Understanding the key elements of small marine engines is crucial for optimal performance and maintenance. These units play a significant role in powering various watercraft, ensuring smooth navigation and enhancing the overall boating experience. Familiarizing oneself with the arrangement and functionality of these components can aid in effective troubleshooting and repair.

Each engine consists of various essential elements that work together seamlessly. Recognizing the individual parts and their respective roles can greatly assist in both routine checks and significant overhauls. Detailed visual representations can serve as valuable references, guiding enthusiasts and technicians alike in their endeavors to keep these machines in peak condition.

Whether you are an experienced mechanic or a boating novice, having access to comprehensive schematics and descriptions is beneficial. These resources can provide clarity on assembly, maintenance, and necessary adjustments, ensuring that your marine engine operates efficiently and reliably over time.

Overview of Mercury 25 HP Outboard

This section provides a comprehensive look at a specific model of a portable marine engine known for its reliability and efficiency. Designed for various boating applications, this engine has become a popular choice among enthusiasts and casual users alike. Its robust construction and straightforward design contribute to its ease of use and maintenance.

Featuring an impressive power-to-weight ratio, this model offers excellent performance on the water, making it suitable for both leisure and commercial activities. The engine’s compact size allows for convenient installation on a range of watercraft, enhancing maneuverability without compromising power.

Maintenance and servicing are simplified, thanks to a well-thought-out design that allows easy access to key components. Understanding the layout and function of each element is crucial for optimizing performance and extending the lifespan of the engine.

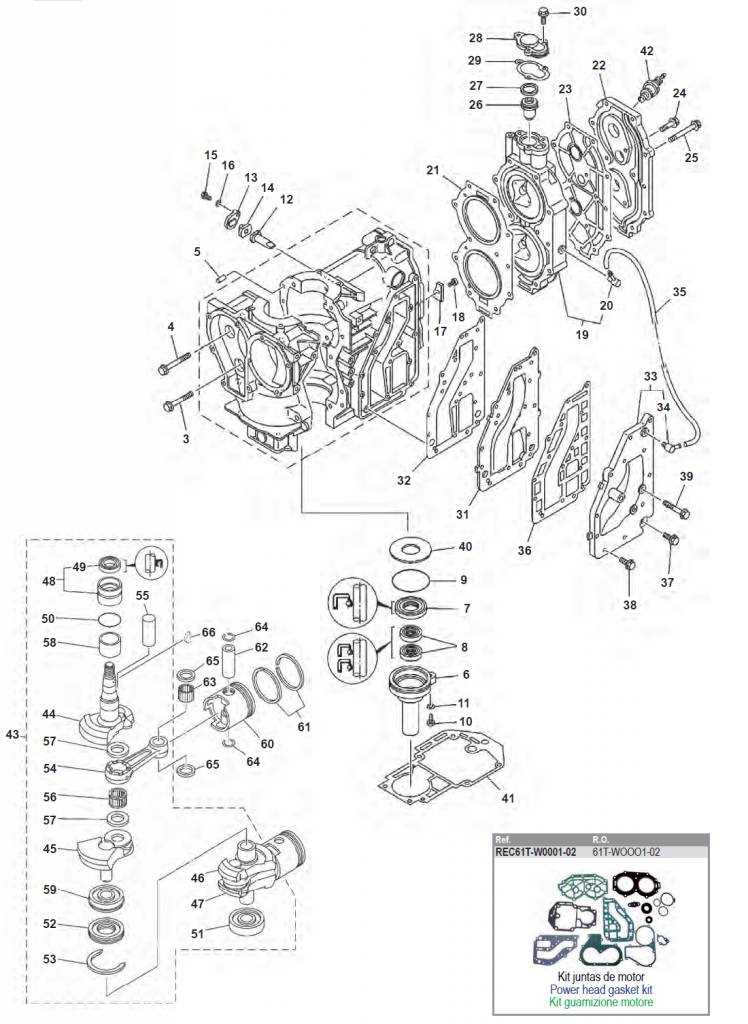

Understanding Engine Components

Comprehending the various elements that constitute a motor is essential for optimal performance and maintenance. Each component plays a crucial role in the overall function of the machine, contributing to efficiency and reliability. A thorough knowledge of these elements can enhance troubleshooting and repair efforts, leading to prolonged durability and enhanced operation.

