For those who rely on dependable power when navigating the waters, understanding the various elements that make up a reliable motor is essential. Each individual piece plays a crucial role in ensuring smooth operation, from the core mechanisms to the smallest supporting elements. Recognizing how these elements interact can help in both routine upkeep and unexpected repairs.

In this guide, we’ll explore the primary features of a well-designed engine system, highlighting the connections and functions that keep everything running efficiently. By familiarizing yourself with the layout and identifying key areas, you’ll be better equipped to maintain and optimize performance over time. Whether you’re performing maintenance or simply getting to know your equipment, this breakdown will be a valuable resource for long-term reliability.

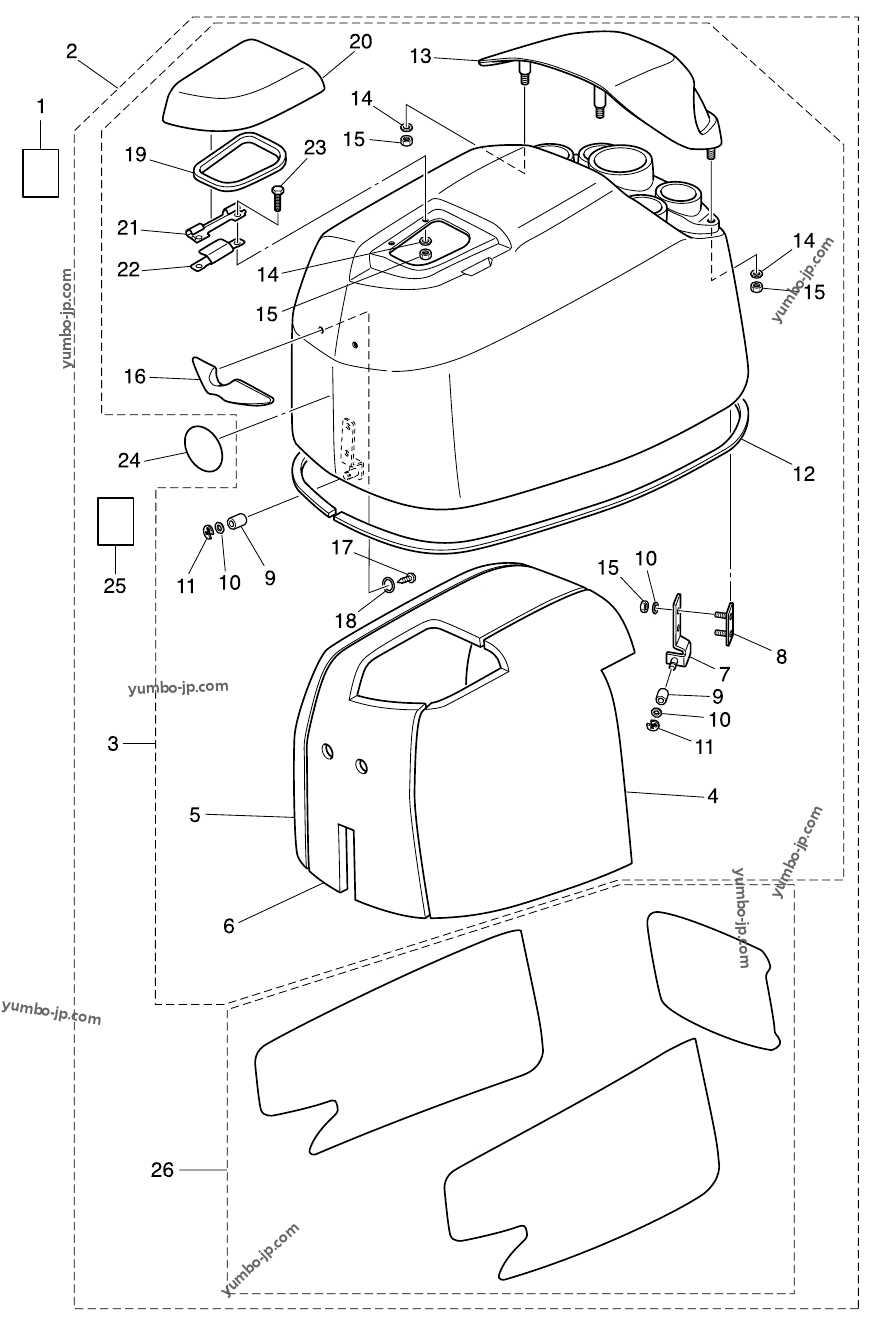

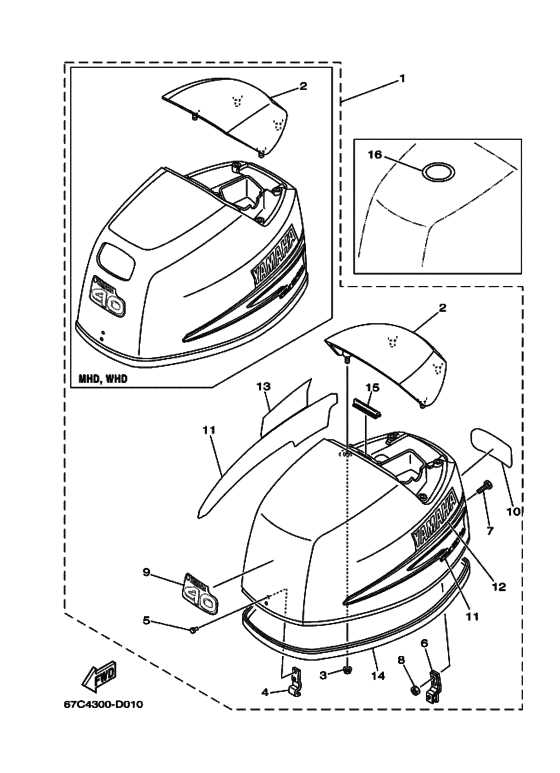

Overview of the Mercury 90HP 4-Stroke Engine

This powerful marine motor is designed for reliability and smooth performance on the water. Offering a balance of efficiency and durability, it caters to a range of boating needs, whether for leisure or work. The engine provides consistent power, allowing for steady acceleration and comfortable cruising, making it a favorite choice among enthusiasts.

