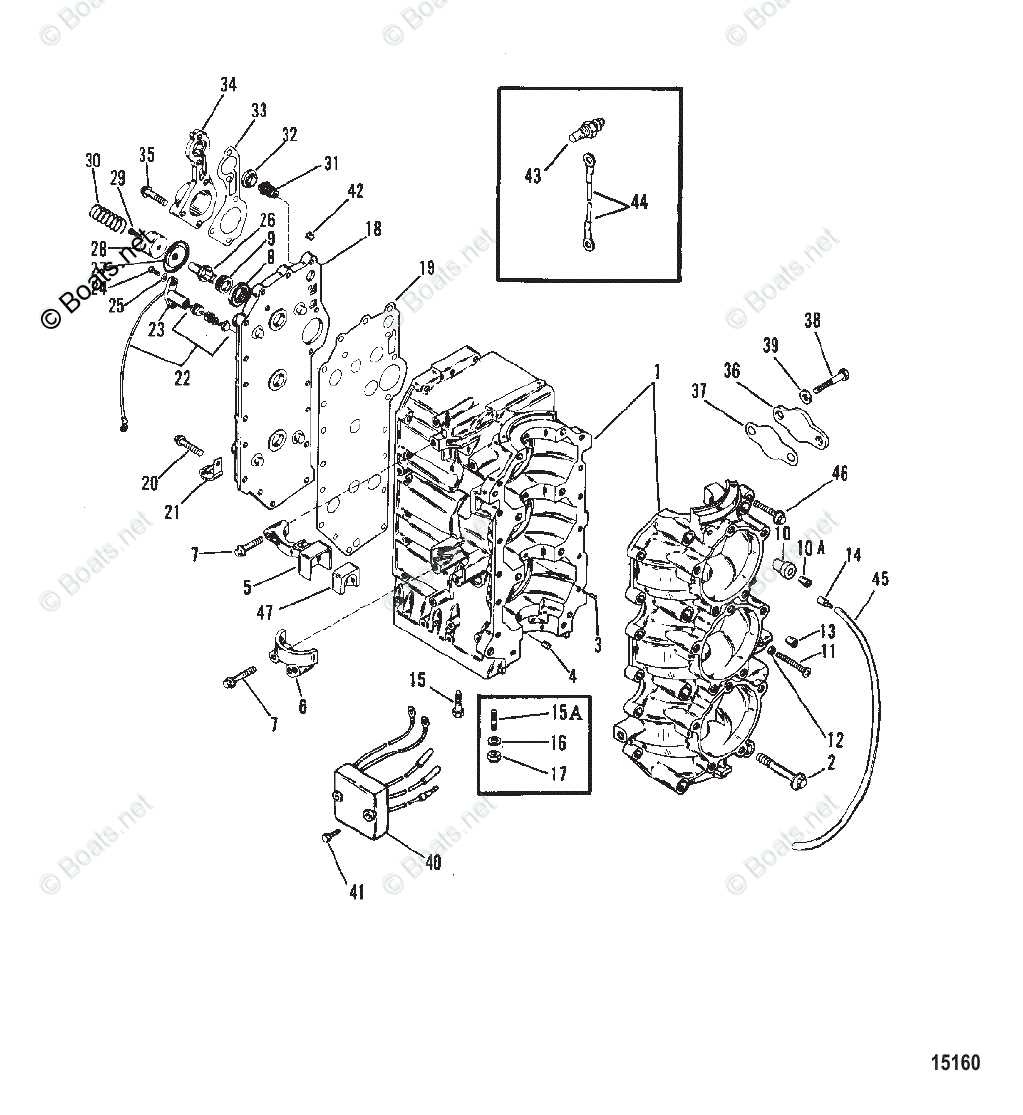

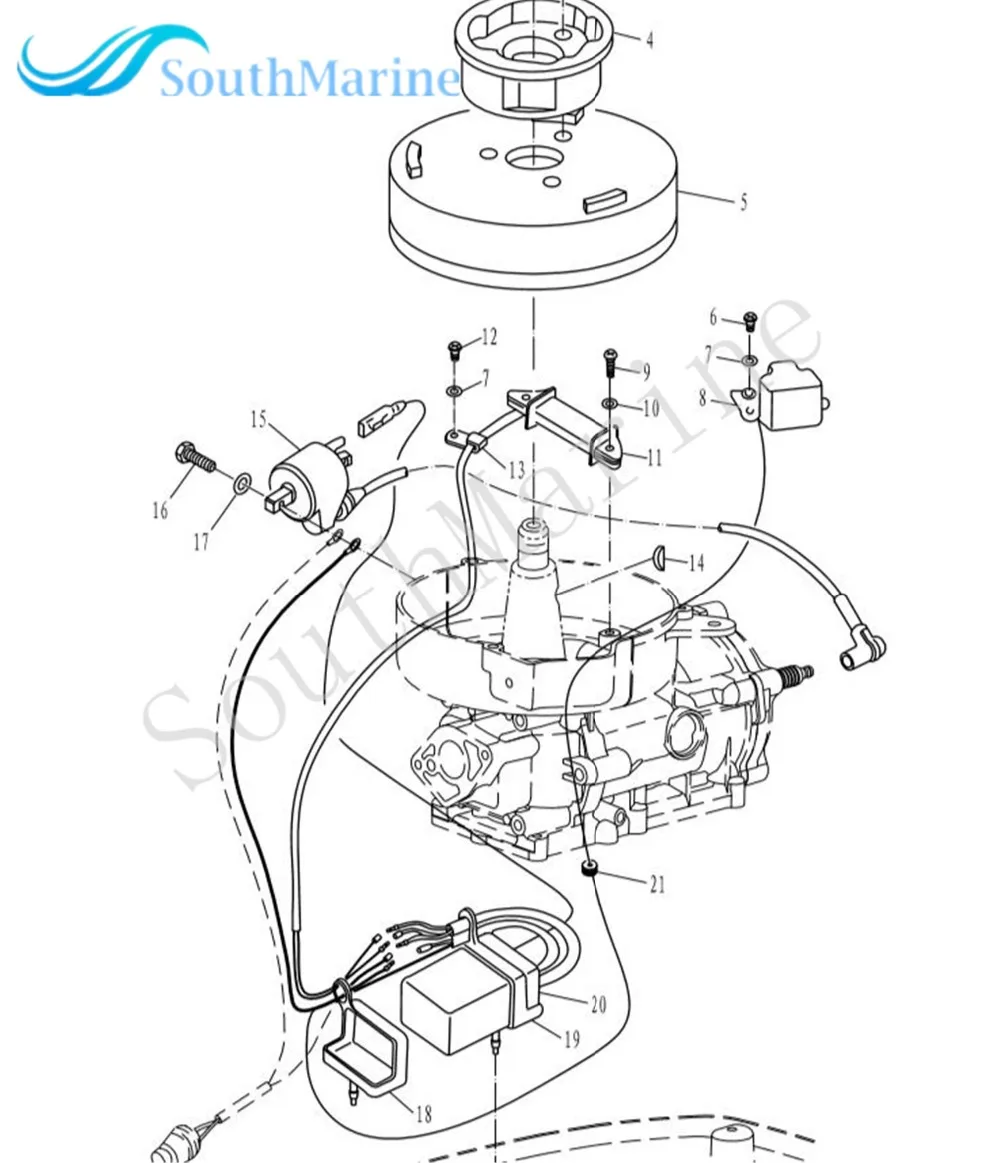

The inner workings of a two-cycle engine are fascinating, showcasing a balance of simplicity and efficiency. This type of engine is commonly utilized in various applications, making it essential for enthusiasts and technicians alike to familiarize themselves with its individual elements. By grasping the layout and function of these components, users can better appreciate how each part contributes to the overall operation.

In this section, we will explore the essential elements that make up the engine assembly, highlighting their roles and interconnections. Each component serves a unique purpose, working harmoniously to ensure optimal performance. Whether you are performing maintenance, troubleshooting issues, or simply gaining knowledge, understanding these components is crucial for effective engagement with the engine.

By delving into the intricate arrangement of these elements, readers will gain valuable insights into the mechanics at play. Familiarity with the configuration will not only enhance comprehension but also empower users to address any challenges that may arise during operation. Let’s embark on this journey to uncover the vital features of a two-cycle engine.

This section aims to provide a comprehensive overview of the internal mechanisms of two-cycle engines, emphasizing their unique components and functionality. By understanding how these elements interact, readers can gain insights into the operation and maintenance of these engines.

