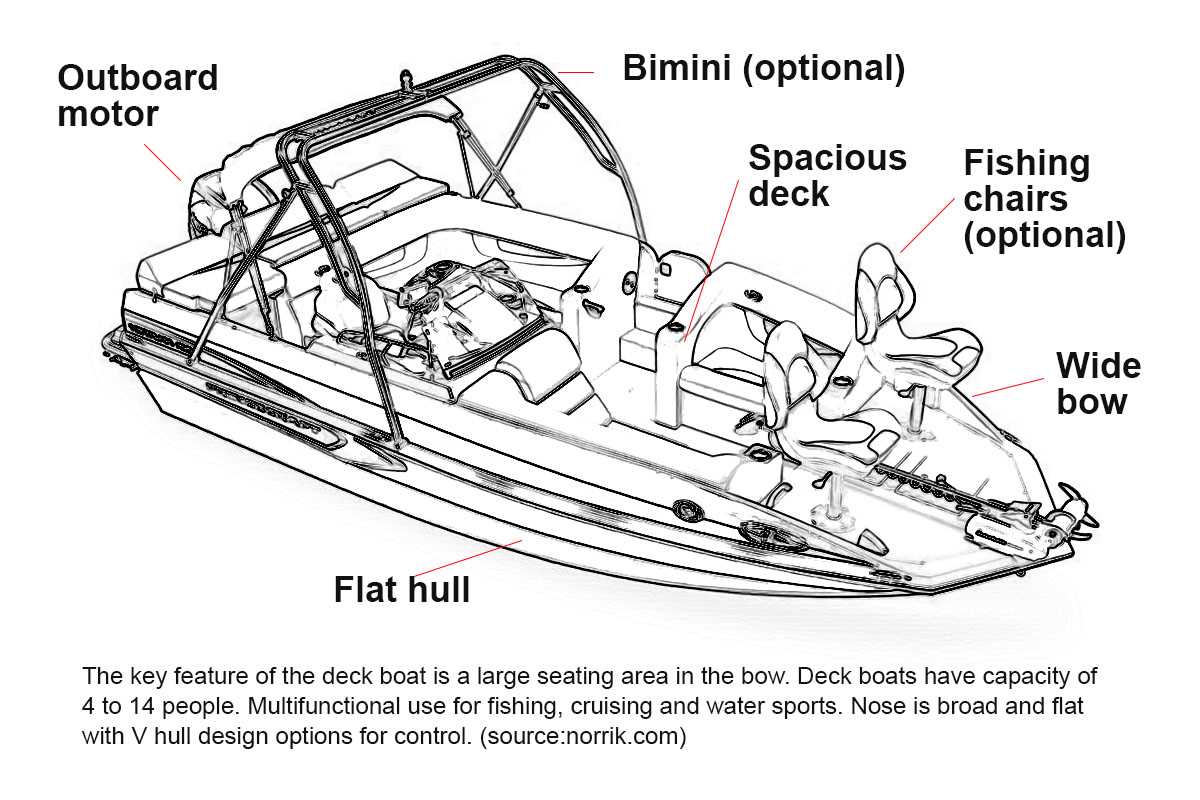

Every watercraft relies on a complex system to convert energy into motion, ensuring smooth and efficient performance. This section delves into the intricate assembly that powers the vessel, highlighting the key elements that work together to propel it forward.

The internal mechanisms are designed to handle varying speeds and conditions, allowing for both leisure and professional use. By examining the essential elements, you can gain a clearer understanding of how each component interacts within the system to produce consistent output.

In this article, we will explore the core elements of this system, offering a closer look at their functions and how they contribute to the overall operation of the machinery.

