This section delves into the essential elements of a compact marine engine known for its reliability and efficiency. Understanding the various components that constitute this power unit is crucial for maintenance and repairs. Each part plays a vital role in ensuring the engine operates smoothly and efficiently.

From the ignition system to the fuel delivery mechanisms, every piece contributes to the overall functionality. A thorough comprehension of these components enables enthusiasts and technicians alike to perform effective troubleshooting and repairs. In this discussion, we will explore the different sections and their respective functions within this robust engine.

With detailed insights into each aspect, readers will gain a clearer understanding of how to maintain and enhance the performance of their marine engines. This knowledge is invaluable for anyone looking to optimize their equipment for better performance on the water.

This section presents a comprehensive exploration of a well-known marine engine, highlighting its essential components and functionality. Understanding the inner workings of this engine provides valuable insights for both enthusiasts and professionals in the boating community. Through careful examination, we will delve into the various elements that contribute to its performance and reliability.

| Heading | Description |

|---|---|

| Engine Specifications | Details regarding the technical specifications and capabilities of the motor. |

| Fuel System Components | Insights into the components involved in the fuel delivery process. |

| Ignition Mechanism | An overview of the ignition system and its role in engine operation. |

| Cooling System | Description of the mechanisms that prevent overheating during use. |

| Lubrication System | Explanation of how lubrication is achieved for optimal performance. |

| Exhaust Setup | Details regarding the exhaust system and its significance. |

| Propulsion Components | Discussion on the parts that facilitate movement and control. |

| Maintenance Requirements | Guidelines on proper upkeep and servicing to enhance longevity. |

| Common Issues | Identification of frequent problems and troubleshooting tips. |

| Replacement Options | Exploration of available aftermarket alternatives for various components. |

Importance of 2 Stroke Engines

The significance of lightweight and compact engine designs cannot be overstated, particularly in applications where power-to-weight ratio is crucial. These engines have a unique operation that allows them to deliver power efficiently, making them ideal for various uses, from small watercraft to portable equipment. Their simplicity and effectiveness contribute to their ongoing popularity across different industries.

Efficiency and Power

One of the main advantages of this type of engine is its ability to generate power in a relatively short time. This results in a high power output for the size and weight of the unit. Moreover, the straightforward construction allows for quick maintenance and repairs, enhancing user convenience.

Applications and Versatility

These engines are found in a wide range of applications, including recreational vehicles, lawn equipment, and marine engines. Their lightweight design makes them suitable for portable applications, allowing for easy transport and operation. This versatility continues to drive their demand in various sectors, affirming their essential role in modern technology.

Key Components of Mercury 15 HP

This section explores the essential elements that contribute to the efficient operation of a 15 HP outboard engine. Understanding these components is crucial for maintaining performance and ensuring longevity in various marine environments.

