When exploring the inner workings of a well-known paintball marker, it’s essential to have a clear understanding of how each element contributes to the overall functionality. Every component plays a vital role in ensuring precision, efficiency, and performance on the field. By breaking down these components, players can gain a deeper appreciation for the design and mechanics behind their gear.

From the core mechanisms that control airflow and firing to the external elements that offer durability and control, every part has a purpose. Knowing how these individual elements interact with each other can greatly improve maintenance and troubleshooting. For both beginners and experienced users, a detailed exploration of the marker’s structure provides valuable insights into optimizing its performance.

In this guide, we will explore each essential piece, explaining how it works within the larger system. With a strong foundation in understanding the key components, you’ll be better equipped to make adjustments, perform repairs, and keep your equipment in top shape.

Understanding the Basics of Invert Mini Parts

When exploring the inner workings of this advanced paintball marker, it’s essential to have a solid grasp of its individual elements. Each component serves a distinct function, contributing to the overall performance and precision of the marker. Gaining familiarity with how these elements fit together can improve maintenance, customization, and overall gameplay.

Key components are designed to ensure smooth operation, efficient air management, and accurate firing. Whether it’s about enhancing durability or fine-tuning performance, understanding the core mechanics of each piece is crucial for both casual players and competitive enthusiasts.

From the trigger system to air valve adjustments, recognizing the roles of these essential elements empowers users to make informed decisions during repairs or upgrades, ensuring optimal results on the field.

Key Components of the Invert Mini Marker

The marker is a sophisticated piece of equipment designed for efficiency and precision. Its construction relies on several critical elements that work in harmony to provide a seamless shooting experience. Each piece plays a vital role in ensuring smooth operation, enhancing the performance, and allowing for easy maintenance and customization.

Frame Assembly: The frame serves as the foundation, housing all internal mechanisms and providing structural support. It’s crafted to be lightweight yet durable, allowing for easy handling during intense gameplay.

Firing Mechanism: Central to the design is the firing system, which manages the release of compressed air or gas to propel paintballs. This component is engineered for reliability and consistency, delivering accurate shots with minimal recoil.

How to Identify Essential Parts in Diagrams

Understanding the key components in graphical representations is crucial for effectively analyzing and interpreting technical information. By focusing on core elements, users can better navigate complex visuals and grasp the underlying systems or mechanisms they illustrate. Recognizing which elements play a central role helps streamline the learning process and enhances troubleshooting or assembly procedures.

To efficiently pinpoint critical elements in any schematic, follow these guidelines:

| Step |

Action |

Purpose |

| 1 |

Identify Labels |

Look for text annotations or numbers that provide insight into key components. |

| 2 |

Focus on Connectors

Disassembling Your Invert Mini Safely

When taking apart your equipment, ensuring both safety and precision is crucial. Proper disassembly will help avoid damage and extend the lifespan of your gear. By following the correct steps and using the appropriate tools, you can ensure a smooth and efficient process.

Here are the recommended steps to carefully dismantle your device:

- First, make sure the air supply is completely disconnected to prevent any accidental release of pressure.

- Unscrew the barrel from the main body for easier handling.

- Remove the grip panels carefully, making sure to keep the screws in a secure place.

- Detach the bolt and spring assembly, checking for any wear or damage as you go.

- Finally, separate the internal components, being mindful of small parts that may fall out during this process.

Common Issues with Invert Mini Components

Understanding the most frequent problems that can arise in the mechanisms of this particular model is essential for maintaining its long-term performance. Various challenges often emerge due to wear, improper handling, or environmental factors, affecting overall functionality and efficiency.

Air Leaks

One of the prevalent issues involves air leaks that can reduce efficiency and lead to inconsistent performance. These leaks typically occur due to damaged seals or loose fittings.

- Check O-rings for wear or cracks.

- Ensure all fittings are properly tightened.

- Inspect hoses for potential damage or tears.

Trigger Problems

Another common issue is related to the trigger system. Malfunctions in this area can result in a lack of responsiveness or double-firing

Maintaining Your Invert Mini for Longevity

Ensuring the long-term performance of your equipment requires regular care and attention to detail. With consistent maintenance, you can avoid common issues, improve reliability, and extend the life of your marker. Below are key practices that will help keep it functioning optimally.

- Regular Cleaning: After every use, thoroughly clean the exterior and interior components. Dust, paint, and debris can accumulate, causing malfunctions if not removed.

- Lubrication: O-rings and moving parts need to be properly lubricated to reduce friction and wear. Use manufacturer-recommended oil or grease for best results.

