The intricate design of marine engines involves a variety of interconnected components, each serving a vital function in the overall performance. Comprehending the arrangement and relationship of these elements is essential for effective maintenance and repair. This section delves into the visual representation of a specific engine model, highlighting its structural complexity.

Through detailed illustrations, users can gain insights into how various assemblies are positioned and interact with one another. Understanding these layouts enhances the ability to identify potential issues, streamline repairs, and ensure optimal operation. Recognizing the significance of each component’s placement contributes to a more efficient and reliable marine engine.

Ultimately, familiarizing oneself with these configurations equips individuals with the knowledge necessary to tackle challenges confidently. The clarity provided by visual aids aids both seasoned technicians and novice enthusiasts in their pursuit of engine mastery.

Components Overview and Functions

This section provides a comprehensive understanding of the various elements within a specific engine model, highlighting their roles and interactions. Each component plays a vital part in ensuring optimal performance and functionality, contributing to the overall efficiency of the system.

Key Elements and Their Roles

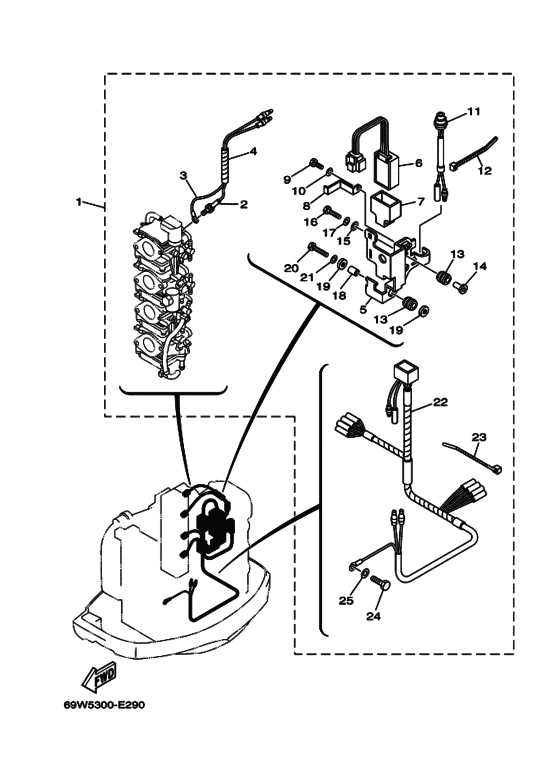

The key elements of the engine include the power unit, fuel delivery system, and electrical components. The power unit is responsible for generating the necessary force for operation, while the fuel delivery system ensures an adequate supply of fuel for combustion. Electrical components manage various functionalities, including ignition and control systems, enabling seamless operation.

Functionality and Interactions

Understanding how these components work together is crucial for diagnosing issues and performing maintenance. For instance, a malfunctioning fuel system can lead to reduced power output, while electrical failures may cause starting issues. Regular inspection and maintenance of these elements are essential for prolonged operational life and performance.

