The effective operation of a small engine relies heavily on the intricate relationship between its various components. Each piece plays a crucial role in ensuring optimal performance and longevity. Familiarizing yourself with these essential elements can significantly enhance maintenance efforts and troubleshooting skills.

For those who own a 20 horsepower outboard motor, grasping the configuration and function of its individual elements is vital. This knowledge empowers users to identify potential issues quickly and understand the assembly as a whole. By recognizing how each section interconnects, one can approach repairs and upgrades with confidence.

Delving into the specifics of engine assemblies allows for better care and efficiency. Whether you’re a seasoned technician or a new enthusiast, having a clear visual reference can facilitate smoother operations. Understanding the layout and relationships between components ultimately contributes to a more reliable and enjoyable boating experience.

Understanding Mercury 20 HP Components

When operating a small marine engine, it’s essential to grasp the various elements that contribute to its performance. Familiarity with the individual components helps in maintenance and troubleshooting, ensuring smooth operation on the water. Each section of the engine plays a crucial role, influencing everything from efficiency to longevity.

| Component | Function |

|---|---|

| Powerhead | Generates propulsion through combustion. |

| Lower Unit | Transfers power to the propeller and aids in steering. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Ignition System | Ignites the air-fuel mixture for efficient power generation. |

| Cooling System | Regulates engine temperature to prevent overheating. |

| Exhaust System | Expels combustion gases and reduces noise. |

Understanding these components enables users to diagnose issues more effectively, enhancing overall enjoyment and reliability while navigating waters. Regular inspection and awareness of each part’s function can lead to a longer lifespan for the engine and improved performance in various conditions.

