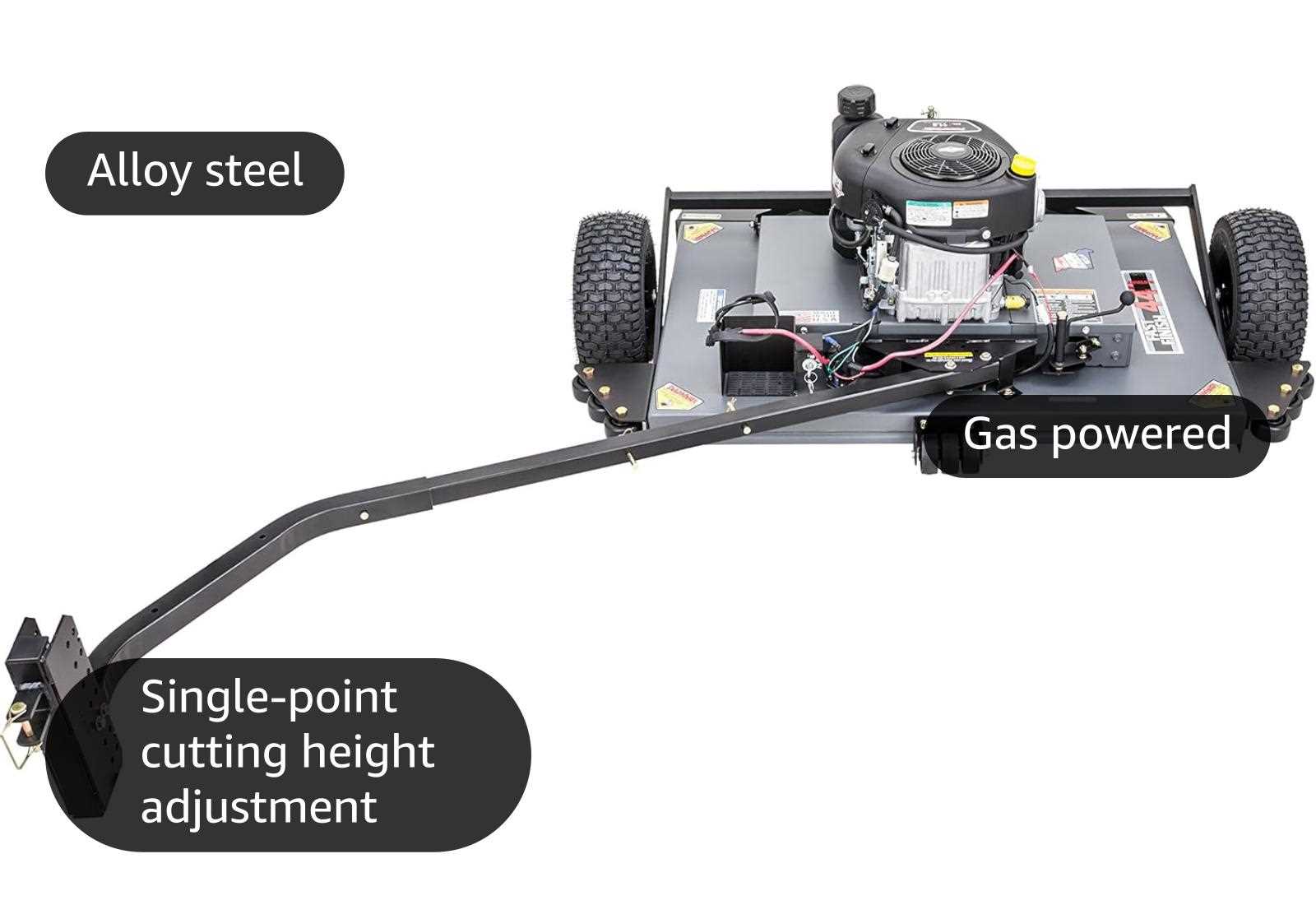

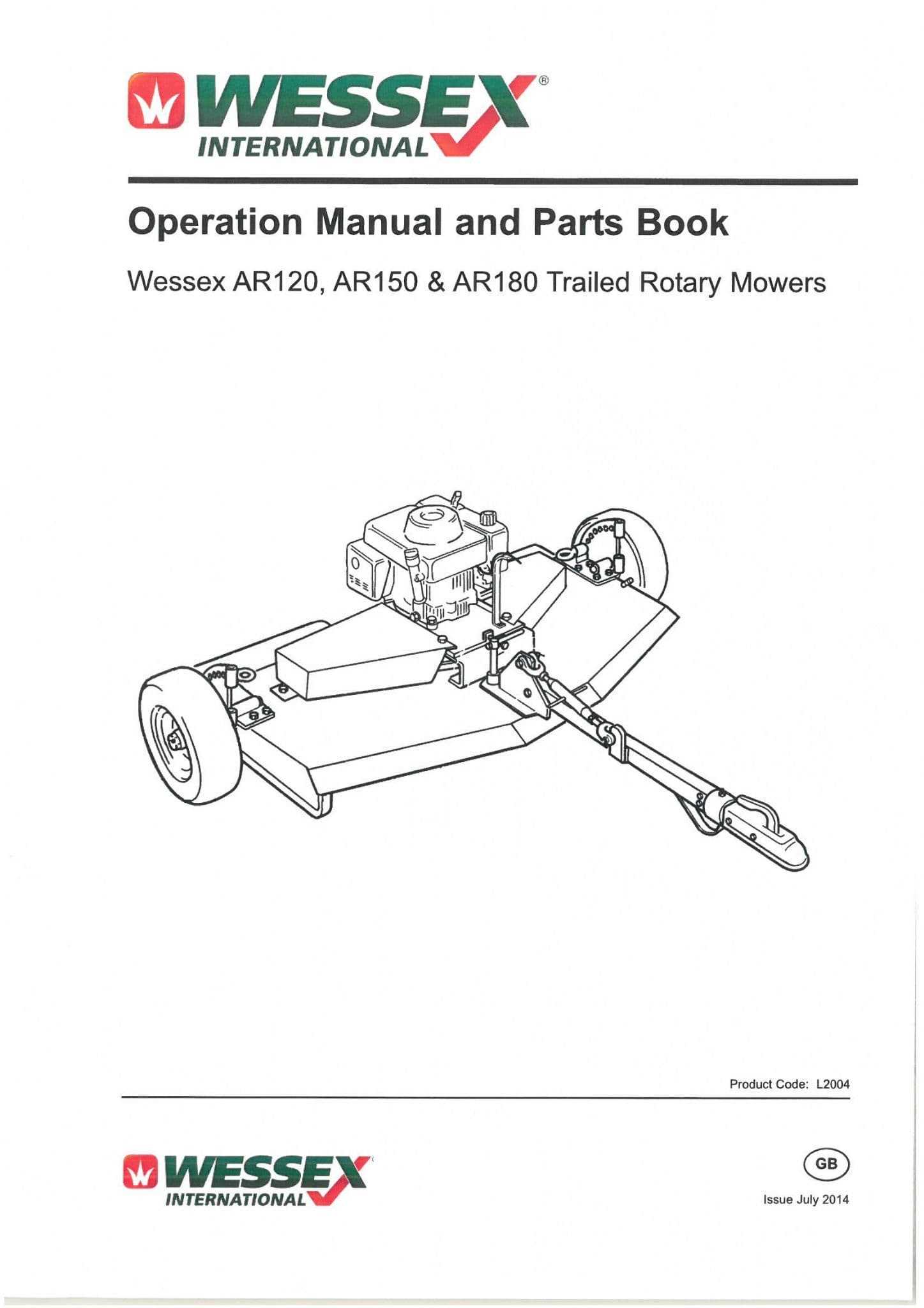

Maintaining an attractive landscape requires the right tools, and knowing how each element functions is essential for optimal performance. A well-designed machine can greatly enhance the efficiency of yard work, making it crucial to comprehend its structure and components. Familiarity with the various elements involved allows users to troubleshoot issues and perform necessary maintenance with ease.