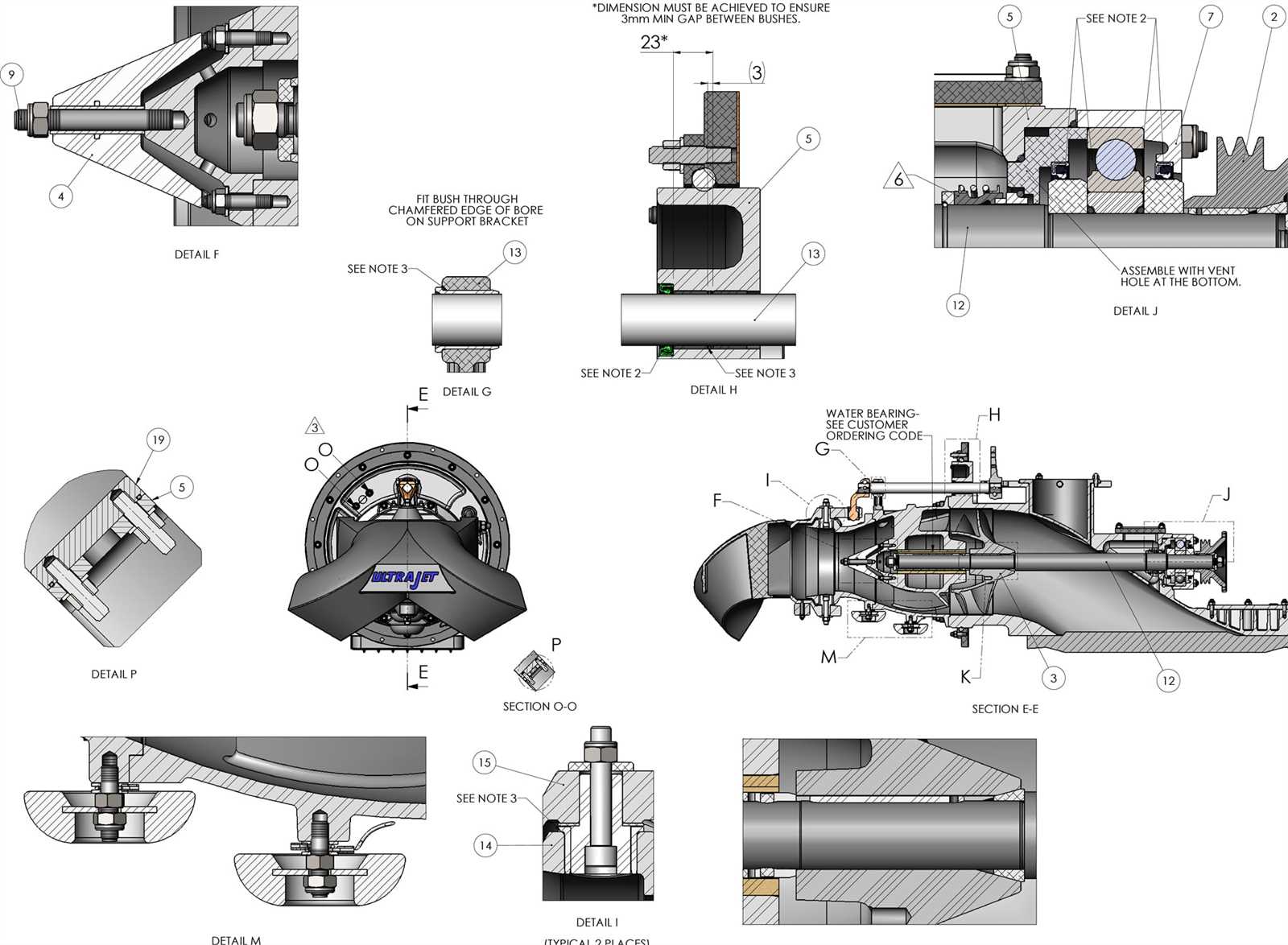

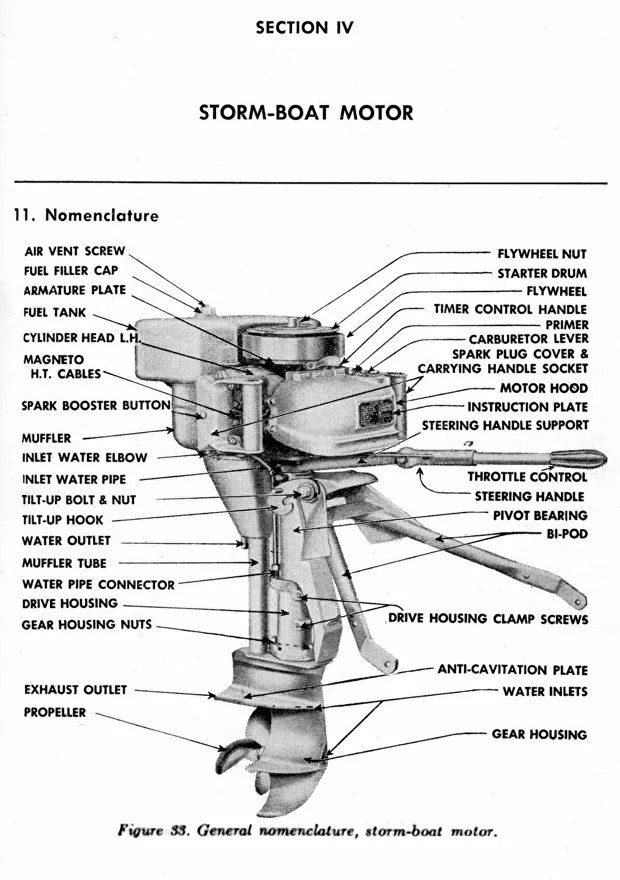

Inboard Motor Parts Diagram

Understanding the layout of internal mechanisms is crucial for those working with marine propulsion systems. Each component plays a significant role in ensuring efficient operation and long-term durability. By familiarizing yourself with the various elements, you can better diagnose issues, perform maintenance, and improve performance.

Key Structural Components

At the heart of this system are several fundamental elements that work in harmony. The driving mechanism connects directly to the vessel’s power source, while the propulsion unit ensures the force is effectively transferred to the water. Supporting elements, such as the cooling and lubrication systems, help maintain optimal functioning.

Auxiliary Systems

Alongside the core structure, additional subsystems are essential for smooth operation. These include electrical circuits for monitoring and control, as well as various safety mechanisms designed to prevent overheating and mechanical failure. Proper understanding of these components ensures reliable and efficient use of the propulsion system.