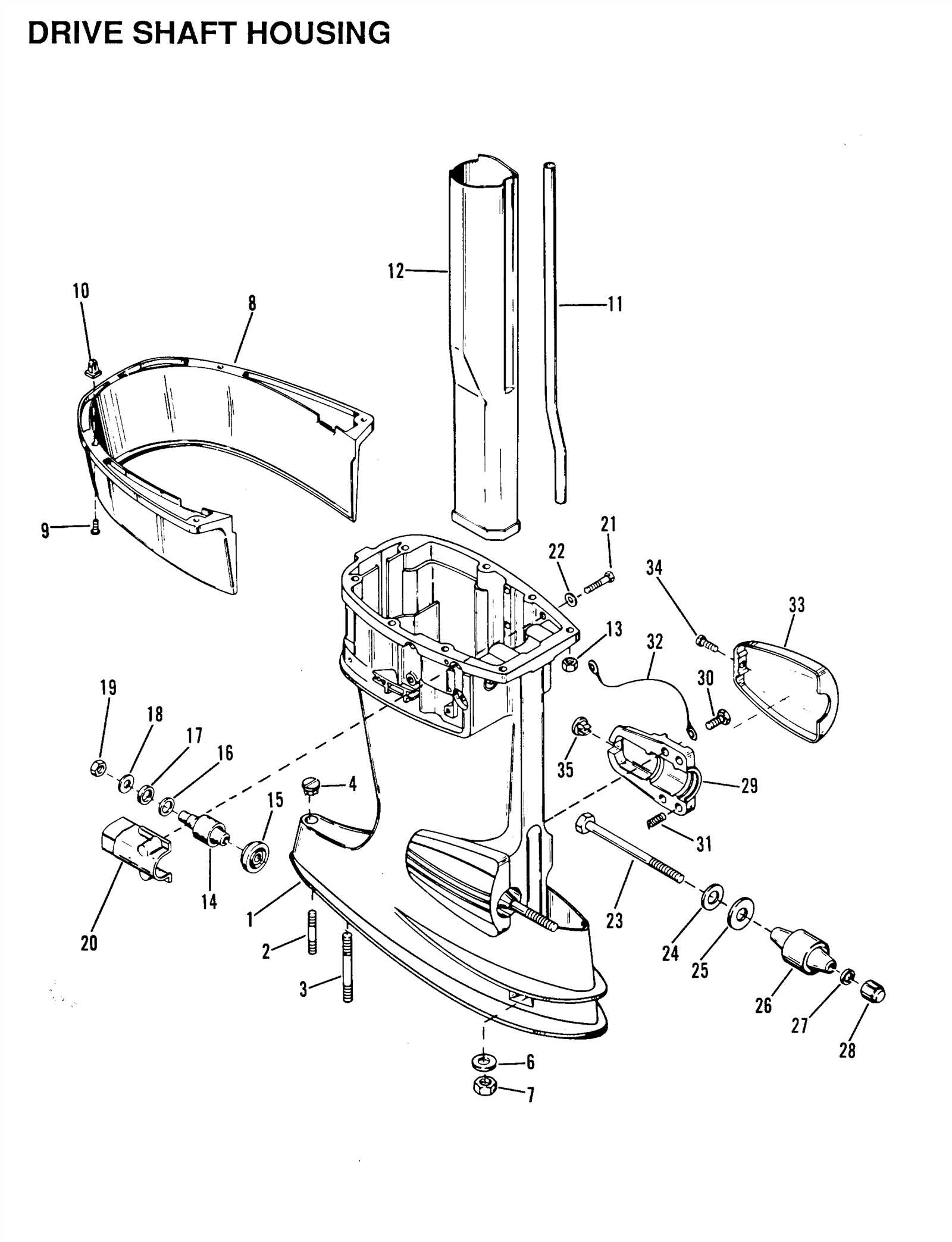

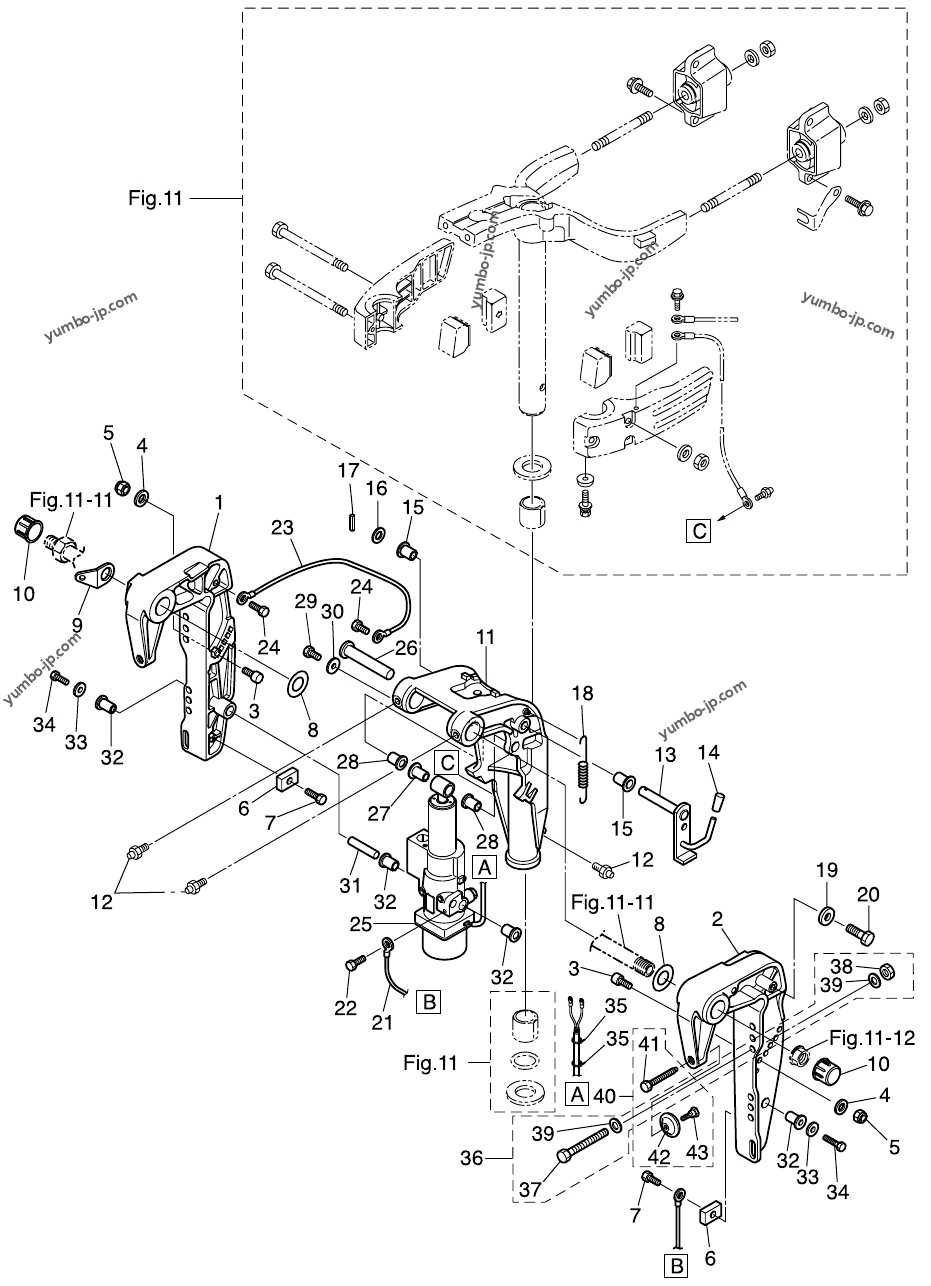

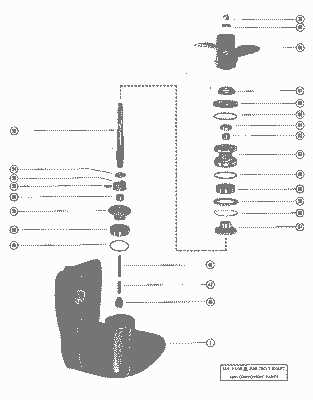

Importance of Parts Diagrams

Understanding the intricate layout of components is crucial for effective maintenance and repair. A visual representation allows users to identify each element’s role, ensuring efficient troubleshooting and assembly.

Enhancing Maintenance Efficiency

- Facilitates quick identification of components

- Streamlines the repair process

- Reduces the likelihood of errors during assembly

Supporting Decision-Making

- Assists in determining necessary replacements

- Helps in visualizing modifications or upgrades

- Enhances understanding of overall functionality

Common Issues with Mercury Outboards

Outboard motors are essential for smooth navigation on water, but they can encounter several typical challenges over time. Understanding these common problems helps boaters maintain their engines effectively, ensuring reliability and performance during outings.

| Issue | Description | Possible Solutions |

|---|---|---|

| Overheating | Engines may overheat due to blocked water intake or faulty thermostats. | Regularly check and clean water intake, replace thermostats if needed. |

| Fuel Problems | Issues like stale fuel or clogged filters can hinder performance. | Use fresh fuel, replace filters, and check for leaks. |

| Electrical Failures | Malfunctions in the ignition or battery can prevent starting. | Inspect connections, test battery health, and replace faulty components. |

| Vibration | Excessive shaking may indicate propeller issues or misalignment. | Check for prop damage and ensure proper alignment. |

Where to Find Official Diagrams

Locating reliable visual references for small engine components is essential for effective maintenance and repairs. Official resources provide accurate representations that help users identify specific elements, ensuring a smoother troubleshooting process. Knowing where to find these resources can save time and enhance the efficiency of any project.

Manufacturer Websites

The best starting point is the official website of the manufacturer. These platforms often feature dedicated sections for support, where users can access a wealth of resources, including visual aids. These resources are typically well-organized and can be searched by model or category, making it easy to find the information you need.

Authorized Dealers and Service Centers

Authorized dealers and service centers can be invaluable sources of information. Many of these establishments maintain a library of manuals and visuals for various models. Engaging with knowledgeable staff can also provide insights and recommendations tailored to your specific needs, ensuring you have the most accurate information at hand.

Key Parts of Mercury 20 HP

This section highlights the essential components that contribute to the performance and functionality of a 20 HP engine. Understanding these elements is crucial for maintenance and optimal operation.

