In this section, we delve into the intricacies of various component configurations and how they function together within a larger system. This overview provides a fundamental understanding, helping users recognize and interpret different elements, ensuring that they are equipped with the knowledge needed for maintenance or replacement.

Exploring the various elements within such assemblies can seem challenging at first, but with a clear breakdown and visual representation, even complex structures become manageable. Each element plays a specific role in the overall operation, and understanding these roles is essential for ensuring smooth functionality and longevity.

We aim to provide a detailed analysis of each section, highlighting key components and their functions. By focusing on these critical elements, users can better grasp the inner workings of the system. This guide also offers tips for identifying common signs of wear and practical advice for effective upkeep, ensuring that your setup remains in peak condition.

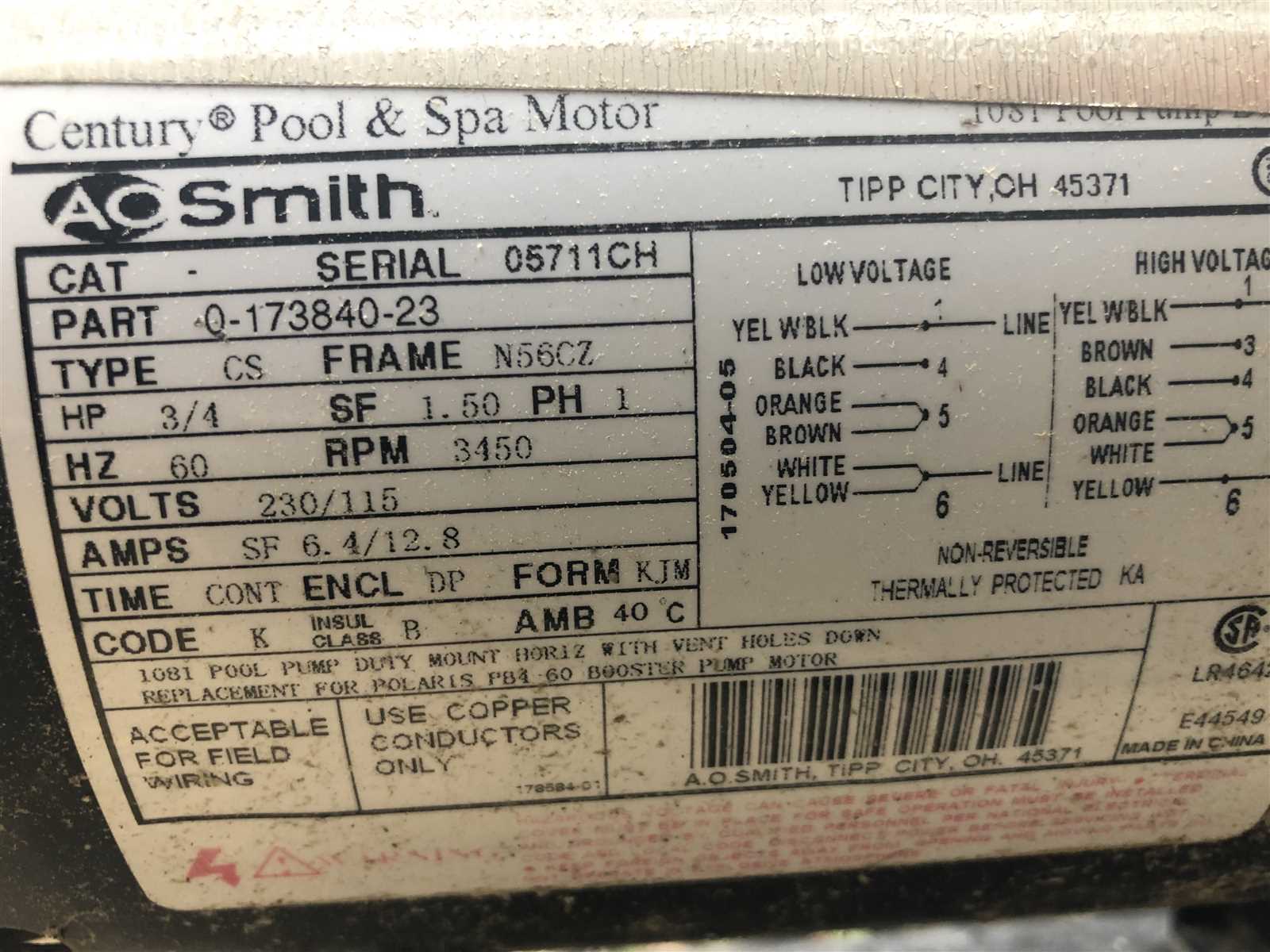

O. Smith Motor Parts Guide

In this section, we explore the various components and elements that make up these essential devices. Understanding the key elements of these machines helps in proper maintenance and repair, ensuring they operate efficiently and last longer.

