The intricate design of winter vehicles plays a pivotal role in their performance and reliability. Understanding the components that make up these machines is essential for enthusiasts and operators alike. Each element contributes to the overall functionality, ensuring an enjoyable experience on snowy terrains.

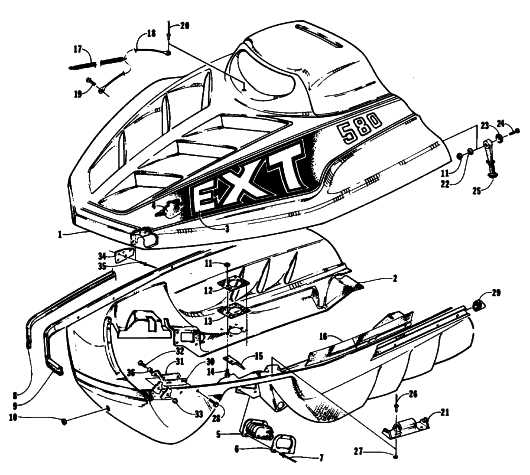

Visual representations serve as valuable tools for grasping the arrangement and interconnectivity of various sections. They allow users to navigate through the complexities of assembly and maintenance, fostering a deeper appreciation for engineering precision. Diving into these illustrations reveals the ultimate insights into how these vehicles operate seamlessly.

By familiarizing oneself with the layout and structure, individuals can enhance their knowledge, enabling informed decisions during repairs or upgrades. This journey not only demystifies the components but also enriches the relationship between the operator and their machine.

Understanding Ski-Doo Parts Diagrams

Comprehending the visual representations of vehicle components is crucial for efficient maintenance and repair. These illustrations serve as guides, helping enthusiasts identify and locate essential elements within their machines.

Key benefits of utilizing these visual aids include:

- Enhanced clarity in understanding component relationships.

- Streamlined repair processes by pinpointing necessary items.

- Improved communication among mechanics and owners.

To effectively navigate these resources, consider the following steps:

- Familiarize yourself with the layout and key notations.

- Identify the specific sections relevant to your needs.

- Cross-reference with actual components for accuracy.

Ultimately, a solid grasp of these visuals can lead to more successful repairs and greater satisfaction in maintaining your machine.

History of Ski-Doo Models

The evolution of winter vehicles has been marked by innovation and adaptability, reflecting changing consumer needs and technological advancements. This journey showcases the progression of design, performance, and user experience, setting a standard in the industry.

Key Milestones

- Initial Development: Introduction of early models focusing on basic functionality.

- Technological Advancements: Integration of powerful engines and lightweight materials.

- Design Innovations: Shifts towards ergonomic designs for enhanced comfort and control.

- Environmental Considerations: Adoption of eco-friendly technologies and fuel efficiency.

Impact on Recreation

- Enhanced Accessibility: Opening up new terrains for enthusiasts.

- Cultural Influence: Establishing a community around winter sports.

- Market Growth: Expansion of the industry, attracting diverse consumers.