Key Features of the Engine

- Fuel efficiency that ensures long journeys without frequent refueling stops

- Optimized cooling system to prevent overheating, even during extended use

- Advanced throttle response for smooth control in various conditions

- Minimal vibrations and noise, enhancing the overall boating experience

Benefits for Boaters

- Enhanced fuel economy helps reduce operational costs

- Durable construction ensures long-term reliability

- Easy maintenance with accessible components for quick servicing

- Perfect for both professional and recreational watercraft activities

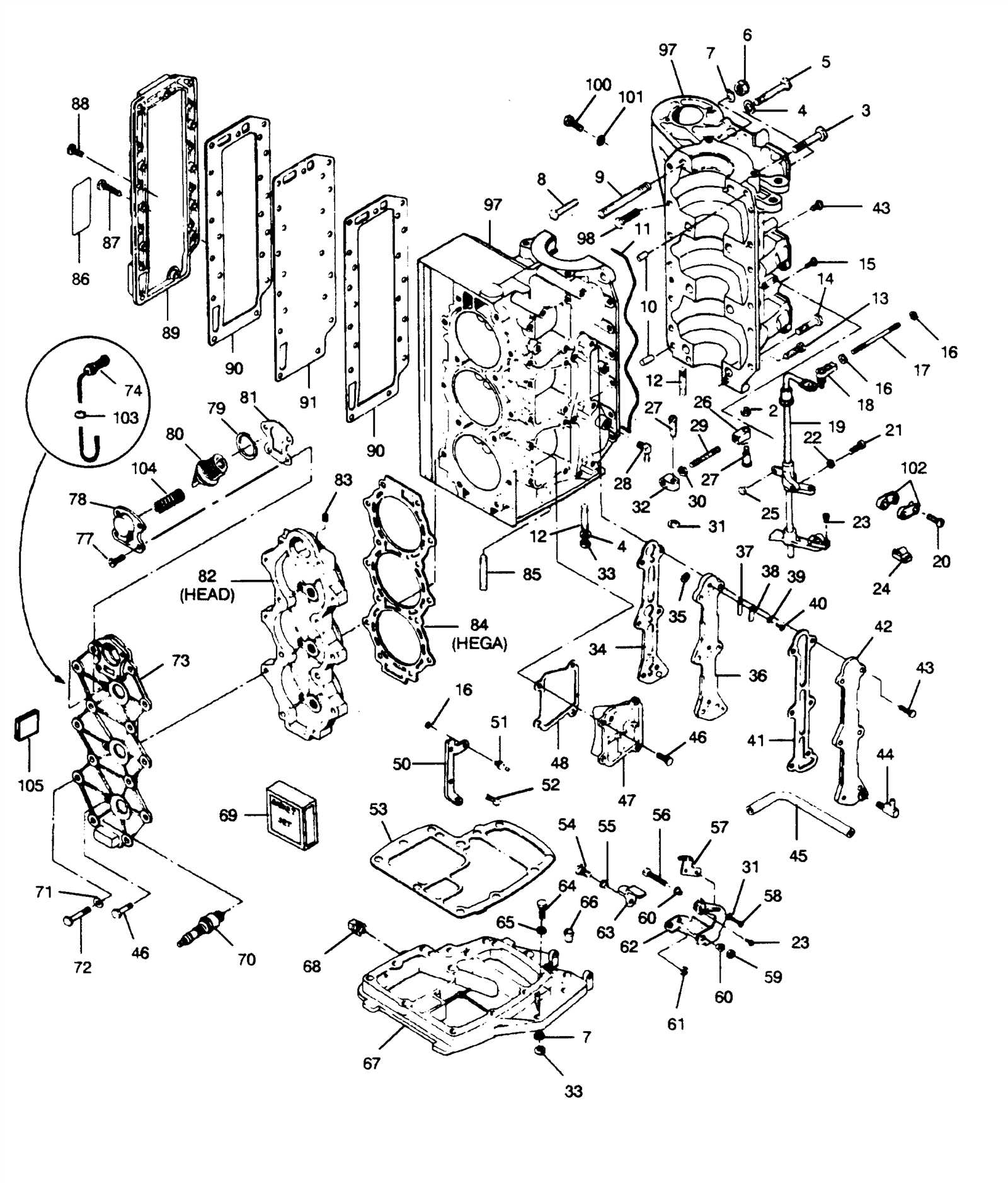

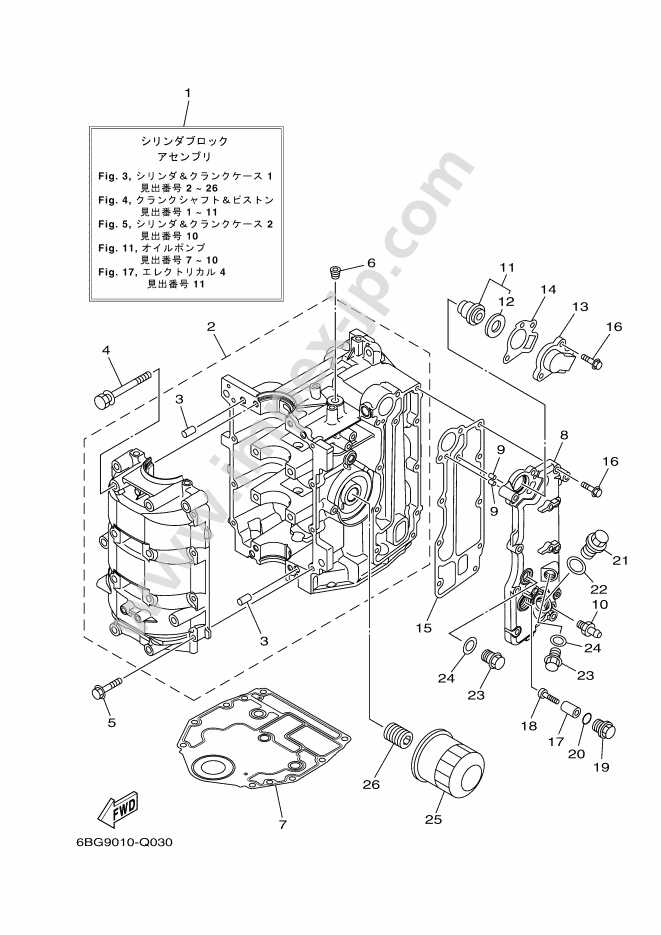

Key Components of the Mercury Outboard Motor

Outboard motors are made up of several crucial elements, each playing a vital role in the smooth and efficient operation of the engine. These components work in unison to ensure propulsion, steering, and overall performance. Understanding these core elements can provide better insights into the workings of the engine and help maintain its reliability on the water.