Identifying the individual components of your equipment can significantly improve your ability to manage and operate it effectively. By examining the layout and functionality of these pieces, users can gain insights into the overall operation and maintenance requirements. This understanding not only aids in enhancing performance but also extends the lifespan of the equipment.

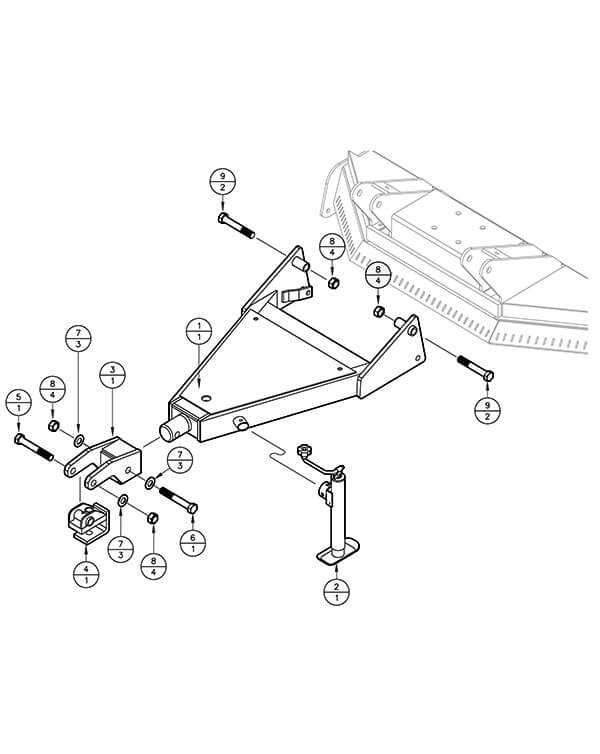

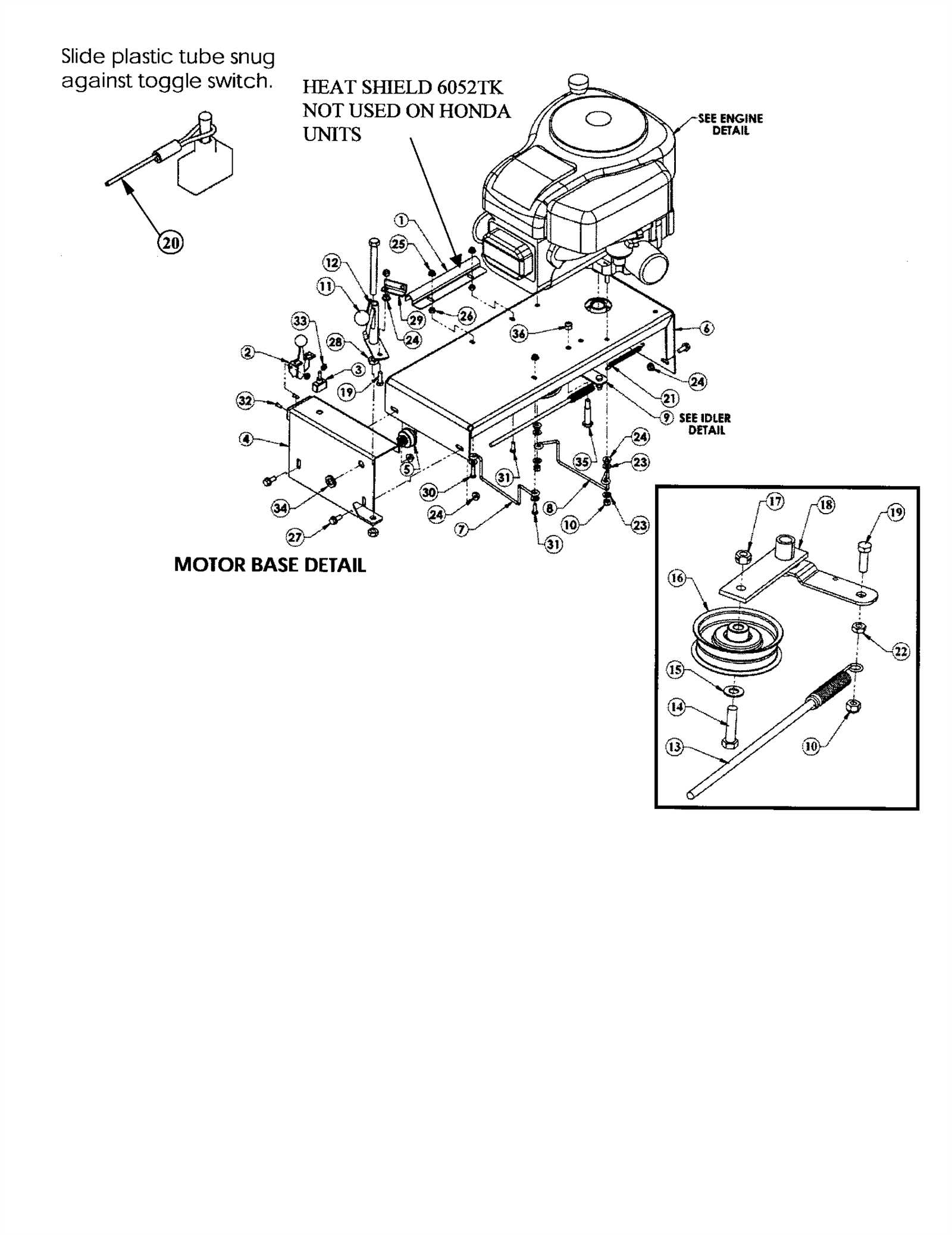