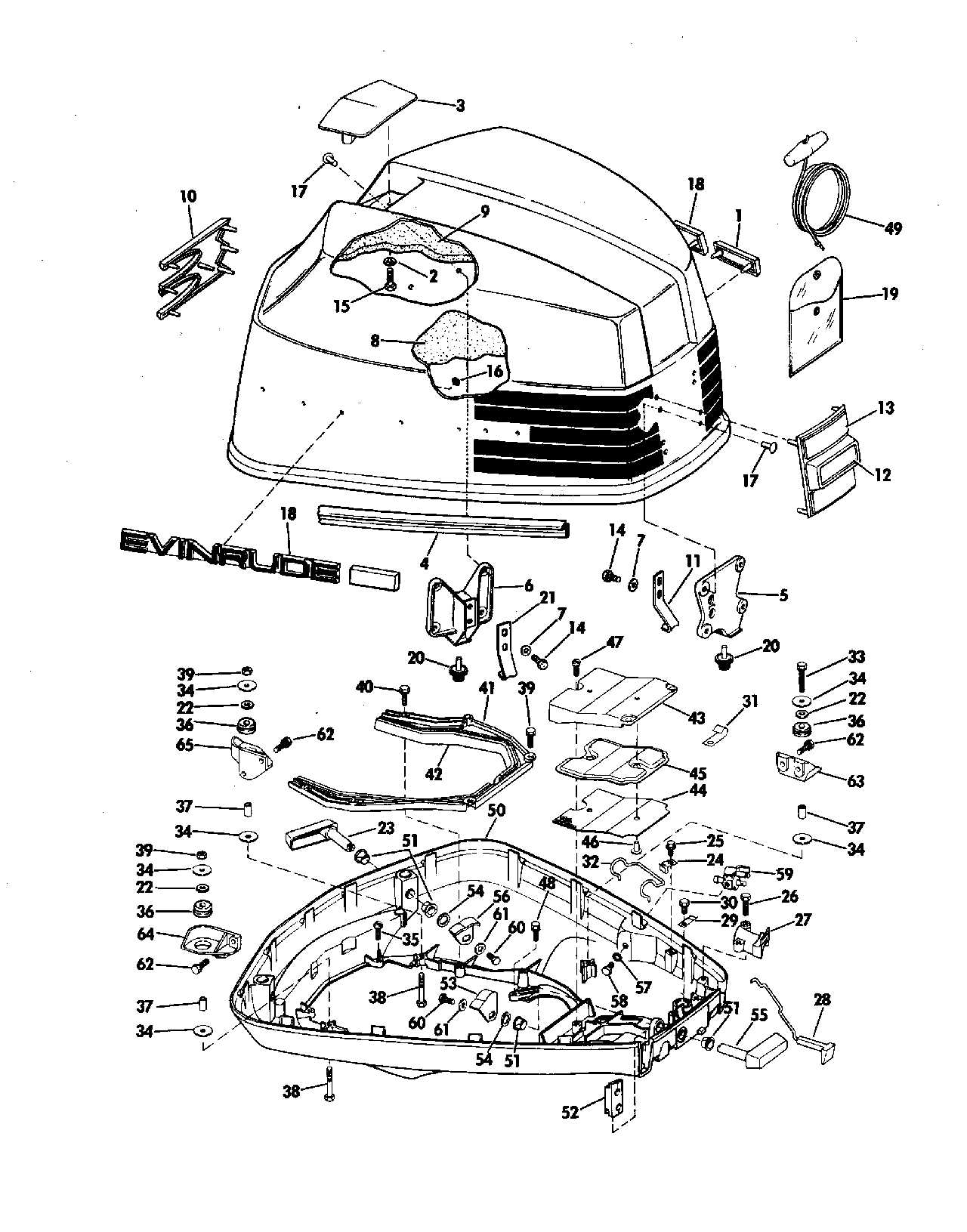

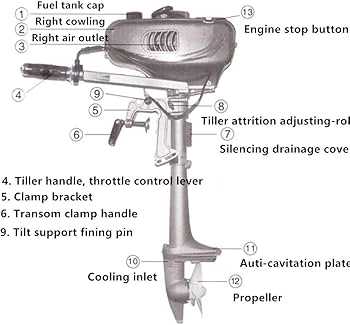

Overview of Inboard Engine Components

The core of a watercraft’s propulsion system relies on a well-orchestrated set of mechanical elements. These essential units work together to ensure efficient operation, transforming power into motion. Understanding these elements and their interactions is crucial for maintaining peak performance and long-term durability.

Main Structural Elements

The key components of the propulsion mechanism include several structural parts that play specific roles in harnessing energy. Each section, whether responsible for delivering fuel, regulating air intake, or managing the exhaust, contributes to the smooth function of the system.

Supporting Mechanisms

In addition to the main structural units, there are auxiliary systems designed to enhance efficiency. These include cooling systems, lubrication setups, and electrical controls. By maintaining a balance between these supporting mechanisms, the overall propulsion system can operate under optimal conditions.