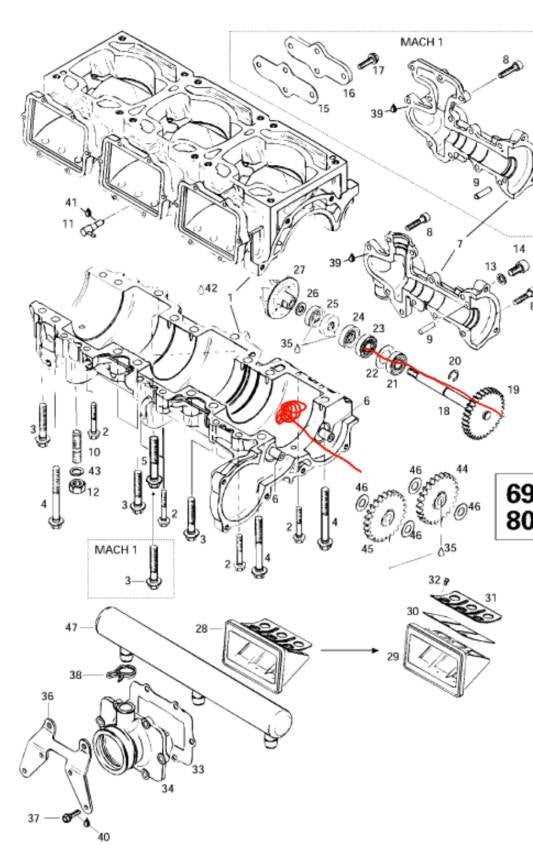

Key Components of 1994 Ski-Doo

Understanding the essential elements of this model provides insights into its performance and functionality. Each component plays a crucial role in ensuring a smooth and enjoyable experience on the snow, making familiarity with these parts beneficial for both maintenance and enhancement of the machine.

Engine and Powertrain

The powerhouse of this model is designed to deliver optimal performance. With its robust engine configuration, it ensures reliable acceleration and speed. Additionally, the powertrain efficiently transmits energy to the tracks, allowing for seamless navigation through various terrains.

Chassis and Suspension

The structural framework and suspension system contribute significantly to stability and comfort. A well-engineered chassis supports the overall design, while the suspension absorbs shocks from uneven surfaces, enhancing the rider’s experience. These elements work together to provide the ultimate ride on winter trails.

Importance of Accurate Diagrams

Having precise visual representations is crucial for understanding complex systems and components. These illustrations serve as a guide for both novice and experienced users, ensuring clarity and efficiency during maintenance or assembly processes.

Enhanced Understanding

Clear representations help users grasp intricate details, making it easier to:

- Identify components

- Understand assembly processes

- Navigate troubleshooting effectively

Time and Cost Efficiency

Accurate visuals contribute to saving both time and resources. By providing:

- Quick reference for repairs

- Reduced likelihood of errors

- Streamlined ordering of necessary components

Common Parts Replacement for 1994 Models

When it comes to maintaining older snowmobiles, certain components often require attention due to wear and tear. Regularly replacing these elements can enhance performance and ensure a smoother ride. Understanding which parts are commonly swapped out can save time and improve the overall experience on the trails.

One frequently replaced component is the drive belt, which is crucial for transferring power from the engine to the track. Over time, these belts can wear down, leading to decreased performance. Another vital part is the fuel filter, essential for keeping the engine running smoothly. A clogged filter can restrict fuel flow, affecting acceleration and efficiency.

Additionally, suspension springs and shock absorbers often require replacement as they can lose their effectiveness over time, impacting handling and comfort. The carburetor, too, may need servicing or replacement, as it is responsible for the fuel-air mixture that powers the engine. Ensuring these components are in good condition can significantly enhance both safety and enjoyment during winter rides.

