When it comes to maintaining your outdoor space, having a reliable machine is crucial. Knowing the intricate elements that make up this equipment can greatly enhance your experience and efficiency. This section delves into the essential components, offering insights into their functions and interrelationships.

Whether you’re performing routine maintenance or troubleshooting an issue, a comprehensive overview of these mechanical systems will empower you to make informed decisions. Familiarity with the layout and roles of each part not only aids in understanding how your equipment operates but also assists in ensuring its longevity.

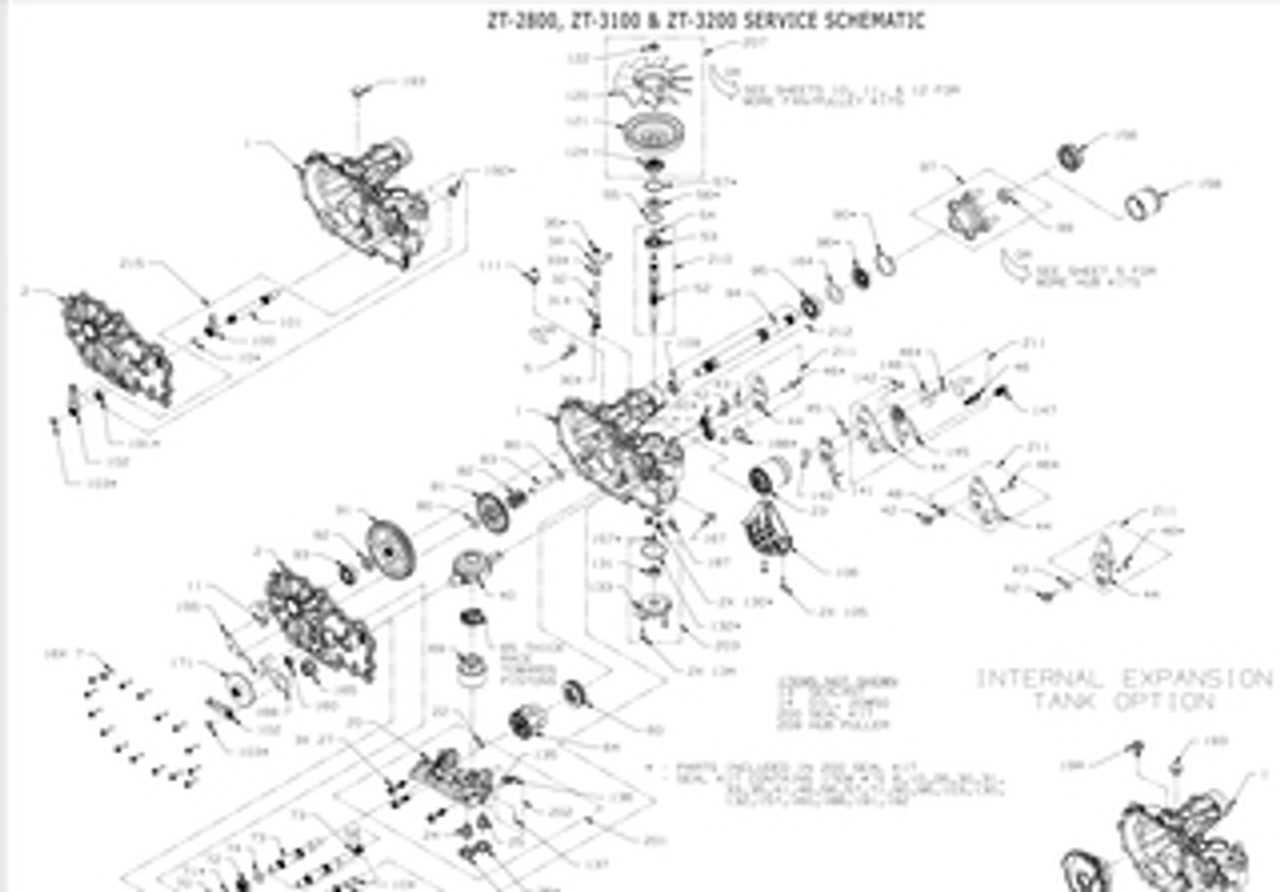

In the following sections, we will explore the visual representation of these components, providing clarity on how they fit together. This knowledge will serve as a valuable resource for anyone looking to optimize their lawn care practices.