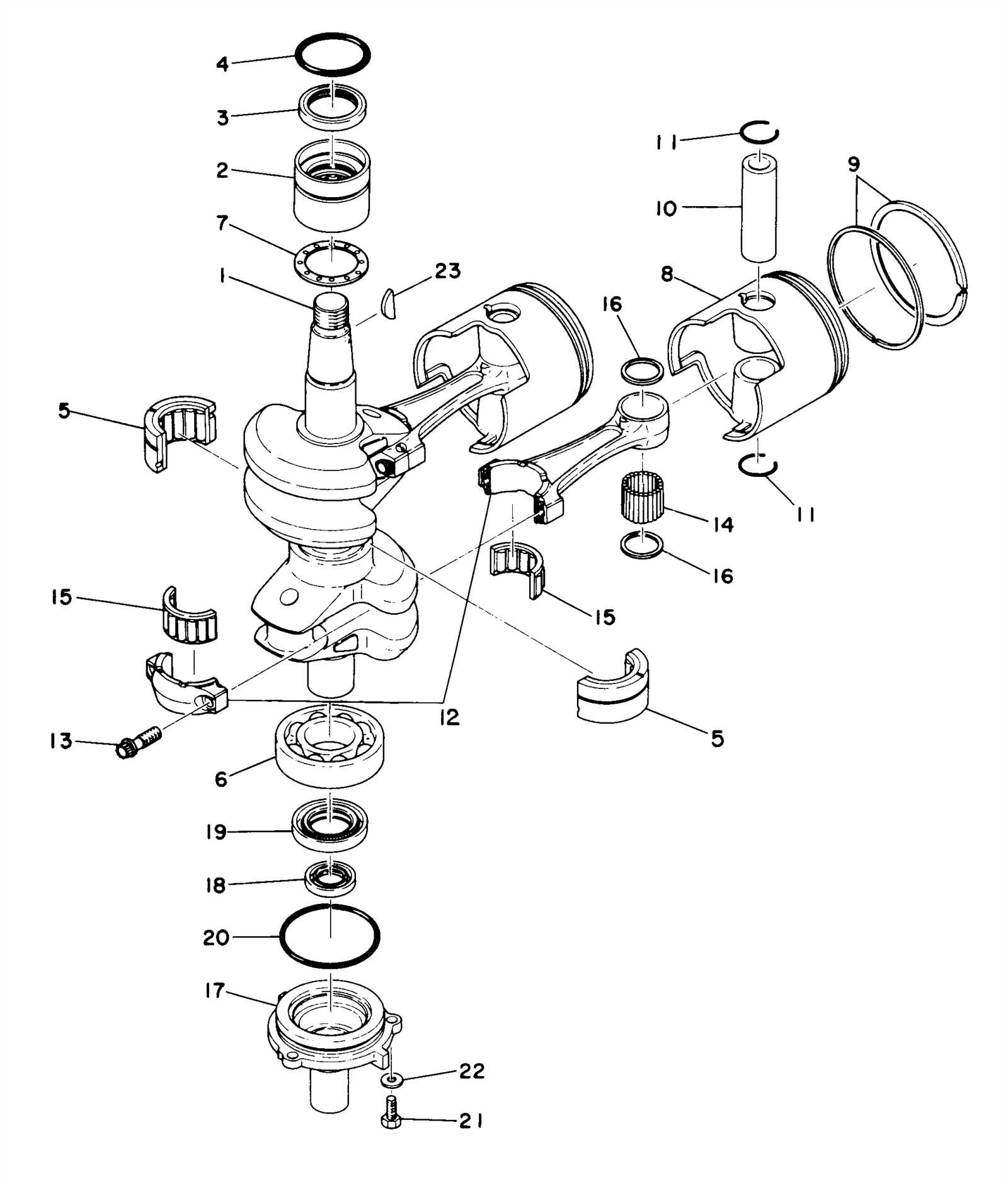

1. Engine Block: The core of the power unit, housing vital elements such as the pistons and cylinders, which are crucial for combustion and power generation.