Main Elements: Each device contains several crucial components that work together to provide functionality. These include the rotating units, power sources, and other critical sections responsible for performance.

Maintenance Tips: Regular inspections and upkeep of each part ensure that the machine remains in good condition. It is important to check and replace worn-out components to maintain peak performance and longevity.

By familiarizing yourself with the different aspects and regularly checking the condition of these elements, you can extend the life and reliability of your equipment.

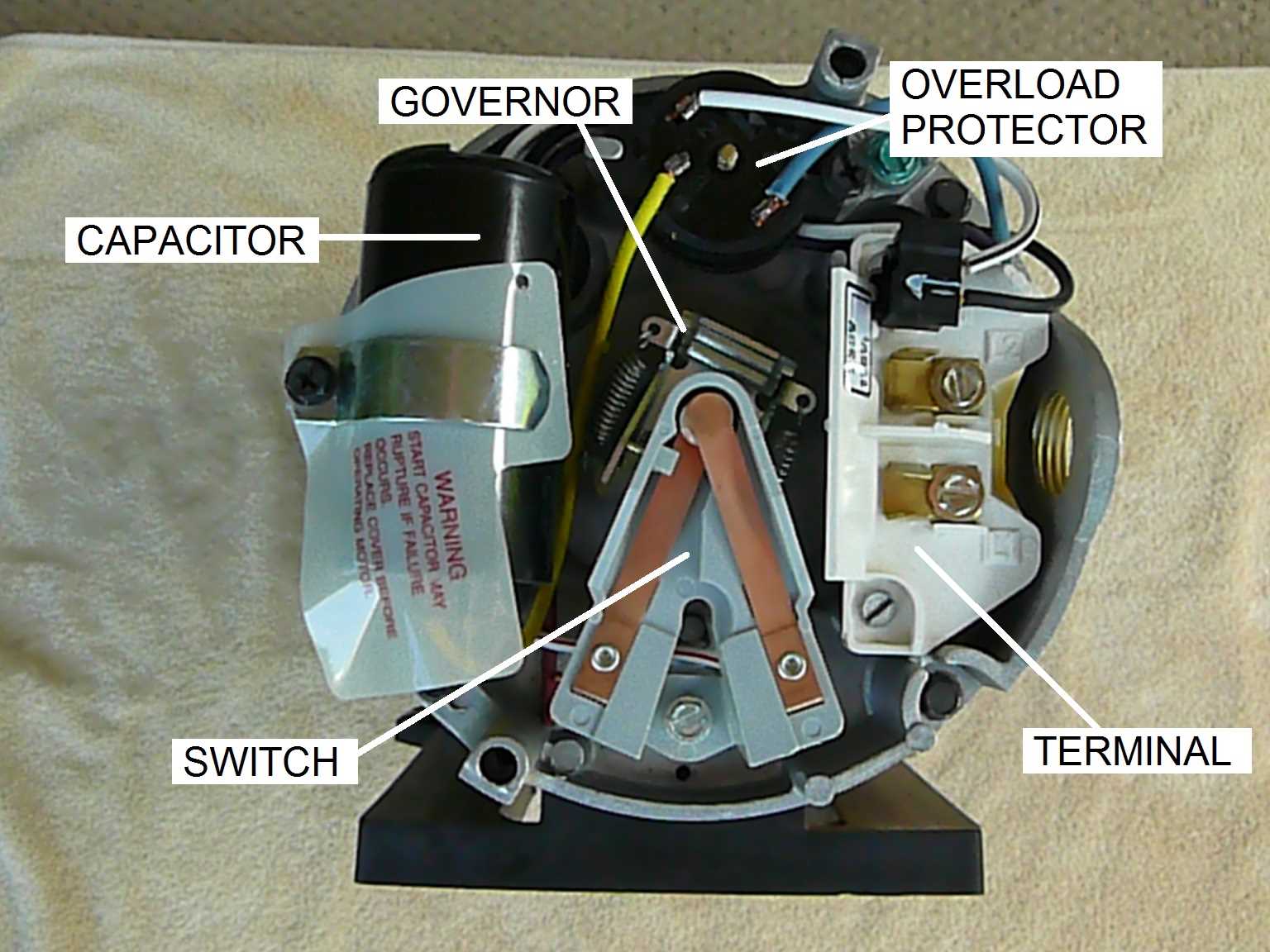

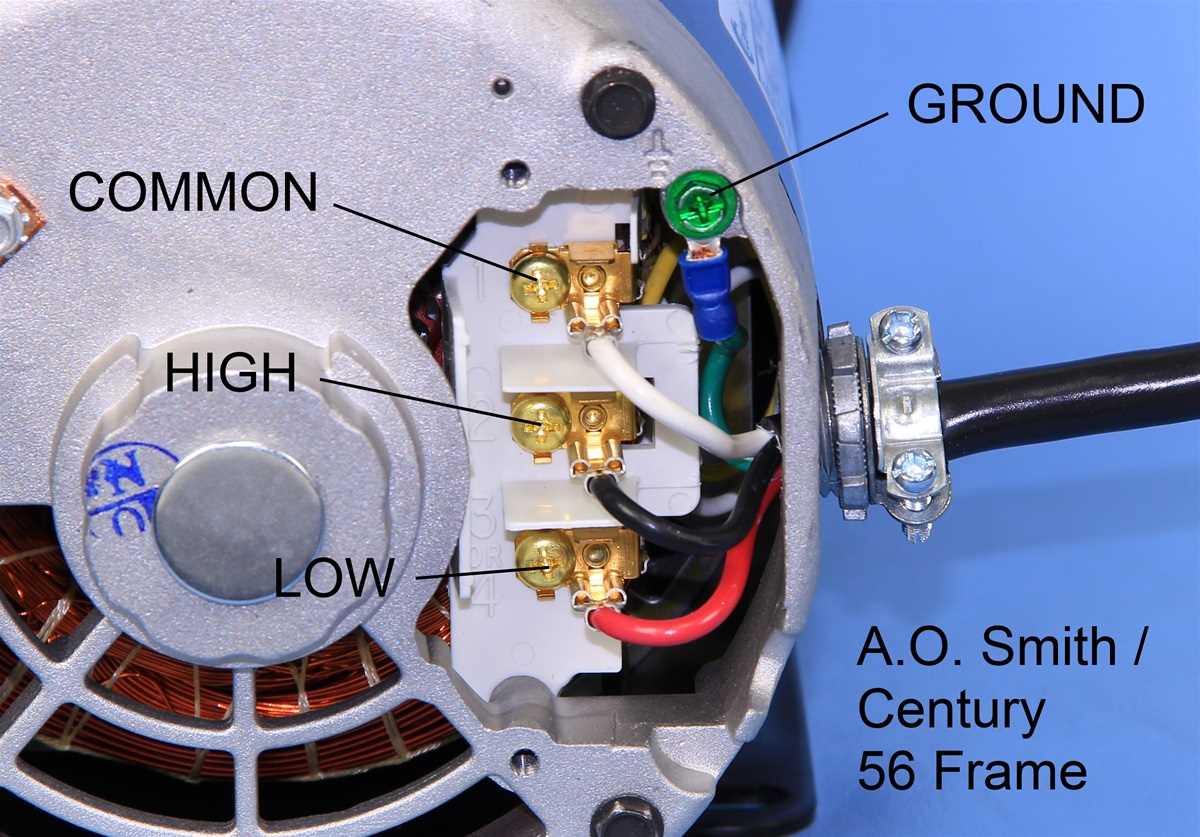

Understanding the Motor Components

In this section, we explore the various elements that make up a typical electrical device used for powering machines. The focus will be on providing a clear overview of each part’s function and how they contribute to the overall operation of the device. Understanding these components is essential for ensuring efficient performance and troubleshooting issues.

Main Elements and Their Functions

The structure includes several key elements, such as the rotating unit, which is responsible for movement, and the stationary section that supports the entire mechanism. Other important parts include the magnetic field generator and the conductive windings, which interact to create the necessary force for movement. Additionally, there are bearings that reduce friction and ensure smooth rotation.

Connections and Additional Features

Connections play a crucial role in delivering electrical power to the device, allowing it to operate efficiently. Insulation materials are also critical, as they protect the sensitive components from damage. Together, these features ensure that the device remains functional and durable over time, making it a reliable choice for various applications.

Identifying Key Motor Parts Efficiently

Understanding the different components within a mechanical system is crucial for ensuring proper maintenance and efficient operation. Recognizing these elements quickly and accurately can help streamline repairs and minimize downtime.

To efficiently identify the essential elements, it is important to familiarize yourself with the structure and functionality of each. This can be achieved by breaking down the system into its main sections and examining their respective functions.

- First, review the central rotating section, which is responsible for generating motion. Observe its shape and attachment points to determine its purpose.

- Next, inspect the static framework, which supports and stabilizes the rotating mechanism. Look for any signs of wear or misalignment.

- Check the control mechanisms that regulate speed and direction. These may include various connectors, switches, or controllers integrated within the assembly.

- Lastly, focus on any additional elements that provide power or manage heat, as they are essential for maintaining performance and preventing damage.

By following these steps, you can efficiently identify and understand the various components, ensuring effective maintenance and troubleshooting.