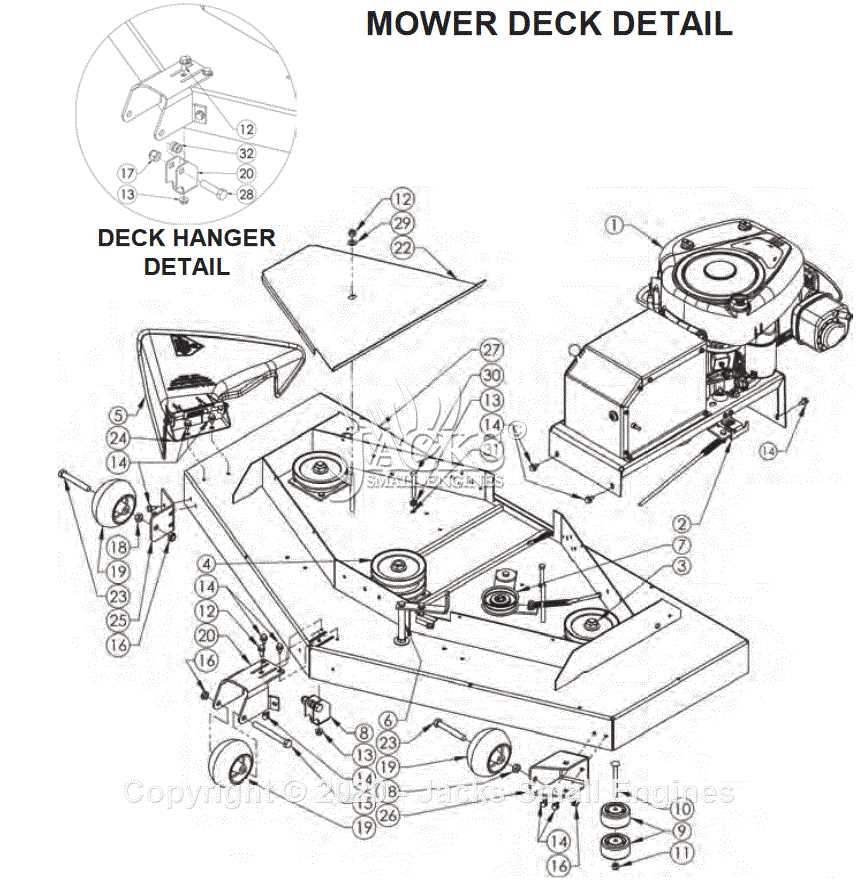

Visual aids play a vital role in this learning process, providing a clear representation of how each part interacts within the system. Recognizing the specific functions of each component helps in diagnosing problems quickly and executing repairs when needed. Thus, delving into the intricacies of these machines can lead to a more productive and rewarding experience in lawn care.

