When navigating the world of marine engines, having a clear understanding of their individual elements is crucial for efficient operation and maintenance. This section focuses on a specific model that is widely appreciated for its performance and reliability. A comprehensive breakdown of its components will help users identify, locate, and understand the various parts that contribute to the engine’s functionality.

Each element plays a significant role in the overall performance of the unit, and recognizing their positions and interactions can greatly enhance troubleshooting efforts. By familiarizing oneself with the configuration of these components, users can gain insight into how to optimize performance and ensure longevity.

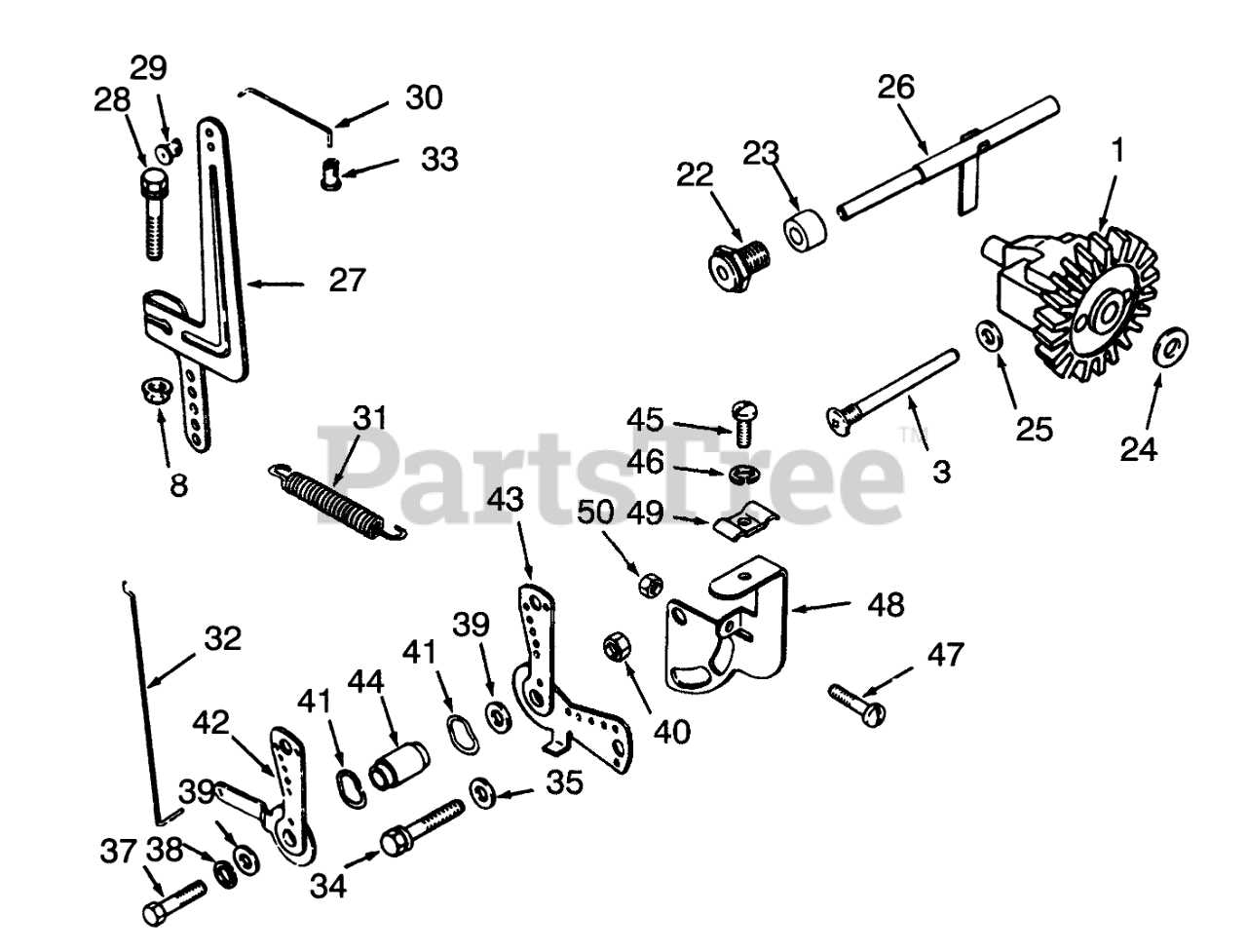

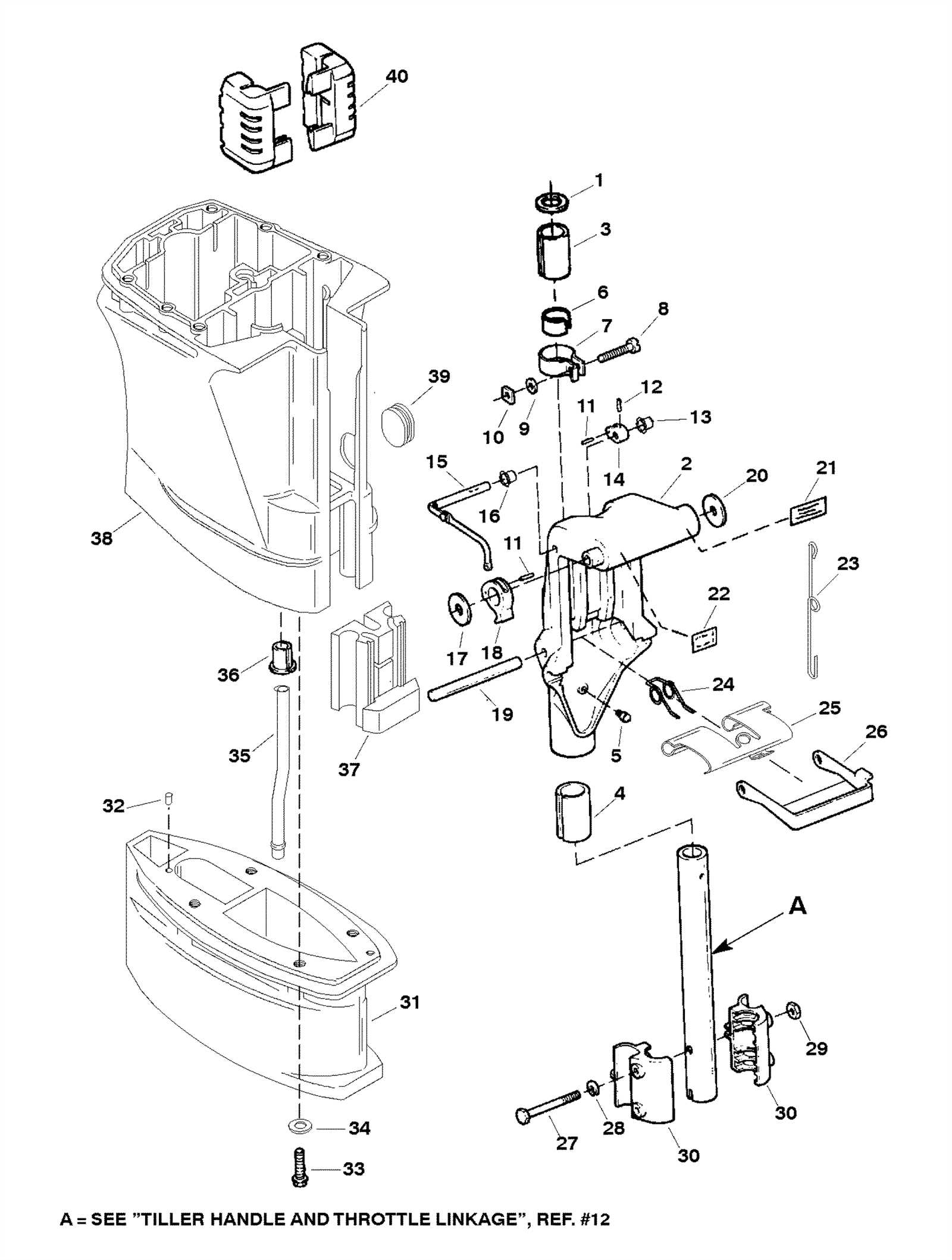

For those seeking to maintain or repair their engine, a detailed representation of the assembly serves as an invaluable resource. It not only aids in locating specific items but also offers a visual reference that can clarify complex mechanical relationships. Understanding these intricate details empowers users to take informed actions and make precise adjustments when necessary.

