reducing back pressure and increasing horsepower.

- Propeller Selection: Choosing the right propeller pitch can significantly affect speed and efficiency, enabling better planing and handling.

Electrical Enhancements

- Ignition System Improvement: Upgrading to a high-performance ignition system can provide a stronger spark, improving combustion and engine responsiveness.

- Battery and Charging System: A more powerful battery and a reliable charging system can ensure consistent performance, especially during long trips.

- Gauge Monitoring: Installing modern gauges can help monitor critical engine parameters, allowing for timely adjustments and maintenance.