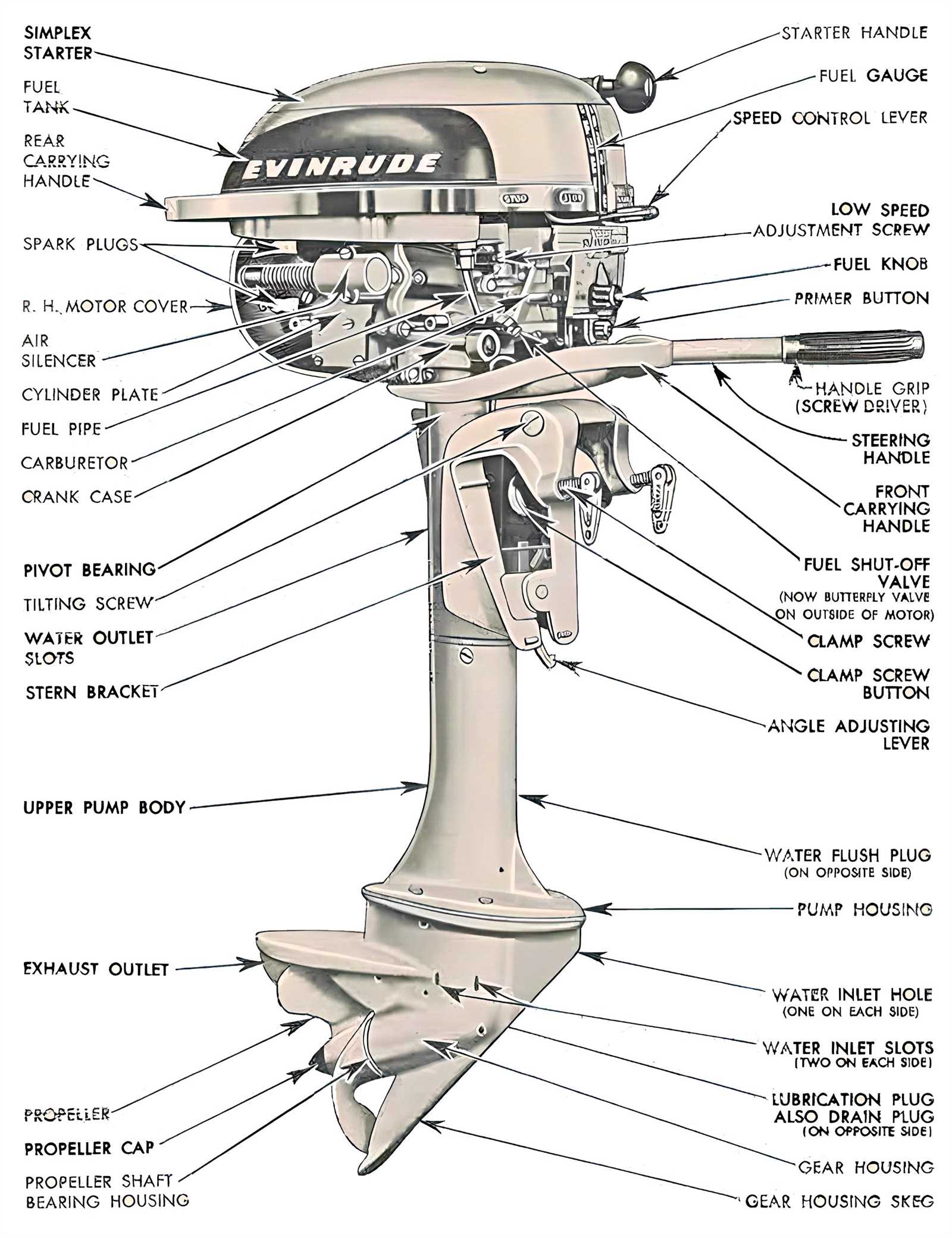

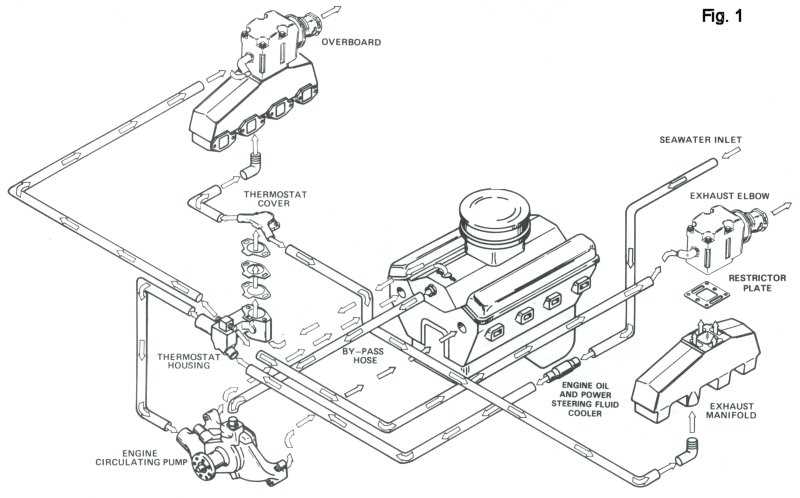

Understanding the Cooling System Layout

Effective heat management is crucial for the smooth operation of mechanical equipment. A well-structured cooling system ensures that temperature levels remain optimal, preventing overheating and potential damage. By distributing fluids through dedicated pathways, this setup maintains a balanced environment for the components.

- Water intake: This section introduces fresh fluid into the system, ensuring a continuous flow for heat regulation.

- Heat exchanger: A vital element where the cooling fluid absorbs excess warmth before being cycled back into the equipment.

- Circulation pumps: These pumps maintain consistent flow rates, ensuring the fluid reaches all critical areas requiring cooling.