Understanding Swisher Mower Components

Gaining insight into the essential elements of a cutting machine is vital for efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality and performance. Familiarity with these elements can enhance your experience and help troubleshoot any issues that may arise.

Main Elements of the Cutting Mechanism

- Blades: These are crucial for achieving a clean cut.

- Deck: The housing that supports the blades and guides the grass.

- Drive System: Responsible for the movement and power transmission.

Supporting Structures and Features

- Frame: Provides the overall support and stability.

- Wheels: Aid in maneuverability across different terrains.

- Handles: Allow for steering and control during operation.

Importance of Accurate Diagrams

Clear and precise illustrations play a crucial role in understanding complex machinery. They serve as essential tools that help users navigate the intricate components and functionalities of equipment. Without these visuals, assembling, maintaining, or troubleshooting devices can become a daunting task.

Accurate representations enhance comprehension, enabling individuals to identify specific elements easily. When details are clearly depicted, users can grasp the relationships between various parts and their operations. This clarity not only aids in effective assembly but also minimizes the risk of errors during repairs or replacements.

Moreover, well-crafted visuals contribute to safety by ensuring that users are aware of potential hazards associated with different components. By following the guidelines illustrated, individuals can work with confidence, knowing they understand how each part functions within the larger system.

In summary, precise illustrations are invaluable for anyone interacting with mechanical systems. They bridge the gap between complexity and understanding, empowering users to engage with their equipment effectively and safely.

Key Parts of Swisher Mowers

Understanding the essential components of lawn care machinery is crucial for effective maintenance and optimal performance. Each element plays a significant role in ensuring the equipment operates smoothly and efficiently, making it vital for users to familiarize themselves with these key features.

Cutting Mechanism

The cutting mechanism is fundamental to achieving a clean and even trim. It typically consists of sharp blades that rotate at high speeds, allowing for precise cutting of grass and other vegetation. Regular inspection and sharpening of these blades are essential for maintaining efficiency.

Chassis and Frame

The chassis and frame provide structural integrity and stability to the unit. Made from durable materials, they are designed to withstand the rigors of outdoor use while supporting the weight of the engine and cutting apparatus. A robust frame ensures longevity and reliable operation over time.

Maintenance Tips for Mower Longevity

Ensuring the durability of your cutting machine requires consistent care and attention. By following a few essential practices, you can enhance performance and extend the lifespan of your equipment. Regular maintenance not only optimizes functionality but also prevents costly repairs down the line.

Regular Inspections

Frequent check-ups are crucial. Examine the blades for wear and tear, ensuring they remain sharp for optimal cutting efficiency. Look for any signs of rust or damage on the frame and components, as early detection can prevent further issues.

Proper Storage and Cleaning

After each use, cleaning your equipment helps remove debris and prevent corrosion. Store it in a dry, sheltered area to protect it from harsh weather. Adequate care during storage will safeguard the machinery and maintain its effectiveness over time.