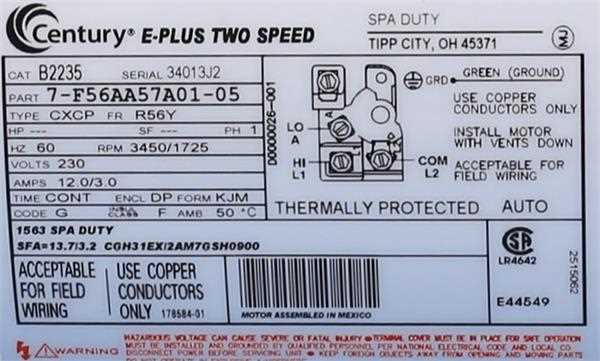

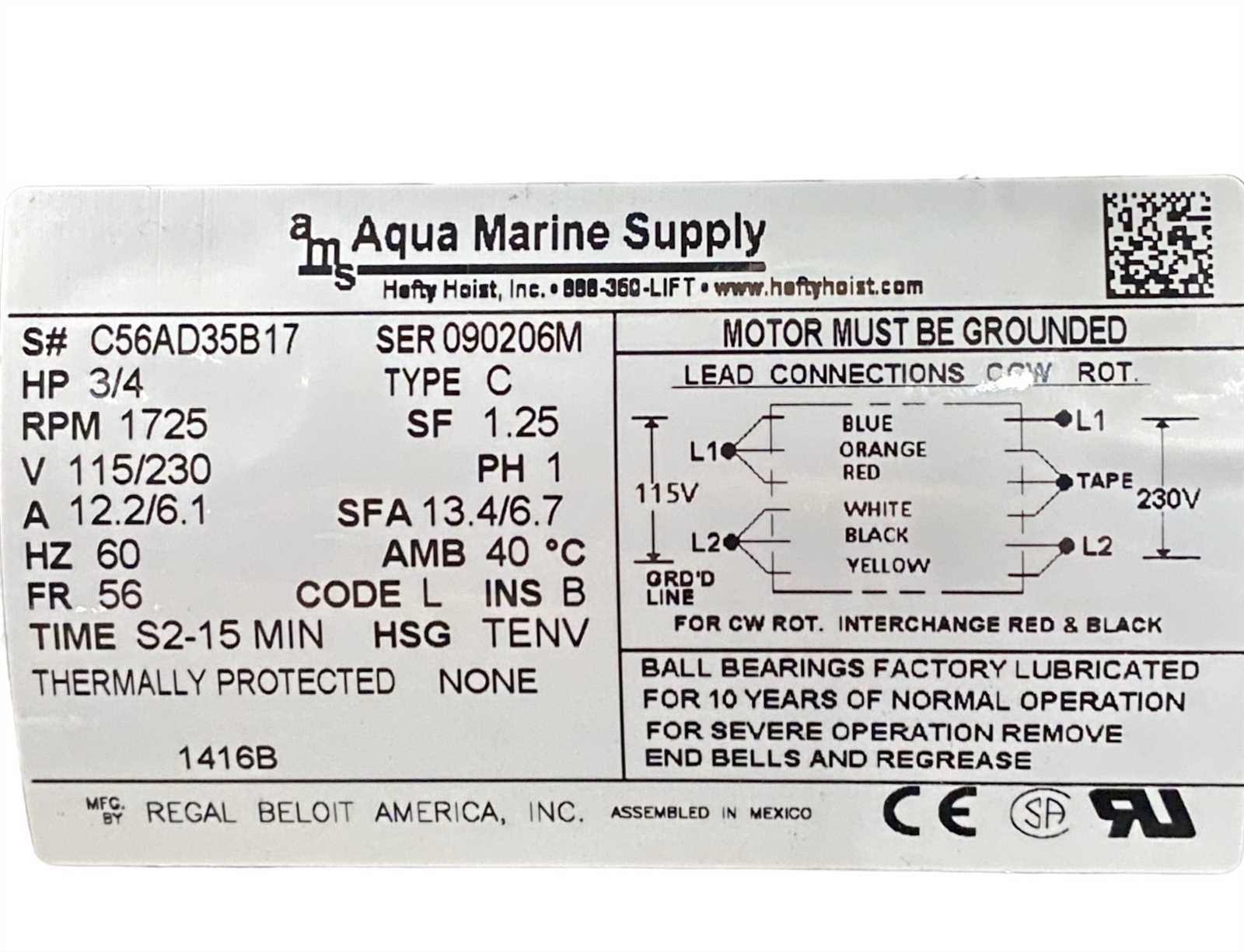

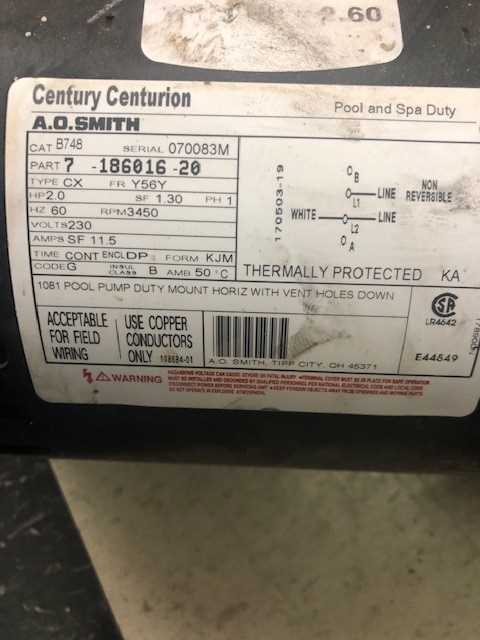

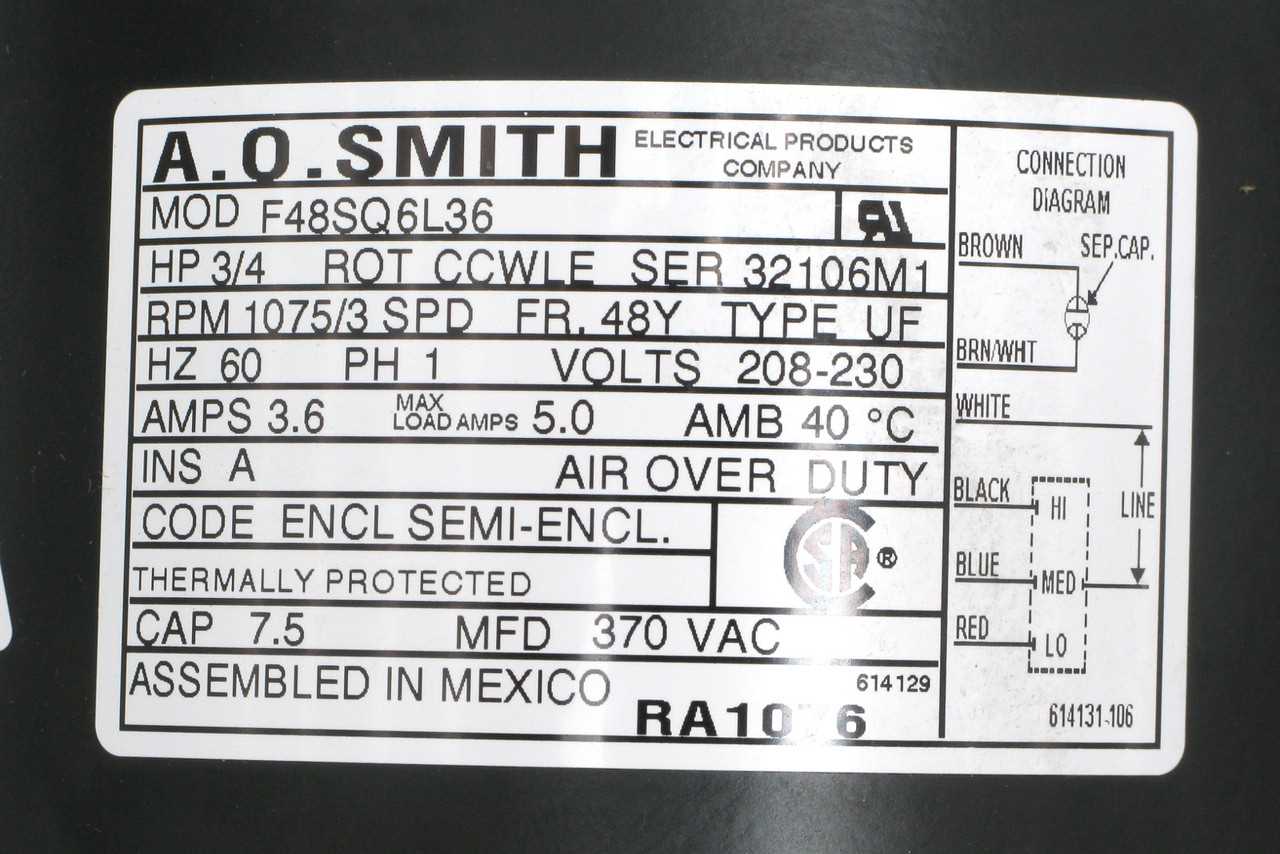

Exploring Motor Diagram Symbols

Understanding various symbols used in electrical schematics is crucial for interpreting the connections and functions of components. These symbols provide a visual representation of how electrical systems are configured, making it easier to troubleshoot, install, and maintain different setups efficiently. Familiarity with these signs helps in identifying components and understanding their roles within the system.

Commonly seen symbols may represent various types of switches, relays, resistors, and other elements. Each symbol has a specific shape and pattern, designed to convey the function it performs in the setup. For example, lines may indicate connections or pathways, while unique shapes can signify specific components like capacitors or coils.