How to Read the Parts Diagram

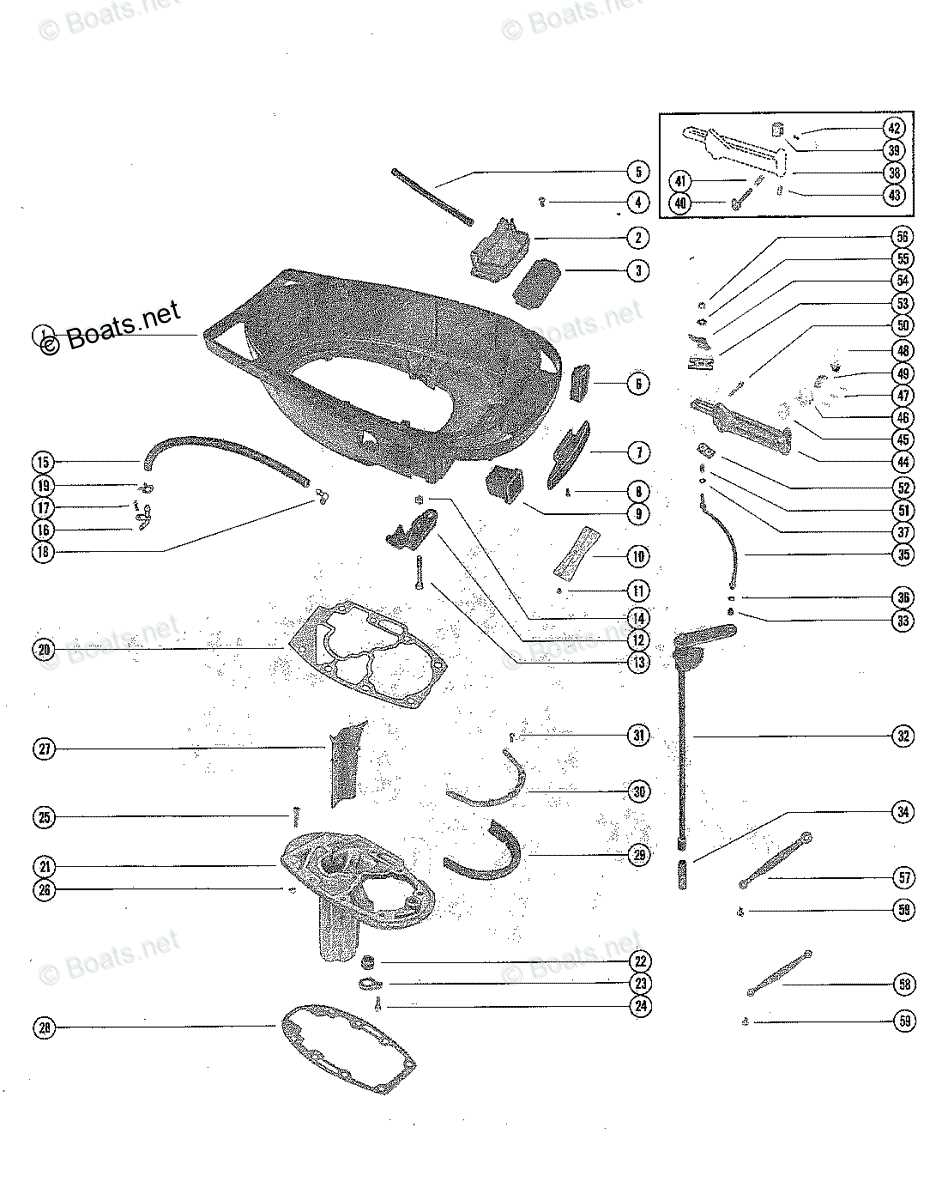

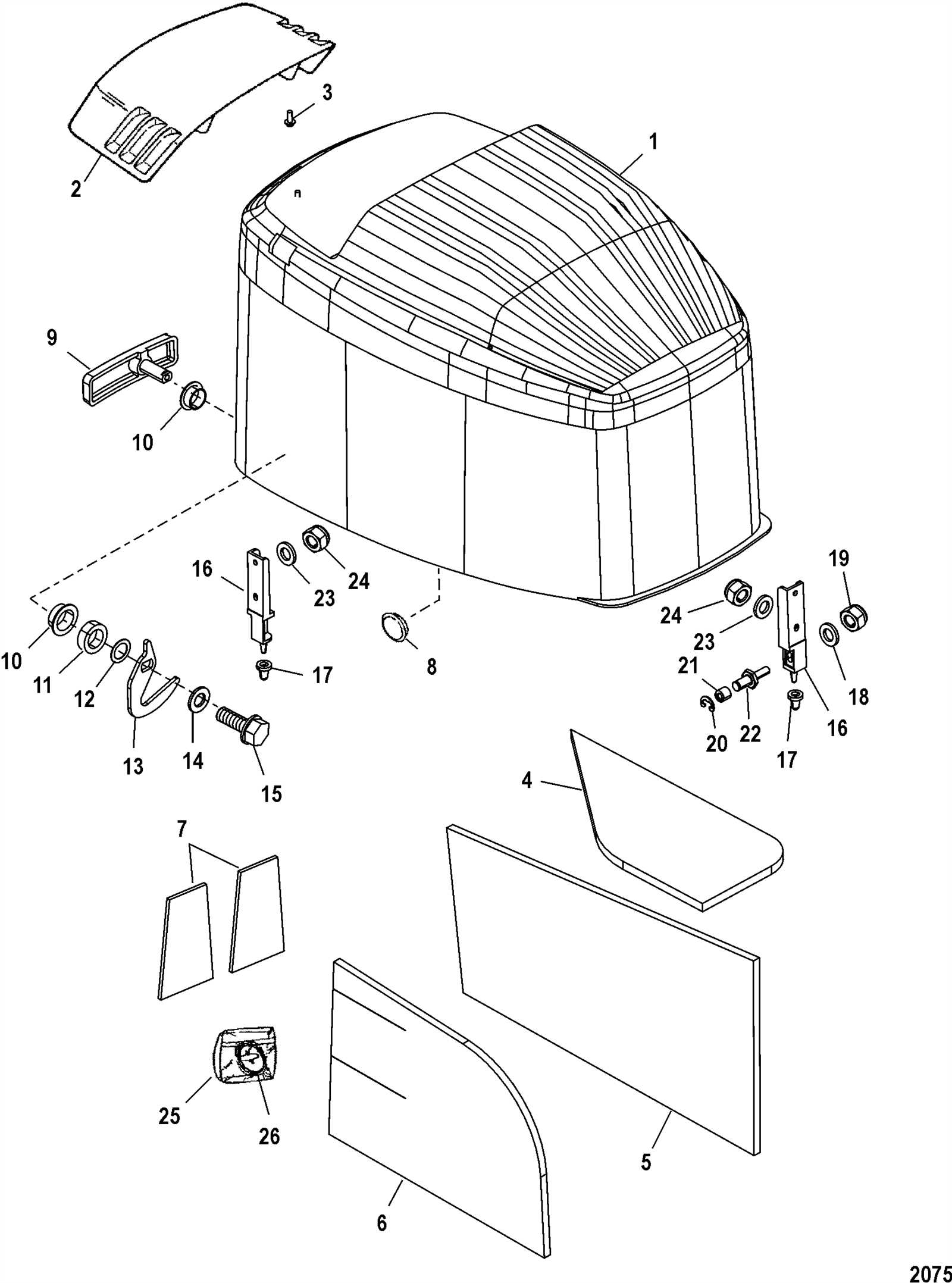

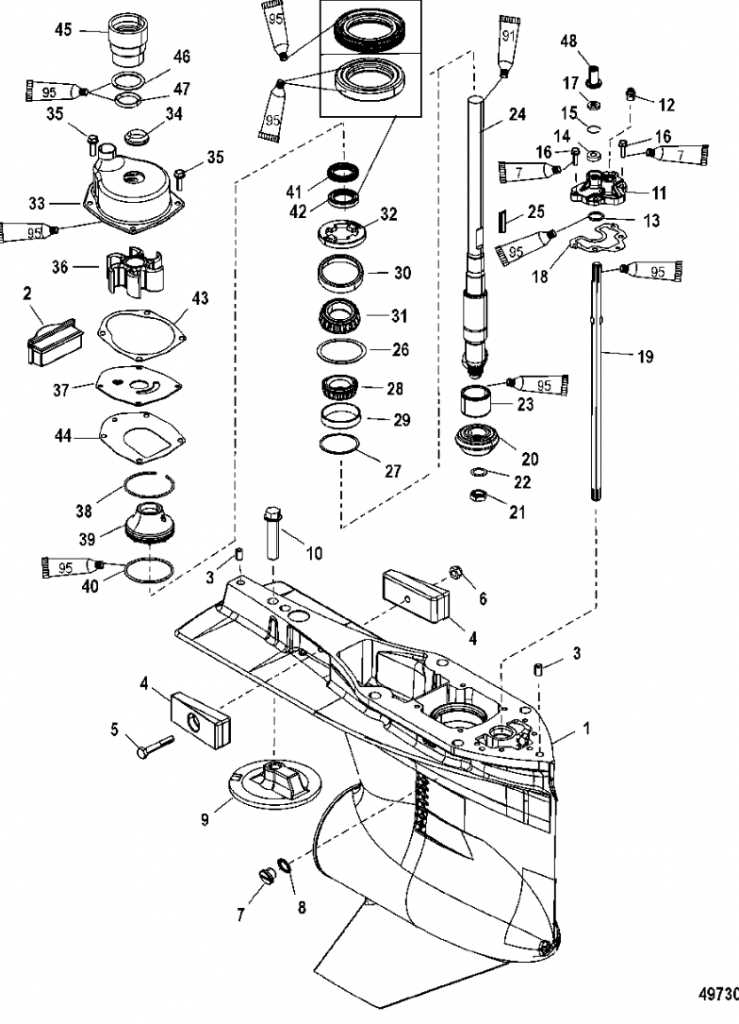

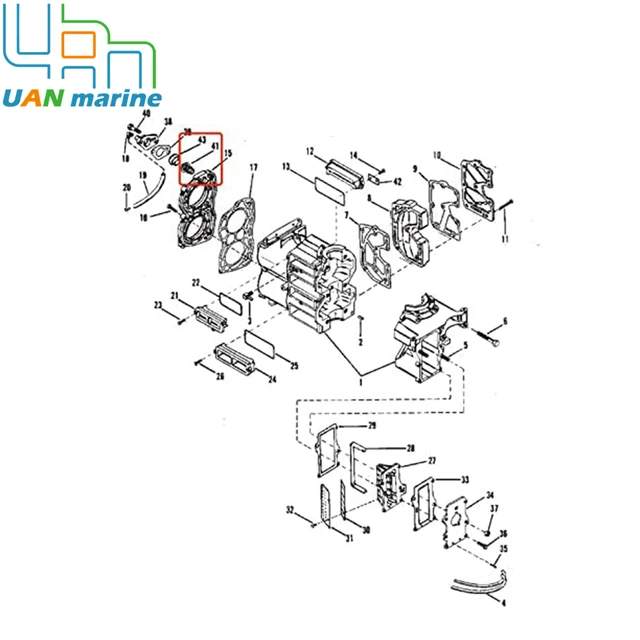

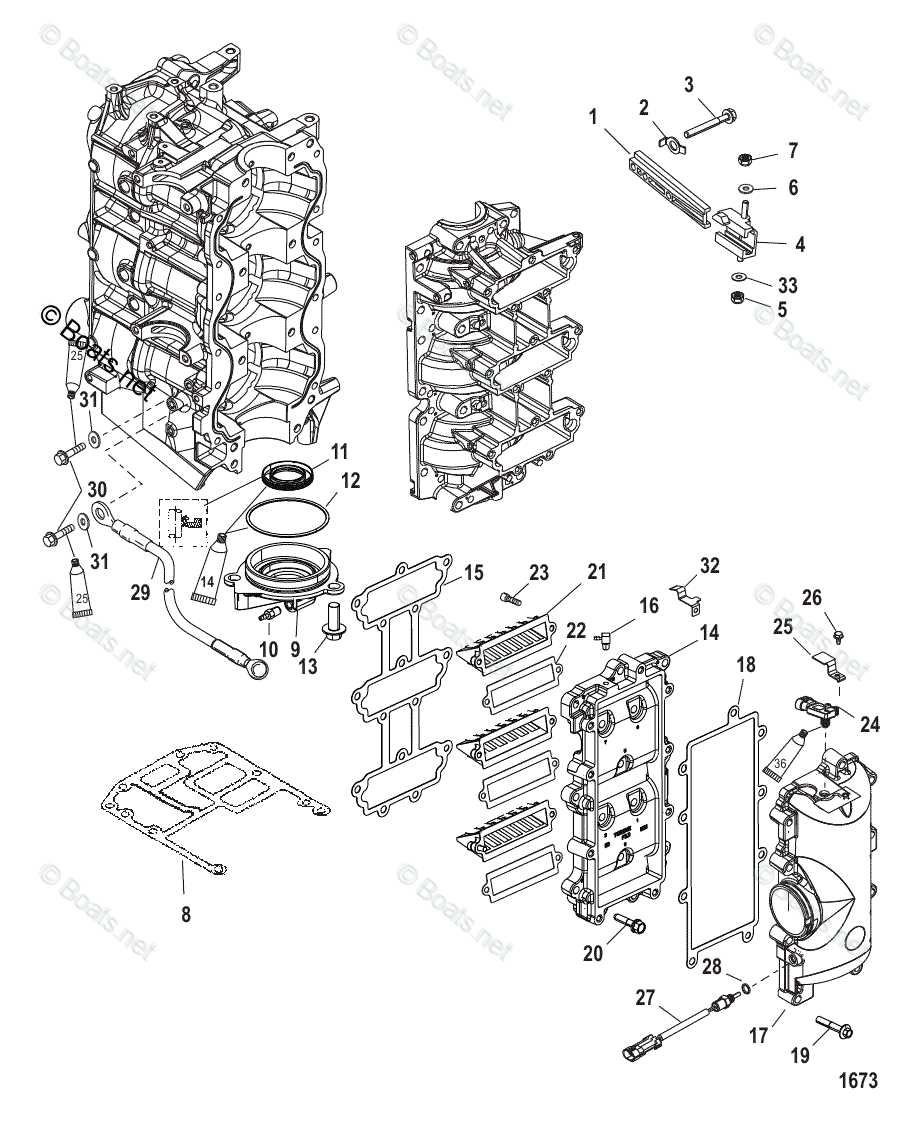

Understanding a schematic representation of components is essential for effective maintenance and repair tasks. This visual guide provides a clear overview of individual elements, their arrangement, and connections within a system. By interpreting these illustrations, users can identify necessary components and comprehend their relationships.

Start by familiarizing yourself with the layout. The illustration typically includes a key that denotes various symbols and