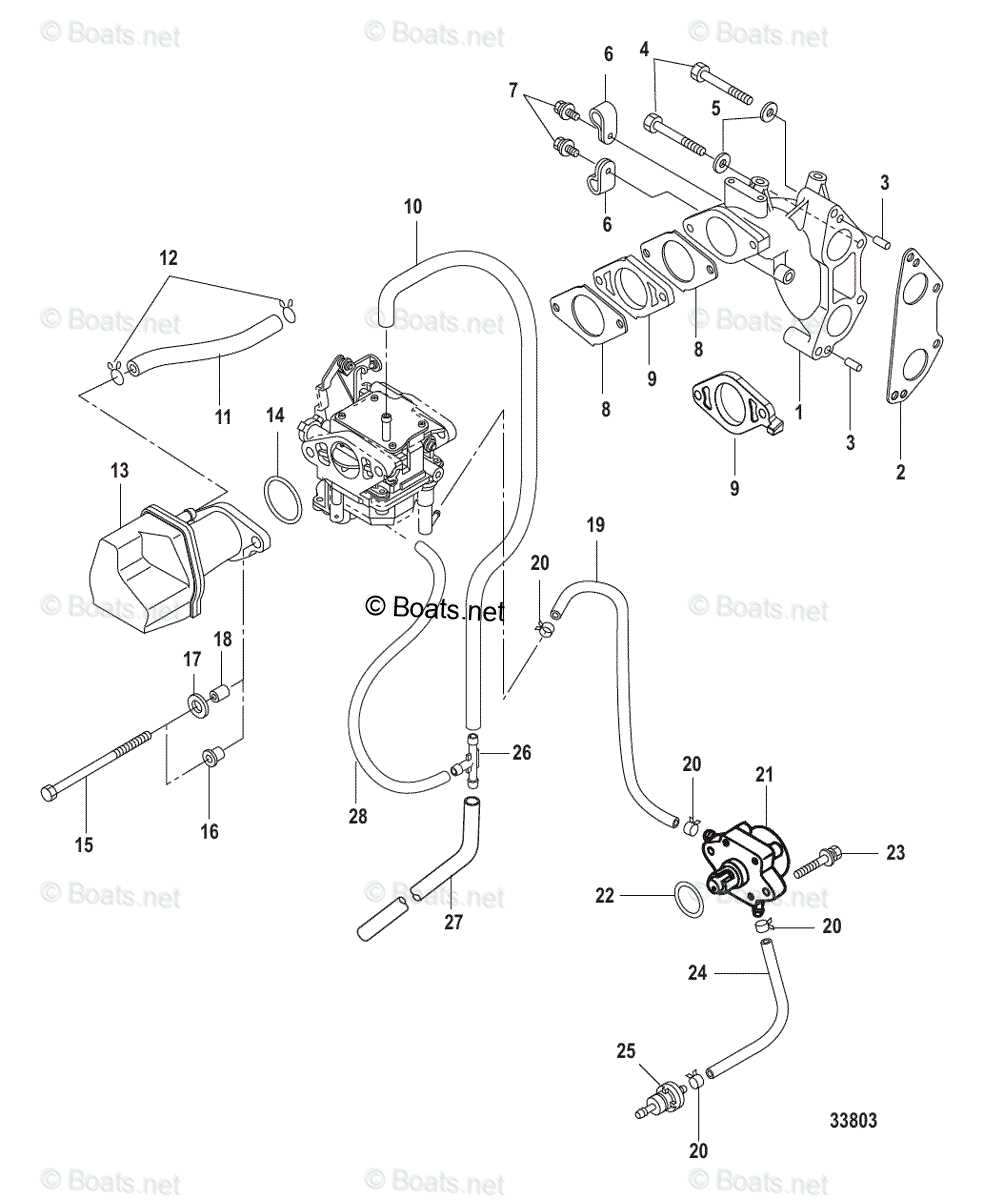

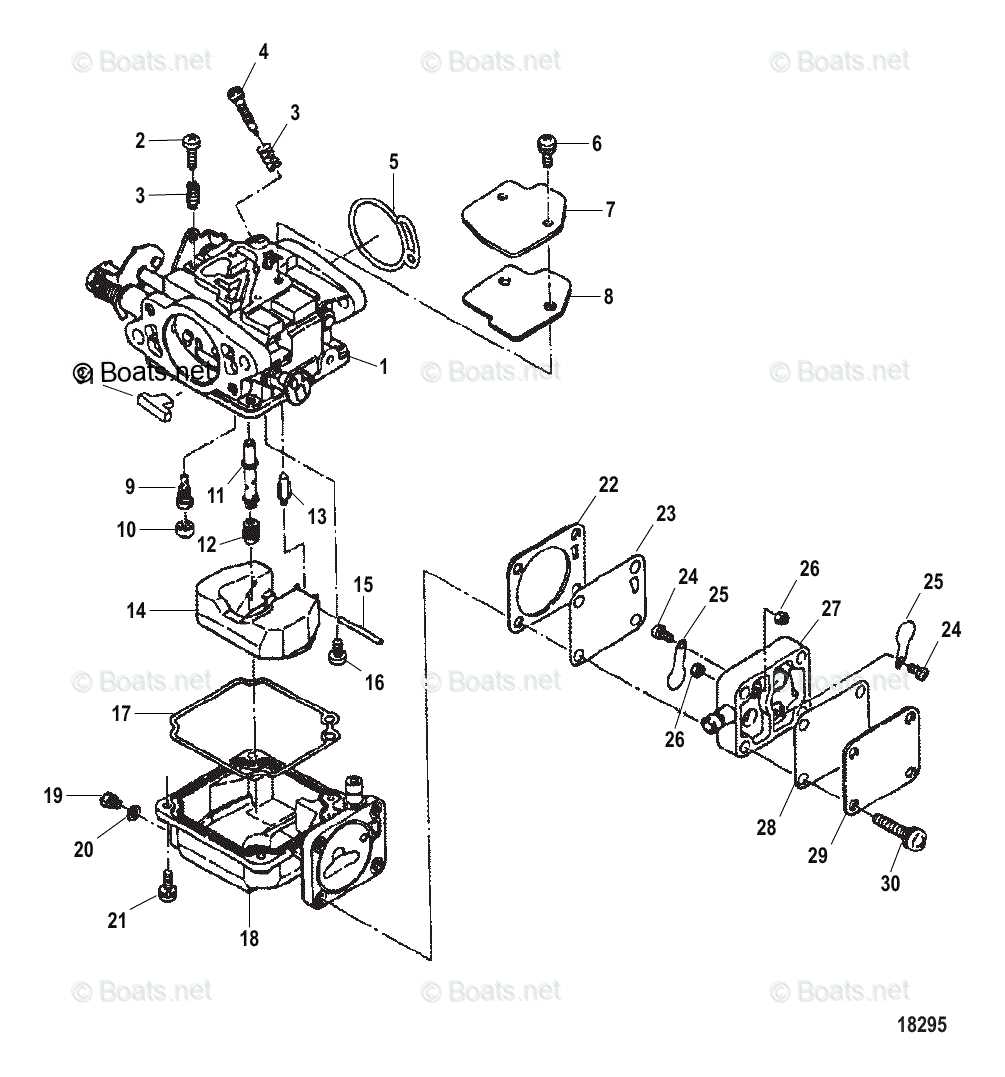

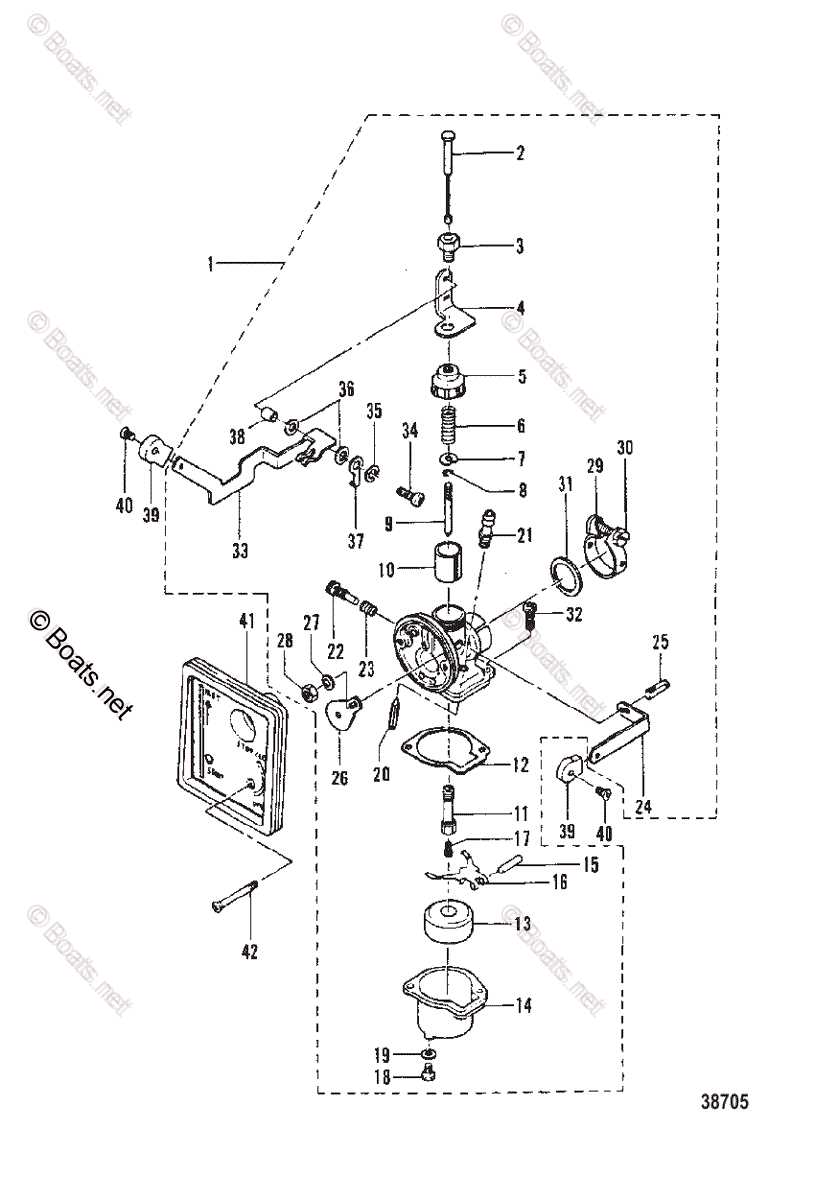

2. Carburetor: This component mixes fuel with air before it enters the combustion chamber, playing a vital role in the engine’s efficiency and responsiveness.

