In the world of landscape care, maintaining optimal functionality of equipment is essential for achieving a pristine environment. A thorough understanding of the intricate elements that contribute to the overall performance of these machines can greatly enhance their longevity and efficiency. This section will delve into the various sections that make up these vital tools, providing clarity on how they work together to deliver impressive results.

Visual aids play a crucial role in grasping the complexity of mechanical structures. By breaking down the assembly into clear segments, one can better appreciate the design and function of each individual piece. This exploration will not only assist in troubleshooting but also foster a deeper connection to the equipment, empowering users to handle maintenance tasks with confidence.

Equipped with the right knowledge, operators can ensure their machines are in peak condition, ready to tackle any task at hand. This guide serves as a resource for understanding the layout and relationships between different components, offering insights that are beneficial for both novice and seasoned users alike. Whether you’re looking to replace worn items or simply enhance your understanding, this overview will illuminate the essential features of turf care machinery.

Understanding Woods L59 Belly Mower

This section delves into the intricacies of a specific type of ground maintenance tool designed for efficient grass cutting and landscaping. By exploring its components and functionality, users can gain insight into its operation and maintenance, ensuring optimal performance.

Key Components

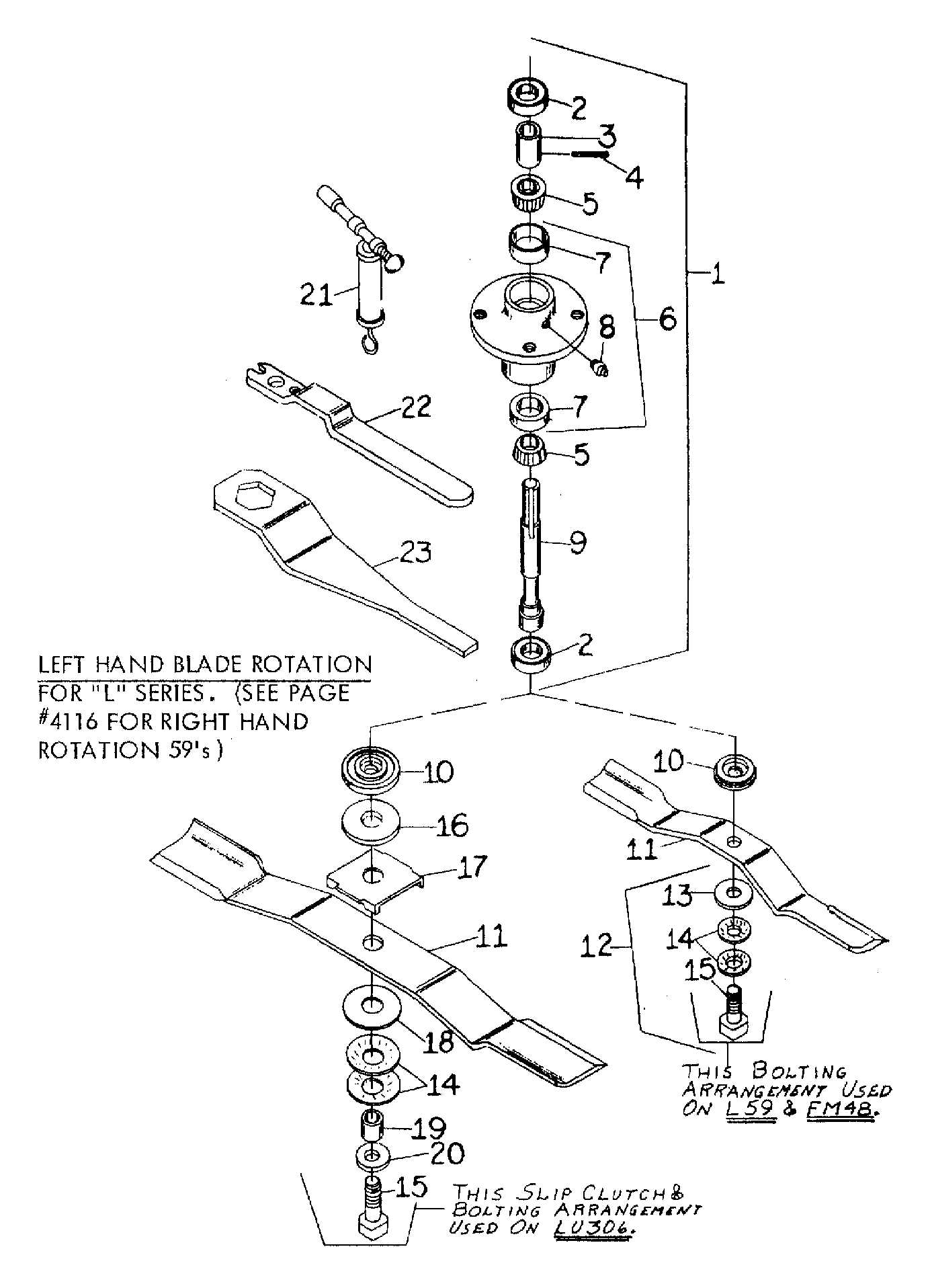

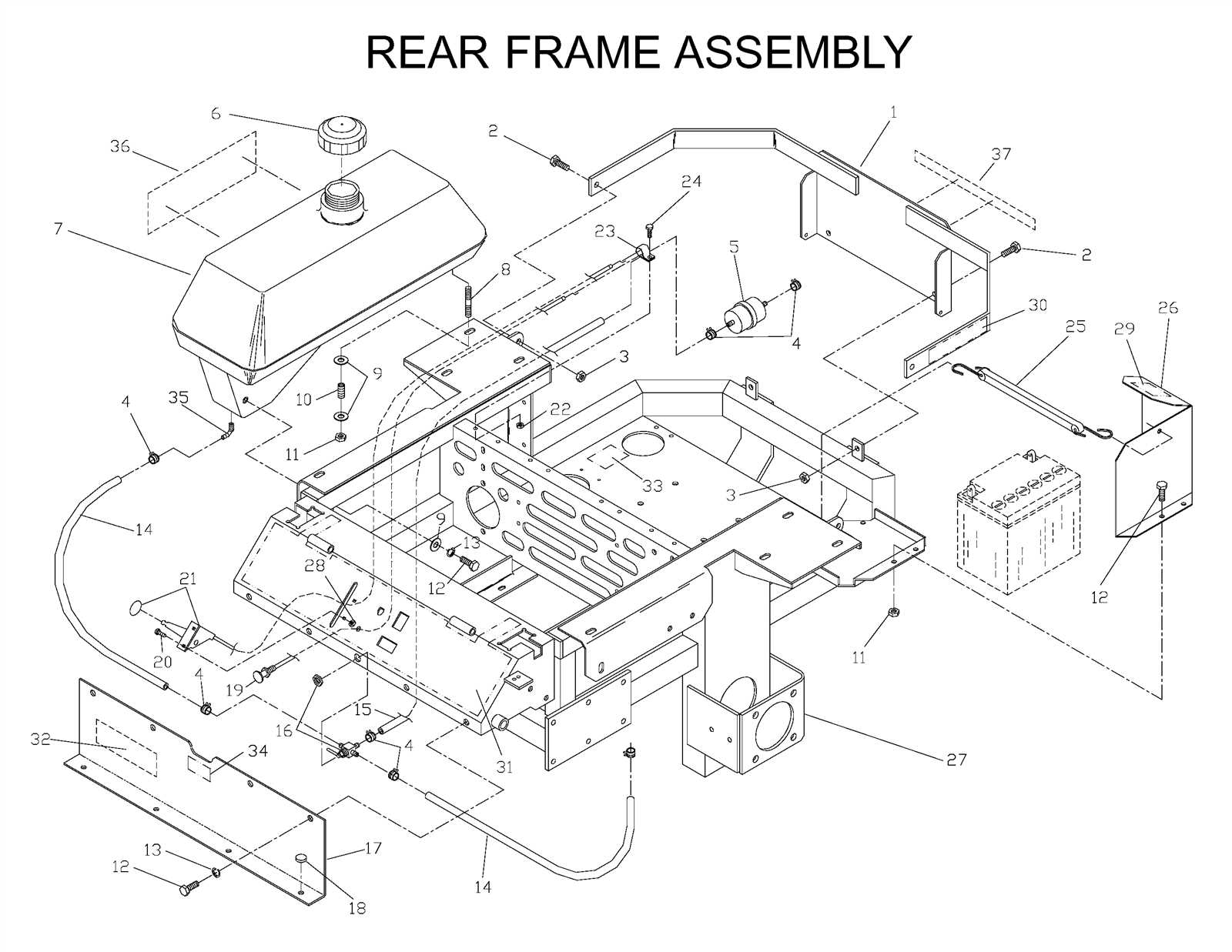

At the heart of this tool lies a series of essential elements that work in harmony. Each part, from the cutting blades to the drive mechanism, plays a pivotal role in achieving a precise cut. Understanding these components allows users to identify potential issues and perform necessary repairs or replacements.

Maintenance Tips

To keep this equipment functioning smoothly, regular upkeep is vital. Routine inspections and timely servicing can prevent wear and tear, extending the lifespan of the tool. Additionally, being familiar with common troubleshooting methods can empower users to address minor problems effectively.

In summary, a comprehensive understanding of this type of equipment enhances both its utility and longevity, making it an indispensable asset for lawn care enthusiasts.

