In the world of outdoor machinery, a thorough understanding of the assembly and various elements is essential for effective maintenance and repair. Having a comprehensive overview of how different components interact enhances the overall functionality of the equipment. This knowledge can significantly extend the lifespan of the machine while ensuring optimal performance during use.

Accurate identification and categorization of each segment are crucial for troubleshooting common issues and facilitating repairs. Users can navigate the complexities of the machinery more effectively when they are familiar with the specific configurations and arrangements of each piece. By recognizing the unique functions of each component, operators can better understand how to address potential malfunctions and implement appropriate solutions.

Furthermore, comprehending the layout of the equipment not only aids in maintenance but also empowers users to make informed decisions regarding upgrades or replacements. This insight fosters a deeper appreciation for the engineering involved in the design and operation of such machinery, ultimately contributing to a more productive experience for the operator.

This section highlights the essential characteristics that define this robust equipment, showcasing its efficiency and practicality in various tasks. The following points outline the standout attributes that make it a preferred choice among users.

- Durable Construction: Designed with high-quality materials, ensuring longevity and reliability even in challenging environments.

- Powerful Engine: Equipped with an efficient power unit that delivers exceptional performance for heavy-duty tasks.

- User-Friendly Controls: Intuitive control layout that simplifies operation, making it accessible for users of all skill levels.

- Versatile Attachments: Compatible with a range of tools and implements, allowing for various applications including mowing, tilling, and hauling.

- Compact Design: Its space-efficient structure enables easy maneuverability in tight spaces, enhancing operational versatility.

- Maintenance-Friendly: Thoughtfully designed for easy access to components, facilitating straightforward upkeep and servicing.

Overall, these features contribute to its reputation as a reliable and efficient choice for those seeking dependable machinery for outdoor tasks.

Identifying Essential Parts

Understanding the critical components of machinery is vital for effective maintenance and operation. By recognizing these key elements, users can ensure that their equipment functions optimally and remains in good condition. This knowledge facilitates troubleshooting and enhances overall performance.

Core Components

Every machine comprises several fundamental elements that play significant roles in its operation. These include the engine, transmission, and chassis. Each of these components works in harmony to deliver the necessary power and functionality. A thorough grasp of how these parts interact is essential for efficient use.

Maintenance and Upgrades

Regular upkeep and potential enhancements of these essential components can lead to improved longevity and efficiency. Regular checks for wear and tear, as well as timely replacements, contribute to maintaining optimal performance. Understanding the available upgrades can also enhance capabilities and adapt the machinery to specific needs.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of outdoor equipment. By adhering to recommended practices and being proactive, you can significantly enhance performance and reliability. Here are some essential maintenance tips to keep your machinery running smoothly for years to come.

Regular Cleaning

Cleaning your equipment regularly is crucial to prevent dirt and debris from causing damage. Make it a habit to inspect and clean the exterior after each use. This simple action can help avoid rust and corrosion, ultimately prolonging the life of the components.

Routine Inspections

Conducting routine inspections allows you to identify potential issues before they escalate. Check the following components regularly:

| Component | Inspection Frequency | Recommended Action |

|---|---|---|

| Air Filter | Every 25 hours of operation | Clean or replace as needed |

| Oil Levels | Before each use | Top off or change if necessary |

| Blades | Every 50 hours of use | Sharpen or replace when dull |

| Belt Condition | Monthly | Inspect for wear and replace if frayed |

By following these guidelines, you can ensure that your equipment remains in optimal condition, ultimately extending its useful life and enhancing performance.

Common Issues and Solutions

This section addresses frequent challenges encountered with lawn maintenance equipment and offers effective solutions to enhance performance and longevity.

1. Engine Starting Problems

One of the most common issues is difficulty in starting the engine. This can be attributed to various factors, including fuel supply, battery health, or ignition system failures.

- Check Fuel Level: Ensure there is enough fuel in the tank and that it is fresh.

- Inspect the Battery: Test the battery charge and clean any corrosion from the terminals.

- Examine the Spark Plug: Look for wear or damage; replace if necessary.

2. Poor Cutting Performance

Another frequent issue is subpar cutting quality, which can result from dull blades or improper height settings.

- Sharpen the Blades: Regularly sharpen the cutting blades to ensure clean cuts.

- Adjust Cutting Height: Set the cutting height appropriately for the type of grass.

- Inspect Deck for Debris: Clear any buildup of grass clippings or debris from the mower deck.