Engine Assembly

The core unit houses vital systems for power generation and efficiency. Key elements include the cylinder block and crankshaft, which work in unison to convert fuel into mechanical energy.

Cooling System

A well-functioning cooling mechanism is vital to prevent overheating. The water pump and thermostat ensure that the engine operates within the ideal temperature range, enhancing longevity and performance.

Tools Required for Maintenance

Proper upkeep of your engine requires specific instruments to ensure everything operates smoothly. Having the right tools at your disposal not only simplifies the maintenance process but also enhances the longevity and efficiency of the unit. Below is a list of essential equipment needed for effective servicing.

| Tool | Description |

|---|---|

| Socket Wrench Set | Used for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Screwdriver Set | Necessary for various screws found in the assembly. |

| Pliers | Useful for gripping and bending components. |

| Oil Filter Wrench | Facilitates the removal of oil filters during changes. |

| Fuel Line Wrench | Helps to work on fuel lines without damaging them. |

| Cleaning Supplies | Includes brushes, cloths, and cleaners to maintain cleanliness. |

Step-by-Step Repair Process

This section outlines a systematic approach to addressing common issues encountered with a small outboard motor. By following these organized steps, users can ensure efficient troubleshooting and restoration of functionality, minimizing downtime and enhancing performance.

Begin by gathering the necessary tools and materials. Familiarize yourself with the motor’s components to streamline the repair process. It is essential to follow a methodical approach, ensuring that each step is executed with care and precision.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to ensure safety while working on the motor. |

| 2 | Inspect the exterior for any visible signs of damage or wear that may require attention. |

| 3 | Remove the necessary covers to access internal components, taking care to note the location of each part. |

| 4 | Examine critical elements such as the fuel system, ignition, and cooling mechanisms for any irregularities. |

| 5 | Replace or repair faulty components as identified during the inspection process. |

| 6 | Reassemble the motor, ensuring all parts are securely fitted and correctly aligned. |

| 7 | Reconnect the power source and conduct a thorough test to confirm that the motor operates as intended. |

Following these steps carefully will help maintain the longevity and efficiency of the outboard motor, allowing for enjoyable and trouble-free usage on the water.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring a safe working environment is paramount. Adhering to specific safety guidelines not only protects the individual but also contributes to the overall efficiency of the repair process.