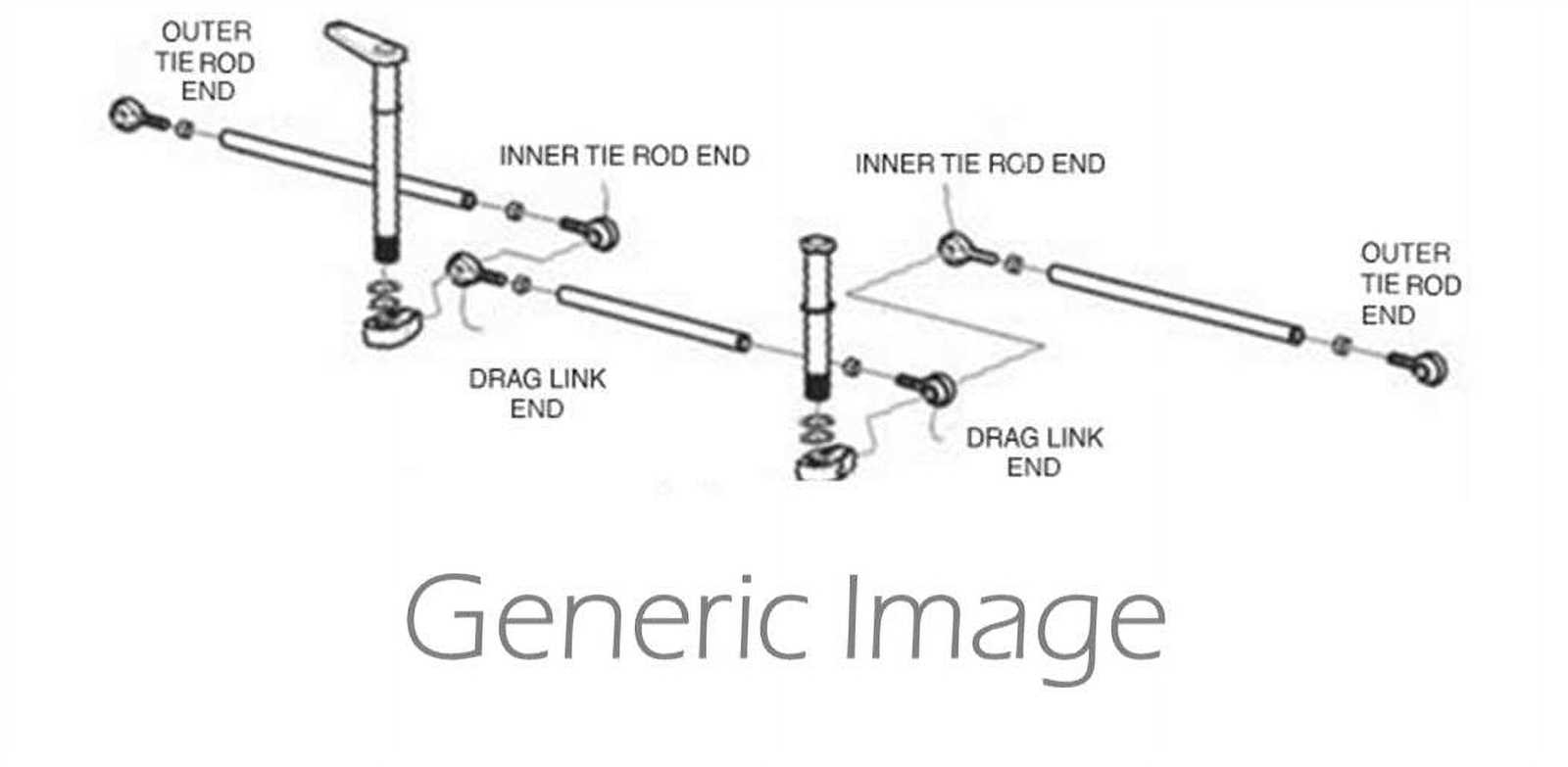

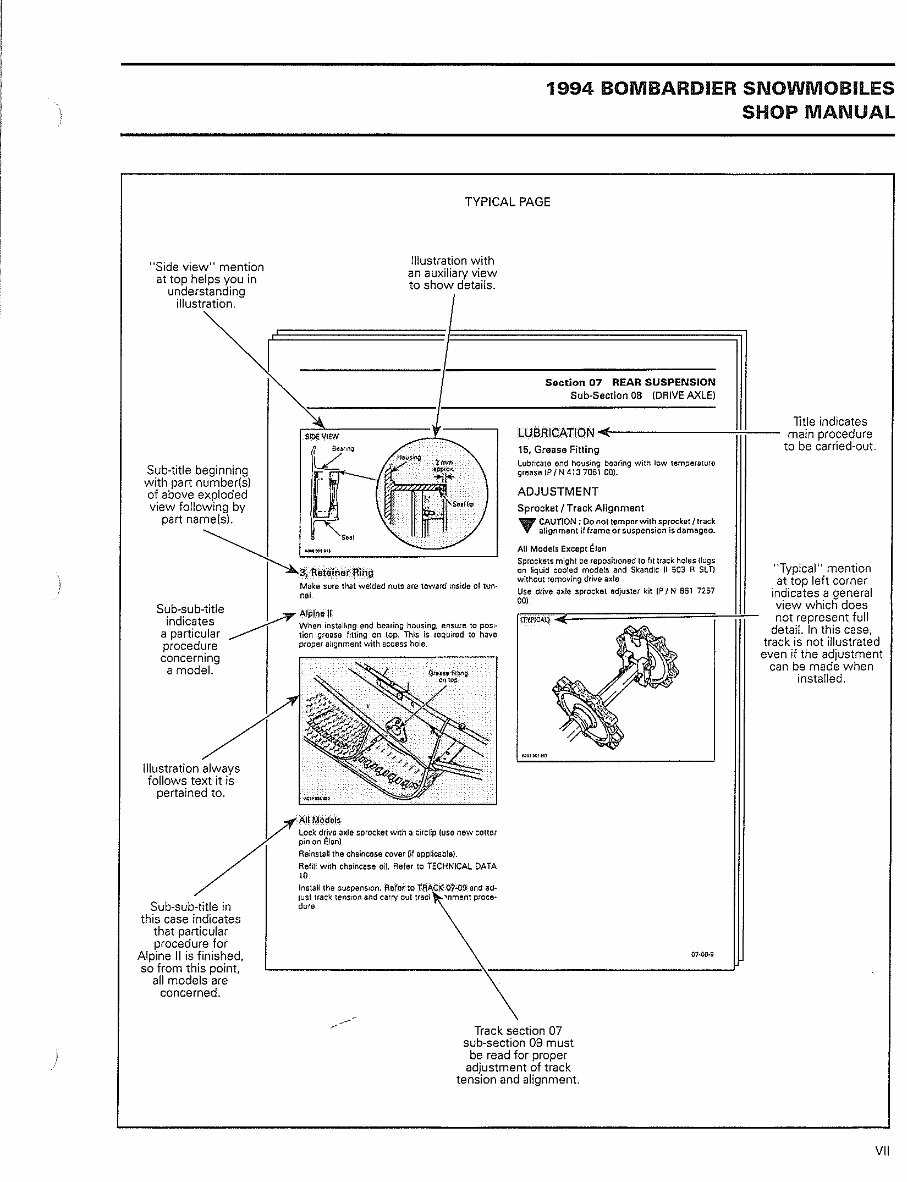

How to Read Parts Diagrams

Understanding visual representations of components is crucial for efficient maintenance and repair. These illustrations provide detailed insights into how various elements interact and fit together, making it easier to identify necessary replacements or upgrades.

When examining these visuals, focus on the following aspects:

| Element | Description |

|---|---|

| Labels | Check for identification numbers and names that correlate with specific components. |

| Connections | Note how parts connect, as this reveals assembly order and compatibility. |

| Symbols | Familiarize yourself with common icons that denote different types of components. |

| Sections | Identify groupings that indicate related parts, simplifying the search for replacements. |

By mastering these elements, you can navigate these illustrations with confidence, ensuring the ultimate understanding of your maintenance needs.

Finding OEM and Aftermarket Parts

Locating the right components for your vehicle can be essential for maintaining its performance and longevity. Whether you’re seeking original equipment or alternative options, understanding where to look and what to consider is crucial.

Original Equipment Manufacturer Options

OEM parts are designed specifically for your model, ensuring compatibility and quality. You can typically find these through authorized dealers, specialized retailers, or online platforms dedicated to genuine parts. This choice often guarantees a higher level of reliability.

Exploring Alternative Solutions

Aftermarket components offer a cost-effective alternative that can also enhance performance. While shopping, it’s vital to research the manufacturer’s reputation and read reviews to ensure you’re getting a reliable product. Comparing warranties and support services can also guide your decision.

Tools Needed for Parts Replacement

When undertaking a replacement task for various components, having the right tools at your disposal is essential. This ensures not only efficiency but also the prevention of damage to the machinery. Proper preparation can make a significant difference in the overall success of the project.

Essential Tools

Begin with basic hand tools, such as wrenches, screwdrivers, and pliers. These are fundamental for loosening and securing components. Additionally, a torque wrench is crucial for applying the correct force to bolts, ensuring safety and functionality.

Specialized Equipment

Depending on the complexity of the job, you might also need specialized equipment like a diagnostic scanner or a compression tester. Such tools can help you delve deeper into issues and verify that replacements have resolved any existing problems.