Key Components Explained

Understanding the essential elements of a marine propulsion system is crucial for anyone involved in boating. Each component plays a significant role in ensuring optimal performance and reliability on the water. This section will delve into the primary features, highlighting their functions and importance in overall operation.

Engine Assembly: The heart of the system, the engine assembly generates the power necessary for movement. It converts fuel into mechanical energy, allowing the vessel to navigate various aquatic environments.

Fuel System: This system is responsible for storing and delivering the fuel to the engine. It ensures that the correct amount of fuel is mixed with air for efficient combustion, significantly impacting performance and fuel efficiency.

Ignition Mechanism: The ignition mechanism is critical for starting the engine. It generates a spark that ignites the fuel-air mixture, facilitating the combustion process necessary for propulsion.

Cooling System: A vital component that prevents the engine from overheating, the cooling system circulates water to absorb heat generated during operation. Proper cooling is essential for maintaining optimal performance and longevity.

Gearbox: The gearbox translates the engine’s rotational force into the propeller’s motion, allowing for effective speed control and maneuverability. This component plays a crucial role in adapting to varying water conditions.

Propeller: The propeller is the final component that translates the engine’s power into thrust. Its design and pitch significantly influence the vessel’s speed and efficiency, making it a critical feature for any watercraft.

Identifying Essential Parts

Understanding the

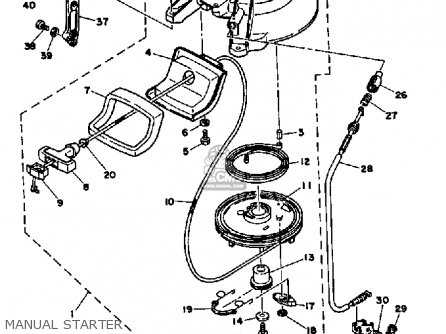

Understanding the Parts Diagram

Grasping the layout of components is essential for effective maintenance and repair of marine engines. This visual representation serves as a vital tool, allowing users to identify and understand each element’s function within the machinery. A clear overview aids in recognizing potential issues and facilitates a smoother repair process.

Key Components Overview

- Powerhead: The heart of the engine, responsible for generating propulsion.

- Lower Unit: Houses the gears and propeller system, crucial for movement through water.

- Fuel System: Manages the delivery of fuel to the engine, impacting performance.

- Ignition System: Initiates the combustion process, essential for engine operation.

Benefits of Familiarity

- Enhanced Troubleshooting: Recognizing each element aids in diagnosing issues quickly.

- Informed Repairs: Understanding how components interact improves repair strategies.

- Effective Upgrades: Knowledge of parts enables informed decisions when upgrading equipment.

Engine Assembly and Functionality

The assembly of a marine propulsion unit plays a crucial role in ensuring optimal performance and reliability on the water. This section delves into the essential components and their respective roles within the engine system. Understanding the functionality of these elements is vital for effective maintenance and troubleshooting, enabling users to achieve peak efficiency from their equipment.

Key Components and Their Roles

Each component within the engine assembly has a specific function that contributes to the overall operation of the machinery. Below is a brief overview of the main elements and their purposes:

| Component | Function |

|---|---|

| Cylinder Block | Houses the cylinders and provides structural support. |

| Piston | Moves up and down within the cylinder, creating compression. |

| Crankshaft | Converts linear motion of the pistons into rotational energy. |

| Ignition System | Initiates combustion by igniting the fuel-air mixture. |

| Fuel System | Delivers fuel to the engine for combustion. |

Operational Mechanics

The operational mechanics of the assembly hinge on the coordinated interaction of its components. As the piston moves, it creates a vacuum that draws in fuel and air. The ignition system then ignites the mixture, causing an explosion that drives the piston downward. This movement is translated into rotational motion by the crankshaft, ultimately providing the thrust necessary for navigation. Regular maintenance and familiarity with these processes are essential for ensuring longevity and performance.