Understanding Ransomes Bobcat Mower Design

The design of landscape maintenance equipment is pivotal for ensuring efficiency and performance in various terrains. Each component plays a crucial role, contributing to the overall functionality and user experience. An intricate balance between durability and ease of use is achieved through thoughtful engineering and innovative design approaches.

Anatomy reveals the intricate mechanics at work, highlighting how every element interacts seamlessly. The layout facilitates not only maneuverability but also accessibility for maintenance and repairs. By examining these aspects, operators can appreciate the craftsmanship that enhances operational reliability.

A thorough comprehension of the structural components allows users to optimize their experience. Recognizing how each piece contributes to the machine’s purpose can lead to improved maintenance practices and prolonged service life. Ultimately, knowledge of the equipment’s design promotes better stewardship and efficient usage.

Key Components of the Mower

Understanding the essential elements of a cutting machine is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance and longevity of the equipment.

Major Elements

- Engine: The heart of the machine, responsible for powering the entire system.

- Deck: The area where cutting takes place, designed for durability and efficiency.

- Blades: Sharp instruments that perform the actual cutting; must be kept in good condition for effective operation.

- Transmission: Transfers power from the engine to the wheels and blades, influencing speed and maneuverability.

- Wheels: Provide mobility and stability, ensuring smooth navigation across various terrains.

Additional Features

- Controls: Interfaces that allow the operator to adjust speed and cutting height with ease.

- Chassis: The framework that houses and supports all components, contributing to overall stability.

- Fuel System: Supplies energy to the engine, requiring regular checks to maintain efficiency.

- Cooling System: Prevents overheating, essential for prolonged usage and optimal performance.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended life of any mechanical equipment. By adhering to a structured maintenance routine, users can significantly reduce the risk of unexpected failures and enhance the performance of their machinery. This proactive approach not only safeguards the investment but also optimizes efficiency and safety.

Routine checks and timely repairs play a crucial role in preventing wear and tear. Neglecting maintenance can lead to minor issues escalating into major problems, resulting in costly repairs or replacements. Therefore, understanding the key components that require attention is vital for any operator.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Fluid Checks | Monthly | Ensures optimal performance and prevents overheating. |

| Filter Replacement | Every 200 hours | Improves efficiency and extends engine life. |

| Blade Inspection | Every 50 hours | Enhances cutting efficiency and reduces stress on the engine. |

| Belts and Cables Check | Quarterly | Prevents breakdowns and ensures reliable operation. |

Implementing these maintenance tasks not only prolongs the lifespan of the equipment but also guarantees consistent performance, making it a worthwhile investment of time and resources. Emphasizing a commitment to regular care will yield benefits for both operators and the machinery itself.

Common Issues and Their Solutions

Operating machinery can present various challenges that may hinder performance. Identifying these common problems is essential for maintaining efficiency and extending the lifespan of the equipment. Below are some frequent issues encountered, along with effective solutions to address them.

One prevalent issue is engine difficulty starting. This may result from a depleted battery, faulty ignition components, or contaminated fuel. Regular maintenance of the battery and ignition system, along with using clean fuel, can help prevent this situation.

Another common concern is uneven cutting. This often stems from dull blades, improper tire pressure, or uneven terrain. Sharpening blades regularly, ensuring tires are inflated to the correct levels, and leveling the cutting deck can significantly improve the quality of the cut.

Overheating engines can also pose a significant problem, typically caused by insufficient coolant, blocked air vents, or dirty filters. Regularly checking coolant levels, clearing any obstructions from air vents, and replacing dirty filters can help keep the engine running smoothly.

Lastly, transmission issues may arise, leading to difficulty in speed adjustments or sudden stops. This could be due to low fluid levels or worn-out components. Ensuring that fluid levels are adequate and replacing worn parts promptly will help maintain smooth operation.

How to Identify Original Parts

Ensuring that components are authentic is crucial for maintaining optimal performance and longevity of equipment. Original items are typically designed to fit perfectly and function according to the manufacturer’s specifications. Recognizing genuine pieces can help avoid unnecessary damage and ensure smooth operation.

- Check for Branding: Look for clearly marked logos or brand names. Manufacturers often engrave or print their logos directly on the product to signify authenticity.

- Examine Packaging: Authentic components usually come in high-quality, branded packaging, with clear labeling and proper documentation, including manuals or warranty information.