Always wear appropriate personal protective equipment, such as gloves and goggles, to guard against potential hazards. Keep the workspace organized and free of obstructions to prevent accidents. Additionally, ensure that all tools are in good condition and suitable for the task at hand.

It’s crucial to disconnect any power sources before beginning work to avoid electric shocks or other dangers. Familiarize yourself with the equipment and its components, as understanding how everything works can help prevent mishaps.

Finally, maintain a clear line of communication with anyone present, especially if working in a team. This collaborative approach can significantly reduce risks and enhance overall safety during repair activities.

Upgrading Parts for Performance

Enhancing the functionality of your outboard motor can significantly improve its efficiency and responsiveness. By carefully selecting high-quality components and making thoughtful modifications, you can unlock the true potential of your engine. This section explores various options to boost performance and achieve a more thrilling experience on the water.

Key Areas for Enhancement

- Fuel System Optimization

- Exhaust Upgrades

- Ignition Improvements

- Propeller Selection

Considerations for Upgrades

- Compatibility with existing systems

- Cost vs. performance benefits

- Installation complexity

- Long-term maintenance and reliability

By taking these factors into account, you can make informed decisions that lead to the ultimate performance enhancements for your outboard experience.

Finding Quality Replacement Parts

When seeking to restore or maintain a small marine engine, identifying high-quality components is essential for ensuring optimal performance and longevity. This section delves into effective strategies for sourcing reliable substitutes that can enhance your vessel’s efficiency.

Researching Reputable Suppliers

Start by investigating well-established retailers or distributors known for their extensive inventory and commitment to customer satisfaction. Reviews and recommendations from fellow enthusiasts can be invaluable in this process.

Utilizing Online Resources

Online marketplaces provide a plethora of options, but it’s crucial to verify the authenticity of sellers. Look for platforms that offer buyer protection and clear return policies.

| Criteria | Description |

|---|---|

| Supplier Reputation | Choose suppliers with positive feedback and a strong track record. |

| Warranty and Returns | Ensure that components come with guarantees and a straightforward return process. |

| Availability | Confirm that the items are in stock and ready for prompt shipping. |

| Price Comparison | Compare prices across multiple sources to find the best deal without sacrificing quality. |

Benefits of Regular Maintenance

Consistent upkeep of machinery ensures optimal performance and longevity. By adhering to a scheduled maintenance routine, users can avoid unexpected failures and enhance the overall efficiency of their equipment.

- Enhanced Performance: Regular checks and tune-ups help maintain peak functionality.

- Extended Lifespan: Proper care significantly prolongs the life of the equipment.

- Cost Savings: Preventative measures can reduce the need for costly repairs in the future.

- Increased Safety: Routine maintenance ensures that all safety features are operational.

- Optimal Efficiency: Well-maintained equipment operates more efficiently, saving time and energy.

Identifying Original vs. Aftermarket Parts

Understanding the differences between authentic components and those produced by third-party manufacturers is crucial for maintaining optimal performance and longevity of your equipment. This section explores key aspects to help users make informed decisions when sourcing replacements.

Key Characteristics of Authentic Components

Genuine items typically exhibit certain traits that distinguish them from alternatives:

- Quality Control: Manufactured under strict standards.

- Packaging: Often features branded packaging and documentation.

- Warranty: Usually comes with a manufacturer’s guarantee.

Common Signs of Aftermarket Alternatives

While third-party options can be more affordable, they may lack certain benefits:

- Inconsistent Quality: Varies widely among manufacturers.

- Packaging: Often generic or unbranded.

- Limited Warranty: May offer little to no guarantee.

FAQs About Mercury 20 HP Parts

This section addresses common inquiries regarding components related to the 20 HP engine model. Here, you will find essential information to help you navigate the specifics of these elements effectively.

Below are some frequently asked questions:

- What are the main components of this engine?

The primary elements include the fuel system, ignition components, and cooling parts.

- How can I identify the correct components?

Check the model number and refer to specific guides or manuals that detail compatibility.

- Where can I purchase quality components?

Reputable marine supply stores and authorized dealers are reliable sources for quality items.

- How often should I replace components?

It is advisable to inspect them regularly and replace any worn or damaged items promptly.

For further inquiries, consult your local expert or technician to ensure optimal performance of your engine.