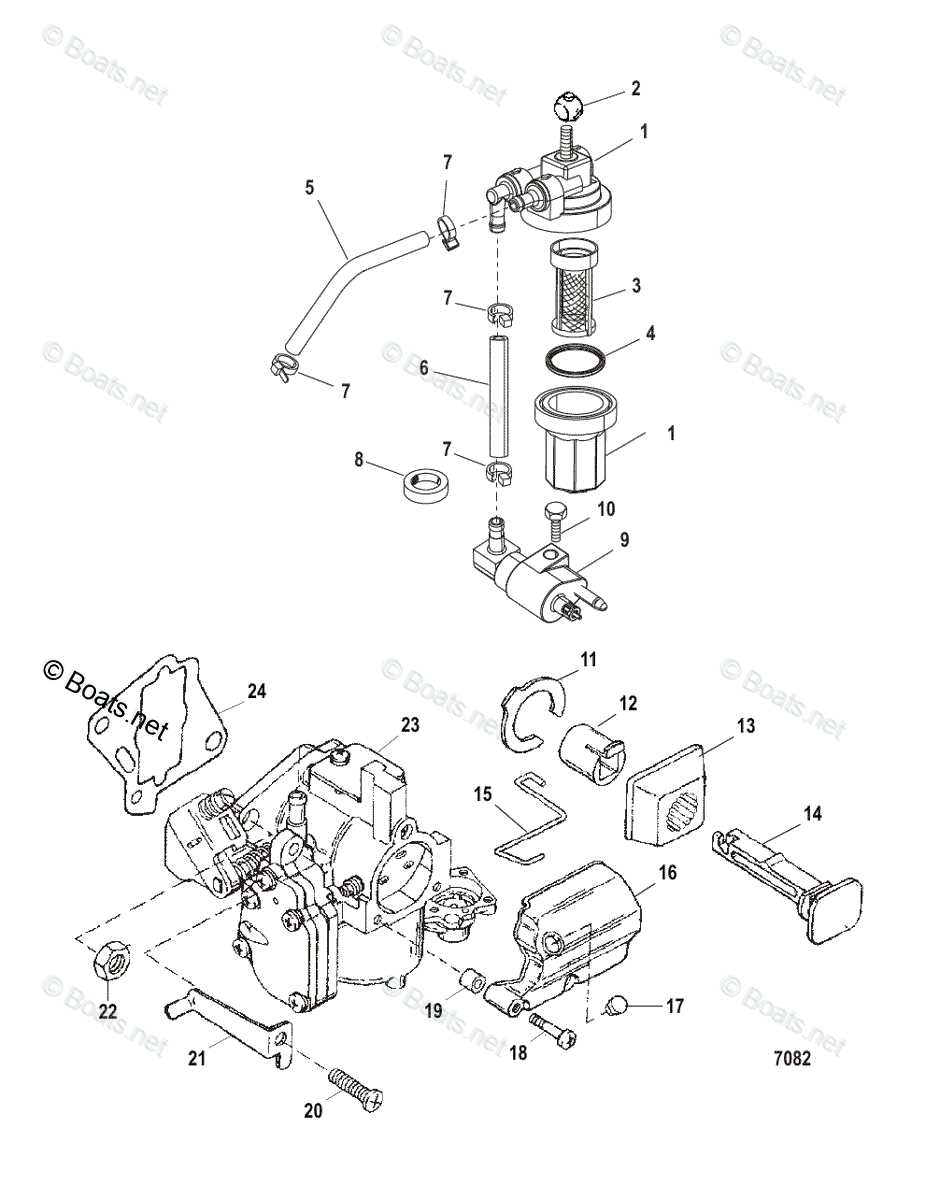

Key Elements of the Engine

The core assembly comprises several critical units, including the power generation section, fuel delivery mechanism, and cooling systems. Each of these components is designed to work in harmony, ensuring that the engine operates smoothly under different conditions. Understanding the interaction between these elements allows for better diagnostics and repairs.

Importance of Maintenance

Regular upkeep of these components is vital for sustaining peak performance. Routine inspections and timely replacements help prevent unexpected breakdowns and extend the engine’s lifespan. Familiarity with the individual parts enables users to identify wear and tear, ensuring that all elements function effectively.