Fuel System Components Overview

The fuel delivery mechanism plays a crucial role in the efficient operation of marine engines. This system ensures that the right amount of fuel reaches the combustion chamber, optimizing performance and enhancing overall functionality.

Key elements of this system include:

- Fuel Tank: The reservoir that stores the fuel before it is fed into the engine.

- Fuel Pump: A component responsible for transporting fuel from the tank to the engine, ensuring a steady flow.

- Fuel Filter: A vital part that removes impurities and contaminants from the fuel, safeguarding engine health.

- Carburetor or Fuel Injectors: These devices mix air and fuel in the correct proportions, facilitating optimal combustion.

- Fuel Lines: Hoses that transport fuel between various components, designed to withstand high pressure and temperature.

- Primer Bulb: A manual pump used to prime the fuel system, ensuring quick starts by removing air from the lines.

Understanding each component’s function is essential for maintaining and troubleshooting the fuel delivery system. Regular inspections and timely replacements can prevent performance issues and extend the lifespan of the engine.

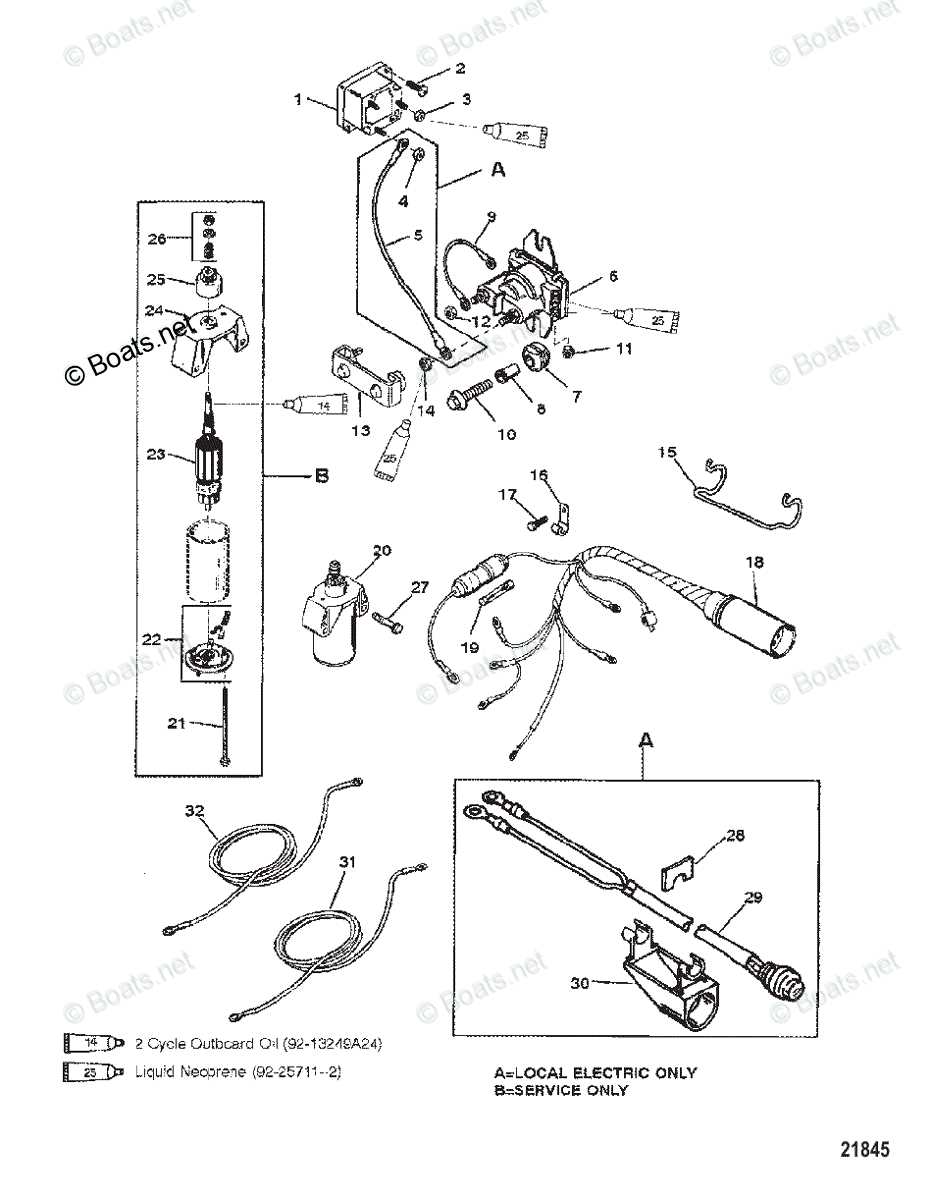

Electrical System Breakdown