3. Fuel Pump: Responsible for delivering fuel from the tank to the carburetor, ensuring that the engine receives an adequate supply for optimal performance.

4. Ignition System: This system generates the spark needed for combustion, involving components like spark plugs and ignition coils, which are critical for starting and running the engine smoothly.

5. Cooling System: This system prevents overheating by circulating water around the engine, ensuring that it operates within a safe temperature range during use.

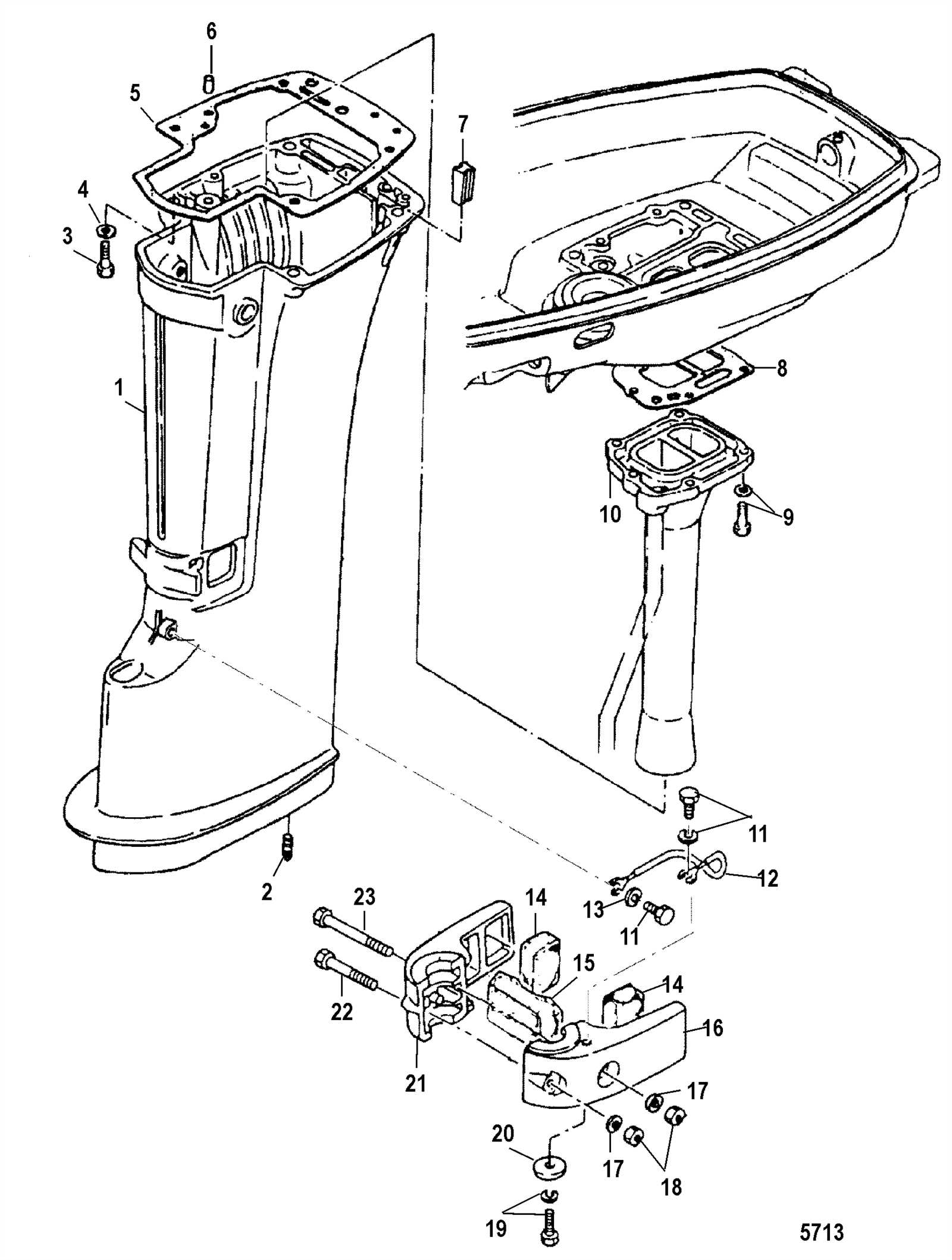

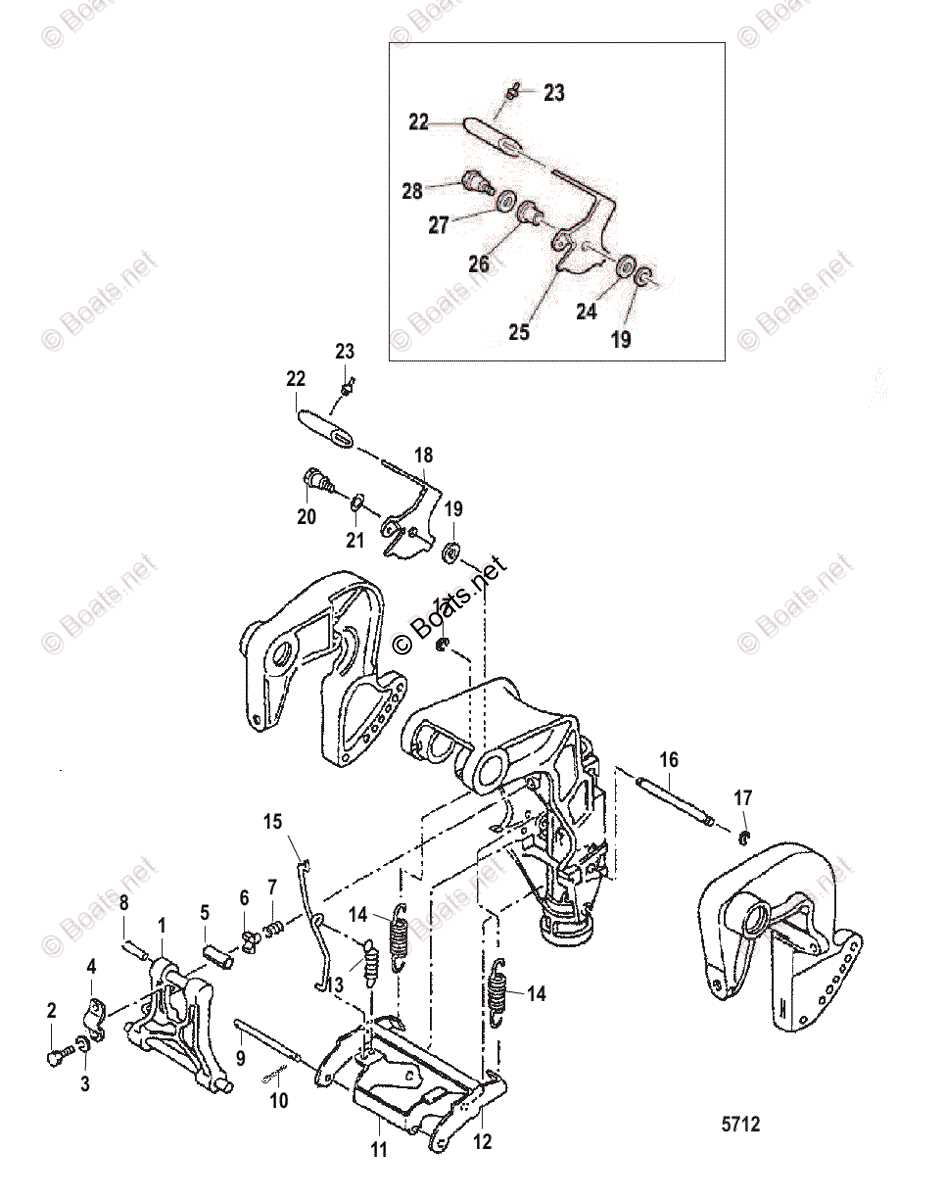

6. Gearcase: Housing the propeller and drive system, this component transfers the engine’s power to the water, enabling movement and steering capabilities.