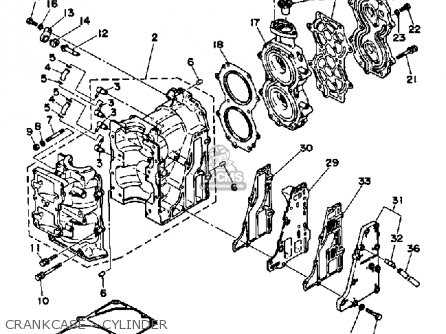

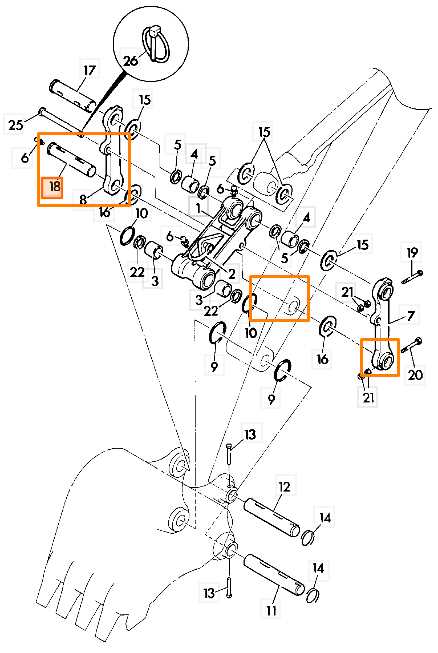

Diagram Interpretation and Usage

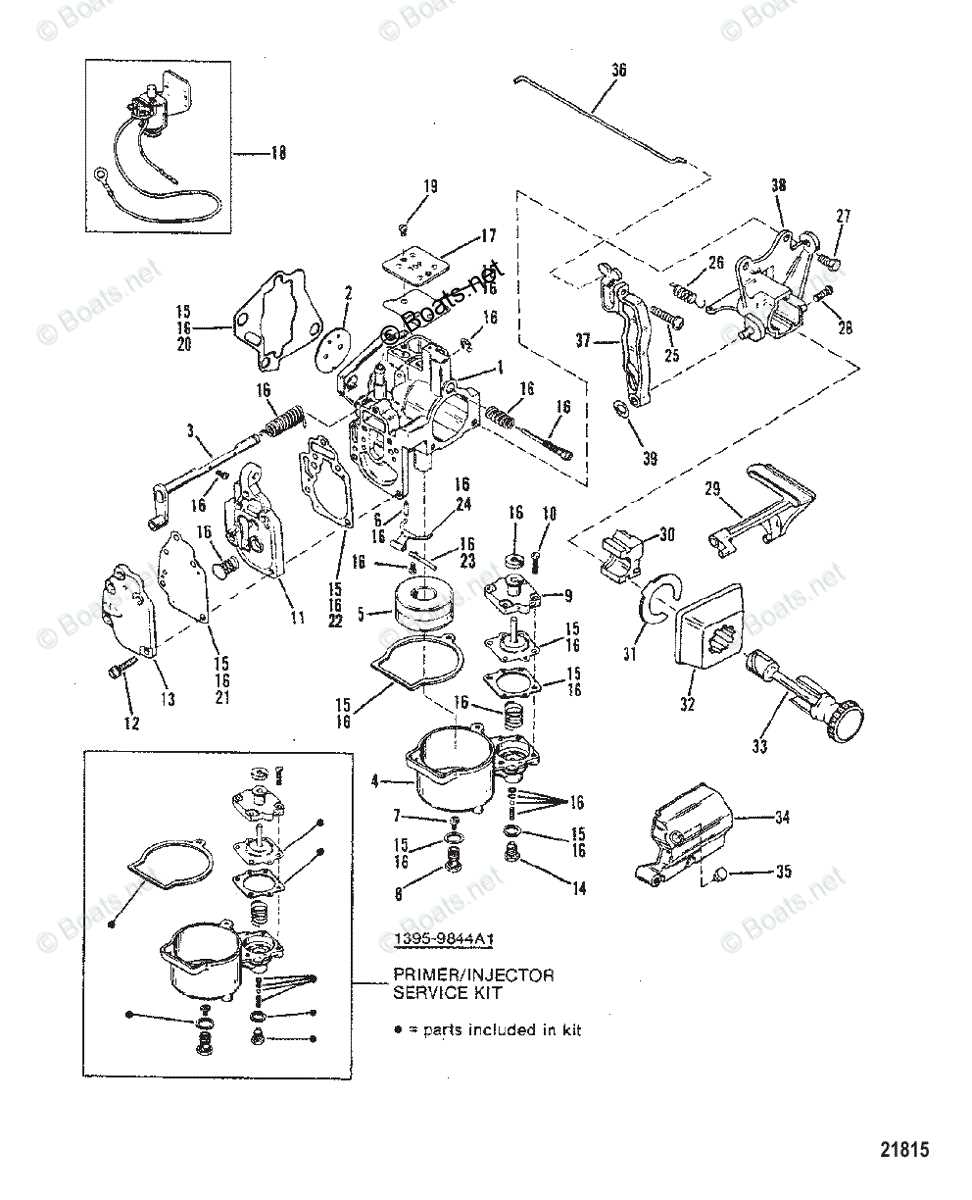

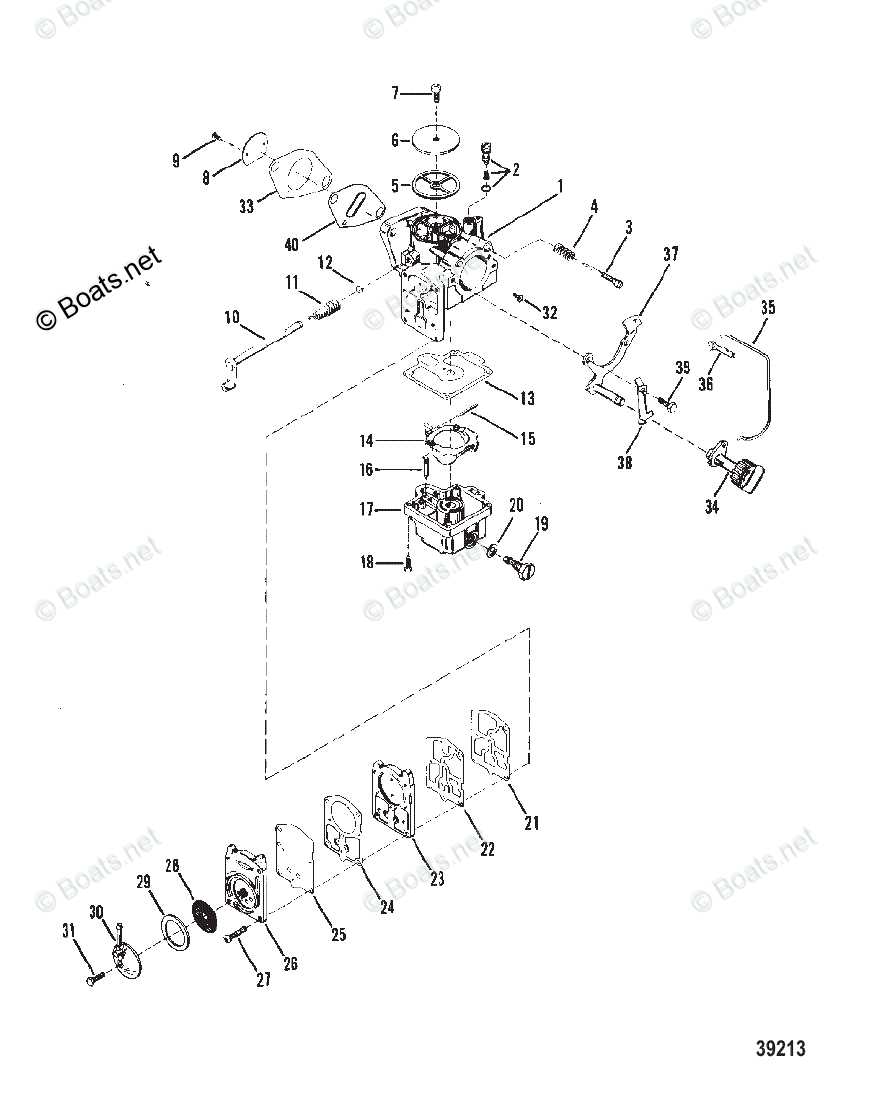

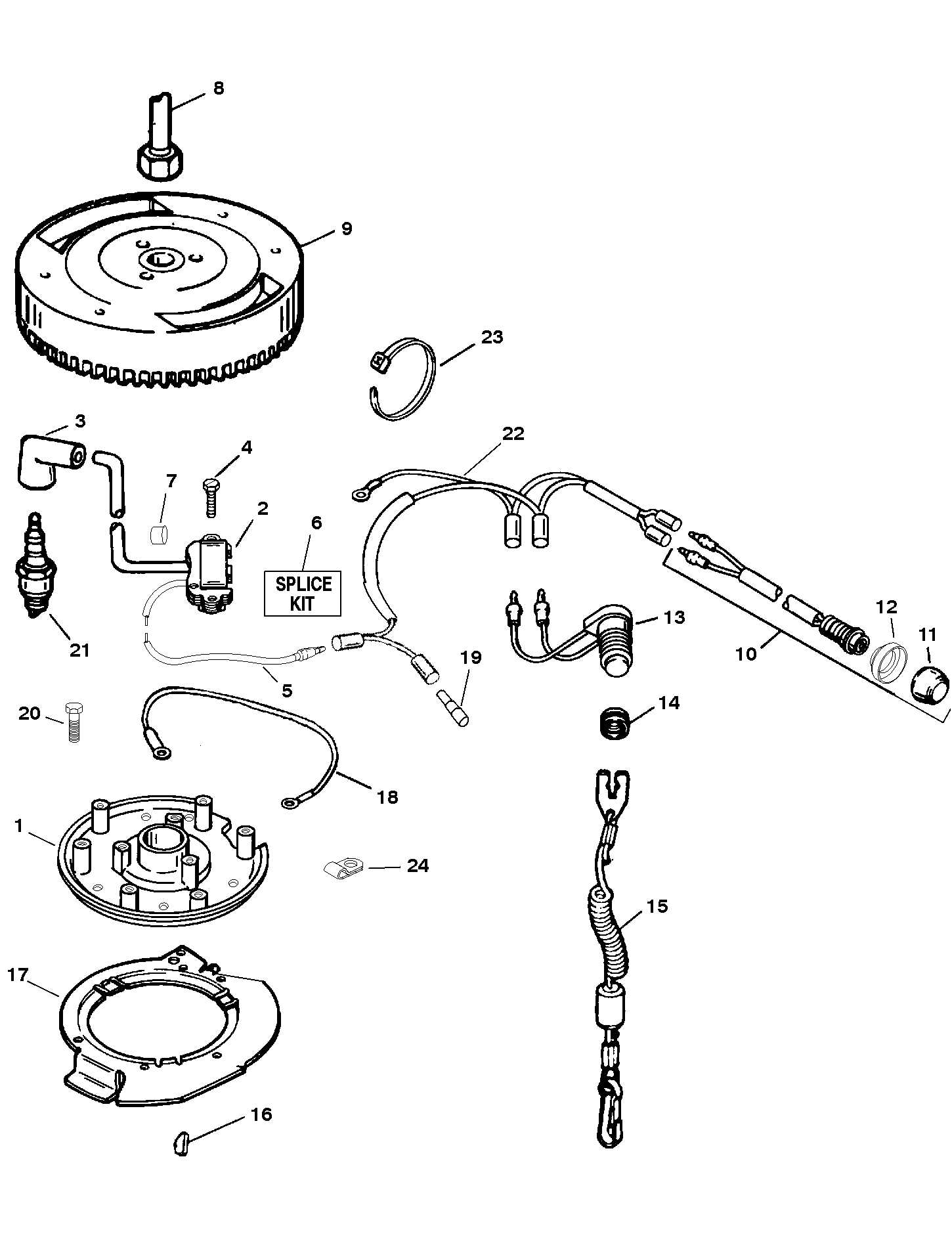

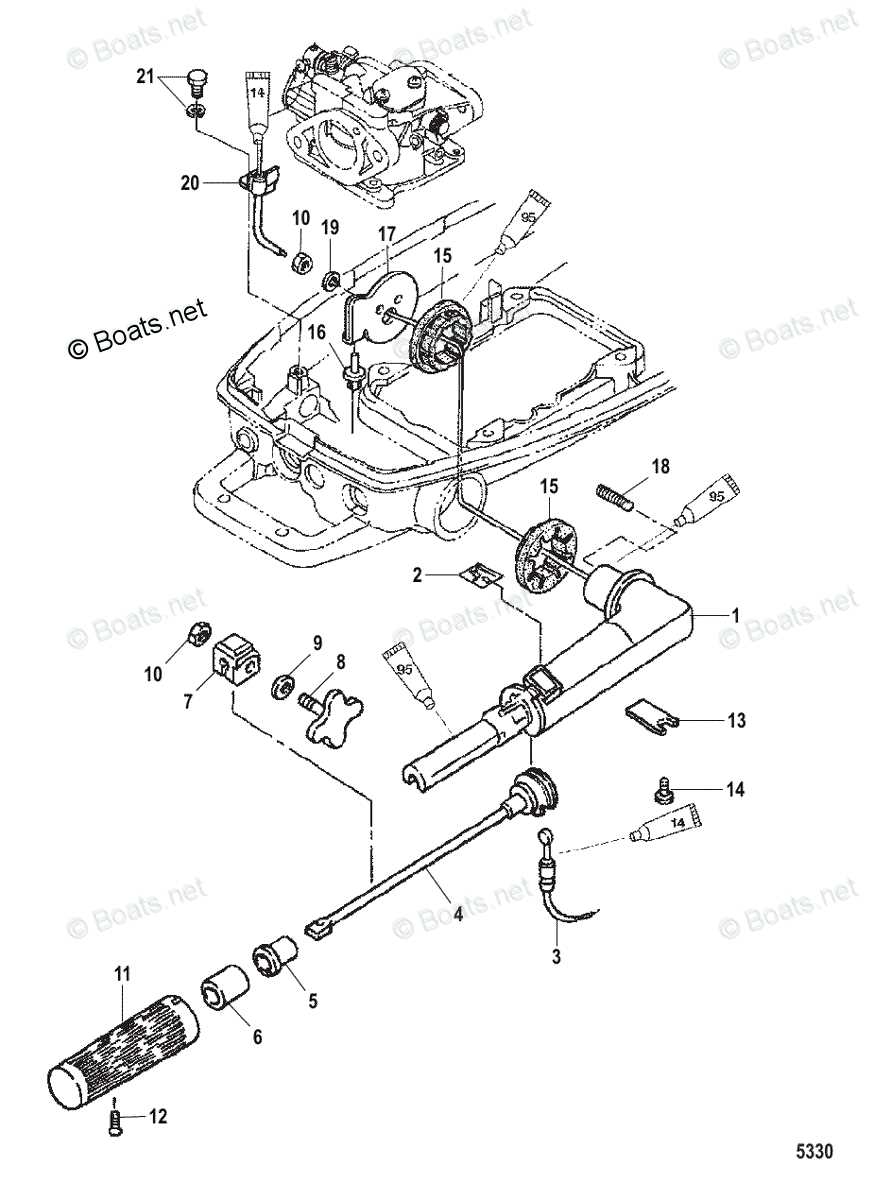

Understanding technical illustrations is essential for anyone working with mechanical equipment. These visual aids provide crucial information about the components and their relationships, enabling users to troubleshoot issues effectively. A clear grasp of these representations enhances maintenance efforts and simplifies repairs.

Reading the Illustration

When examining a technical illustration, it’s important to familiarize oneself with the symbols and notations used. Each element typically corresponds to a specific feature or assembly, allowing for easy identification of parts and their functions. Pay attention to the layout, as it often indicates the sequence of assembly or disassembly, guiding users through the process seamlessly.

Practical Applications

The insights gained from interpreting these visuals can significantly impact the efficiency of repairs and maintenance. Users can pinpoint problems quickly, reduce downtime, and ensure that all components are correctly aligned during reassembly. Additionally, referring to these guides fosters a better understanding of the overall mechanics, ultimately enhancing the user’s skill set.

Key Parts and Their Functions

Understanding the essential components of a marine engine is crucial for effective operation and maintenance. Each element plays a significant role in ensuring smooth performance and reliability on the water. Familiarity with these crucial elements can help owners troubleshoot issues and perform routine checks more efficiently.