- Discharge outlet: Expels the heated fluid, making room for cooler liquid to enter and continue the process.

The fluid cycle is essential for maintaining optimal performance, ensuring every component remains within safe temperature limits. A well-maintained cooling layout contributes significantly to longevity and efficiency.

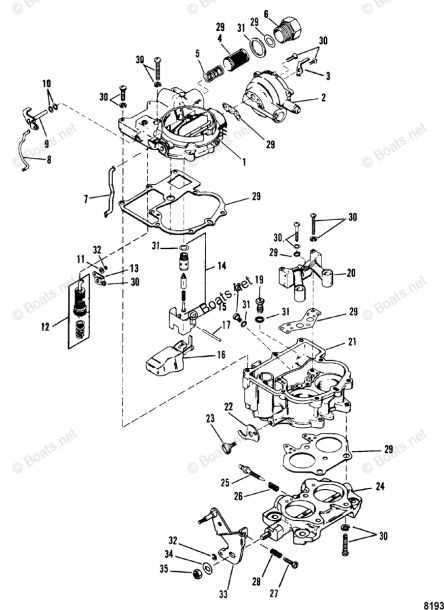

Key Elements of the Fuel System

The fuel system is designed to ensure the efficient and safe transfer of energy sources to the engine. Its components work in harmony to maintain a steady flow of fuel, regulate pressure, and ensure optimal performance. Each part plays a vital role in enabling smooth combustion and avoiding disruptions.

| Component | Description |

|---|---|

| Fuel Pump | Responsible for moving the fuel from the tank to the engine, ensuring the right pressure for efficient operation. |

| Fuel Filter | Removes impurities from the fuel to protect the engine and maintain a smooth flow. |

| Fuel Injector | Precisely sprays fuel into the combustion chamber, optimizing the air-fuel mixture for efficient combustion. |