notations used throughout. Recognizing these symbols is crucial for accurate interpretation. Additionally, pay attention to the orientation and grouping of components, as this often indicates functionality and connections.

Next, identify the connections between elements. Arrows or lines may represent electrical or mechanical links, showing how each component interacts within the system. Understanding these interactions can aid in troubleshooting and ensure a proper assembly during repairs. Take note of any numbered parts, as these references can be used for ordering replacements or further investigation.

Identifying Essential Components

Understanding the critical elements of a system is vital for effective maintenance and operation. Recognizing each component’s function and position can significantly enhance troubleshooting and repair processes. This section provides an overview of key features that are often found in such configurations.

Key Features Overview

Each configuration typically includes various essential elements, each serving a unique purpose. Familiarizing yourself with these components can aid in diagnosing issues and ensuring optimal performance. Common elements include connectors, sensors, and control units, which work in unison to facilitate efficient operation.

Importance of Component Identification

Identifying these crucial elements is not only beneficial for maintenance but also enhances safety and reliability. By recognizing the roles and placements of these parts, users can perform necessary checks and replacements more confidently. Proper identification leads to fewer errors and improved overall system efficiency. Regular assessments can help detect potential problems before they escalate.

Common Maintenance Parts Explained

Regular upkeep of your watercraft ensures optimal performance and longevity. Understanding the essential components involved in this maintenance process can significantly enhance your experience on the water. These vital elements play critical roles in the functionality and reliability of your vessel, making it imperative to familiarize yourself with them.