Key Components of Two-Cycle Engines

- Cylinders and Pistons

- Crankshaft Assembly

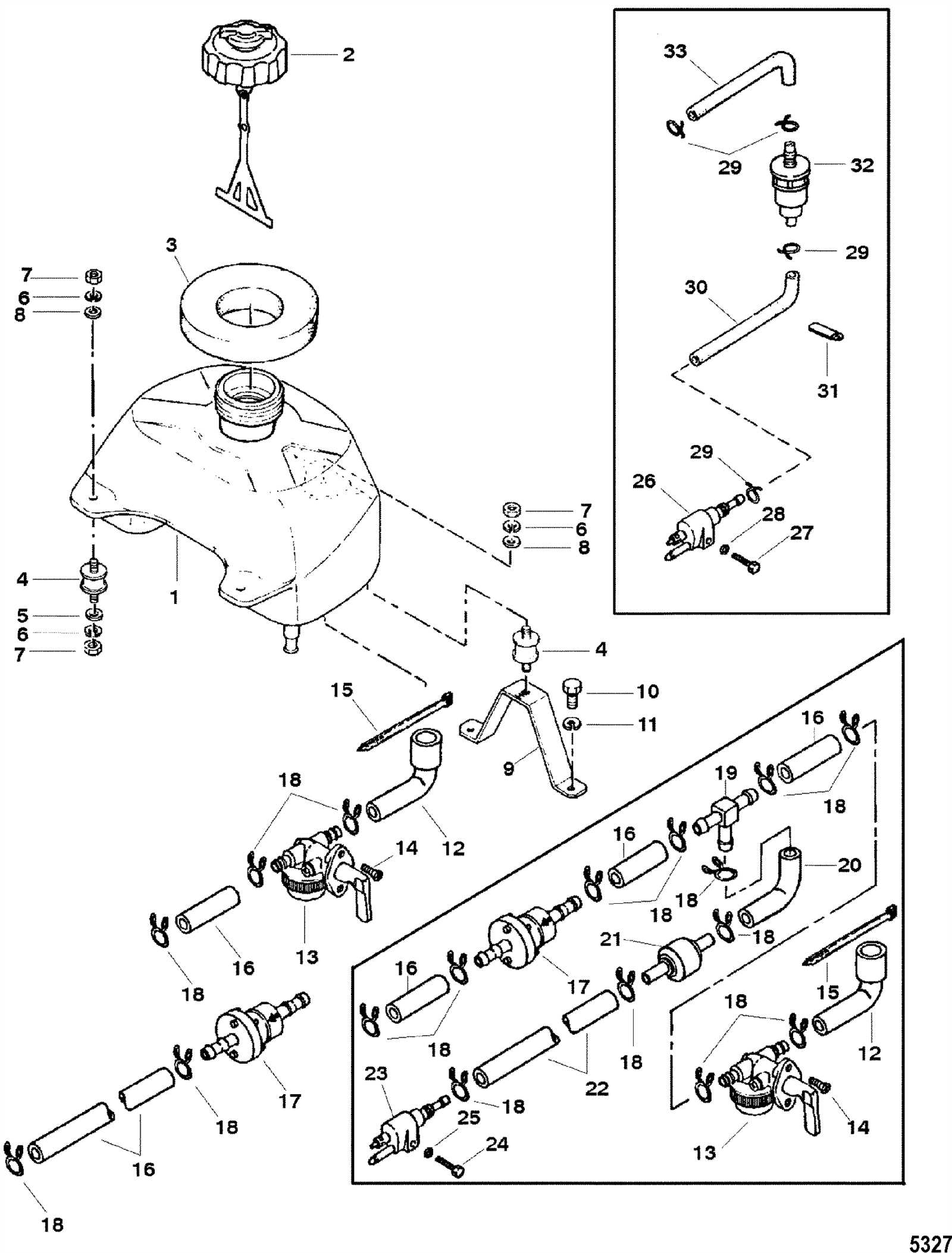

- Fuel System

- Ignition Components

- Exhaust System

Functionality of Major Elements

- How the combustion process occurs

- Role of the crankshaft in power delivery

- Fuel delivery mechanisms

- Importance of proper exhaust flow

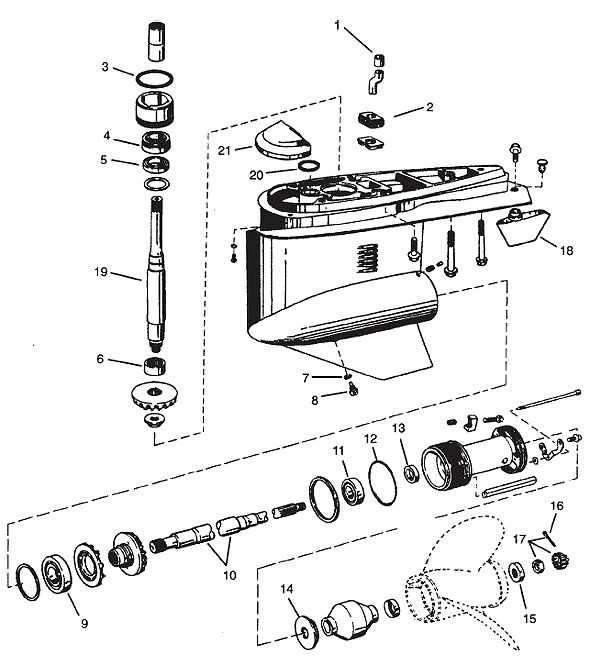

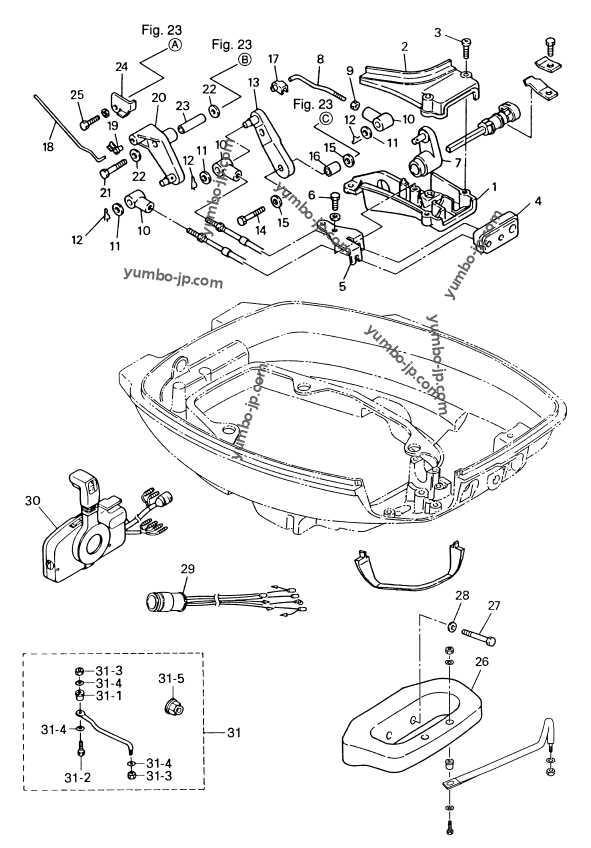

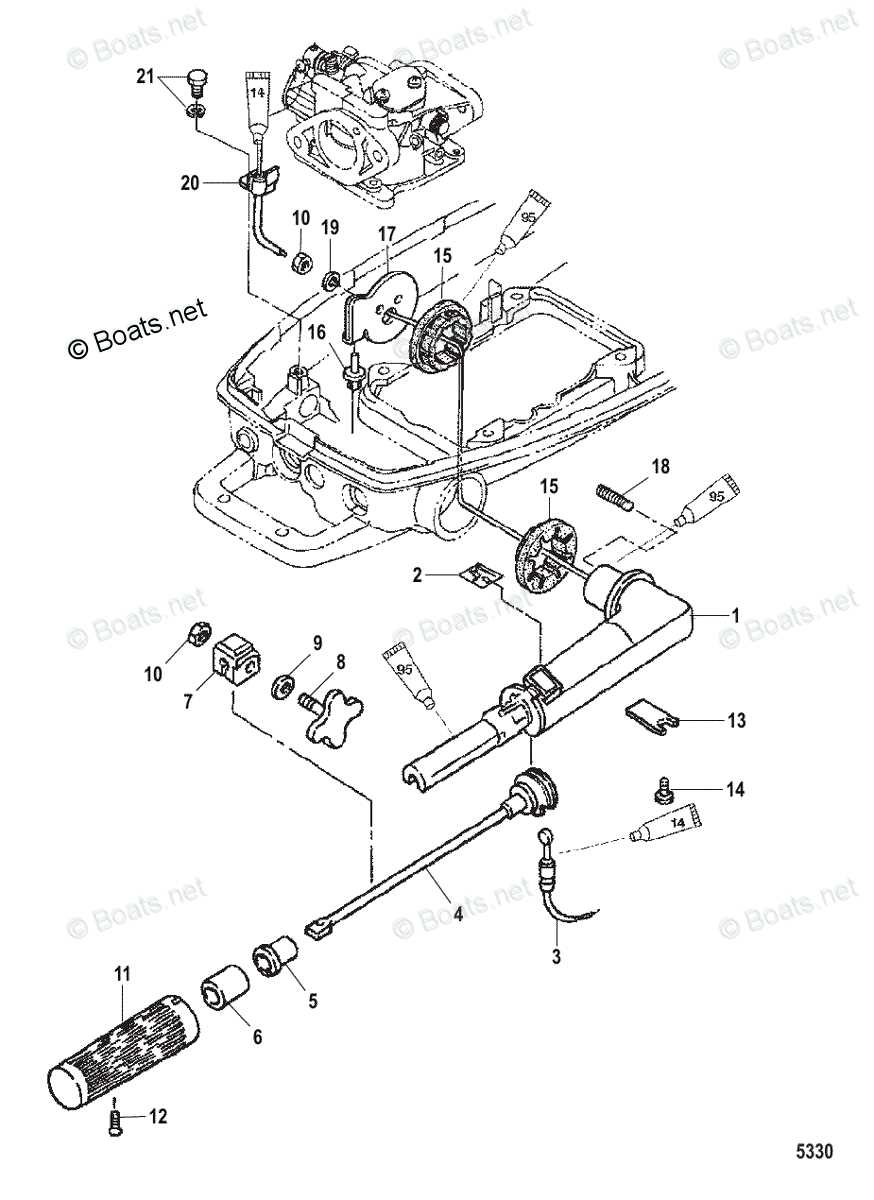

Key Components of Mercury Outboards

Understanding the essential elements of marine engines is crucial for effective maintenance and operation. Each component plays a vital role in ensuring smooth performance and reliability on the water. Familiarity with these key parts allows for better troubleshooting and enhances overall boating experience.

Core Elements

At the heart of any engine are the core elements that drive functionality. These include the combustion chamber, fuel delivery system, and ignition system. Each of these components must work in harmony to convert fuel into the mechanical energy required for propulsion. Regular inspections and maintenance of these core elements can significantly extend the lifespan of the engine.

Supportive Features

In addition to core elements, several supportive features contribute to the overall efficiency of marine engines. Cooling systems, exhaust mechanisms, and electrical components ensure that the engine operates within optimal parameters. Understanding how these features interact can help owners address potential issues before they escalate, ensuring a safe and enjoyable boating experience.