Parts Replacement Process Explained

Understanding the procedure for component substitution is crucial for maintaining equipment efficiency. This guide outlines the essential steps involved in replacing various elements, ensuring optimal functionality and longevity.

Before commencing the replacement procedure, gather the necessary tools and familiarize yourself with the specific components needing replacement. Proper preparation minimizes delays and enhances the overall efficiency of the task.

| Step | Description |

|---|---|

| 1 | Turn off the equipment and disconnect it from any power sources to ensure safety during the process. |

| 2 | Remove any covers or protective casings that may obstruct access to the components requiring replacement. |

| 3 | Carefully detach the faulty component, noting its connection points for accurate reinstallation of the new piece. |

| 4 | Install the new component, ensuring it is securely connected and properly aligned with the existing structure. |

| 5 | Reattach any covers or protective casings that were removed, ensuring everything is sealed properly. |

| 6 | Reconnect the equipment to the power source and perform a thorough test to confirm successful installation and functionality. |

Following these outlined steps will facilitate a smooth and efficient replacement process, allowing for optimal performance and reliability of the equipment.

Locating Genuine Spare Parts

Finding authentic replacement components is essential for maintaining the functionality and longevity of your equipment. Utilizing high-quality items ensures optimal performance and reliability, which can significantly reduce the risk of malfunctions. When seeking replacements, it’s vital to focus on reputable sources that guarantee authenticity and compatibility.

Authorized Dealers

One of the most reliable ways to acquire genuine components is through authorized retailers. These suppliers are recognized by manufacturers and often provide certified items that meet strict quality standards. By purchasing from these sources, you can be confident that you are receiving parts designed specifically for your equipment.

Online Marketplaces

Reputable online platforms can also serve as excellent resources for finding authentic components. When shopping online, it is crucial to verify the credibility of the seller and read customer reviews to ensure the quality of the items. Look for sellers that offer warranties and return policies to protect your investment.

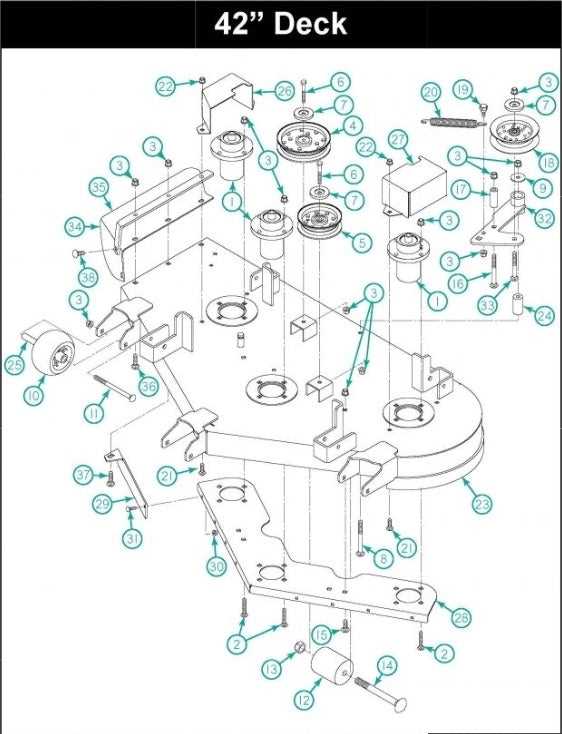

Assembly Guidelines for Components

Proper assembly of components is crucial for ensuring the efficient operation and longevity of machinery. Each element plays a vital role in the overall functionality, making it essential to follow specific guidelines during the installation process. This section outlines key considerations and steps to ensure a successful assembly.

Preparation and Tools

Before beginning the assembly, gather all necessary tools and components. Ensure that the workspace is clean and organized to avoid misplacing parts. Familiarize yourself with the specifications of each component to understand their intended positions and functions. Using the right tools will not only expedite the process but also prevent damage to the components.

Assembly Process

Start by aligning components according to the layout provided in the reference materials. Ensure that each part fits snugly without excessive force, as this may lead to misalignment or damage. Double-check all connections before securing them, as a loose component can cause operational issues later. Once everything is in place, securely tighten fasteners while taking care not to overtighten, which could compromise the integrity of the components.

Tools Needed for Repairs

Having the right equipment is essential for conducting effective maintenance and repair tasks. This section outlines the various tools that can facilitate the restoration and upkeep of your machinery, ensuring that you can perform the necessary procedures with efficiency and precision.