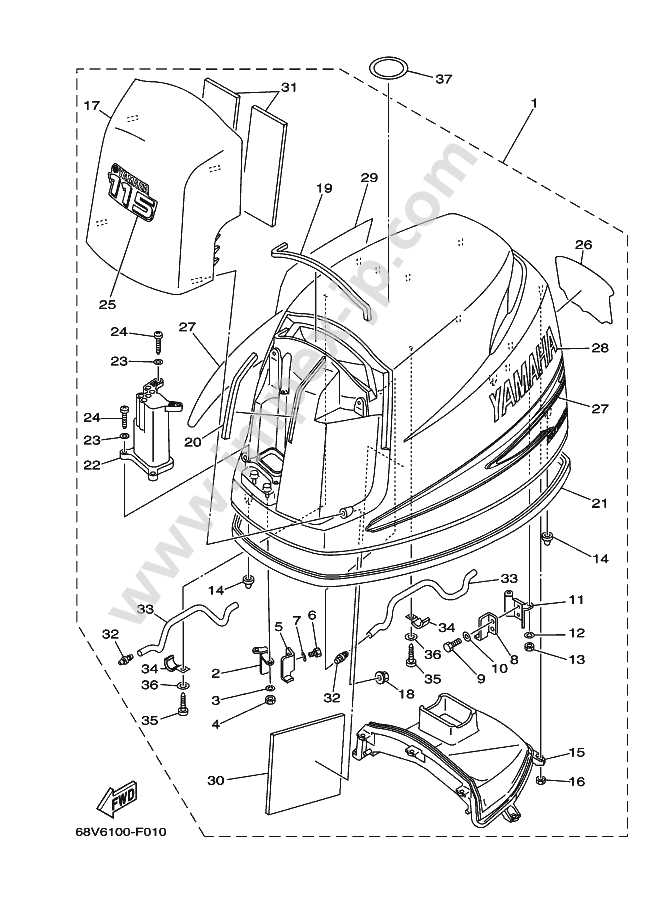

Understanding the Parts Diagram

Comprehending the components of a small engine is essential for effective maintenance and repair. A visual representation helps users identify and understand each element’s role within the system, enabling informed decisions during servicing. This guide will delve into the various sections typically found in such illustrations, enhancing overall knowledge of engine mechanics.

Main Components Overview

- Powerhead: The engine’s core where combustion occurs.

- Lower Unit: Houses the propulsion system, including the propeller.

- Fuel System: Comprises elements that deliver fuel to the combustion chamber.

- Ignition System: Responsible for initiating the combustion process.

Interrelation of Elements

Each segment operates in conjunction with others, creating a cohesive mechanism. Understanding how these pieces interact is vital for troubleshooting and optimization. Regular examination and familiarity with these relationships can lead to improved performance and longevity of the engine.

- Identify each part from the illustration.

- Study the connections between components.

- Keep a record of maintenance performed on each section.

Common Issues with 15 HP Motors

Engines in the 15 horsepower range are widely used for various applications, but they can encounter several common challenges. Understanding these issues can help in maintaining optimal performance and longevity.

One frequent problem is starting difficulties, which may arise from fuel supply issues or electrical system malfunctions. Ensuring that the fuel is fresh and the electrical connections are secure can mitigate these challenges.

Another common concern involves overheating. This can be caused by insufficient cooling water flow, clogged cooling passages, or low oil levels. Regular maintenance, including checking water intake and ensuring proper lubrication, is essential to prevent overheating.

Additionally, vibration can lead to mechanical failures if not addressed. Loose mounting bolts or misaligned components can contribute to excessive vibration. Routine inspections and adjustments can help maintain stability during operation.

Lastly, exhaust problems may occur, often due to blockages or issues with the exhaust system. Keeping the exhaust components clean and free from debris is crucial for effective operation.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your outboard engine. By following a few straightforward guidelines, you can extend the life of your equipment and maintain its efficiency. Here are some key practices to consider.

Routine Inspections

- Check the fuel system regularly for leaks or blockages.

- Inspect the ignition components for wear and tear.

- Examine the cooling system to prevent overheating issues.

Proper Storage

- Clean the engine thoroughly before storing it to remove any salt or debris.

- Use a protective cover to shield it from the elements.

- Store in a dry, climate-controlled environment to avoid corrosion.

By adhering to these maintenance suggestions, you can ensure that your engine remains in peak condition for years to come.

How to Identify Spare Parts

Understanding how to recognize components is crucial for maintaining and repairing machinery effectively. Accurate identification ensures you select the correct elements, enhancing performance and longevity. This process can seem daunting, but with the right approach, it becomes manageable.

1. Review the User Manual: Begin by consulting the user manual for your equipment. This document often includes valuable information regarding component specifications and part numbers, serving as a vital resource for identification.