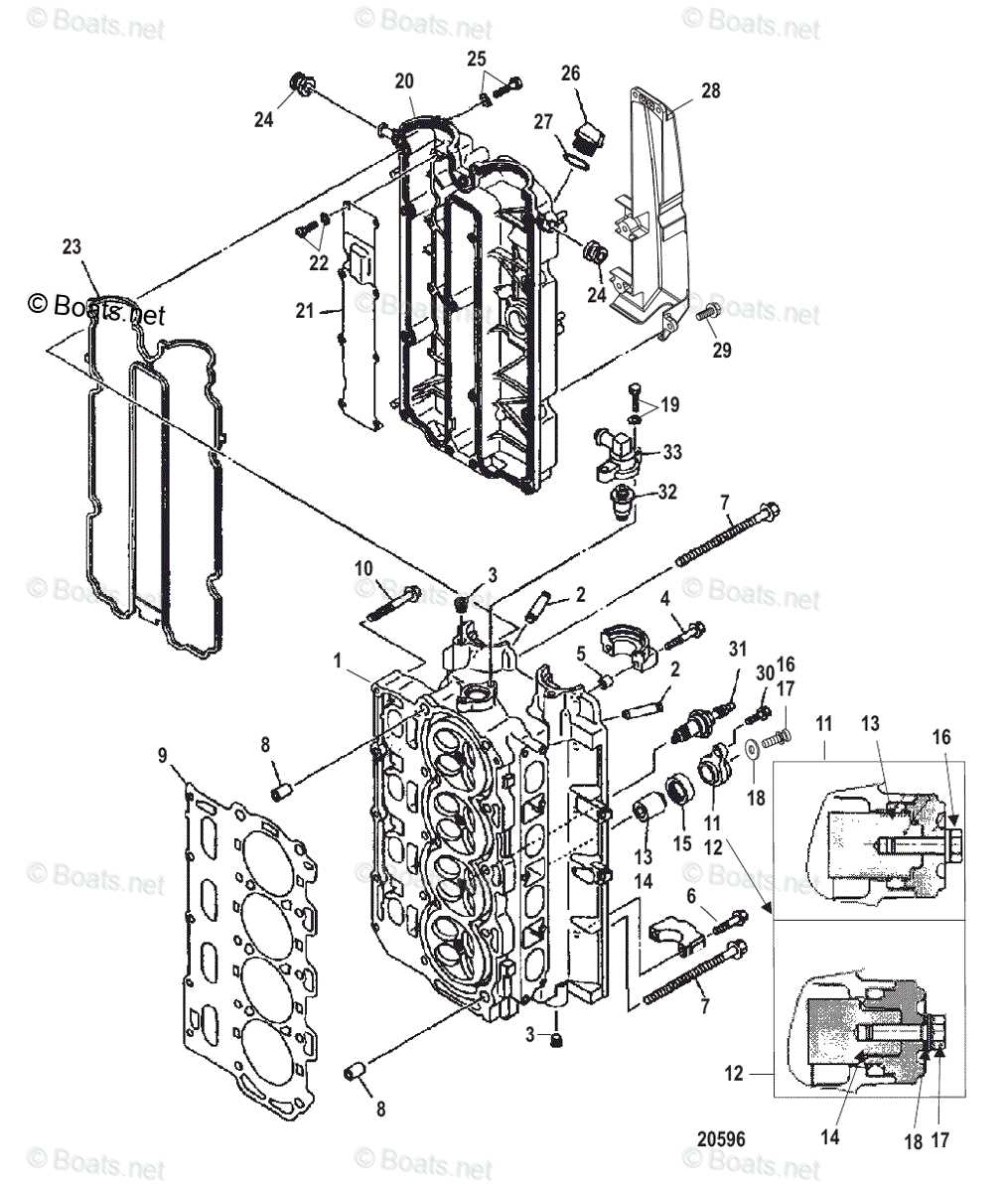

Power Unit

The heart of any outboard engine, the power unit, generates the energy needed for movement. It houses the essential systems that convert fuel into mechanical energy, driving the vessel forward. Maintaining this section is key for optimal performance and longevity.

Propulsion System

This system transfers the generated energy to the water, enabling movement. It consists of components designed to provide thrust and direction control. Regular inspection of this system ensures consistent performance and responsiveness while on the water.