- Inspection of Seals: Routinely check seals for signs of wear or damage. Replacing worn-out seals prevents air leaks

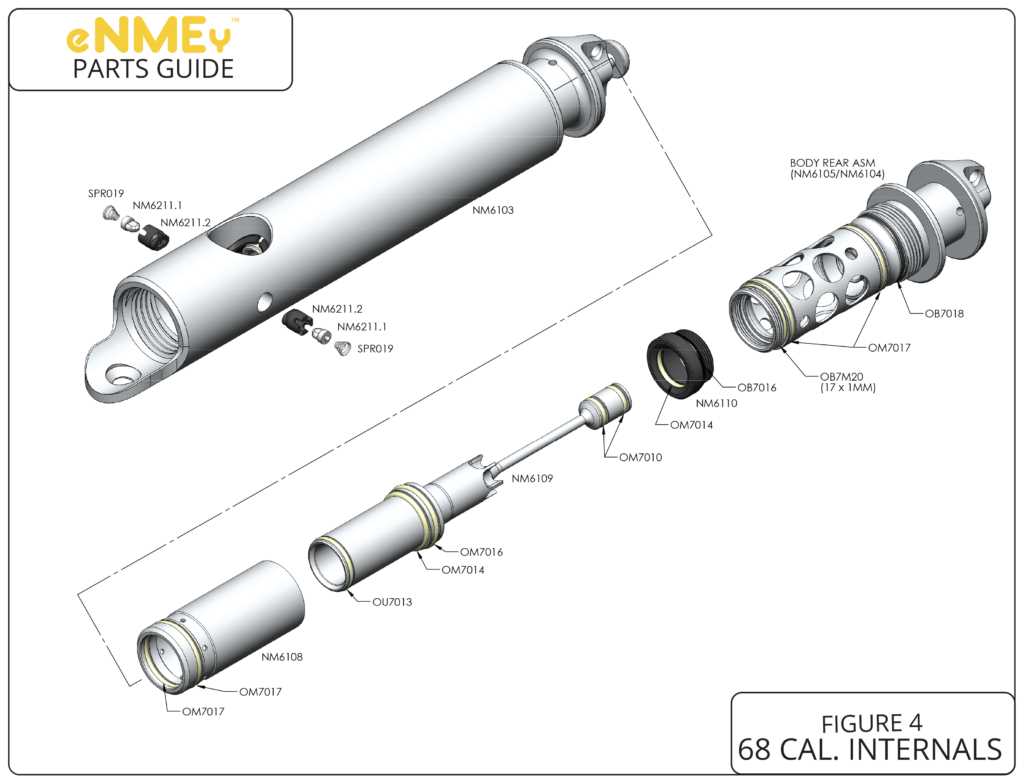

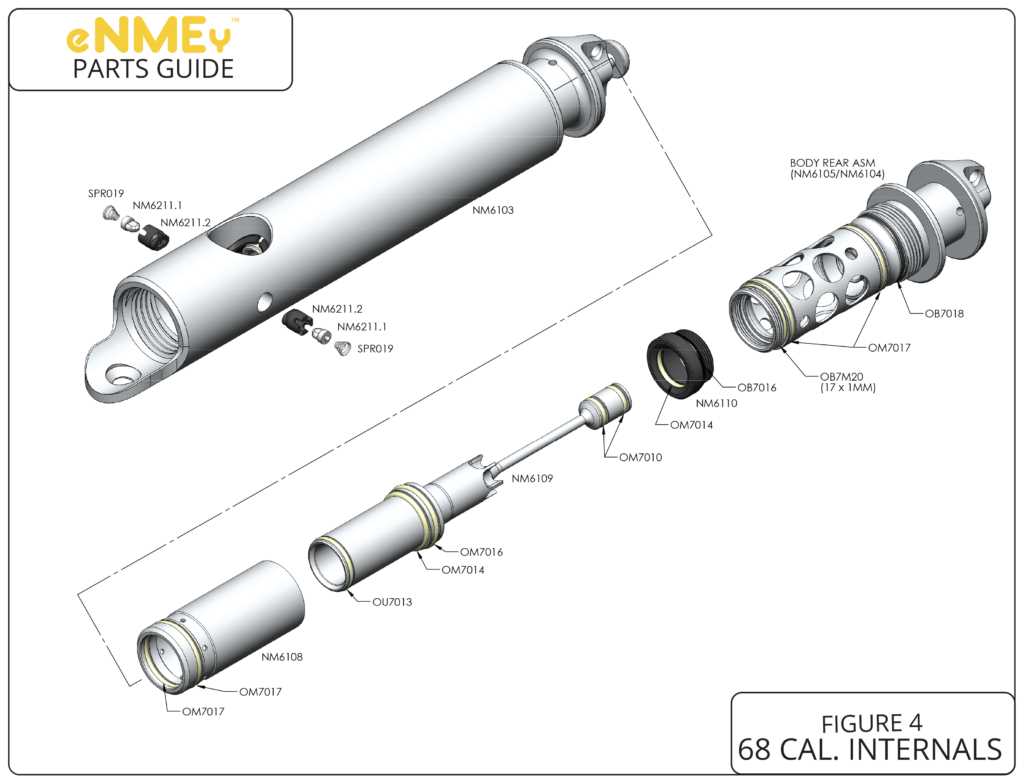

Exploring Internal Mechanisms of the Invert Mini

The intricate structure of this compact paintball marker showcases a seamless blend of precision engineering and innovative design. Understanding how its components interact reveals the sophisticated balance between power, speed, and efficiency. In this section, we delve into the core elements that drive its performance, offering insights into how its various systems work together to deliver a highly responsive and accurate experience on the field.