Key Components of Belly Mower

Understanding the essential elements of a grass-cutting implement is crucial for effective maintenance and optimal performance. Each component plays a vital role in ensuring smooth operation and durability over time.

- Cutting Deck: The main structure housing the blades, designed for efficient grass trimming.

- Blades: Sharp metal pieces that rotate to slice through the grass with precision.

- Spindle Assembly: The mechanism that supports and drives the blades, allowing them to rotate at high speeds.

- Height Adjustment Mechanism: A system enabling the operator to set the cutting height for desired grass length.

- Frame: The foundational structure providing stability and support to all components.

- Drive Belt: A rubber belt that transfers power from the engine to the blades, facilitating their movement.

- Safety Features: Components designed to protect the user from potential hazards during operation.

Recognizing and maintaining these key elements can enhance the longevity and efficiency of the grass-cutting implement.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as a guide to understanding the arrangement and functionality of each element, ensuring efficient operation and longevity.

Here are some key reasons why these visual aids are essential:

- Clarity: Illustrations provide a clear view of the relationships between various components, making it easier to identify issues.

- Efficiency: With a comprehensive reference, users can quickly locate and address problems without unnecessary trial and error.

- Training: These visuals are invaluable for educating new users about the machinery, facilitating faster learning and confidence.

- Inventory Management: Knowing what each part looks like helps in maintaining proper stock levels and ordering replacements.

- Assembly and Disassembly: Clear visuals aid in understanding the correct sequence of actions, reducing the risk of errors during repairs.

Overall, these representations are fundamental tools that enhance the effectiveness of maintenance practices and ensure the proper functioning of equipment over time.

Identifying Common Replacement Parts

Understanding the various components of your equipment is essential for maintaining its optimal performance. Recognizing common elements that may require attention can significantly enhance the lifespan and efficiency of your machinery. This section highlights key components that often need to be replaced due to wear and tear.

Common Components Needing Replacement

One of the most frequently replaced elements is the cutting blade. Over time, blades can become dull or damaged, resulting in reduced effectiveness. Regular inspection and timely replacement ensure that the equipment performs at its best.

Other Essential Elements

Another crucial component is the drive belt. This part experiences significant stress during operation and can wear out or break. Keeping an eye on the condition of the drive belt can prevent unexpected breakdowns and maintain seamless functionality. Additionally, bearings and pulleys are vital for smooth operation, and their deterioration can lead to performance issues. Regular maintenance checks are recommended to identify and address these common concerns.

Maintenance Tips for Mower Longevity

Ensuring the durability and efficiency of your grass cutting equipment requires regular care and attention. By following a few essential guidelines, you can significantly extend its operational life and enhance performance.

- Regular Cleaning: Remove grass clippings and debris after each use to prevent corrosion.

- Oil Changes: Replace the oil periodically to keep the engine lubricated and running smoothly.

- Blade Maintenance: Sharpen blades regularly for a clean cut, and replace them when necessary.

- Check Belts and Cables: Inspect for wear and replace damaged components promptly.

- Fuel Quality: Use fresh fuel and consider adding a fuel stabilizer to prevent degradation.

Implementing these practices will not only enhance performance but also contribute to the ultimate longevity of your equipment.

How to Read Parts Diagrams

Understanding visual representations of mechanical components is essential for effective maintenance and repair. These illustrations offer a comprehensive view of an assembly, allowing users to identify individual elements, their functions, and how they interconnect. By mastering the interpretation of these visuals, users can efficiently locate, order, and replace necessary components.

Identifying Components

Each symbol or illustration in the representation corresponds to a specific piece. Familiarizing yourself with common shapes and notations will facilitate quicker identification. Most diagrams will label each component with a unique identifier, which can be cross-referenced with a parts list.

Understanding Relationships

In addition to identifying components, it’s important to comprehend how these elements interact. Lines often indicate connections, while arrows may suggest the direction of movement or flow. Recognizing these relationships can clarify the assembly process and highlight potential areas for troubleshooting.

| Symbol | Meaning |

|---|---|

| Circle | Connection point |

| Arrow | Direction of movement |

| Square | Component or housing |

| Dashed Line | Optional or alternative path |

Finding OEM vs. Aftermarket Parts

When it comes to maintaining outdoor equipment, the choice between original manufacturer components and third-party alternatives is crucial. Each option presents distinct advantages and disadvantages that can significantly impact performance, longevity, and cost-effectiveness. Understanding these differences can help users make informed decisions for their machinery needs.

OEM Components

Original Equipment Manufacturer components are designed specifically for a particular brand and model, ensuring a perfect fit and optimal functionality. These parts often come with a warranty and are crafted to meet high-quality standards. Users can expect reliability and performance that aligns with the original specifications of their machinery.