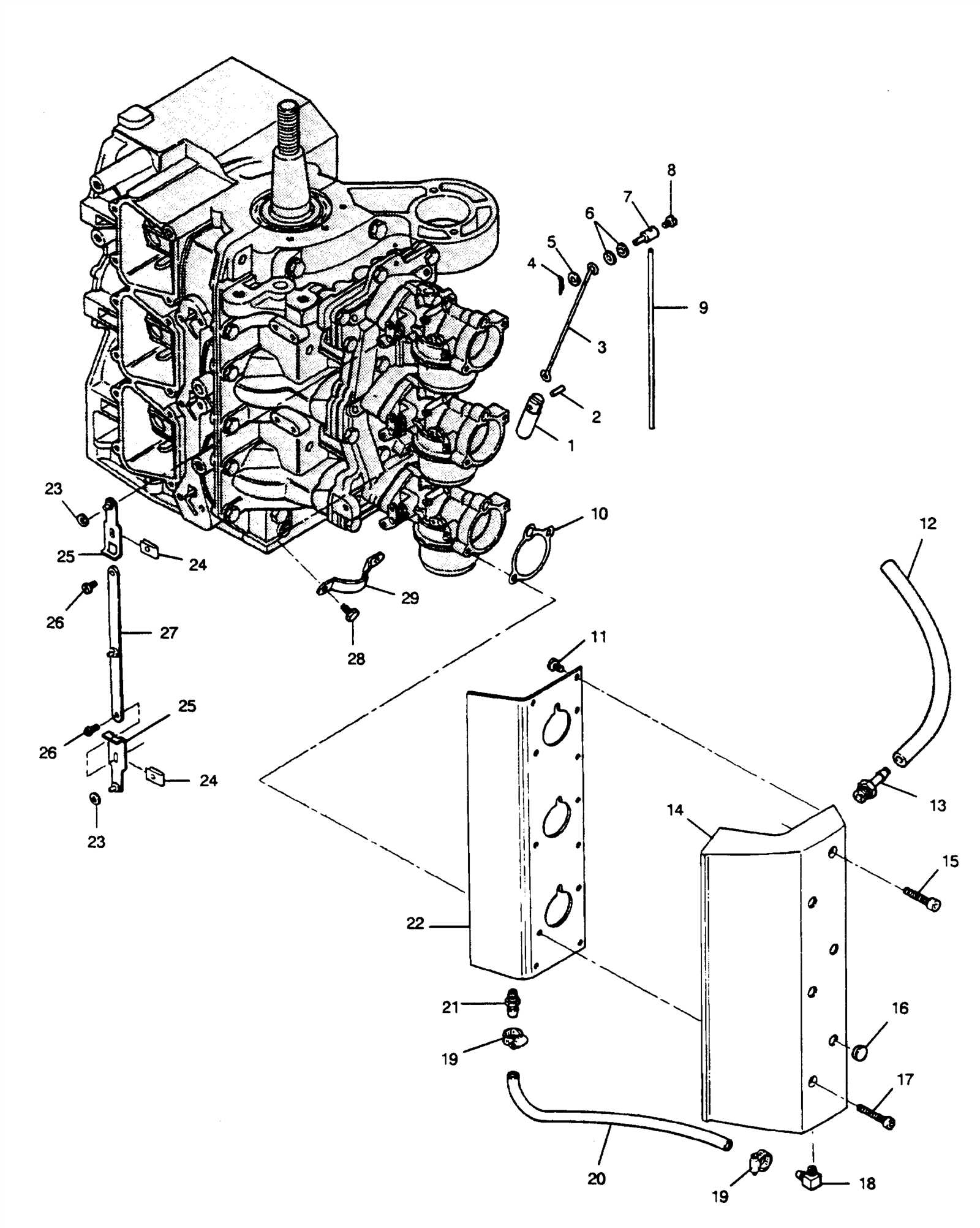

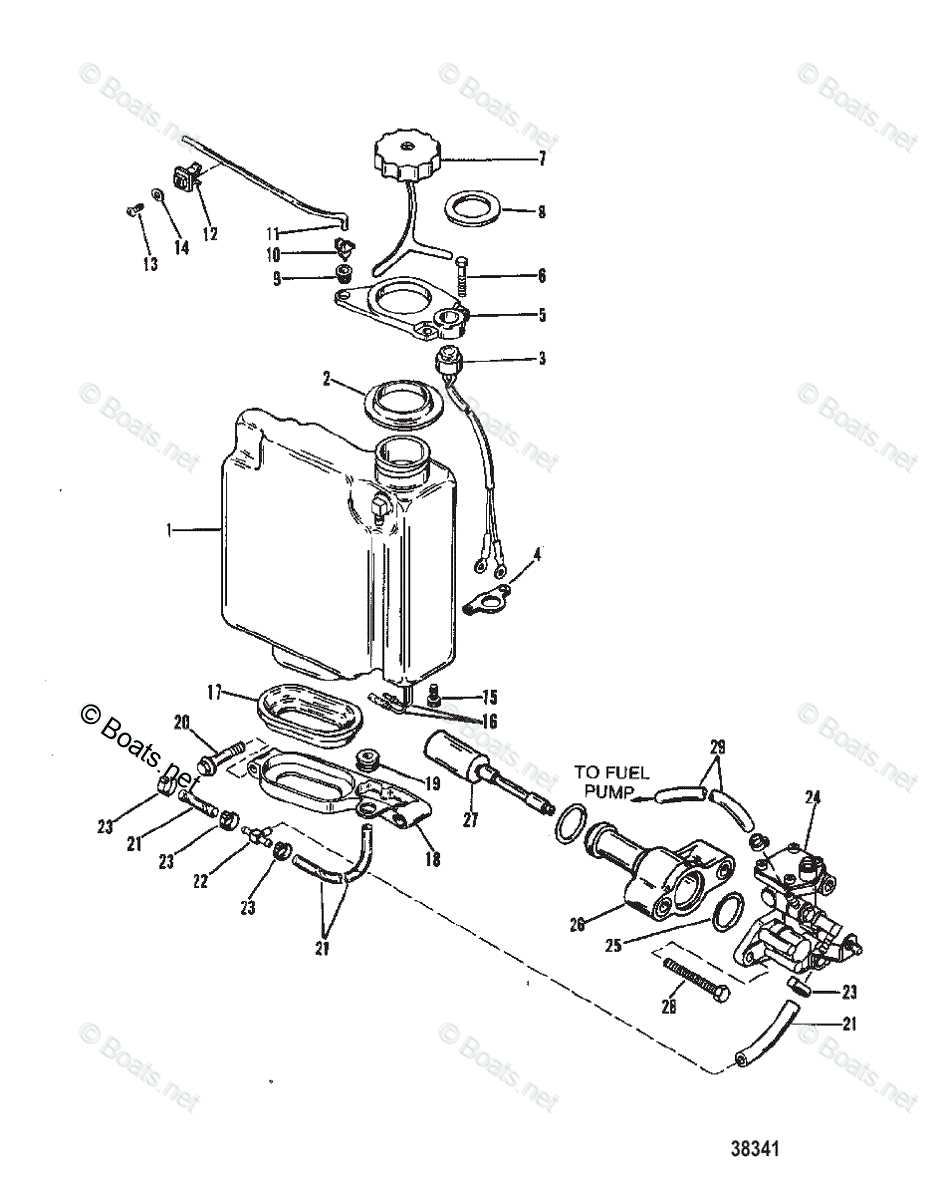

Understanding the Fuel System Layout

The fuel system is a crucial component designed to ensure the efficient operation of the engine. It manages the flow of fuel, enabling proper combustion and overall performance. By guiding fuel from the storage area to the engine, the system plays a vital role in maintaining functionality and reliability during operation.

At the core of this layout are several key components working in harmony. The fuel tank acts as the primary storage, while lines and pumps direct the flow towards the combustion area. Filters help maintain the quality of fuel by preventing impurities from entering sensitive parts, and injectors precisely regulate the amount of fuel delivered.

A proper understanding of how these elements interact can help diagnose issues related to engine efficiency and performance. Familiarizing yourself with this system ensures smoother maintenance and can extend the lifespan of various components.