| Fuel Lines |

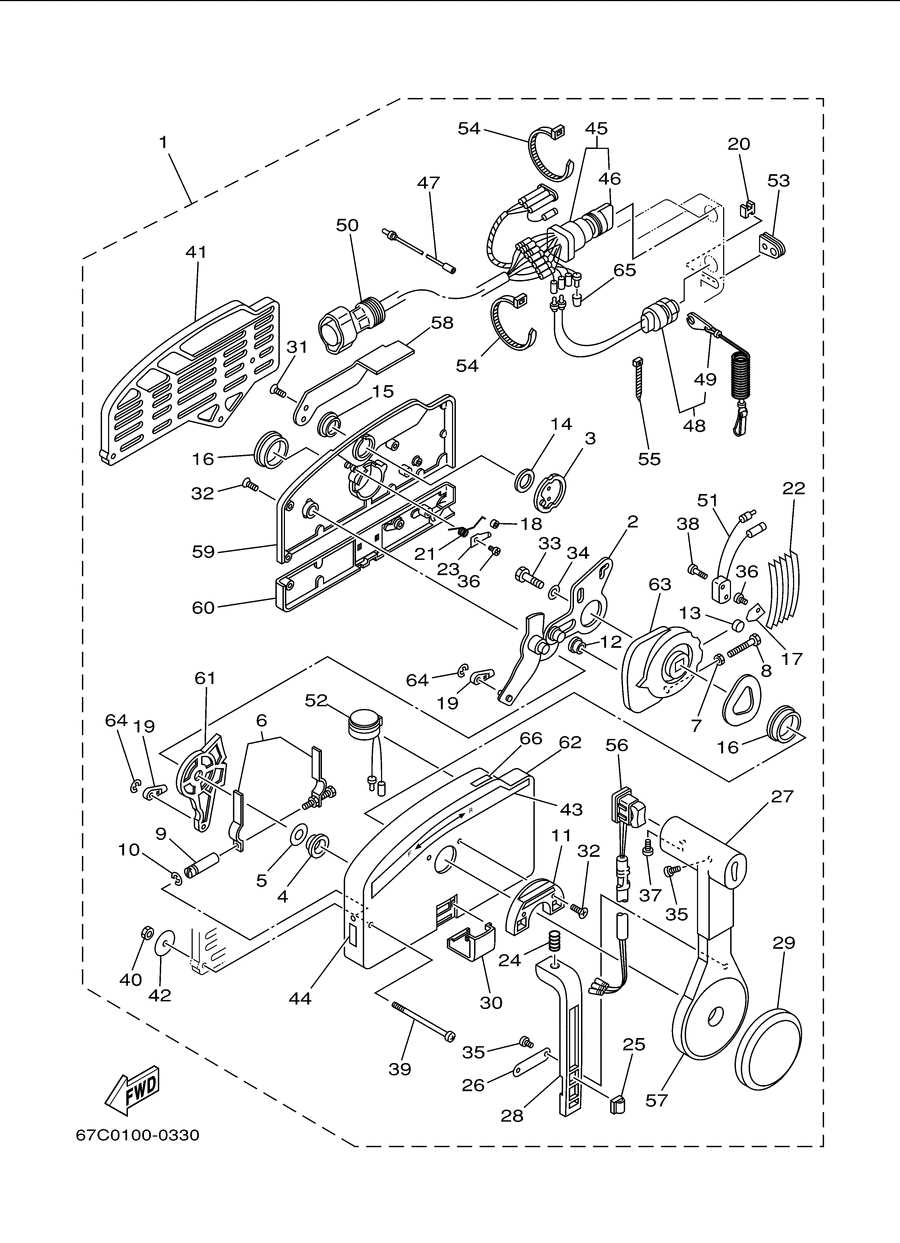

Exploring the Ignition System Structure

The ignition mechanism plays a crucial role in the operation of various machines, ensuring a reliable and controlled spark that sets off the combustion process. Understanding how this system functions provides valuable insights into how energy is efficiently transferred to create motion. Key Components of the Ignition Mechanism

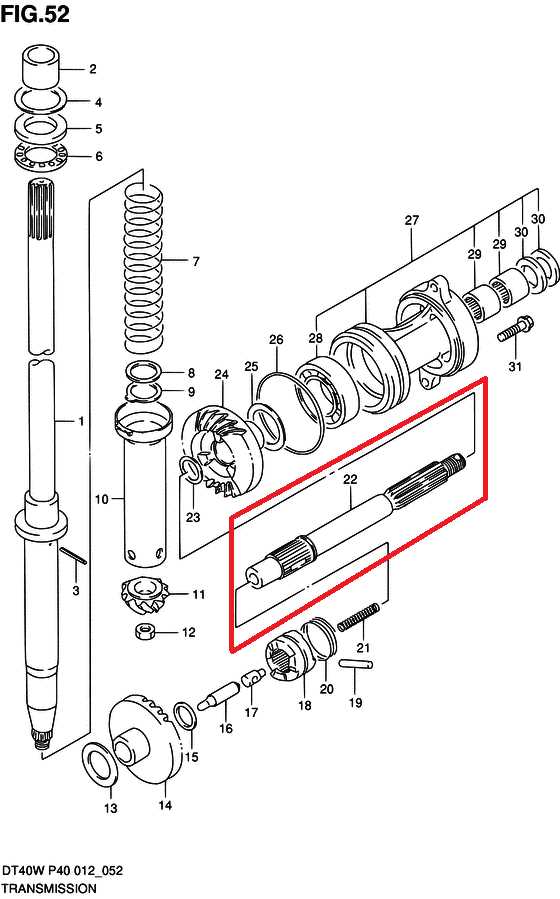

How the System OperatesWhen the ignition is activated, the energy from the battery is routed to the coil, where it is intensified. The distributor then ensures that the amplified current reaches the spark plug, creating the spark that initiates combustion. This sequence is repeated continuously to keep the machine running smoothly. Functions of the Propulsion MechanismThe propulsion system plays a crucial role in the effective movement of watercraft, enabling them to traverse various aquatic environments. This assembly is designed to convert power into thrust, allowing vessels to glide smoothly over the surface of the water. Understanding the functions of this mechanism is essential for optimizing performance and ensuring safety during navigation. Power Transmission