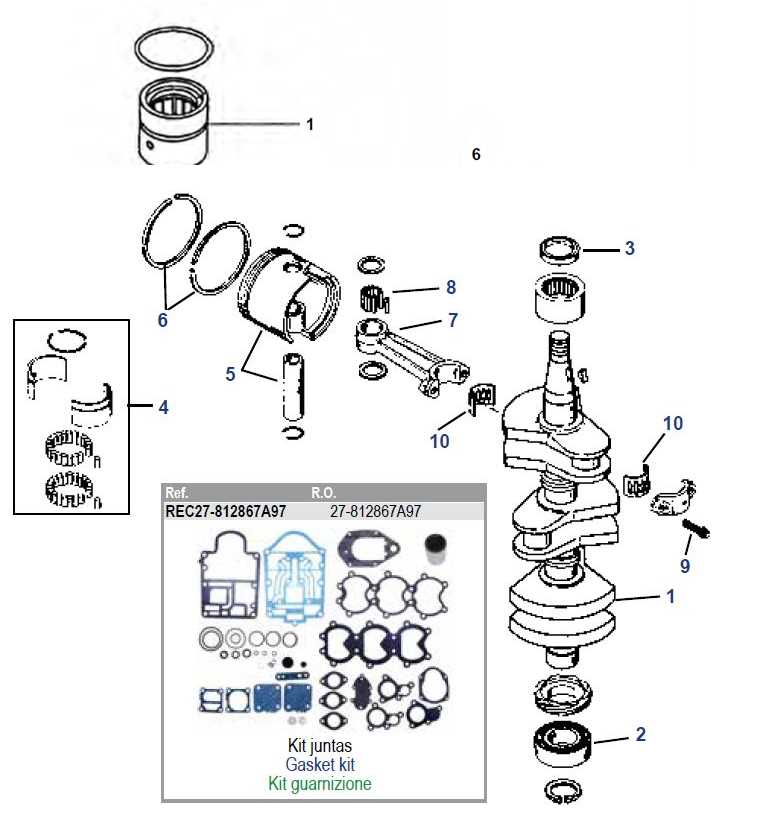

Powerhead and Its Significance

The powerhead is the heart of the engine, housing the vital mechanisms that generate propulsion. This component includes the cylinder, piston, and crankshaft, all working together to convert fuel into energy. A well-functioning powerhead is essential for achieving optimal performance and speed.

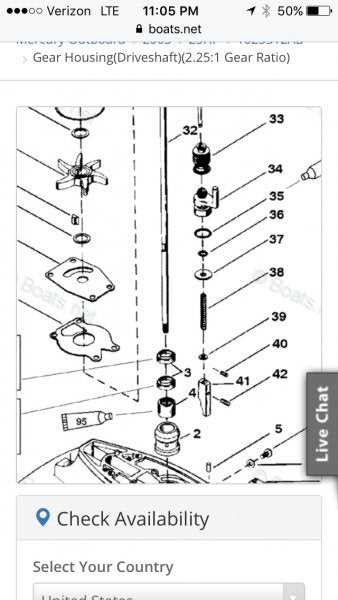

Gear Case Functionality

The gear case serves as the connecting link between the engine and the propeller, transmitting power to drive the vessel. It contains gears that adjust the rotation speed and torque, enabling effective maneuverability. Maintaining this part is critical, as any malfunction can lead to reduced efficiency and control.

Maintenance Tips for Longevity

Ensuring the durability of your marine engine involves regular upkeep and attention to detail. Proper maintenance not only enhances performance but also extends the lifespan of your equipment, allowing you to enjoy countless hours on the water without worry.

Regular Inspection: Frequent checks are crucial for identifying wear and tear early. Examine key components such as the fuel system, electrical connections, and the propeller. Addressing minor issues promptly can prevent more significant problems later on.

Fluid Changes: Routine replacement of essential fluids, including engine oil and fuel, is vital. Clean fluids reduce the risk of corrosion and improve the overall efficiency of your machine.

Cleanliness Matters: Keeping your engine free from debris and contaminants will promote optimal performance. Rinse the exterior after use in saltwater and ensure that cooling passages remain clear to avoid overheating.

Proper Storage: When not in use, store your engine in a dry and protected environment. Covering it with a suitable tarp can shield it from dust and moisture, preventing deterioration over time.

Professional Servicing: Consider seeking professional maintenance at regular intervals. Experienced technicians can provide insights and services that are essential for maintaining your equipment’s functionality.

Common Issues and Solutions

This section addresses frequent problems encountered with marine propulsion systems and offers effective remedies. Understanding these challenges can help users maintain optimal performance and extend the lifespan of their equipment.