Common Issues with Pull Behind Mowers

When operating a towed cutting device, several challenges may arise that can affect performance and efficiency. Understanding these common problems can help operators troubleshoot and maintain their equipment effectively. Below are some frequent issues encountered with these machines.

| Issue | Description | Possible Solutions |

|---|---|---|

| Uneven Cutting | Inconsistent height of the grass can lead to an unkempt appearance. | Check wheel height settings and adjust as needed. |

| Clogging | Debris build-up in the cutting deck can hinder performance. | Regularly clean the underside of the deck to prevent accumulation. |

| Blade Dullness | Worn blades can result in tearing rather than clean cuts. | Sharpen or replace blades periodically for optimal performance. |

| Power Issues | Insufficient power can lead to stalling or slow operation. | Inspect the engine and fuel system for blockages or leaks. |

| Tire Problems | Pneumatic tires may experience pressure loss or wear. | Check tire pressure regularly and replace worn tires as necessary. |

How to Identify Mower Parts

Understanding the components of your equipment is essential for effective maintenance and troubleshooting. Recognizing each element’s function not only aids in repairs but also enhances overall performance. This guide will help you familiarize yourself with the different sections and features, ensuring you can address any issues that arise efficiently.

Familiarizing with Common Components

Start by learning the basic sections such as the cutting mechanism, drive system, and frame. Each of these segments plays a crucial role in the functionality of your equipment. For example, the cutting mechanism is responsible for achieving the desired height and quality of the cut. Familiarity with these components allows for easier identification and understanding of their importance.

Utilizing Reference Materials

Consulting manuals or online resources can be incredibly helpful. These materials often include detailed illustrations and descriptions of each section. Take notes on the terminology and functions, which can greatly assist in pinpointing specific issues when they arise. Visual aids can serve as a quick reference during maintenance tasks, making the process smoother and more efficient.

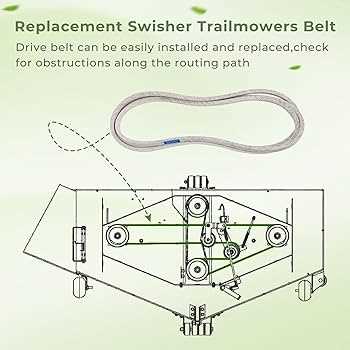

Replacement Parts for Swisher Mowers

Maintaining equipment is essential for optimal performance and longevity. When components wear out or become damaged, timely replacement ensures that the functionality and efficiency of your machinery are preserved. Understanding the different options available for replacements can help streamline this process.

Common Components for Replacement

Various elements may need attention, from cutting blades to belts and bearings. Identifying which items require replacement is crucial for maintaining peak performance. Below are some commonly needed elements:

| Component | Description | Importance |

|---|---|---|

| Blades | Essential for cutting grass effectively. | Critical for achieving a clean cut and healthy lawn. |

| Belts | Transfer power from the engine to the blades. | Vital for operational efficiency. |

| Bearings | Support rotating components. | Ensure smooth operation and reduce friction. |

Finding Quality Replacements

When searching for new components, prioritize quality and compatibility with your equipment. Using genuine or high-quality alternatives can significantly enhance durability and performance. Researching suppliers and reading reviews can guide you to reputable sources.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment, ensuring optimal performance and longevity. By following the outlined steps, you can tackle common issues effectively and efficiently.

- Identify the Problem: Begin by assessing the symptoms. Is there unusual noise, reduced performance, or visible wear?

- Gather Necessary Tools: Ensure you have the right tools for disassembly and reassembly. Common tools include wrenches, screwdrivers, and pliers.

- Consult the Manual: Refer to the equipment manual for specific guidelines and diagrams that aid in the repair process.

- Disassemble Carefully: Start removing components in a logical order. Keep track of screws and parts to avoid loss.

- Inspect Each Part: Examine components for damage or wear. Replace any faulty pieces with quality replacements.

- Reassemble: Follow your disassembly steps in reverse. Ensure all parts are secured tightly.

- Test the Equipment: After reassembly, run a test to confirm the issue is resolved and everything functions smoothly.

By adhering to this guide, you can efficiently restore your equipment to its ultimate condition.

Tools Needed for Maintenance

Regular upkeep of your equipment is essential for optimal performance and longevity. Having the right tools on hand can make the process more efficient and straightforward. Below are the necessary instruments and supplies to ensure that your machinery remains in top condition.

Essential Instruments

A basic toolkit should include wrenches, screwdrivers, and pliers for adjusting and securing various components. A socket set is also invaluable for accessing hard-to-reach areas. Additionally, a set of replacement blades can be crucial for maintaining cutting efficiency.