One of the primary functions of the propulsion assembly is to transfer energy from the engine to the water. This process involves the conversion of rotational motion into a force that propels the vessel forward. The efficiency of power transmission is vital, as it directly influences the speed and maneuverability of the craft. Thrust GenerationThe mechanism is also responsible for generating thrust, which is the driving force that moves the vessel through water. By creating a difference in pressure between the front and rear of the system, the propulsion unit allows the craft to accelerate and maintain speed. The design and configuration of this component significantly affect the overall performance and handling of the watercraft. Insight into the Lubrication SystemThe lubrication system plays a crucial role in maintaining the efficiency and longevity of any mechanical system. By ensuring that various components are adequately lubricated, it reduces friction and wear, ultimately enhancing overall performance. This system facilitates the movement of oil or grease through key areas, providing essential protection against heat and corrosion. In a well-designed lubrication setup, specific pathways allow the lubricant to reach critical surfaces. This ensures that every moving part receives the necessary amount of fluid for optimal operation. Additionally, filters and pumps are often integrated to maintain cleanliness and pressure, which is vital for preventing premature failures. Understanding the intricacies of this system can lead to better maintenance practices and improved reliability in performance. Electrical Components and Their RolesUnderstanding the electrical components within a propulsion system is essential for optimal functionality and maintenance. Each element contributes to the overall performance, ensuring seamless operation and reliability. The interplay among these components facilitates the efficient transfer of energy, which is crucial for various functions. Key electrical elements include:

Each of these elements plays a vital role in maintaining the integrity and functionality of the entire system. Proper understanding and management of these components can significantly enhance the longevity and reliability of the setup. Steering and Control Mechanism Details

The efficiency and precision of navigation are paramount in any vessel, and the steering and control systems play a vital role in achieving these objectives. These systems are designed to provide the operator with the ability to guide the craft smoothly and accurately, ensuring a safe and enjoyable experience on the water. Understanding the components involved in these systems is essential for effective maintenance and troubleshooting. Key elements include the steering wheel or tiller, which allows the user to direct the movement, and various linkages that transmit this input to the rudder or outdrive. Additionally, control devices such as throttle and gear selectors are integral in managing the vessel’s speed and direction. Maintenance tips for steering and control mechanisms are crucial for long-lasting performance. Regular inspection of cables, joints, and hydraulic systems helps identify potential wear and tear before they lead to larger issues. Proper lubrication of moving parts and the timely replacement of worn components can significantly enhance the longevity and reliability of these systems. Examining the Exhaust System DesignThe exhaust mechanism plays a crucial role in optimizing performance and ensuring efficiency in aquatic propulsion systems. Its primary function is to manage the expulsion of gases generated during the operation of the engine, while also minimizing noise and environmental impact. Key components of the exhaust mechanism include:

Design considerations for the exhaust mechanism often focus on:

Overall, the thoughtful engineering of the exhaust mechanism contributes significantly to the performance and reliability of aquatic propulsion systems. Maintenance Tips for Engine LongevityEnsuring the long-lasting performance of your engine requires consistent care and attention. Proper upkeep not only enhances functionality but also prevents costly repairs down the line. By adhering to a routine maintenance schedule and implementing best practices, you can significantly extend the lifespan of your mechanical system. Regular Inspections

Conducting frequent evaluations of the engine’s components is crucial. Look for signs of wear, leaks, and other irregularities. Early detection of issues can save time and resources, allowing for timely interventions before they escalate into serious problems. Fluid Checks and ChangesMaintaining optimal fluid levels is essential for smooth operation. Regularly check oil, coolant, and other vital fluids, replacing them according to the manufacturer’s recommendations. Clean fluids help reduce friction and prevent overheating, contributing to the overall health of your engine. Common Issues with Inboard Motors

Understanding the typical challenges encountered with propulsion systems is essential for maintaining performance and safety. These complications can arise from various components and systems, leading to decreased efficiency and operational difficulties. Addressing these problems promptly can prevent further damage and enhance the overall functionality of the vessel. Overheating ProblemsOne of the most frequent issues faced is overheating. This can result from a malfunctioning cooling system, blocked water intake, or insufficient coolant levels. Regular maintenance and inspection are crucial to ensure that the cooling system operates effectively, preventing severe damage. Fuel System Failures

Fuel system malfunctions can lead to performance issues, including stalling or difficulty starting. Common causes include clogged filters, fuel line leaks, or degraded fuel quality. Timely replacement of filters and regular fuel quality checks can significantly mitigate these risks. |