Functionality of Engine Parts

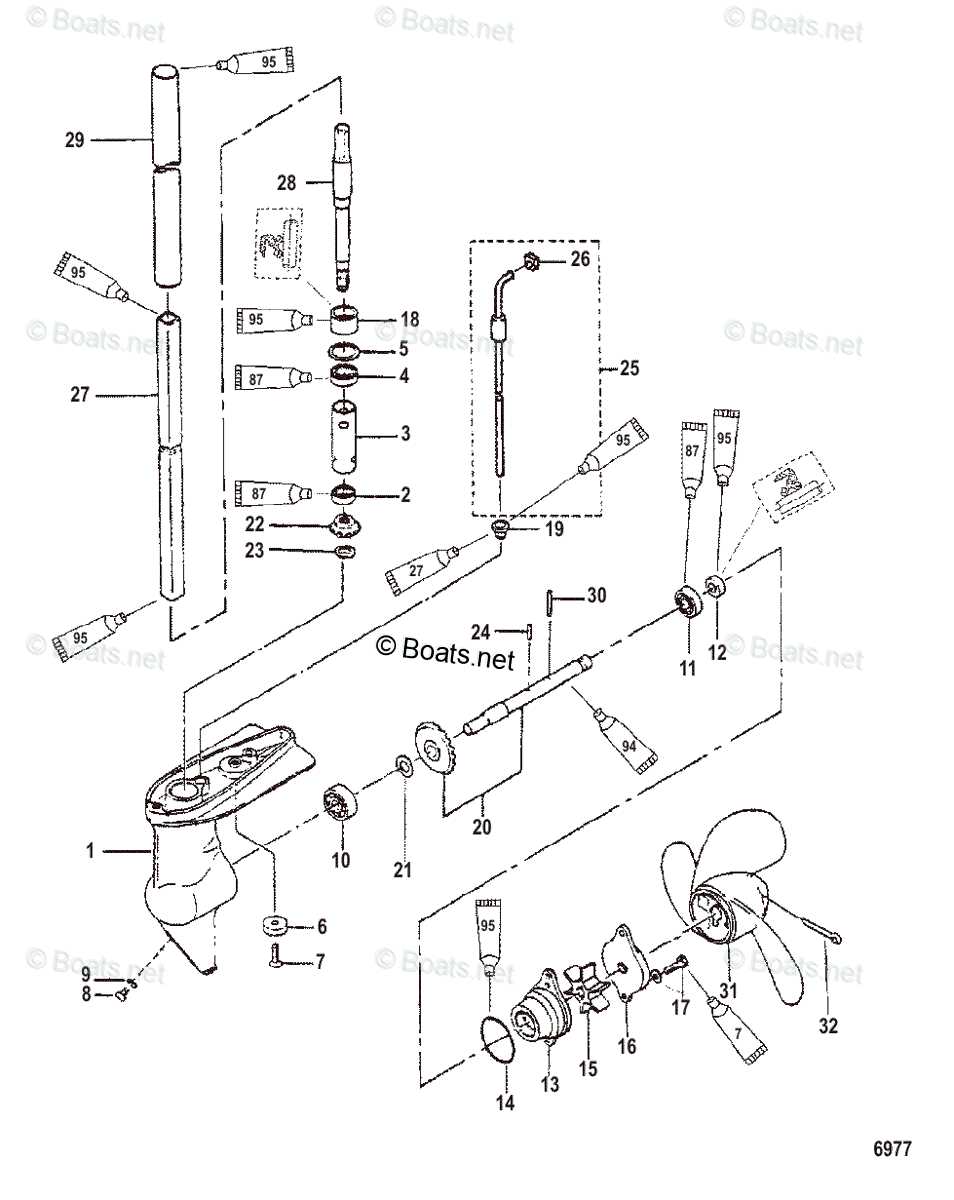

This section delves into the various components of a marine propulsion system, exploring their specific roles and interactions that contribute to overall efficiency and performance. Understanding the functionality of each element is essential for troubleshooting, maintenance, and optimization.

Core Components

The primary elements within the engine work in unison to generate power and propel the vessel. Each unit has a distinct function, from fuel intake to exhaust expulsion, ensuring smooth operation. Below is a summary of key components and their purposes:

| Component | Function |

|---|---|

| Piston | Compresses the fuel-air mixture and converts pressure into mechanical energy. |

| Cylinder | Houses the piston, providing a controlled environment for combustion. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Ignition System | Initiates the combustion process by creating a spark at the right moment. |

| Fuel System | Delivers the appropriate amount of fuel to the combustion chamber. |

Supporting Elements

In addition to the core components, there are several auxiliary systems that enhance performance and longevity. These elements play crucial roles in maintaining optimal conditions within the engine.

| Supporting Element | Function |

|---|---|

| Cooling System | Regulates temperature to prevent overheating during operation. |

| Lubrication System | Reduces friction between moving parts, enhancing durability. |

| Exhaust System | Safely expels combustion byproducts from the engine. |

Common Issues in Outboard Motors

When it comes to marine propulsion systems, various challenges can arise, impacting performance and reliability. Understanding these common problems can help in maintaining optimal functionality and extending the lifespan of the equipment.

- Fuel Issues:

- Contaminated fuel

- Clogged filters

- Poor fuel quality

- Cooling System Failures:

- Overheating

- Clogged passages

- Faulty water pump

- Electrical Problems:

- Dead batteries

- Corroded connections

- Faulty ignition systems

- Mechanical Failures:

- Worn bearings

- Damaged seals

- Excessive vibrations

Addressing these common issues promptly can lead to a more efficient and dependable performance on the water.

Maintenance Tips for Longevity

Ensuring the extended life of your aquatic engine requires regular care and attention. Simple maintenance tasks can prevent major issues and enhance performance, allowing you to enjoy your time on the water without interruptions. Here are key practices to keep your device running smoothly for years to come.