The electrical framework of a marine engine plays a crucial role in ensuring optimal performance and reliability. It encompasses various components that work in harmony to deliver power and control functions essential for smooth operation. Understanding the intricacies of this system can significantly enhance maintenance and troubleshooting efforts.

Key elements of this structure include the ignition unit, wiring harness, and battery connections. Each component serves a specific function, from initiating the engine to powering navigational lights and instrumentation. Regular inspection and maintenance of these parts are vital to prevent electrical failures that could compromise performance on the water.

Additionally, understanding how each element interacts within the overall system can aid in identifying potential issues before they escalate. This knowledge not only improves the efficiency of repairs but also extends the lifespan of the entire assembly, ensuring a safer and more enjoyable boating experience.

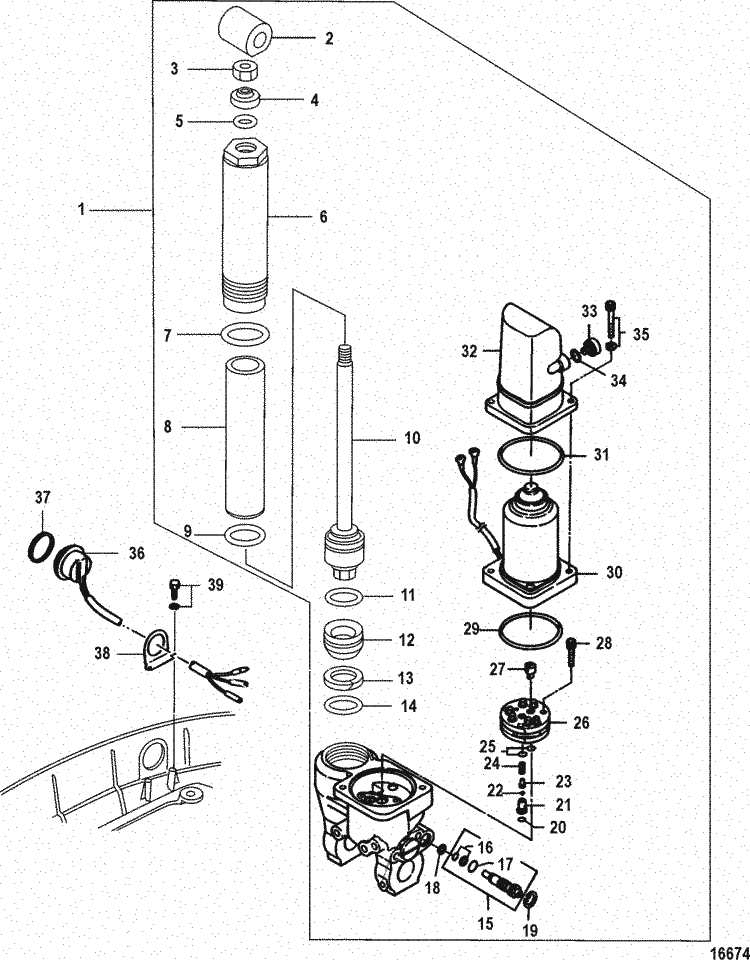

Cooling System Elements

The efficiency of any marine engine heavily relies on its cooling mechanism. This system plays a crucial role in maintaining optimal operating temperatures, ensuring the longevity and reliability of the unit. By regulating heat effectively, the components involved help prevent overheating and associated damages.