Core Components

At the heart of this marker lies a combination of mechanical and pneumatic systems. These systems collaborate to ensure rapid firing, efficient gas usage, and minimal recoil. The valve mechanism, in particular, plays a crucial role in regulating air flow, while the bolt assembly is responsible for loading and firing with precision.

Functionality and Interaction

Each of the internal elements must function harmoniously to maintain the marker’s overall performance. The following

Using Diagrams for Invert Mini Repairs

Visual representations can significantly enhance the repair process of various compact devices. These illustrations provide a clear understanding of components and their arrangement, aiding in effective troubleshooting and restoration. Employing such graphics streamlines the workflow and minimizes errors during repairs.

Here are some key advantages of utilizing visuals in repair tasks:

- Clarity: Images can simplify complex assemblies, making it easier to identify each element.

- Efficiency: Step-by-step visuals help technicians follow procedures swiftly, reducing downtime.

- Accuracy: Having a clear reference can minimize the risk of misplacing or incorrectly assembling components.

To effectively incorporate visuals in repair routines, consider the following strategies:

- Gather Resources: Collect a variety of illustrations that cover different models and issues.

- Organize Information: Create a structured reference guide that categorizes visuals based on specific repairs.

- Train Staff: Ensure that all team members are familiar with how to use these references during repairs.

In conclusion, implementing visual aids in repair processes can lead to improved accuracy and efficiency. By leveraging these resources, technicians can enhance their skill set and deliver higher-quality service.

Upgrading Parts for Enhanced Performance

In the pursuit of superior efficiency and functionality, enhancing various components of a system plays a crucial role. By replacing or modifying key elements, one can achieve remarkable improvements in overall operation, responsiveness, and durability. This process not only optimizes performance but also extends the lifespan of the entire setup.

Upgrading individual elements can significantly impact the way a system performs under various conditions. Increased power and efficiency can be realized by choosing advanced alternatives designed to meet higher demands. For instance, utilizing more robust materials or innovative technologies can lead to enhanced reliability and effectiveness.

Moreover, thoughtful modifications allow for better adaptability to changing environments and user needs. Implementing state-of-the-art solutions ensures that a system remains competitive and relevant in a fast-paced landscape. By prioritizing the enhancement of crucial components, users can enjoy a transformative experience that not only meets but exceeds expectations.

Tools You Need for Invert Mini Maintenance

To ensure optimal performance and longevity of your equipment, having the right tools at your disposal is crucial. Proper upkeep not only enhances functionality but also prevents potential issues from escalating into costly repairs. Below is a comprehensive list of essential instruments that will aid in maintaining your gear efficiently.

| Tool |

Purpose |

| Allen Wrenches |

For tightening and loosening screws in various assemblies. |

| Lubricant |

To reduce friction and ensure smooth operation of moving parts. |

| Cleaning Cloths |

For wiping down surfaces and removing dirt or debris. |

| O-ring Picks |

To assist in the removal and installation of seals and gaskets. |

| Screwdrivers |

To facilitate adjustments and repairs to small components. |

| Pressure Gauge |

To monitor and ensure proper pressure levels in the system. |

| Multimeter |

For checking electrical connections and diagnosing issues. |

| Bench Vise |

To securely hold components while working on them. |

Having these essential tools readily available will significantly enhance your ability to conduct effective maintenance, ensuring that your equipment continues to function at its best.

Troubles

Encountering obstacles is a common aspect of any intricate system. These challenges can arise unexpectedly, often leading to frustration and delays. Understanding the nature of these issues is crucial for efficient problem-solving and maintaining smooth operations.

Common sources of difficulties include:

- Design flaws that may not be evident until implementation.

- Miscommunication among team members or stakeholders.

- External factors that can disrupt the intended workflow.

- Inadequate resources, whether human or material.

To effectively manage these challenges, consider the following strategies:

- Conduct thorough analysis to identify potential pitfalls early.

- Establish clear communication channels among all parties involved.

- Prepare contingency plans to address unforeseen disruptions.

- Regularly assess resource allocation to ensure availability.

By proactively addressing these issues, teams can enhance resilience and adaptability, ultimately leading to greater success.

|