Regular Inspections

Conduct thorough checks of all essential components on a routine basis. Look for signs of wear, corrosion, or loose connections. Early detection of minor problems can prevent costly repairs later. Always refer to your user manual for specific inspection points.

Proper Storage Techniques

When not in use, store your engine in a dry, protected environment. Remove fuel to prevent degradation, and ensure that all fluids are at optimal levels. Covering your equipment can shield it from dust and moisture, which are detrimental to its longevity.

Additionally, regularly replacing filters and fluids will keep the internal mechanisms clean and efficient. Remember that preventive maintenance is often more effective than reactive repairs.

By implementing these simple strategies, you can significantly enhance the durability and reliability of your aquatic engine.

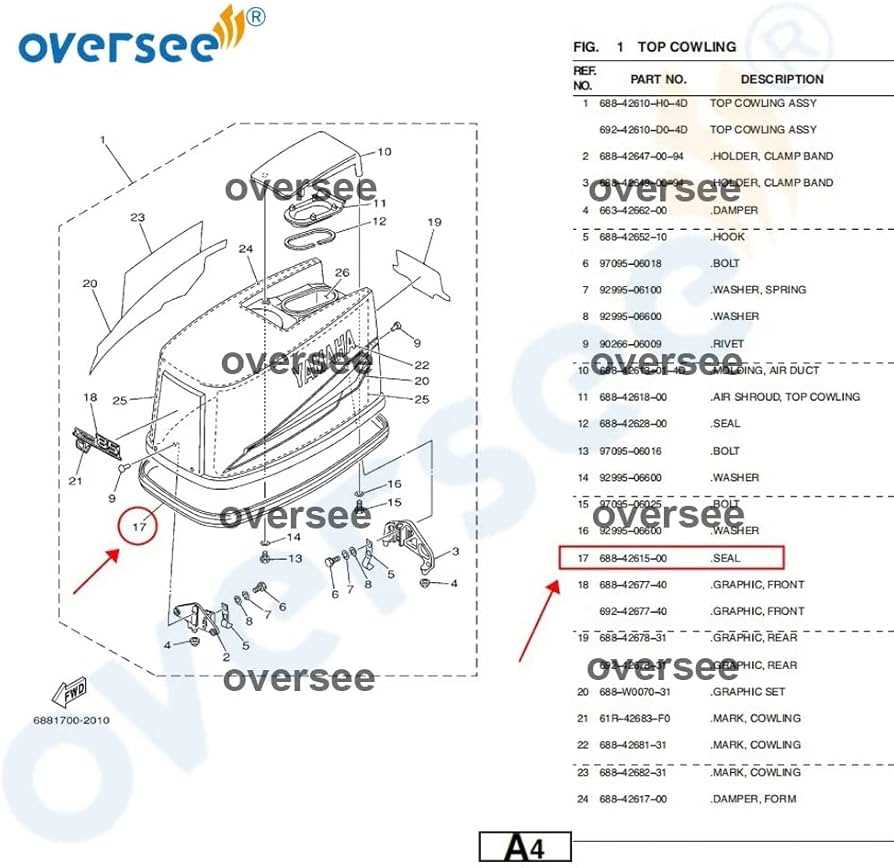

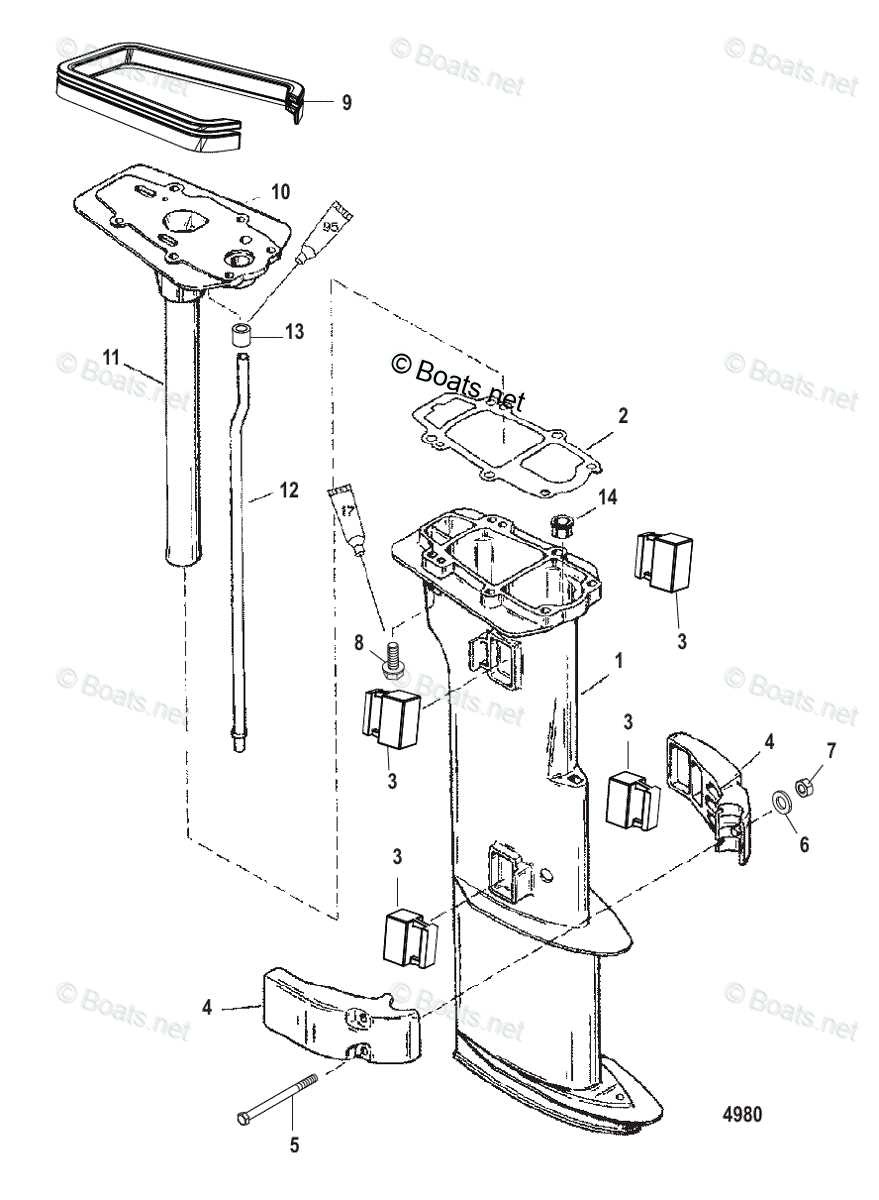

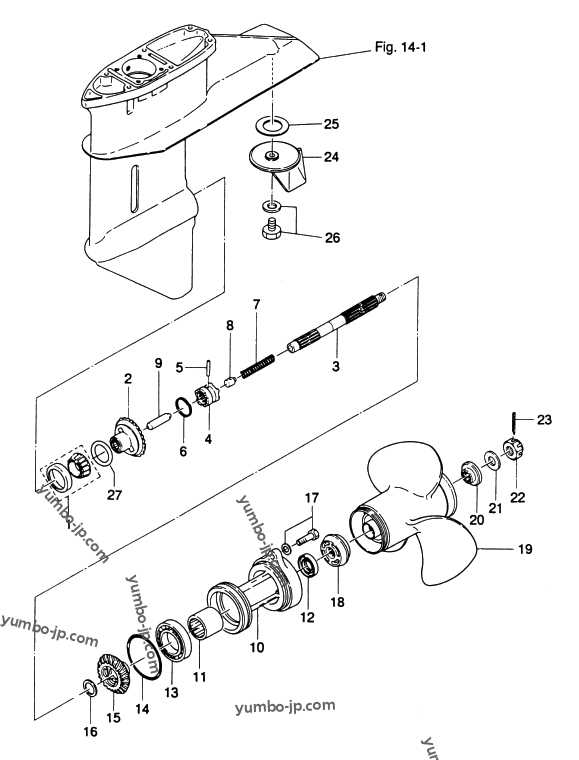

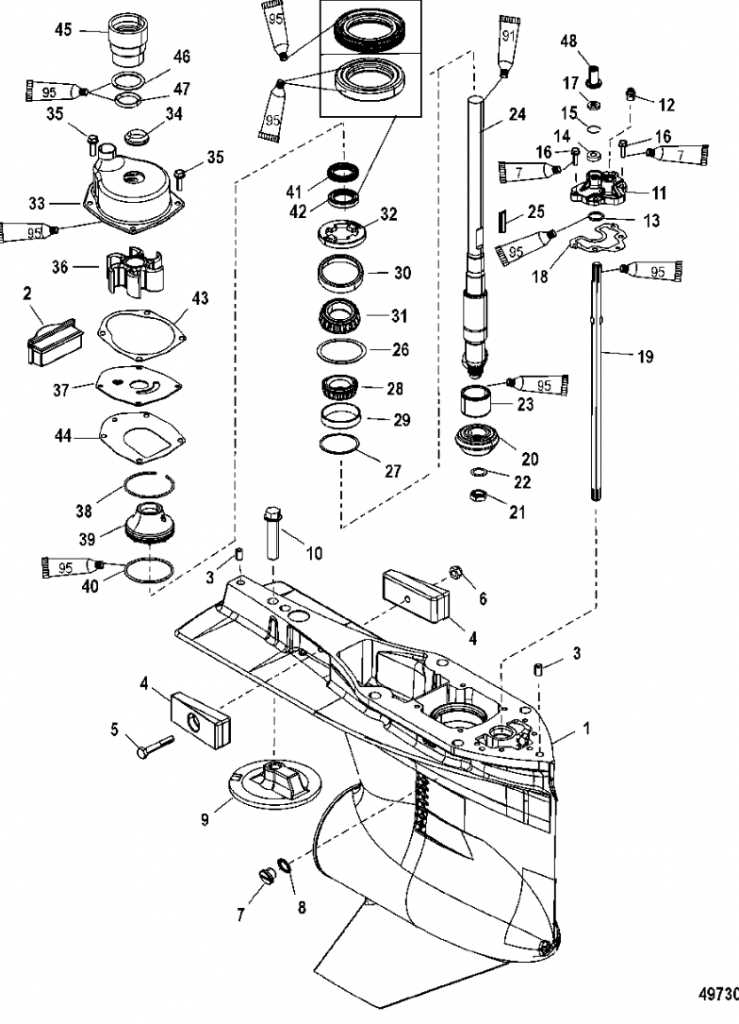

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations provide a clear view of the relationships and arrangements among various elements, enabling users to identify and locate each section accurately. Mastering the interpretation of these visuals can significantly enhance one’s ability to work with machinery.