Fuel Filter: This component is crucial for keeping impurities from entering the engine. A clean fuel filter ensures that the engine receives a steady supply of uncontaminated fuel, which is vital for efficient operation.

Oil Filter: This part removes debris and contaminants from the engine oil, promoting smoother engine performance. Regular replacement of the oil filter is essential for maintaining optimal lubrication and reducing wear on engine components.

Spark Plugs: These are key to the ignition process, providing the necessary spark to ignite the fuel-air mixture within the engine. Replacing worn spark plugs can lead to improved fuel efficiency and overall performance.

Belts and Hoses: These flexible components are vital for transferring power and fluids throughout the engine system. Regular inspection and replacement of frayed or cracked belts and hoses can prevent leaks and ensure smooth operation.

By staying informed about these essential elements, boat owners can proactively address maintenance needs, ultimately leading to a more enjoyable and worry-free experience on the water.

Installation Guidelines for Key Parts

This section provides essential instructions for the proper installation of critical components within your engine. Adhering to these guidelines will ensure optimal performance and longevity of the system.

Before beginning the installation, it is vital to gather all necessary tools and equipment. Proper preparation will facilitate a smooth installation process. Consider the following steps:

- Review the manufacturer’s specifications and recommendations.

- Inspect each component for any damage or defects prior to installation.

- Ensure that all required tools are on hand to avoid interruptions.

Follow these installation steps for key components:

- Engine Block: Align the block with the mounting points and secure it with bolts, ensuring they are tightened to the recommended torque specifications.

- Crankshaft: Carefully insert the crankshaft into the block, making sure it rotates freely without obstruction.

- Camshaft: Position the camshaft and secure it in place, verifying that it aligns correctly with the timing gears.

- Valves: Install the valves, ensuring they seat properly and operate smoothly within their guides.

After completing the installation, conduct a thorough inspection to confirm that all components are securely in place and functioning correctly. This will help prevent issues and enhance the reliability of your engine.

Troubleshooting Common Issues

Identifying and resolving frequent challenges can enhance the performance and longevity of your engine system. Understanding potential complications and their solutions is essential for maintaining optimal functionality.

Here are some common issues and their possible remedies:

- Starting Problems:

- Check the fuel level and ensure the tank is filled.

- Inspect the battery for charge and connections.

- Examine the ignition system for any faults.

- Overheating:

- Verify that the cooling system is filled with the appropriate fluid.

- Inspect the thermostat for proper operation.

- Ensure that there are no blockages in the cooling passages.

- Unusual Noises:

- Listen for knocking sounds, which may indicate internal damage.

- Check for loose components that may be causing rattling.

- Assess the exhaust system for leaks or breaks.

Regular inspections and proactive measures can help mitigate these issues and enhance the overall performance of your engine setup.

Replacement Parts Availability

Ensuring the availability of essential components is crucial for maintaining the performance and longevity of any machinery. When it comes to sourcing replacement items, various options are typically accessible to ensure that users can find the necessary components to keep their equipment running smoothly. Understanding where to look and what to consider can significantly enhance the maintenance experience.

Common Sources for Components

- Authorized Dealers: These vendors provide genuine components that meet manufacturer standards.

- Aftermarket Suppliers: Alternative options that may offer cost-effective solutions, although quality can vary.

- Online Retailers: Websites specializing in machinery components often have a wide range of products available for quick delivery.

- Local Repair Shops: Often carry essential components or can order them directly from suppliers.

Factors to Consider

- Compatibility: Ensure that the item matches the specifications required for your equipment.

- Quality: Consider the reputation of the supplier and the materials used in the components.

- Cost: Compare prices across different sources to find the best deal without sacrificing quality.

- Warranty: Check if the replacement item comes with a guarantee for added security.