Maintenance Supplies

Don’t forget about lubricants, cleaners, and filters. Oil and grease are vital for reducing friction and wear. Cleaning agents will help remove debris and buildup, while filters ensure that fluids remain clean and effective. Keeping these supplies stocked will facilitate smoother maintenance tasks.

Where to Purchase Parts Online

Finding components for your outdoor equipment can be a straightforward process if you know where to look. The online marketplace offers a plethora of options, making it easy to locate and acquire the necessary items for your maintenance needs.

Specialized Retailers are often the best source for high-quality components. These websites typically provide extensive catalogs, ensuring you can delve into specific requirements with ease. Look for customer reviews and ratings to gauge reliability.

General E-commerce Platforms like major retail sites can also be useful. They often feature a wide range of products, including aftermarket options that might serve as cost-effective alternatives. However, be cautious and verify the compatibility of the items you choose.

Manufacturer Websites frequently have direct sales, allowing you to purchase genuine components. This option guarantees that you receive the ultimate quality and compatibility with your equipment.

Lastly, consider auction and classifieds sites for potentially unique finds. These platforms can yield great deals, though it’s important to assess the condition and authenticity of the listings before making a purchase.

Understanding Mower Assembly Process

The process of assembling a grass-cutting machine is essential for achieving optimal performance and durability. Each component plays a crucial role in ensuring the unit operates smoothly and efficiently. By understanding the arrangement and functionality of these elements, users can enhance their maintenance skills and troubleshooting capabilities.

Key Components and Their Functions

Every grass-cutting device consists of various elements, each designed to perform specific tasks. The engine serves as the powerhouse, providing the necessary energy to drive the entire system. The cutting deck is responsible for housing the blades, while the wheels facilitate movement across different terrains. Additionally, the handles offer control and stability, ensuring user comfort during operation.

Steps for Successful Assembly

To successfully assemble the equipment, start by organizing all components and tools. Refer to the user manual for a detailed layout of each part’s placement. Begin by securely attaching the engine to the frame, followed by the installation of the cutting deck. Make sure to align the blades correctly to ensure even cutting. Finally, attach the wheels and handles, ensuring all connections are tight and secure. Regular checks on assembly integrity can prevent future issues.

By understanding the assembly process, users can better appreciate the mechanics behind their grass-cutting machines and ensure they remain in top working condition.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial for both the technician and the equipment. Adhering to specific guidelines can prevent accidents and enhance the overall efficiency of the repair process. Here are essential safety measures to keep in mind while working on machinery.

Preparation Steps

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure that the machine is powered off and disconnected from any energy sources before starting repairs.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

During Repairs

- Keep your workspace organized to minimize the risk of accidents.

- Avoid wearing loose clothing or jewelry that could get caught in moving parts.

- Use tools and equipment as intended, following the manufacturer’s instructions.

- Stay focused and avoid distractions while performing repairs.

By following these precautions, you can create a safer environment, significantly reducing the risk of injuries and ensuring effective maintenance procedures.

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of your equipment can lead to a significantly better experience. With the right enhancements, you can optimize functionality, ensure durability, and increase overall productivity. This section explores key upgrades that can elevate performance to the ultimate level.

Engine Enhancements: Consider upgrading to a more powerful engine for improved speed and cutting ability. A higher horsepower unit can handle tougher terrains and thicker vegetation with ease.

Blade Upgrades: High-quality, sharper blades can dramatically enhance cutting precision and reduce the effort needed for maintenance. Look for specialized blade designs tailored to specific conditions.

Wheel and Tire Improvements: Upgrading tires to a more robust, puncture-resistant type can provide better traction and stability, ensuring a smoother operation across diverse surfaces.

Transmission Systems: An enhanced transmission can provide smoother gear transitions and improved responsiveness, allowing for greater control and efficiency during use.

Accessory Add-Ons: Consider adding attachments such as mulchers or baggers to expand functionality and make cleanup easier, ultimately saving time and effort.