Aftermarket Alternatives

Third-party alternatives provide a broader selection and often come at a more affordable price. While some aftermarket options may match or even exceed the quality of OEM components, others can vary significantly. It is essential to research and select reputable manufacturers to ensure compatibility and durability, as poor-quality alternatives may lead to premature failure or increased maintenance costs.

Assembly Instructions for Belly Mower

Proper installation of your cutting attachment is essential for optimal performance and longevity. Following systematic steps ensures that all components fit securely and function as intended, allowing for efficient operation in various terrains.

Step 1: Begin by laying out all components in an organized manner. Verify that you have all necessary items by cross-referencing with your assembly list.

Step 2: Attach the main frame to the vehicle’s mounting brackets. Ensure that bolts are tightened to the manufacturer’s specifications, utilizing a torque wrench for accuracy.

Step 3: Position the cutting mechanism beneath the frame. Align the connection points carefully and insert the required pins or bolts to secure it in place.

Step 4: Connect the drive components, ensuring that all belts and pulleys are properly aligned. This step is crucial for the smooth transmission of power.

Step 5: After all parts are assembled, double-check each connection and fastener. A thorough inspection will help prevent any operational issues during use.

Step 6: Once everything is secured, conduct a test run at low speed. Observe for any unusual noises or vibrations, indicating misalignment or loose fittings.

Following these instructions will aid in achieving a safe and effective setup for your cutting attachment, ensuring a seamless experience during operation.

Common Issues and Troubleshooting

Understanding typical problems that may arise with your equipment is essential for effective maintenance and repair. Identifying these issues early can help you avoid costly downtime and ensure optimal performance. Below are some common challenges and suggested solutions to keep your machinery running smoothly.

1. Uneven Cutting: If the cutting results are inconsistent, check the blade height and alignment. Ensure that the blades are sharp and free of debris, as dull or clogged blades can lead to an uneven finish.

2. Excessive Vibration: This issue may indicate loose components or damaged blades. Inspect all attachments and tighten any loose bolts. Replacing bent or broken blades will also help reduce vibration.

3. Engine Stalling: Stalling can be caused by fuel issues or air blockage. Make sure the fuel tank is filled with clean fuel, and check the air filter for dirt buildup. Cleaning or replacing the filter can improve engine performance.

4. Overheating: If the machine runs too hot, it may be due to a clogged cooling system or low oil levels. Regularly check and clean the cooling fins and ensure the oil is at the recommended level.

5. Difficulty Starting: Starting issues may stem from a weak battery or ignition problems. Inspect the battery for corrosion and replace it if necessary. Additionally, check the spark plug for wear and replace it if it appears damaged.

By addressing these common concerns promptly, you can enhance the longevity and efficiency of your equipment.

Where to Buy Replacement Parts

Finding components for your equipment can be straightforward if you know the right sources. Many options are available for acquiring high-quality alternatives that ensure optimal functionality and longevity.

Online Retailers

- Check specialized websites dedicated to outdoor machinery.

- Explore large e-commerce platforms offering a wide range of selections.

- Consider manufacturer’s official sites for authentic components.

Local Stores

- Visit home improvement centers that often stock essential items.

- Look for local dealerships specializing in machinery.

- Consult repair shops that might carry or order specific elements.

Researching and comparing prices and quality can lead to the ultimate purchase decision for your needs.

Benefits of Regular Maintenance

Consistent upkeep of equipment is essential for ensuring optimal performance and longevity. By investing time in routine care, owners can prevent costly repairs and enhance efficiency, ultimately leading to a more reliable operation.

Improved Performance

Regular maintenance helps to keep machinery running at peak efficiency. Addressing minor issues promptly can prevent them from escalating into major problems, ensuring smooth functionality.

Cost-Effectiveness

Investing in regular service can save significant expenses over time. Proper care reduces the likelihood of unexpected breakdowns, which often incur higher repair costs.

| Maintenance Activity | Frequency | Benefit |

|---|---|---|

| Oil Change | Every 50 hours | Enhances engine life |

| Blade Sharpening | Every 25 hours | Ensures clean cuts |

| Filter Replacement | Every season | Improves air flow |

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and the integrity of the equipment is paramount. Proper precautions can prevent accidents and injuries while facilitating a smoother repair process. Always prioritize safety by adhering to recommended guidelines and using the appropriate protective gear.

Essential Safety Gear

Wearing the right protective equipment is crucial for safeguarding against potential hazards. Here are some items to consider:

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from sharp edges and chemicals. |

| Goggles | Shield eyes from debris and harmful substances. |

| Steel-Toed Boots | Provide foot protection from heavy equipment. |

| Ear Protection | Reduce noise exposure when operating machinery. |

General Safety Tips

Before starting any repairs, ensure the equipment is turned off and disconnected from power sources. Familiarize yourself with the machinery’s manual to understand its components. Maintain a clean workspace to prevent slips and trips, and always have a first aid kit readily available for emergencies.