Central to the cooling arrangement is the water pump, which draws in water from the surrounding environment. This vital component ensures a steady flow of coolant throughout the engine, facilitating efficient heat exchange. Additionally, the thermostat acts as a temperature regulator, opening and closing to control the flow of coolant based on the engine’s temperature needs.

Another key element is the heat exchanger, which transfers excess heat from the engine to the incoming water, allowing for effective temperature management. Furthermore, the cooling jackets encase critical engine components, ensuring that heat is evenly distributed and dissipated. Regular inspection and maintenance of these elements are essential for optimal performance and to prevent potential overheating issues.

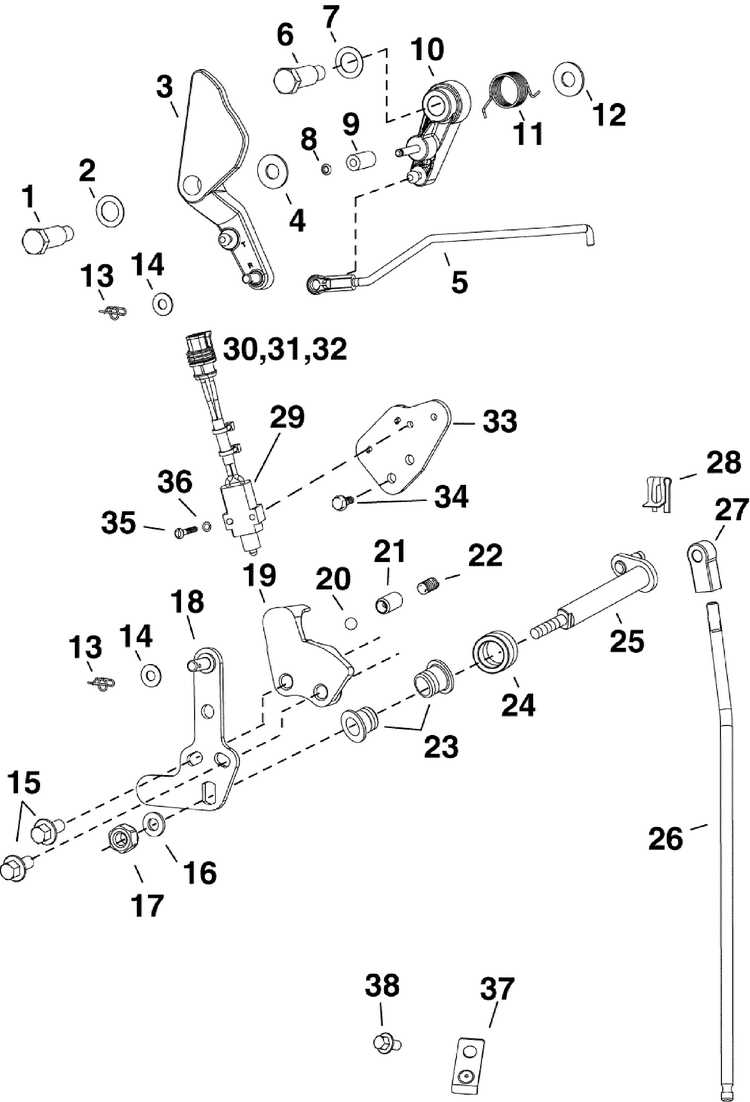

Propulsion and Gear Mechanisms

The efficiency of marine propulsion systems is pivotal for optimal performance and maneuverability. This section delves into the intricacies of the mechanisms responsible for converting engine power into effective motion. Understanding these components enhances the ability to maintain and optimize watercraft performance.