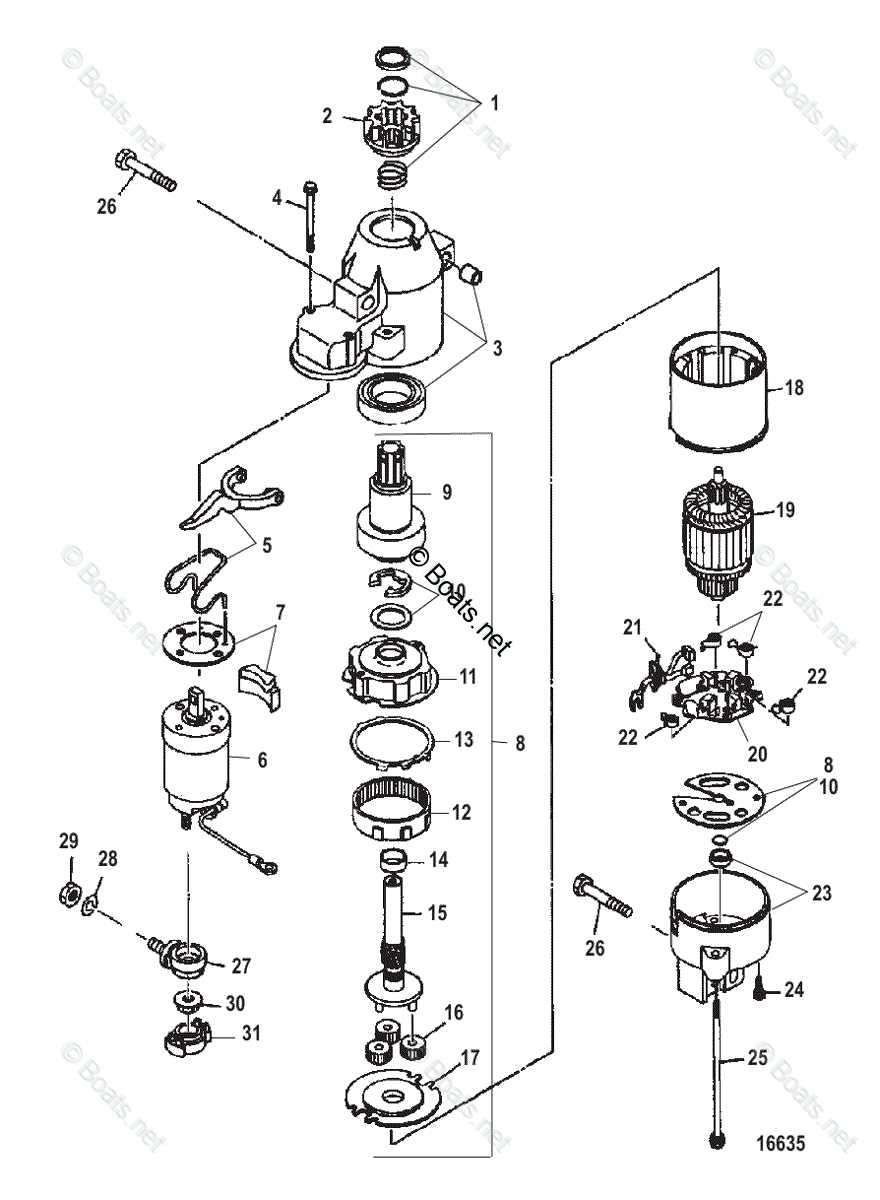

Ignition System Breakdown and Functionality

The ignition system plays a crucial role in ensuring smooth engine performance by delivering the necessary spark at the right moment. This coordinated process involves several components that work together to ignite the fuel mixture within the engine’s cylinders. Understanding how these elements interact provides valuable insight into how the engine operates effectively.

- Ignition Coil: Converts the battery’s low voltage into the high voltage needed to create a spark at the spark plugs.

- Spark Plugs: Responsible for igniting the air-fuel mixture by generating the spark required for combustion.

- Control Module: Regulates the timing of the spark, ensuring it occurs at the optimal point during the engine cycle.

- Wiring: Connects the various parts, ensuring proper voltage flow and communication between components.

The system operates in a precise sequence, allowing the engine to maintain power and efficiency. By ensuring the timing and strength of the spark are consistent, the engine can run smoothly and respond accurately to throttle inputs.