- Inspect Serial Numbers: Many genuine products include a unique serial number that can be cross-referenced on the manufacturer’s official website to verify authenticity.

- Quality of Materials: Original pieces are typically made from durable and high-quality materials, ensuring better performance. Counterfeit items may use cheaper materials, which can affect longevity and safety.

- Source of Purchase: Buying from authorized dealers or certified distributors is a reliable way to ensure the authenticity of the product. Always avoid unknown or suspicious vendors.

Benefits of Using OEM Components

Opting for original equipment manufacturer (OEM) components offers numerous advantages when maintaining and repairing machinery. These components are designed specifically for your equipment, ensuring compatibility and optimal performance.

- Guaranteed Quality: OEM parts are manufactured to meet high standards, ensuring they function as expected and maintain the longevity of your machine.

- Perfect Fit: Since OEM components are designed for particular models, they fit seamlessly, reducing the need for modifications or adjustments.

- Increased Durability: These parts are crafted from high-quality materials, offering greater resistance to wear and tear compared to generic alternatives.

- Manufacturer Support: Using OEM parts often ensures access to manufacturer support, such as warranties and technical assistance.

- Better Performance: Machines with OEM components generally perform better, as the parts are engineered for efficiency and precision.

Incorporating these components into your routine maintenance can enhance the overall reliability and lifespan of your equipment, making them a preferred choice for professional upkeep.

Step-by-Step Repair Process

In order to restore the equipment’s functionality, it’s essential to follow a structured approach. By addressing each issue systematically, the machinery can be brought back to optimal performance. This guide will cover essential procedures, providing clear instructions for a smooth repair process.

-

Identify the malfunction: Carefully examine the device for visible signs of wear or damage. Listen for unusual sounds or vibrations, which can help pinpoint the underlying problem.

-

Disconnect the power source: For safety, ensure that the machine is completely turned off and disconnected from any energy supply before beginning repairs.

-

Remove external panels or coverings: Use appropriate tools to access the internal components. Be cautious and keep track of screws and small parts to prevent loss.

-

Inspect internal components: Check the key mechanisms for signs of breakage, rust, or loose connections. Common areas to assess include belts, bearings, and electrical circuits.

-

Replace or repair faulty parts: If a component is broken or excessively worn, replace it with a new one. In some cases,

Diagram Interpretation for Beginners

Understanding technical illustrations can be challenging for newcomers, but it’s a vital skill for effective troubleshooting and maintenance. These visual guides are designed to simplify complex systems by representing their components and connections in a clear and structured way. By learning to break down these drawings into manageable sections, beginners can quickly grasp how different parts function together.

The key is to recognize common symbols, lines, and shapes that represent various elements. Once familiar with these visual cues, it becomes easier to follow the flow of the system, identify relationships between elements, and locate specific components. With practice, interpreting such visuals will enhance your ability to perform repairs and modifications efficiently.

Where to Find Replacement Parts

When dealing with maintenance or repairs, one of the essential steps is locating the correct components to restore your equipment’s functionality. Reliable sources for purchasing spare elements are crucial for ensuring that your machine runs smoothly and efficiently over time.

- Authorized Dealers: Contacting official distributors is often the best way to ensure you’re getting genuine components, specifically designed for your machine’s model and version.

- Online Marketplaces: Numerous online platforms provide a wide selection of replacement pieces. These sources allow users to compare prices and find competitive offers.

- Specialized Shops: Certain stores specialize in specific brands or equipment types, often carrying hard-to-find items and offering expert advice.

- Second-Hand Sellers: For those seeking more affordable alternatives, checking pre-owned markets can be a good option. However, be cautious to inspect the condition of the pieces carefully.

By exploring these options, you can maintain your equipment efficiently, ensuring long-term performance and durability.

Online Resources for Mower Owners

Maintaining outdoor equipment can be made easier with the right set of tools and information available at your fingertips. Access to various online platforms helps users find technical documents, maintenance guides, and troubleshooting tips for their equipment, ensuring smooth and efficient operation.

Resource Type Description Manufacturer Websites Direct access to official documentation, service manuals, and updates for a wide range of equipment models. Forums and Communities Engage with experienced owners and technicians, share insights, and get advice on common issues and solutions. Video Tutorials Step-by-step video guides that cover everything from routine maintenance to complex repairs. Online Retailers Find replacement components and accessories, often with user reviews and detailed product descriptions to help with selection.