2. Examine Existing Components: Inspect the parts currently installed in your machinery. Look for any visible markings, numbers, or manufacturer names that can assist in pinpointing replacements. Take note of the size, shape, and connection types, as these details are essential for finding compatible elements.

3. Utilize Online Resources: Leverage online platforms and forums dedicated to machinery enthusiasts. Many communities share insights and diagrams that can help identify specific components. Searching for your model alongside relevant keywords can yield helpful results.

4. Consult with Experts: If uncertainty remains, reach out to professionals or local suppliers. Their expertise can provide clarity on which components are needed, ensuring you acquire the right replacements without unnecessary trial and error.

By following these steps, you can confidently navigate the process of identifying the necessary components, leading to more efficient repairs and maintenance.

Assembly Process Explained

The assembly of a marine engine is a crucial procedure that ensures optimal performance and reliability. This section outlines the fundamental steps involved in bringing together various components to create a functioning unit. A thorough understanding of this process can significantly enhance the efficiency and lifespan of the engine.

Preparation Steps

Before commencing assembly, it’s essential to prepare all necessary components and tools. Inspect each element for any signs of wear or damage, as this can affect overall functionality. Having a clean workspace also promotes an organized and efficient assembly process.

Assembly Techniques

When assembling the engine, follow a systematic approach to ensure that each component is installed correctly. Begin with the base structure, securing each piece in place. Utilize the appropriate fasteners and torque specifications to avoid any issues during operation. It’s important to refer to the manufacturer’s guidelines for specific instructions on aligning and fitting components.

Final checks are vital to confirm that everything is assembled correctly. Inspect for any loose fittings or misalignments before performing a functional test. Proper assembly techniques not only enhance performance but also contribute to the longevity of the engine.

Where to Find Genuine Parts

Finding authentic components for your outboard motor can be a straightforward process if you know where to look. It’s essential to source reliable suppliers to ensure the longevity and performance of your engine.

One of the best places to start your search is through authorized dealerships. These establishments often carry a comprehensive selection of genuine components and have knowledgeable staff who can assist with your needs. Additionally, they may offer warranty coverage for the items purchased, providing peace of mind.

Online marketplaces are another viable option. Reputable websites that specialize in marine equipment frequently stock authentic items and can provide detailed descriptions and specifications. However, it’s crucial to verify the seller’s reputation and ensure they are authorized to distribute genuine goods.

Lastly, consider joining forums or groups dedicated to marine enthusiasts. These communities can offer valuable recommendations for trustworthy sources and may even have members willing to sell or trade authentic components. Engaging with fellow boaters can lead you to hidden gems in the market.

Upgrading Your Engine Performance

Enhancing the functionality of your motor can lead to significant improvements in power and efficiency. With a few strategic modifications, you can achieve a noticeable boost in performance, whether for recreational activities or competitive purposes. This section explores various methods to optimize your engine, ensuring a more enjoyable and efficient experience.

Essential Modifications

- Air Intake System: Upgrading to a high-performance air filter can increase airflow, leading to improved combustion.

- Exhaust System: A more efficient exhaust system can help reduce back pressure, enhancing power output.

- Fuel System: Consider installing a performance fuel pump and injectors to ensure an adequate fuel supply.

Tuning Your Engine

- Adjust the carburetor settings for optimal air-fuel mixture.

- Reprogram the engine control unit (ECU) for enhanced performance parameters.

- Regular maintenance checks to ensure all components are functioning efficiently.

By implementing these upgrades and adjustments, you can significantly elevate the performance of your motor, leading to a more responsive and powerful driving experience.

Expert Resources for Troubleshooting

When dealing with engine malfunctions, access to reliable information and expert guidance is essential for effective resolution. Various resources can aid in diagnosing issues, ensuring proper maintenance, and enhancing overall performance.

Utilizing comprehensive manuals, online forums, and instructional videos can provide invaluable insights. These tools not only offer step-by-step guidance but also connect users with seasoned professionals who can share their experiences and solutions.

| Resource Type | Description | Benefits |

|---|---|---|

| User Manuals | Detailed documentation provided by manufacturers. | Authoritative guidance on operation and maintenance. |

| Online Forums | Community-driven platforms for sharing knowledge. | Access to real-life experiences and troubleshooting tips. |

| Video Tutorials | Visual demonstrations of repair and maintenance tasks. | Step-by-step visual guidance for easier comprehension. |

| Technical Support | Assistance from experienced professionals. | Direct help for complex issues and specific inquiries. |