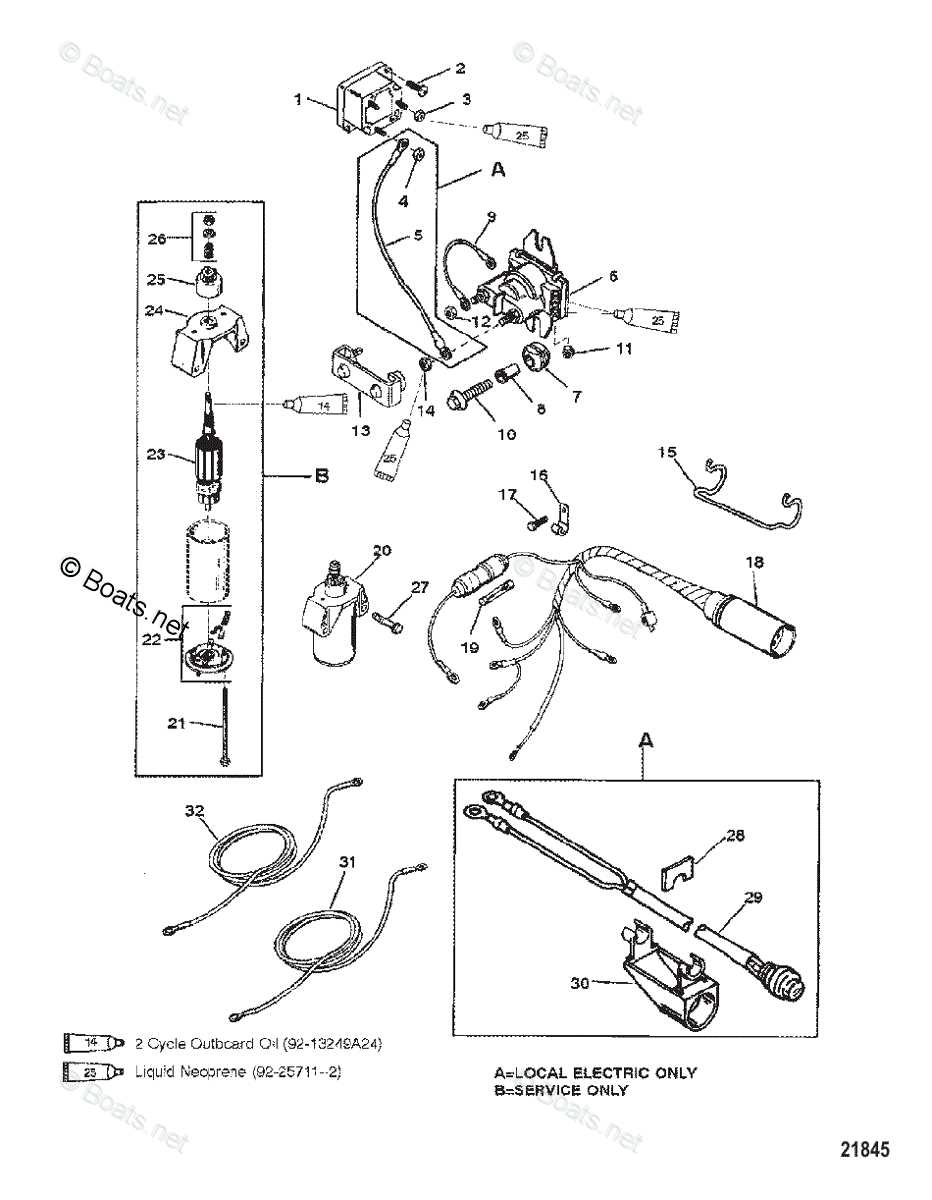

Engine Fails to Start

One of the most common challenges is when the engine does not ignite. This issue can stem from various sources, including a drained battery, faulty ignition system, or fuel delivery problems. To troubleshoot, check the battery charge and connections, inspect the spark plugs for wear, and ensure that fuel is reaching the combustion chamber.

Overheating

Another prevalent concern is overheating, which can lead to severe damage if not addressed promptly. Causes may include a blocked cooling system, low coolant levels, or a malfunctioning thermostat. Regularly inspect the cooling passages for debris, ensure adequate coolant levels, and replace any defective components to maintain safe operating temperatures.

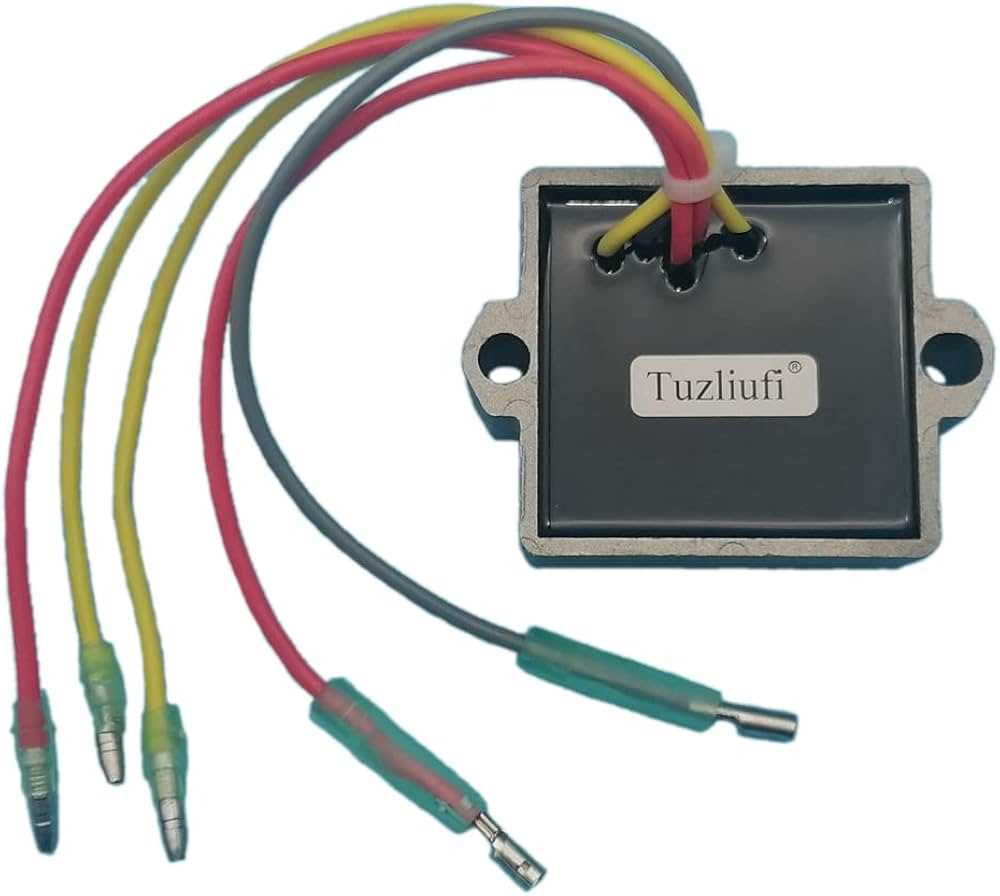

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for maintaining the performance and longevity of your engine. Distinguishing original elements from imitations can save you time, money, and frustration in the long run. Here are some effective strategies to help you recognize genuine items.