Impact of Each Part on Performance

Every component of a mechanical system plays a critical role in determining its overall efficiency and functionality. Understanding how these elements interact and contribute to the device’s operation can provide valuable insights into optimizing performance and reliability. This section explores the influence of individual components on the system’s effectiveness and how variations in their design or condition can impact overall output.

Key Components and Their Effects

Various elements within the assembly contribute differently to performance metrics. From the power unit to the control mechanisms, each part has its distinct function that can enhance or impede operational efficiency. Here are some essential components and their respective impacts:

| Component | Function | Performance Impact |

|---|---|---|

| Power Unit | Supplies energy | Directly affects output power and responsiveness |

| Control Mechanism | Regulates operations | Influences precision and accuracy of actions |

| Cooling System | Maintains temperature | Prevents overheating, ensuring consistent performance |

| Structural Frame | Provides stability | Affects durability and resistance to stress |

Conclusion on Performance Factors

The interplay between various components determines the overall efficiency of the system. Regular maintenance and timely upgrades of these elements can lead to improved performance and prolonged lifespan. Understanding each part’s significance enables better decision-making when it comes to repairs, modifications, or enhancements.

Safety Precautions When Working

Ensuring safety during maintenance and repairs is crucial to prevent accidents and injuries. Following appropriate guidelines can help create a secure environment while handling equipment. Understanding potential hazards and taking preventive measures can significantly reduce risks.

Before beginning any task, it is essential to wear the appropriate protective gear, including gloves, goggles, and masks. This equipment serves as a barrier against harmful substances and sharp objects that may cause injury. Additionally, maintaining a clean and organized workspace is vital to avoid tripping hazards and ensure easy access to tools and components.

Always disconnect power sources before commencing any work. This simple step can prevent electric shocks and equipment damage. Furthermore, familiarize yourself with the specific machinery you are working on, including its operational procedures and safety features. In case of uncertainty, consulting the relevant manuals or seeking assistance from experienced personnel is advisable.

Recommended Tools for Repairs

When undertaking maintenance or restoration of aquatic engines, having the right tools is essential for efficiency and effectiveness. A well-equipped toolkit not only streamlines the repair process but also enhances safety and accuracy during tasks. Below is an overview of key implements that every technician should consider for successful interventions.

Essential Hand Tools

Basic hand tools form the backbone of any repair endeavor. Items such as wrenches, screwdrivers, and pliers allow for the manipulation and fastening of components with precision. Investing in a quality set can significantly reduce the time spent on repairs, ensuring that each task is performed with the necessary attention to detail.

Diagnostic Equipment

In addition to traditional hand tools, diagnostic devices are invaluable for troubleshooting and identifying issues within the machinery. Equipment like multimeters and compression testers help in assessing the performance of various systems, enabling technicians to pinpoint faults quickly. Utilizing these tools can lead to more informed decisions and efficient resolutions during repair projects.

Frequently Asked Questions

This section addresses common inquiries that users often have regarding the various components and schematics of their marine engines. Understanding these elements can significantly enhance maintenance and troubleshooting processes.

What should I do if a component is missing?

If you discover that a certain element is absent, it is essential to consult a detailed reference guide or contact a professional for assistance. Replacing missing items promptly can prevent further complications and ensure optimal functionality.

How can I identify the correct components for my engine?

Identifying the appropriate elements for your engine involves consulting a comprehensive resource or manual specific to your model. Always double-check compatibility to avoid potential issues during installation.

Resources for Further Information

For individuals seeking to deepen their understanding of engine components and their configurations, various sources provide valuable insights. These resources can enhance knowledge and assist in practical applications, whether for maintenance or repair purposes.

Books and Manuals

- Technical manuals offer detailed descriptions and specifications.

- Repair guides provide step-by-step instructions for troubleshooting and assembly.

- Reference books cover historical and technical aspects of engine technology.

Online Platforms

- Websites dedicated to marine engines host forums and articles from experienced users.

- YouTube channels feature tutorials and visual aids for assembly and repair.

- Online retailers often have specifications and user reviews to guide purchases.