Power Transfer Systems

At the core of any propulsion system lies the power transfer mechanism, which facilitates the conversion of rotational energy into thrust. This involves various elements, including driveshafts and couplings, which play a crucial role in linking the engine to the propeller. By ensuring smooth energy transfer, these components enhance overall efficiency and responsiveness.

Propeller Dynamics

The propeller acts as the final element in the propulsion chain, translating engine power into forward movement. The design and pitch of the blades significantly influence the vessel’s speed and handling characteristics. Adjustments to these parameters can lead to improved performance, enabling better control and fuel efficiency on the water.

Maintenance Tips for Key Parts

Regular upkeep of essential components is vital for ensuring optimal performance and longevity of your marine engine. By paying attention to specific areas, you can prevent potential issues and enhance efficiency during operation.

Inspecting Fuel System: Ensure that the fuel lines are free of cracks or leaks. Replace any worn hoses promptly. Regularly check the fuel filter and replace it according to the manufacturer’s recommendations to keep the engine running smoothly.

Caring for the Cooling System: Maintain the cooling system by flushing it periodically to remove any debris or mineral buildup. Inspect the water pump impeller for wear and replace it as needed to prevent overheating.

Examining the Ignition Components: Regularly check spark plugs for signs of wear or carbon buildup. Clean or replace them to ensure proper ignition and performance. Additionally, inspect the ignition coils for any signs of damage.

Checking the Steering and Control Cables: Ensure that the steering mechanism operates smoothly. Lubricate cables and connections to prevent rust and ensure responsiveness. Replace any frayed cables to maintain safe handling.

Cleaning and Protecting the Exterior: Regularly clean the engine’s exterior to prevent salt and grime buildup. Use appropriate cleaners and coatings to protect against corrosion, ensuring the longevity of the finish.

Common Issues and Solutions

When operating marine engines, users may encounter various challenges that can affect performance and reliability. Understanding these common issues and knowing how to address them is essential for ensuring a smooth boating experience.

One prevalent problem is difficulty starting the engine, which can stem from several factors such as a weak battery, fuel delivery issues, or ignition system faults. Regularly checking the battery’s charge and connections, inspecting fuel lines for blockages, and ensuring spark plugs are clean can help mitigate this issue.

Another common concern is overheating. This can occur due to a blocked cooling system, low coolant levels, or malfunctioning thermostats. To prevent overheating, it is crucial to inspect the cooling system for debris, ensure that the coolant is at the proper level, and test the thermostat regularly for optimal operation.

Performance issues, such as loss of power or irregular acceleration, may also arise. These symptoms can be linked to clogged fuel filters, improper propeller selection, or air leaks in the intake system. Routine maintenance, including replacing fuel filters and selecting the appropriate propeller size, can greatly enhance engine efficiency.

Finally, unusual noises or vibrations while the engine is running often indicate underlying mechanical problems. Checking for loose components, worn bearings, or imbalanced propellers is essential to identify and resolve these issues early on. Regular inspections and maintenance can prevent further damage and extend the life of the engine.

Where to Find Replacement Parts

When it comes to maintaining marine engines, sourcing the right components is essential for optimal performance. There are various avenues to explore when looking for suitable replacements, whether for routine maintenance or repairs.

Here are some recommended options for locating the necessary components:

| Source | Description |

|---|---|

| Authorized Dealers | Visit certified retailers that specialize in marine engines. They often have a comprehensive inventory and knowledgeable staff to assist you. |

| Online Marketplaces | Websites like eBay and Amazon provide a wide selection of components, often at competitive prices. Check seller ratings and reviews for reliability. |

| Local Marine Shops | Explore nearby shops dedicated to boating supplies. These establishments frequently carry a range of components and can offer personalized service. |

| Manufacturer’s Website | Visit the official site of the engine’s manufacturer for a direct source of components. They often have parts catalogs and ordering options available. |

| Salvage Yards | Check marine salvage yards for used components. These places can offer significant savings, but inspect items carefully for wear and condition. |