Maintenance Tips for Ski-Doo Owners

Proper upkeep is essential for ensuring the longevity and optimal performance of your winter vehicle. Regular attention to key components can prevent costly repairs and enhance your overall riding experience. Here are some valuable practices that every owner should incorporate into their maintenance routine.

Regular Inspections

Conducting frequent inspections of your machine can identify potential issues before they escalate. Check for any signs of wear and tear on essential elements such as belts, brakes, and track conditions. Additionally, ensure that fluid levels are adequate and that the battery is in good working order.

Seasonal Preparation

Before each winter season, prepare your vehicle by thoroughly cleaning it and addressing any maintenance needs. This includes lubricating moving parts, changing the oil, and replacing any worn components. Properly storing your vehicle during off-seasons can also protect it from environmental damage and prolong its life.

Identifying Parts by Model Number

Understanding how to recognize components through their specific identification numbers is crucial for effective maintenance and repairs. Each model features unique identifiers that streamline the process of sourcing replacements and upgrades.

When seeking to identify components, consider the following steps:

- Locate the Model Number: Check the owner’s manual or the manufacturer’s label on the vehicle for the precise model number.

- Use Official Resources: Access the manufacturer’s website or authorized dealer for a comprehensive list of components linked to your model.

- Consult Repair Guides: Utilize repair manuals that often include detailed breakdowns of each model’s specifications.

In addition to these steps, keep in mind the following tips for effective identification:

- Cross-reference with Online Databases: Many online platforms offer searchable databases where you can input your model number for immediate results.

- Join Community Forums: Engaging with fellow enthusiasts can provide valuable insights and shared experiences in identifying parts.

- Document Findings: Maintain a record of your model numbers and corresponding components for future reference.

By following these strategies, you can ensure a smoother experience in identifying and acquiring the necessary components for your vehicle.

Where to Source Ski-Doo Manuals

Finding reliable guides and documentation for your snowmobile can greatly enhance your maintenance and repair experience. Here are some valuable sources to consider:

- Official Manufacturer Websites: Check the brand’s website for digital copies or downloadable resources.

- Online Retailers: Platforms like Amazon or eBay often have manuals available for purchase.

- Forums and Community Groups: Engage with enthusiasts in online communities; they frequently share or sell their manuals.

- Local Dealerships: Visit or contact dealerships for access to physical or electronic copies of documentation.

- Library Resources: Many public libraries offer technical manuals as part of their collection.

By exploring these avenues, you can effectively access the information you need for your vehicle.

DIY Repairs vs. Professional Services

When it comes to maintaining your vehicle, enthusiasts often face the choice between tackling repairs independently or enlisting the help of experts. Each approach has its own set of advantages and considerations that can significantly impact both the outcome and your wallet.

Advantages of DIY Repairs

Opting for self-repair can lead to substantial savings and a rewarding sense of accomplishment. Enthusiasts gain valuable hands-on experience and a deeper understanding of their equipment, which can prove beneficial in future maintenance tasks.

Benefits of Professional Assistance

On the other hand, hiring professionals ensures that repairs are performed efficiently and correctly. Experts often possess specialized tools and knowledge, reducing the likelihood of mistakes that could lead to further issues down the line.

| Factor | DIY Repairs | Professional Services |

|---|---|---|

| Cost | Lower, but depends on tools | Higher, but often includes warranty |

| Time | Variable, can be lengthy | Generally quicker |

| Skill Level | Required, can be learned | Expertise guaranteed |

| Outcome | Varied, depends on experience | Consistent quality |

Upgrading Components for Performance

Enhancing the efficiency of your vehicle can significantly elevate your riding experience. By focusing on specific elements, you can achieve a notable boost in power and handling. This approach not only improves overall performance but also extends the lifespan of your machine.

Key Areas for Improvement

- Engine Modifications

- Suspension Upgrades

- Exhaust Enhancements

Benefits of Upgrades

- Increased Speed

- Better Handling

- Improved Fuel Efficiency

Focusing on these upgrades will allow enthusiasts to delve into the ultimate potential of their machines, making every ride more exhilarating.