Examine Packaging and Labels

Authentic components typically come in high-quality packaging with clear branding and serial numbers. Look for any inconsistencies or misspellings on the label, as these may indicate a counterfeit product. Additionally, verify that the packaging includes the manufacturer’s contact information and warranty details.

Check for Certification Marks

Original items often feature certification marks or seals of approval. These symbols ensure that the product meets specific quality standards. Always verify the legitimacy of these marks by cross-referencing them with the manufacturer’s official website.

Replacement Procedures for Major Parts

Replacing significant components in marine engines is crucial for maintaining optimal performance and longevity. This process often involves a series of systematic steps that ensure proper installation and functionality. Familiarizing yourself with the replacement protocols can significantly enhance the efficiency of your vessel.

Essential Tools and Equipment

Before commencing any replacement tasks, it is vital to gather the necessary tools and equipment. Having the right tools at hand not only facilitates the process but also minimizes the risk of damage to surrounding components.

| Tool | Description |

|---|---|

| Wrench Set | Used for loosening and tightening bolts on various components. |

| Screwdriver Set | Essential for removing screws from covers and panels. |

| Pliers | Useful for gripping and manipulating small parts. |

| Torque Wrench | Ensures bolts are tightened to manufacturer specifications. |

Step-by-Step Replacement Process

Follow these steps to effectively replace major components:

- Begin by disconnecting the power source to prevent accidental startups.

- Remove any covers or panels to access the components needing replacement.

- Carefully detach the old component, taking note of its connection points.

- Install the new component, ensuring all connections are secure and aligned.

- Reassemble any covers or panels that were removed during the process.

- Reconnect the power source and conduct a thorough test to verify functionality.

Tools Required for Repairs

To effectively carry out maintenance and fix issues with a marine engine, having the right tools is essential. Proper equipment not only simplifies the repair process but also ensures that tasks are completed safely and efficiently. Below is a comprehensive list of necessary tools that will aid in various repair tasks.

Essential Tools

- Socket set: A variety of sizes is required to handle different bolts and screws.

- Screwdrivers: Both flathead and Phillips types should be available.

- Wrenches: Adjustable and fixed wrenches for various nut sizes.

- Pliers: Needle-nose and standard pliers for gripping and twisting wires.

- Torque wrench: For applying precise torque settings to fasteners.

Specialized Equipment

- Multimeter: Useful for checking electrical components and diagnosing issues.

- Fuel line tool: Essential for servicing fuel lines without damaging them.

- Propeller puller: Helps in removing the propeller safely.

- Engine stand: Provides stability and support while working on the engine.

Having these tools readily available will significantly improve the efficiency of repair tasks, allowing for a thorough and effective servicing experience.

Safety Precautions During Maintenance

Ensuring safety during the upkeep of marine engines is paramount. Proper precautions help prevent accidents and damage to both the equipment and the individual performing the maintenance. Adhering to established guidelines can significantly enhance the safety of the working environment.

Before beginning any maintenance tasks, consider the following essential measures:

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Ensure the engine is turned off and cooled down to prevent burns or injuries.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Have a fire extinguisher readily accessible in case of emergencies.

- Keep tools organized and within reach to prevent accidents while searching for items.

Additionally, it is vital to follow specific instructions provided in the maintenance manual to ensure compliance with safety standards. Regular inspections of tools and equipment can also contribute to a safer working environment.

By prioritizing safety, you can perform maintenance effectively and reduce the risk of unforeseen incidents.

Upgrades for Enhanced Performance

Improving the efficiency and capability of your marine engine can significantly enhance your boating experience. Various modifications and enhancements can be applied to achieve better speed, fuel economy, and overall performance. By focusing on specific components, you can unlock the true potential of your vessel.

Essential Modifications

Several modifications can be implemented to optimize engine performance. Upgrading certain components not only increases power but also enhances reliability during operation. These adjustments are particularly beneficial for avid boaters seeking improved handling and responsiveness.

Performance Enhancement Options

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Propeller | Replacing the stock propeller with a high-performance variant for better thrust. | Increased speed and improved fuel efficiency. |

| Ignition System Upgrade | Installing a more efficient ignition system to enhance spark delivery. | Improved acceleration and smoother operation. |

| Fuel System Optimization | Upgrading fuel lines and filters for better flow and filtration. | Enhanced power output and reduced maintenance. |

Resources for Further Assistance

When navigating the complexities of engine maintenance and repair, having access to reliable resources can significantly enhance the experience. This section provides various avenues for acquiring additional support, whether through manuals, online forums, or professional services.

Online Communities

Participating in online forums dedicated to marine engines can be invaluable. These platforms allow enthusiasts and experts to share their knowledge, troubleshoot issues, and provide guidance. Engaging with these communities can lead to useful tips and practical advice tailored to specific challenges.

Official Documentation

Accessing official manuals and documentation is crucial for understanding the intricacies of your engine. These resources often contain detailed instructions, maintenance schedules, and troubleshooting guides. Utilizing these materials ensures that you follow recommended practices, enhancing the longevity and performance of your equipment.