Here are some key points to consider when analyzing these representations:

| Element | Description |

|---|---|

| Labels | Look for annotations that specify each component. These can include part numbers, names, and specific functions. |

| Connections | Pay attention to lines and arrows indicating how components are linked or interact with one another. |

| Views | Different perspectives may be provided. Familiarize yourself with top, side, and front views to gain a comprehensive understanding. |

| Grouping | Note how similar elements are clustered together. This can help identify assembly sequences and related functionalities. |

By focusing on these aspects, you can effectively navigate through complex visuals and ensure that your repairs or maintenance tasks are executed with precision and confidence.

Replacement Parts Availability

Access to essential components for marine engines is crucial for ensuring optimal performance and longevity. A wide range of suppliers and manufacturers offer high-quality replacements, catering to various needs and preferences. With the right resources, finding the necessary items becomes a streamlined process, allowing for efficient repairs and maintenance.

Numerous online platforms and local retailers stock these essential components, often providing detailed information about compatibility and specifications. This makes it easier for enthusiasts and professionals alike to identify suitable alternatives, ensuring that all requirements are met without compromising quality. Many manufacturers also offer original equipment options, guaranteeing reliability and performance.

Additionally, the availability of aftermarket alternatives provides a cost-effective solution for those looking to optimize their investment. By comparing different options, users can choose the most appropriate items to suit their budget and performance goals. This ensures that all maintenance needs can be addressed promptly and effectively.

Upgrading Mercury Motor Components

Enhancing the performance of your engine can lead to significant improvements in efficiency and reliability. By carefully selecting upgraded components, enthusiasts can optimize functionality and extend the lifespan of their watercraft. This section explores various options available for enhancing your engine’s capabilities.

- Improved Fuel Systems

- Enhanced Cooling Mechanisms

- Advanced Ignition Components

- High-Performance Propellers

Upgrading to a better fuel system can maximize combustion efficiency. Consider replacing outdated injectors or carburetors to achieve better throttle response and fuel economy.

Cooling systems play a vital role in maintaining optimal operating temperatures. Upgrading to a high-capacity cooling system can prevent overheating and enhance overall engine performance.

Ignition components are crucial for reliable starts and smooth operation. Investing in a high-performance ignition system can lead to improved spark delivery and fuel combustion.

Propeller selection is key to achieving the desired speed and maneuverability. Exploring high-performance options can result in better acceleration and overall handling.

Each upgrade offers unique advantages, so it’s essential to assess your specific needs and objectives. Implementing these enhancements can transform your engine experience on the water.

Safety Precautions During Repairs

When undertaking maintenance or repairs on aquatic propulsion devices, adhering to safety measures is essential. Ensuring a secure working environment not only protects the individual performing the task but also extends the lifespan of the equipment. Proper precautions can prevent accidents and facilitate a smoother repair process.

Wear Protective Gear: Always don appropriate safety equipment, including gloves, goggles, and a face shield. These items safeguard against harmful substances and potential injuries from sharp components.

Work in a Ventilated Area: Ensure that the workspace is well-ventilated to avoid inhaling toxic fumes, especially when handling chemicals or fuels. Proper airflow minimizes health risks significantly.

Disconnect Power Sources: Before beginning any repair work, make certain to disconnect all power supplies. This prevents unexpected starts or electrical shocks, contributing to a safer environment.

Keep Tools Organized: Maintain a tidy workspace by organizing tools and materials. This practice reduces the likelihood of accidents caused by tripping or misplacing essential equipment during repairs.

Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions and specifications. Adhering to these guidelines ensures that repairs are performed correctly and safely, reducing the risk of future issues.

Dispose of Waste Properly: Handle and dispose of any waste materials in accordance with local regulations. Proper disposal minimizes environmental impact and reduces health hazards associated with improper waste management.

Performance Enhancements for Outboards

Boosting the efficiency and speed of marine engines involves a combination of technological upgrades and meticulous tuning. By focusing on key components and their interactions, enthusiasts can significantly elevate their vessel’s capabilities, enhancing both agility and overall performance on the water.

Upgrading Fuel Systems

Improving fuel delivery is essential for maximizing output. Utilizing high-performance injectors and optimizing fuel lines can result in better combustion efficiency, translating to increased power and reduced fuel consumption.

Tuning the Propulsion System

Enhancing the propulsion system is crucial for achieving superior performance. Selecting the right propeller size and pitch, along with regular maintenance, ensures optimal thrust and speed, allowing vessels to reach their full potential while navigating various conditions.

Resources for Further Learning

Enhancing your knowledge about specific equipment can lead to better maintenance and improved performance. This section provides valuable resources for anyone looking to deepen their understanding and skills.

Online Tutorials and Videos

- YouTube channels focused on marine engines

- Webinars hosted by industry experts

- Online courses on mechanical systems

Books and Manuals

- Technical manuals specific to your equipment

- Guides on engine repair and maintenance

- Reference books on marine technology