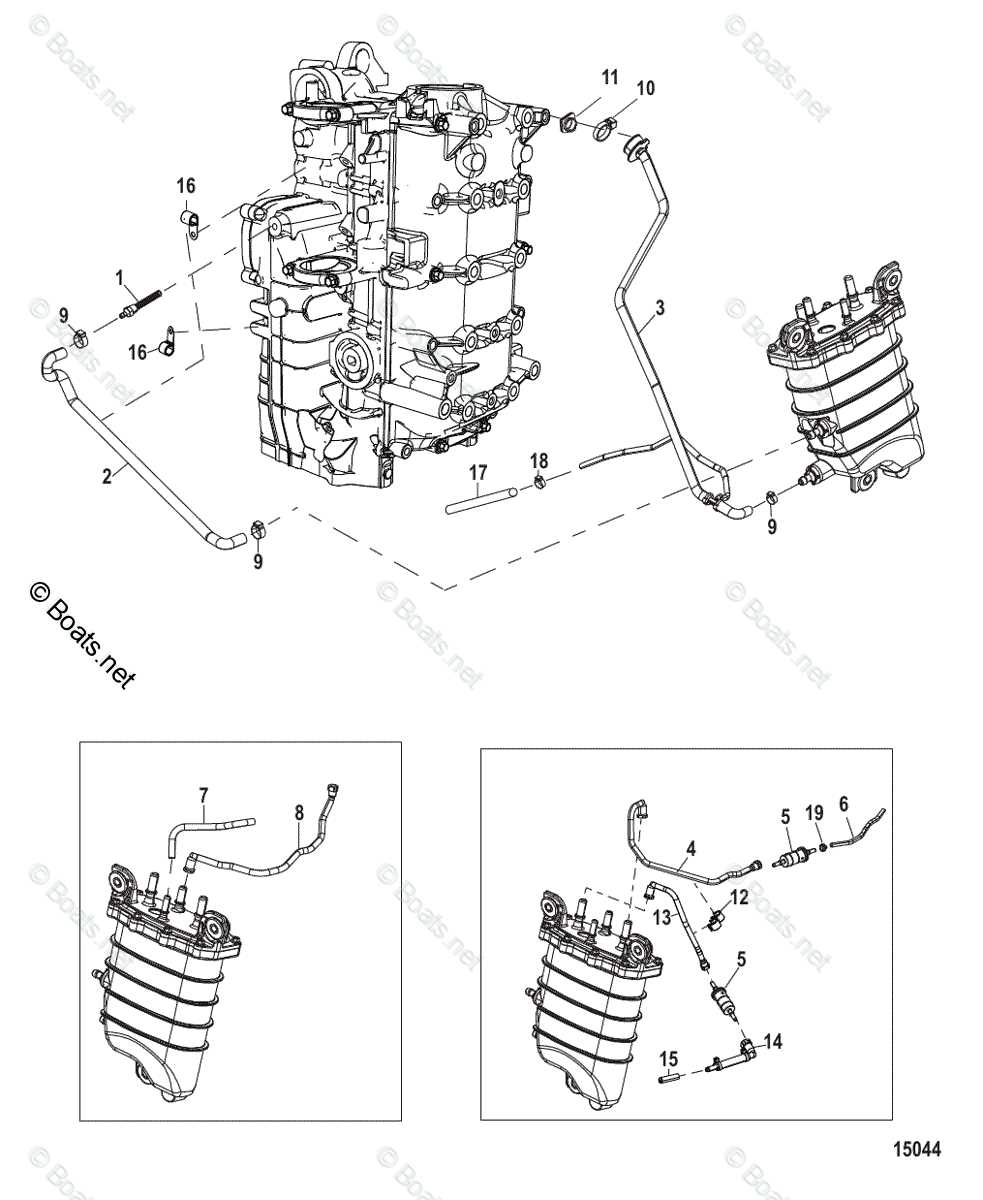

Cooling System Parts and Diagram

The cooling mechanism of a boat engine plays a crucial role in ensuring optimal performance and longevity. By regulating temperature and preventing overheating, this system allows the engine to run smoothly, even under high-stress conditions. Understanding how the cooling components work together is essential for maintaining the engine’s overall health.

Key Components of the Cooling System

Among the essential elements of this setup are components that manage water flow and temperature control. The water pump, for instance, draws in liquid from external sources, helping to keep the engine at a stable temperature. Additionally, thermostats and hoses ensure proper circulation and distribution of cooling fluids, protecting critical engine areas from damage caused by excess heat.

How the System Functions

The cooling process typically begins with water being pulled through an intake valve and circulated via a series of channels. Once it absorbs the heat generated by the engine, the liquid is expelled, allowing the motor to remain within safe operating temperatures. This constant flow of coolant prevents potential breakdowns and extends the lifespan of the engine.

Mercury 90HP 4-Stroke Exhaust Components

Understanding the exhaust assembly of a powerful marine engine is crucial for optimal performance and longevity. This section explores the key elements involved in the exhaust system, emphasizing their significance in maintaining efficient operation and minimizing emissions. A well-functioning exhaust structure is essential for the effective expulsion of gases, thereby enhancing overall engine efficiency.

Main Exhaust Manifold

The principal exhaust manifold serves as a critical component, directing gases away from the engine. It is designed to withstand high temperatures while efficiently channeling exhaust flows. Proper maintenance of this part ensures that exhaust gases are expelled effectively, reducing the risk of back pressure and enhancing engine performance.

Risers and elbows are essential elements that connect the manifold to the exhaust outlet. These components facilitate the transition of exhaust gases from the horizontal plane to the vertical, allowing for effective discharge into the atmosphere. Regular inspection of these parts is necessary to prevent blockages and ensure the smooth operation of the exhaust system.

Throttle and Control Linkage Overview

The interaction between the throttle mechanism and control linkages is crucial for optimal performance in marine engines. This section delves into the components that facilitate this interaction, ensuring precise operation and responsiveness. A well-designed linkage system enhances the overall functionality of the engine, allowing for smooth acceleration and effective speed regulation.

Understanding the various elements involved in the throttle and control linkage system helps in recognizing their significance in maintaining engine efficiency and reliability. Each component plays a vital role in transmitting input from the control handles to the engine, making it essential for proper installation and maintenance.

| Component | Description |

|---|---|

| Throttle Cable | A flexible wire that connects the throttle handle to the engine, allowing for the adjustment of the fuel-air mixture. |

| Control Lever | A manual interface that enables the operator to adjust the engine speed and power output. |

| Linkage Arm | A mechanical arm that transmits motion from the control lever to the throttle assembly. |

| Adjustment Screw | A component used to fine-tune the tension of the throttle cable, ensuring proper responsiveness. |

| Mounting Bracket | A support structure that secures the linkage components to the engine or boat frame. |

Lubrication System: Parts and Operation

The lubrication mechanism is vital for maintaining the efficiency and longevity of an engine. It ensures that all moving components are adequately coated with oil, reducing friction and wear. This system not only protects the engine from overheating but also contributes to overall performance by facilitating smooth operation of internal parts.