Interpreting these visual elements correctly ensures a proper understanding of the system’s structure and helps in diagnosing potential issues or malfunctions. Studying these notations is essential for anyone involved in working with or maintaining electrical setups, as it provides a foundation for accurate and effective analysis.

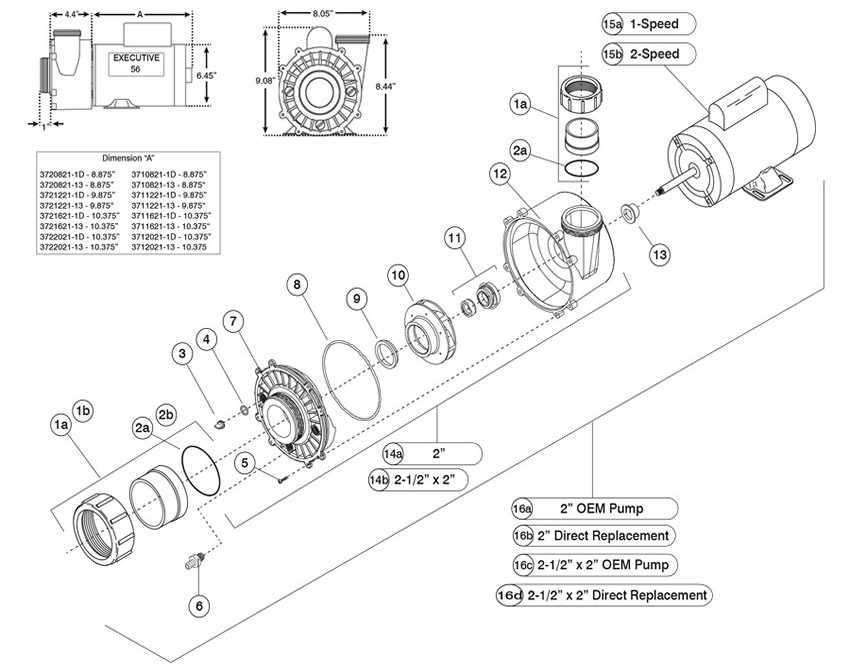

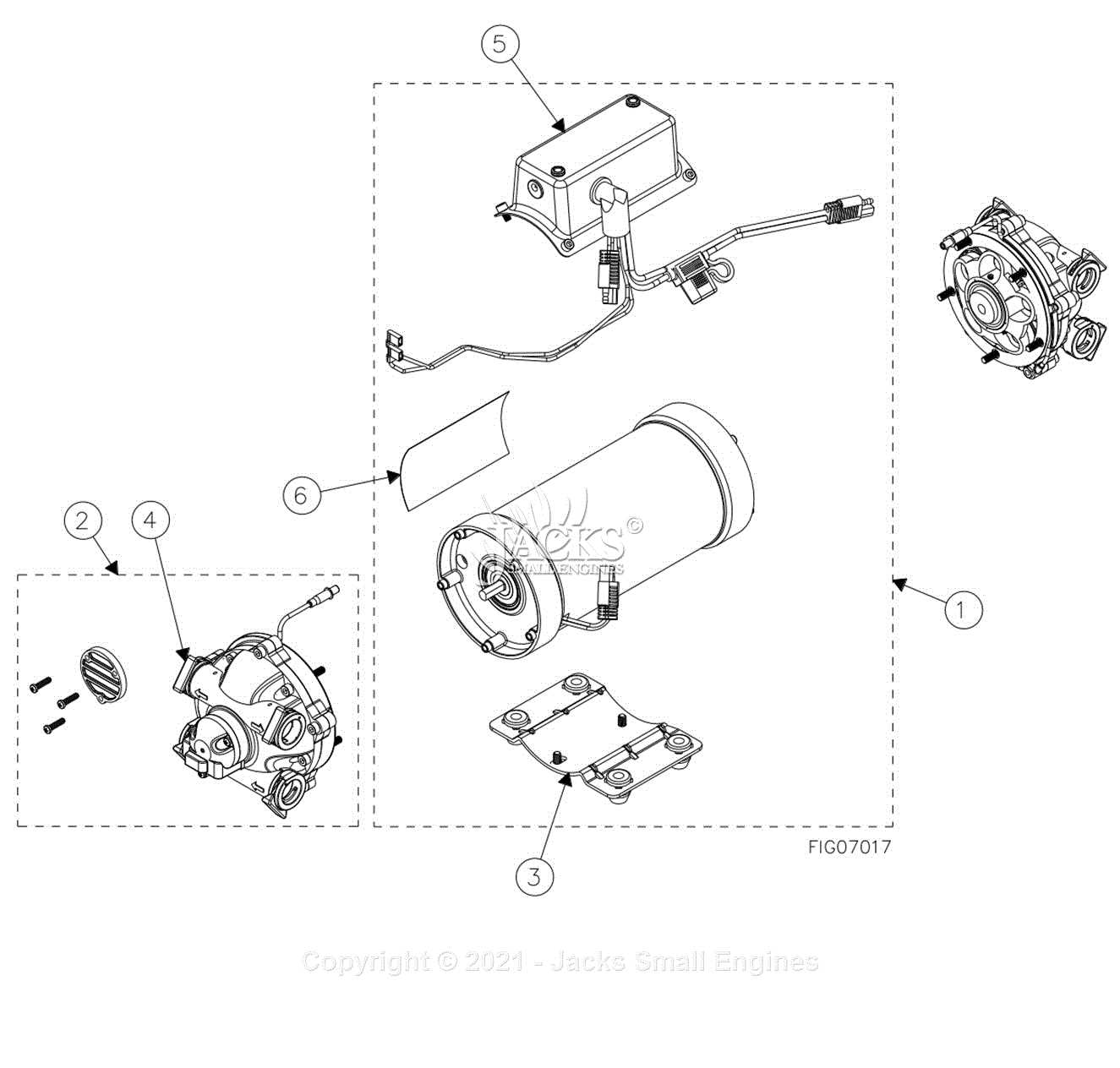

How to Read a Parts Diagram

Understanding a technical illustration is essential for effectively identifying and assembling various components. Such diagrams provide a visual guide to the structure and placement of different elements, ensuring clarity during repair or maintenance tasks.

Identifying the Components

First, locate the legend or key, which usually explains the symbols, numbers, or labels associated with each element. Familiarize yourself with these details to correctly match the items in the illustration with their descriptions.

Following the Layout

Observe the arrangement and order of the elements. Diagrams often follow a logical flow, either from top to bottom or left to right, guiding the viewer through the assembly or disassembly process. Pay attention to lines or arrows that may indicate connections or movement directions.

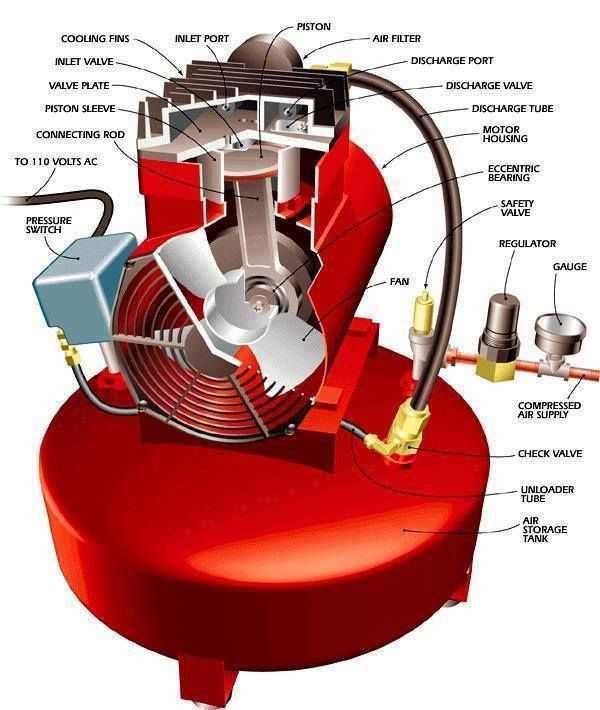

Common Motor Parts Explained

Understanding the various components of a power unit is essential for maintenance and troubleshooting. Each element plays a significant role in the overall functionality, ensuring smooth operation and efficiency. Recognizing how these components work together can help users diagnose issues and improve performance.

The first key component is the rotor, which is responsible for generating motion within the unit. It rotates within a magnetic field, producing the necessary mechanical energy. Another important element is the stator, which houses the windings that create the magnetic field. Together, these two components facilitate the conversion of electrical energy into kinetic energy.

Another vital aspect is the housing, which provides protection and structural integrity to the assembly. It prevents external elements from interfering with internal operations while ensuring proper alignment of the inner components. Additionally, bearings are crucial for reducing friction and allowing smooth rotation, enhancing the overall efficiency of the entire system.

Power supplies also play a significant role by providing the necessary voltage and current for operation. The control system regulates the performance, allowing users to manage speed and torque based on specific requirements. Understanding these fundamental components is crucial for anyone involved in maintenance or repair, as it equips them with the knowledge to keep their equipment running optimally.

Maintenance Tips for Motor Parts

Proper upkeep of components is crucial for ensuring the longevity and efficiency of any mechanical system. By following a few simple practices, you can prevent potential issues and enhance the performance of your equipment.