Basic Hand Tools

Begin with a selection of hand tools that are fundamental for most repair jobs. Essential items include wrenches, screwdrivers, and pliers. These instruments allow for easy disassembly and assembly of components, enabling you to address issues promptly. Additionally, a good-quality socket set can enhance your ability to work on various fittings and fasteners.

Specialized Equipment

For more complex tasks, consider acquiring specialized tools that cater to specific needs. A torque wrench is invaluable for ensuring that bolts are tightened to the correct specifications, while a multimeter can help diagnose electrical issues. Having a reliable set of diagnostic tools will enable you to identify problems accurately, leading to more effective repairs and prolonged equipment life.

Upgrading Parts for Better Performance

Enhancing the efficiency and functionality of your equipment can be achieved by selecting high-quality components. By focusing on critical areas such as power transmission, comfort, and durability, you can significantly improve overall operation and longevity. This section explores various upgrade options that can elevate performance levels and provide a smoother experience.

Key Areas for Improvement

- Engine Enhancements: Upgrading to a more powerful engine or optimizing the existing one can lead to better performance and efficiency.

- Transmission Systems: Consider replacing gears or belts with higher-grade alternatives to improve power transfer.

- Suspension Upgrades: Enhanced suspension components can provide better stability and comfort, especially on uneven terrain.

- Wheels and Tires: Choosing high-performance tires can improve traction and handling, making operations more effective.

Benefits of Upgrading

- Increased efficiency and productivity during use.

- Improved durability and reduced wear and tear on existing systems.

- Enhanced comfort and control for the operator.

- Potential cost savings in maintenance and repairs over time.

Historical Significance of Model L

The introduction of this innovative agricultural machine marked a turning point in farming practices. Its design and functionality greatly influenced the way tasks were performed on the field, streamlining processes that previously required considerable labor and time. This advancement not only enhanced productivity but also paved the way for further technological developments in the agricultural sector.

Impact on Agricultural Practices

This machine revolutionized the farming landscape by introducing a level of efficiency that was unprecedented. Farmers were able to cover larger areas in shorter amounts of time, which translated into increased yields and better crop management. Its versatility allowed it to be utilized for various tasks, from tilling to mowing, making it an essential tool for both small-scale and commercial operations.

Legacy and Cultural Importance

The enduring legacy of this machine can be seen in its continued popularity among enthusiasts and collectors. It symbolizes a significant era in agricultural history, representing the transition from manual labor to mechanization. This shift not only changed farming methods but also had a lasting impact on rural communities, influencing economic stability and growth.

Community Resources and Support

Access to collective knowledge and assistance can significantly enhance the experience of maintaining and repairing outdoor machinery. Enthusiasts and owners often benefit from shared resources, enabling them to tackle challenges more effectively. Local clubs, online forums, and dedicated websites serve as valuable platforms for exchanging information and advice.

Online Forums and Groups

Engaging with online communities allows individuals to connect with fellow users and experts who share similar interests. These platforms provide a space for discussing issues, sharing experiences, and offering solutions. Participants can post questions, upload photos, and receive guidance from those who have faced similar situations.

Local Clubs and Workshops

Joining a local association can foster camaraderie among enthusiasts. These groups often organize workshops, repair days, and meet-ups where members can learn from each other. Such events create opportunities for hands-on learning and sharing techniques, promoting a supportive environment for all skill levels.

Comparative Analysis with Other Models

This section delves into the distinctions and similarities found when evaluating this particular equipment against its contemporaries. By exploring various features, functionalities, and designs, we can gain insights into how it stands out in a crowded marketplace.

One notable aspect of comparison involves the engine performance and efficiency. Different models may exhibit variations in power output and fuel consumption, influencing their suitability for diverse tasks.

- Engine Types: Some variants utilize two-stroke engines, while others favor four-stroke designs, impacting durability and operational costs.

- Transmission Systems: Variations in transmission types, such as manual versus automatic, affect ease of use and maintenance.

- Accessory Compatibility: Certain models offer a broader range of attachments, enhancing versatility for various tasks.

Another area worth examining is the design and ergonomics. User comfort and accessibility can significantly influence overall satisfaction and productivity.

- Operator Controls: Some designs feature more intuitive control layouts, making operation simpler for users of all experience levels.

- Seating Arrangements: Variances in seating comfort and adjustability can affect long-term usage, especially during extended operations.

In conclusion, a thorough analysis of these elements allows potential buyers to make informed decisions, selecting the equipment that best aligns with their specific needs and preferences.