Understanding the various elements of this system and how they function together is essential for proper maintenance and troubleshooting. Below is a detailed overview of the components involved in the lubrication setup, along with their roles.

| Component | Function |

|---|---|

| Oil Pump | Pumps oil from the sump to the necessary parts, ensuring consistent lubrication. |

| Oil Filter | Removes impurities and debris from the oil, maintaining its quality. |

| Oil Reservoir | Stores the lubricant, allowing for efficient circulation throughout the system. |

| Oil Lines | Transport lubricant to various components, providing coverage where needed. |

| Return Lines | Channel used oil back to the reservoir for recirculation. |

Each element plays a crucial role in ensuring that the entire system operates effectively. Regular inspections and maintenance of these components can prevent potential issues and enhance engine performance.

Electrical Wiring and Key Components

This section delves into the essential elements of electrical connections and primary components that contribute to the effective functioning of outboard motors. Understanding the intricacies of these systems is crucial for ensuring optimal performance and reliability.

Wiring Harness: A well-structured wiring harness serves as the backbone of the electrical system, connecting various components and allowing seamless communication between them. Proper installation and maintenance of the harness are vital to prevent electrical faults.

Ignition System: The ignition setup is responsible for initiating the combustion process. Key components include spark plugs, coils, and wiring. Regular inspection of these elements ensures efficient engine performance and reduces the likelihood of misfires.

Charging System: The charging mechanism keeps the battery adequately powered. It includes the alternator and voltage regulator. Monitoring these components is essential for maintaining battery health and ensuring that all electrical systems function correctly.

Control Panel: The control panel provides the user interface for monitoring and managing various functions. It typically includes switches, gauges, and warning lights. Familiarity with the control panel layout enhances user experience and promotes safer operation.

Maintaining a comprehensive understanding of these electrical connections and components not only facilitates troubleshooting but also enhances the overall longevity and efficiency of the motor.

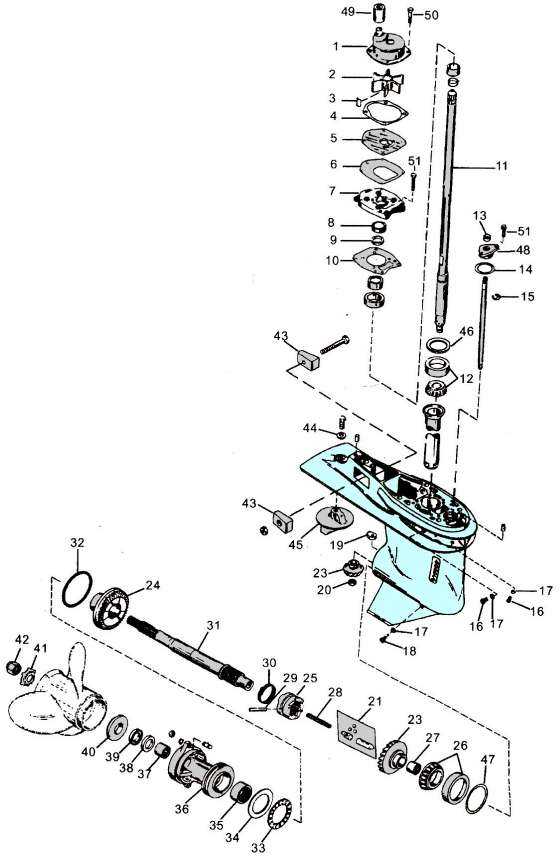

Lower Unit and Propeller Assembly Explained

The lower section of a marine propulsion system plays a crucial role in ensuring efficient movement through the water. This assembly is responsible for transferring power from the engine to the propeller, allowing for optimal performance and maneuverability. Understanding its components and functionality is essential for effective maintenance and troubleshooting.

At the heart of this assembly lies the gear case, which houses vital gears and components that facilitate the necessary torque and rotation. This section also contains the drive shaft, which connects the engine’s output to the propeller. The design of the gear case often includes an oil reservoir to ensure smooth operation and reduce wear on the moving parts.

The propeller itself is a critical element that converts rotational energy into thrust. Available in various designs and sizes, it significantly impacts the vessel’s speed and efficiency. Selecting the appropriate propeller is key to achieving the desired performance characteristics and optimizing fuel consumption.

Maintenance Tips for Mercury 90HP 4-Stroke

Regular upkeep is crucial for ensuring the longevity and optimal performance of your outboard motor. By following a consistent maintenance schedule, you can prevent potential issues and enhance efficiency. Here are essential suggestions to keep your engine running smoothly.

Routine Inspections

Performing frequent checks on your motor can help identify wear and tear early. Focus on the following components:

- Check the oil level and quality regularly.

- Inspect fuel lines for leaks or cracks.

- Examine the cooling system for blockages.

- Look over the propeller for damage or debris.

Seasonal Care

Adapting your maintenance routine to the seasons can ensure optimal performance. Consider these seasonal tips:

- Change the oil and filter before the start of the boating season.

- Flush the cooling system after each use in saltwater to prevent corrosion.

- Store the motor in a dry, sheltered area during winter months.

- Inspect the battery and connections, cleaning any corrosion.