Regular Inspections

Conducting routine examinations is essential for identifying wear and tear. Here are some key areas to focus on:

- Check for any signs of corrosion or rust.

- Inspect for loose connections or components.

- Look for unusual noises or vibrations during operation.

Cleaning and Lubrication

Keeping components clean and well-lubricated can significantly improve performance. Consider the following steps:

- Clean surfaces with appropriate solvents to remove dirt and debris.

- Apply suitable lubricants to moving parts to reduce friction.

- Ensure that excess lubricant is wiped away to prevent buildup.

Replacing Worn Out Components

Over time, certain elements within a system may become less effective or completely fail, necessitating their replacement to maintain optimal functionality. This process involves identifying and substituting these diminished components with new or refurbished ones to ensure the equipment operates smoothly and efficiently.

Identifying Deteriorated Elements

Before proceeding with the replacement, it is crucial to accurately diagnose which components have worn out. Common indicators include unusual noises, reduced performance, and visible signs of damage. Regular inspections can help in spotting these issues early on.

Steps for Replacement

Once the faulty components are identified, follow these steps for successful replacement:

- Gather Necessary Tools: Ensure you have all required tools and replacement components ready before starting the procedure.

- Power Off the Equipment: Always disconnect the power supply to avoid accidents during the replacement process.

- Remove the Worn Components: Carefully take out the damaged parts, ensuring not to damage surrounding elements.

- Install New Components: Position the new parts in their designated spots, making sure they are secured properly.

- Test the System: After reassembly, restore power and test the equipment to confirm that the new components are functioning as intended.

By taking these steps, you can effectively restore the performance of your equipment, ensuring longevity and reliability in its operation.

Optimizing Motor Performance

Enhancing the functionality of machinery is crucial for achieving efficiency and reliability in various applications. By focusing on several key aspects, users can significantly improve the overall effectiveness and lifespan of their equipment. This section explores essential strategies and considerations for maximizing performance.

Key Factors to Consider

- Maintenance: Regular upkeep ensures that all components function smoothly.

- Calibration: Proper adjustments optimize performance and reduce energy consumption.

- Compatibility: Using compatible components prevents issues related to fitting and functionality.

- Environment: Ensuring suitable operating conditions can enhance performance and prevent overheating.

Best Practices for Enhancement

- Conduct routine inspections to identify wear and tear.

- Replace worn components promptly to prevent further damage.

- Keep the operating area clean to avoid debris interference.

- Utilize high-quality lubricants to reduce friction and improve efficiency.

- Implement monitoring systems to track performance metrics in real-time.

By prioritizing these elements, users can achieve optimal operation and prolong the service life of their equipment, ensuring it runs at peak efficiency. Continuous improvement and adherence to best practices play a pivotal role in maximizing output and reliability.

Troubleshooting Motor Issues

When dealing with electrical machinery, encountering operational difficulties can be frustrating. Identifying the underlying causes of these issues is crucial for effective resolution. By systematically examining the components and their interactions, you can pinpoint the source of malfunction and restore functionality.

Common Symptoms and Their Solutions

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No Power | Disconnected power supply or faulty circuit | Check connections and replace fuses if necessary |

| Overheating | Excessive load or poor ventilation | Reduce load and ensure proper airflow |

| Unusual Noises | Worn bearings or misalignment | Inspect bearings for wear and realign components |

| Intermittent Operation | Loose wiring or failing components | Tighten connections and test for defective parts |

Preventive Measures

Regular maintenance and inspections can significantly reduce the likelihood of operational failures. Ensure that all components are clean, well-lubricated, and free from debris. Adhering to recommended operational guidelines will extend the lifespan of your equipment and enhance its performance.

Upgrading and Modifying Motor Parts

Enhancing and customizing components of a machine can significantly improve its performance and longevity. By implementing thoughtful upgrades, users can tailor their equipment to meet specific needs, whether for increased efficiency, better durability, or enhanced functionality. This section will explore various strategies for improving these elements, focusing on practical modifications that yield substantial benefits.

When considering enhancements, it is essential to identify the areas that will provide the most significant impact. Below is a table outlining common upgrades and their advantages:

| Upgrade Type | Description | Benefits |

|---|---|---|

| High-Performance Bearings | Replace standard bearings with high-performance options. | Reduced friction, increased speed, and improved reliability. |

| Enhanced Cooling Systems | Install advanced cooling components to maintain optimal temperature. | Prevents overheating, leading to longer service life. |

| Upgraded Power Supply | Utilize a more robust power source. | Provides consistent energy, enhancing overall functionality. |

| Precision Control Units | Incorporate advanced control technology for better handling. | Increased responsiveness and accuracy in operations. |

Each enhancement requires careful consideration and a clear understanding of the potential impact on overall performance. By choosing the right modifications, users can achieve their desired outcomes, making their machines more efficient and effective in various applications.